How to Implement Piezoelectric Sensors in Large-scale Networks

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensing Background and Objectives

Piezoelectric sensing technology has evolved significantly over the past few decades, driven by advancements in materials science and electronics. This technology harnesses the piezoelectric effect, where certain materials generate an electrical charge in response to applied mechanical stress. The journey of piezoelectric sensing began with simple pressure and force measurements but has since expanded to encompass a wide range of applications across various industries.

The current trend in piezoelectric sensing is moving towards miniaturization, increased sensitivity, and integration with smart systems. This evolution is particularly relevant in the context of large-scale networks, where the ability to deploy numerous sensors across expansive areas offers unprecedented opportunities for data collection and analysis. The integration of piezoelectric sensors into these networks promises to revolutionize fields such as structural health monitoring, environmental sensing, and industrial process control.

The primary objective of implementing piezoelectric sensors in large-scale networks is to create a comprehensive, real-time monitoring system capable of detecting and measuring a variety of physical parameters. These may include vibration, pressure, acceleration, and strain across extensive areas or complex structures. By achieving this, organizations can enhance safety, optimize performance, and reduce maintenance costs in applications ranging from civil infrastructure to aerospace engineering.

Another crucial goal is to develop sensors that are energy-efficient and capable of harvesting energy from their environment. This aspect is particularly important for large-scale networks, where power supply and maintenance can be significant challenges. Piezoelectric materials offer the unique advantage of potentially serving dual roles as both sensors and energy harvesters, contributing to the development of self-powered sensing networks.

Furthermore, the implementation of piezoelectric sensors in large-scale networks aims to improve data collection and analysis capabilities. The objective is to create systems that can process and interpret vast amounts of data in real-time, enabling rapid decision-making and predictive maintenance strategies. This involves developing advanced signal processing algorithms and integrating machine learning techniques to extract meaningful insights from the sensor data.

As we look towards the future, the field of piezoelectric sensing in large-scale networks is poised for significant growth. The ongoing research focuses on enhancing sensor durability, expanding the range of detectable parameters, and improving integration with wireless communication technologies. These advancements will pave the way for more robust, versatile, and intelligent sensing systems capable of addressing complex challenges across various domains.

The current trend in piezoelectric sensing is moving towards miniaturization, increased sensitivity, and integration with smart systems. This evolution is particularly relevant in the context of large-scale networks, where the ability to deploy numerous sensors across expansive areas offers unprecedented opportunities for data collection and analysis. The integration of piezoelectric sensors into these networks promises to revolutionize fields such as structural health monitoring, environmental sensing, and industrial process control.

The primary objective of implementing piezoelectric sensors in large-scale networks is to create a comprehensive, real-time monitoring system capable of detecting and measuring a variety of physical parameters. These may include vibration, pressure, acceleration, and strain across extensive areas or complex structures. By achieving this, organizations can enhance safety, optimize performance, and reduce maintenance costs in applications ranging from civil infrastructure to aerospace engineering.

Another crucial goal is to develop sensors that are energy-efficient and capable of harvesting energy from their environment. This aspect is particularly important for large-scale networks, where power supply and maintenance can be significant challenges. Piezoelectric materials offer the unique advantage of potentially serving dual roles as both sensors and energy harvesters, contributing to the development of self-powered sensing networks.

Furthermore, the implementation of piezoelectric sensors in large-scale networks aims to improve data collection and analysis capabilities. The objective is to create systems that can process and interpret vast amounts of data in real-time, enabling rapid decision-making and predictive maintenance strategies. This involves developing advanced signal processing algorithms and integrating machine learning techniques to extract meaningful insights from the sensor data.

As we look towards the future, the field of piezoelectric sensing in large-scale networks is poised for significant growth. The ongoing research focuses on enhancing sensor durability, expanding the range of detectable parameters, and improving integration with wireless communication technologies. These advancements will pave the way for more robust, versatile, and intelligent sensing systems capable of addressing complex challenges across various domains.

Market Analysis for Large-scale Sensor Networks

The market for large-scale sensor networks incorporating piezoelectric sensors is experiencing significant growth, driven by the increasing demand for smart infrastructure, industrial automation, and environmental monitoring. These networks offer real-time data collection and analysis capabilities, enabling organizations to optimize operations, enhance safety, and improve decision-making processes.

In the infrastructure sector, there is a growing need for structural health monitoring systems that can detect and assess damage in bridges, buildings, and other critical structures. Piezoelectric sensors integrated into large-scale networks provide continuous monitoring of vibrations, stress, and strain, allowing for early detection of potential issues and proactive maintenance.

The industrial automation market is another key driver for large-scale piezoelectric sensor networks. Manufacturing facilities are adopting these systems to monitor equipment performance, predict maintenance needs, and optimize production processes. The ability to detect minute changes in vibration patterns and stress levels helps prevent costly downtime and improves overall equipment effectiveness.

Environmental monitoring applications are also fueling market growth. Large-scale sensor networks equipped with piezoelectric sensors are being deployed to monitor seismic activity, air quality, and water resources. These systems provide valuable data for climate research, disaster prevention, and resource management.

The automotive industry is emerging as a significant market for piezoelectric sensor networks. Advanced driver assistance systems (ADAS) and autonomous vehicles rely on extensive sensor networks to gather data about the vehicle's surroundings and internal systems. Piezoelectric sensors play a crucial role in detecting impacts, measuring tire pressure, and monitoring engine performance.

The healthcare sector is showing increasing interest in large-scale piezoelectric sensor networks for patient monitoring and medical research. These systems can be used to track vital signs, detect falls, and monitor patient movement patterns, enabling more personalized and efficient care delivery.

As smart cities continue to evolve, the demand for comprehensive sensor networks is expected to grow. Piezoelectric sensors integrated into urban infrastructure can monitor traffic flow, detect structural issues in buildings and roads, and enhance public safety through improved emergency response systems.

The market for large-scale piezoelectric sensor networks faces some challenges, including high initial implementation costs and concerns about data privacy and security. However, ongoing advancements in sensor technology, data analytics, and network infrastructure are addressing these issues and driving down costs, making these systems more accessible to a wider range of organizations and applications.

In the infrastructure sector, there is a growing need for structural health monitoring systems that can detect and assess damage in bridges, buildings, and other critical structures. Piezoelectric sensors integrated into large-scale networks provide continuous monitoring of vibrations, stress, and strain, allowing for early detection of potential issues and proactive maintenance.

The industrial automation market is another key driver for large-scale piezoelectric sensor networks. Manufacturing facilities are adopting these systems to monitor equipment performance, predict maintenance needs, and optimize production processes. The ability to detect minute changes in vibration patterns and stress levels helps prevent costly downtime and improves overall equipment effectiveness.

Environmental monitoring applications are also fueling market growth. Large-scale sensor networks equipped with piezoelectric sensors are being deployed to monitor seismic activity, air quality, and water resources. These systems provide valuable data for climate research, disaster prevention, and resource management.

The automotive industry is emerging as a significant market for piezoelectric sensor networks. Advanced driver assistance systems (ADAS) and autonomous vehicles rely on extensive sensor networks to gather data about the vehicle's surroundings and internal systems. Piezoelectric sensors play a crucial role in detecting impacts, measuring tire pressure, and monitoring engine performance.

The healthcare sector is showing increasing interest in large-scale piezoelectric sensor networks for patient monitoring and medical research. These systems can be used to track vital signs, detect falls, and monitor patient movement patterns, enabling more personalized and efficient care delivery.

As smart cities continue to evolve, the demand for comprehensive sensor networks is expected to grow. Piezoelectric sensors integrated into urban infrastructure can monitor traffic flow, detect structural issues in buildings and roads, and enhance public safety through improved emergency response systems.

The market for large-scale piezoelectric sensor networks faces some challenges, including high initial implementation costs and concerns about data privacy and security. However, ongoing advancements in sensor technology, data analytics, and network infrastructure are addressing these issues and driving down costs, making these systems more accessible to a wider range of organizations and applications.

Current Challenges in Piezoelectric Network Implementation

The implementation of piezoelectric sensors in large-scale networks faces several significant challenges that need to be addressed for successful deployment. One of the primary obstacles is the scalability of the network infrastructure. As the number of sensors increases, the complexity of data management, communication protocols, and network topology grows exponentially. This scalability issue can lead to bottlenecks in data transmission and processing, potentially compromising the real-time responsiveness of the system.

Power management presents another critical challenge. Piezoelectric sensors, while capable of harvesting energy from mechanical vibrations, often generate limited power. In large-scale networks, ensuring a consistent and sufficient power supply for all sensors becomes increasingly difficult. This challenge is particularly acute in remote or hard-to-access locations where traditional power sources may not be available.

Data integrity and reliability are also major concerns in piezoelectric sensor networks. Environmental factors such as temperature fluctuations, humidity, and electromagnetic interference can affect sensor readings, leading to inaccurate or inconsistent data. Ensuring data quality across a vast network of sensors requires sophisticated calibration techniques and robust error detection mechanisms.

The heterogeneity of sensor types and data formats in large-scale networks poses interoperability challenges. Different piezoelectric sensors may have varying sensitivities, frequency responses, and output formats. Integrating these diverse sensors into a cohesive network and standardizing data formats for unified analysis and interpretation can be complex and resource-intensive.

Security and privacy concerns are paramount, especially when dealing with sensitive data in industrial or healthcare applications. Protecting the network from unauthorized access, data breaches, and malicious attacks while maintaining the integrity and confidentiality of sensor data is a significant challenge that requires advanced encryption and authentication protocols.

Maintenance and longevity of the sensor network present ongoing challenges. Large-scale networks may span vast geographical areas, making physical access for maintenance, repair, or replacement of sensors difficult and costly. Developing robust, long-lasting sensors and implementing effective remote diagnostics and self-healing mechanisms are crucial for the sustained operation of the network.

Finally, the cost-effectiveness of implementing and operating large-scale piezoelectric sensor networks remains a significant hurdle. The initial investment in sensor hardware, network infrastructure, and data management systems can be substantial. Balancing the costs against the potential benefits and ensuring a positive return on investment is a complex challenge that requires careful planning and optimization of network design and resources.

Power management presents another critical challenge. Piezoelectric sensors, while capable of harvesting energy from mechanical vibrations, often generate limited power. In large-scale networks, ensuring a consistent and sufficient power supply for all sensors becomes increasingly difficult. This challenge is particularly acute in remote or hard-to-access locations where traditional power sources may not be available.

Data integrity and reliability are also major concerns in piezoelectric sensor networks. Environmental factors such as temperature fluctuations, humidity, and electromagnetic interference can affect sensor readings, leading to inaccurate or inconsistent data. Ensuring data quality across a vast network of sensors requires sophisticated calibration techniques and robust error detection mechanisms.

The heterogeneity of sensor types and data formats in large-scale networks poses interoperability challenges. Different piezoelectric sensors may have varying sensitivities, frequency responses, and output formats. Integrating these diverse sensors into a cohesive network and standardizing data formats for unified analysis and interpretation can be complex and resource-intensive.

Security and privacy concerns are paramount, especially when dealing with sensitive data in industrial or healthcare applications. Protecting the network from unauthorized access, data breaches, and malicious attacks while maintaining the integrity and confidentiality of sensor data is a significant challenge that requires advanced encryption and authentication protocols.

Maintenance and longevity of the sensor network present ongoing challenges. Large-scale networks may span vast geographical areas, making physical access for maintenance, repair, or replacement of sensors difficult and costly. Developing robust, long-lasting sensors and implementing effective remote diagnostics and self-healing mechanisms are crucial for the sustained operation of the network.

Finally, the cost-effectiveness of implementing and operating large-scale piezoelectric sensor networks remains a significant hurdle. The initial investment in sensor hardware, network infrastructure, and data management systems can be substantial. Balancing the costs against the potential benefits and ensuring a positive return on investment is a complex challenge that requires careful planning and optimization of network design and resources.

Existing Large-scale Network Integration Solutions

01 Piezoelectric sensor design and fabrication

This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.- Piezoelectric sensor design and fabrication: This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.

- Applications of piezoelectric sensors in automotive industry: Piezoelectric sensors find extensive use in the automotive sector for various monitoring and control purposes. This includes applications such as tire pressure monitoring, engine knock detection, and vehicle stability control systems. The sensors provide real-time data to improve vehicle performance, safety, and efficiency.

- Integration of piezoelectric sensors in electronic devices: This category covers the incorporation of piezoelectric sensors into consumer electronics and smart devices. It includes applications such as touch-sensitive interfaces, motion detection, and haptic feedback systems. The integration of these sensors enhances user interaction and device functionality across a range of products.

- Piezoelectric sensors for structural health monitoring: Piezoelectric sensors play a crucial role in monitoring the health and integrity of various structures. This includes applications in civil engineering, aerospace, and industrial settings. The sensors can detect vibrations, stress, and damage in structures, allowing for predictive maintenance and improved safety measures.

- Signal processing and data analysis for piezoelectric sensors: This category focuses on the methods and technologies used to process and analyze the signals generated by piezoelectric sensors. It includes advanced algorithms, data fusion techniques, and noise reduction methods to improve the accuracy and reliability of sensor readings. These advancements enhance the overall performance and applicability of piezoelectric sensing systems.

02 Applications of piezoelectric sensors

Piezoelectric sensors find applications in diverse fields such as automotive, aerospace, medical devices, and consumer electronics. This category explores the integration of these sensors in different systems for measuring pressure, acceleration, force, and vibration. It also covers novel uses in emerging technologies like touchscreens and wearable devices.Expand Specific Solutions03 Signal processing and data analysis for piezoelectric sensors

This category deals with the methods and systems for processing and analyzing signals from piezoelectric sensors. It includes advanced algorithms, data fusion techniques, and noise reduction strategies to improve the accuracy and reliability of sensor measurements. The focus is on enhancing the interpretation of sensor data for more precise and meaningful results.Expand Specific Solutions04 Piezoelectric sensor arrays and networks

This category covers the development and implementation of piezoelectric sensor arrays and networks. It includes strategies for sensor placement, interconnection, and data aggregation from multiple sensors. The focus is on creating distributed sensing systems for applications such as structural health monitoring, environmental sensing, and large-scale data collection.Expand Specific Solutions05 Energy harvesting and self-powered piezoelectric sensors

This category explores the development of self-powered piezoelectric sensors and energy harvesting techniques. It includes methods for converting mechanical energy into electrical energy to power the sensor and associated electronics. The focus is on creating autonomous sensing systems that can operate without external power sources, particularly useful in remote or inaccessible locations.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The implementation of piezoelectric sensors in large-scale networks is in a growth phase, with increasing market size driven by applications in IoT, smart infrastructure, and industrial monitoring. The technology is maturing rapidly, but challenges remain in scalability and integration. Key players like Robert Bosch GmbH, Honeywell International Technologies Ltd., and Kistler Holding AG are leading innovation, while research institutions such as Nanjing University of Aeronautics & Astronautics and Centre National de la Recherche Scientifique contribute to advancing the field. The competitive landscape is diverse, with both established companies and emerging startups vying for market share in this promising sector.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive solution for implementing piezoelectric sensors in large-scale networks, particularly focused on automotive and industrial applications. Their approach integrates piezoelectric sensors with their extensive expertise in MEMS technology and IoT connectivity[1]. Bosch's system utilizes a distributed architecture with intelligent sensor nodes that perform local processing and data reduction, minimizing network traffic and improving response times[3]. They've implemented advanced energy management techniques, including low-power modes and energy harvesting, to extend battery life in wireless sensor nodes[5]. Bosch's solution also incorporates their Cross-Domain Computing Platform, which enables seamless integration of sensor data across multiple systems and applications[7]. For large-scale deployments, they've developed automated commissioning tools and over-the-air update capabilities, simplifying maintenance and ensuring long-term reliability[9].

Strengths: Extensive experience in automotive and industrial applications, advanced MEMS technology, and integrated IoT solutions. Weaknesses: Potentially complex integration with non-Bosch systems, and possible higher costs for smaller-scale deployments.

Chengdu Kaitian Electronics Co., Ltd.

Technical Solution: Chengdu Kaitian Electronics has developed a cost-effective solution for implementing piezoelectric sensors in large-scale networks, particularly targeting smart city and environmental monitoring applications. Their approach utilizes low-cost, mass-produced piezoelectric sensors combined with custom-designed signal conditioning circuits[1]. The company has created a mesh network topology that allows for self-organizing and self-healing networks, improving reliability and coverage in urban environments[3]. Kaitian's system incorporates LoRaWAN technology for long-range, low-power communication, enabling wide area coverage with minimal infrastructure[5]. They've also developed a cloud-based data management platform that provides real-time analytics and visualization tools, making it easier for city planners and environmental agencies to interpret and act on sensor data[7].

Strengths: Cost-effective solution, self-organizing network topology, and integration with smart city infrastructure. Weaknesses: Potentially lower precision compared to high-end industrial solutions, and possible limitations in harsh environmental conditions.

Core Innovations in Piezoelectric Sensor Design

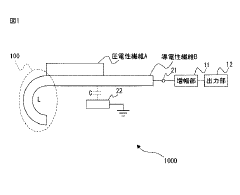

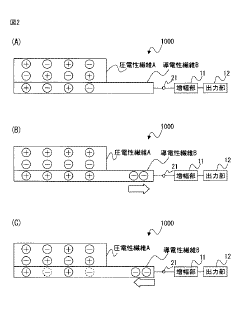

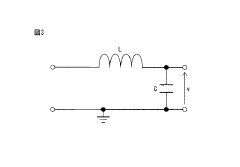

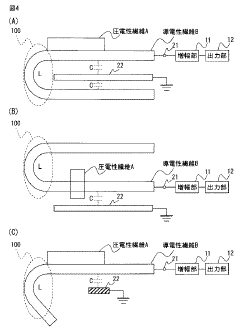

Piezoelectric sensor

PatentActiveJP2017146283A

Innovation

- A piezoelectric sensor design that combines conductive fibers arranged in a bent configuration with piezoelectric fibers in partial contact and spaced apart, incorporating a ground portion and an output terminal, along with an electric circuit for signal detection and amplification, utilizing a braided structure with polylactic acid as a main component.

Energy Harvesting Potential in Piezoelectric Networks

Piezoelectric sensors in large-scale networks offer significant potential for energy harvesting, presenting a sustainable solution for powering distributed sensing systems. These sensors leverage the piezoelectric effect, which generates an electric charge in response to mechanical stress or vibration. In the context of large-scale networks, this energy harvesting capability can be harnessed to create self-powered sensor nodes, reducing or eliminating the need for traditional power sources.

The energy harvesting potential of piezoelectric networks is particularly promising in environments with abundant mechanical energy, such as industrial settings, transportation infrastructure, and urban areas. For instance, in smart city applications, piezoelectric sensors embedded in roads or sidewalks can capture energy from vehicular and pedestrian traffic. This harvested energy can then be used to power various sensing and communication functions within the network.

One of the key advantages of piezoelectric energy harvesting in large-scale networks is its scalability. As the network expands, the cumulative energy harvesting capacity increases proportionally, potentially leading to a self-sustaining system. This scalability is particularly valuable in applications where traditional power infrastructure is challenging to implement or maintain, such as in remote environmental monitoring or structural health monitoring of large structures.

The efficiency of energy harvesting in piezoelectric networks depends on several factors, including the type and quality of piezoelectric materials used, the design of the energy harvesting circuitry, and the nature of the mechanical energy source. Recent advancements in piezoelectric materials, such as the development of high-performance ceramics and polymers, have significantly improved the energy conversion efficiency of these systems.

Furthermore, the integration of energy storage technologies, such as supercapacitors or thin-film batteries, with piezoelectric harvesters can enhance the overall energy management of the network. These storage solutions allow for the accumulation of harvested energy during periods of high mechanical activity, ensuring a stable power supply during low-activity periods.

The potential applications of energy harvesting in piezoelectric networks extend beyond mere power generation. The harvested energy can be used as a sensing mechanism itself, providing valuable data on the intensity and frequency of mechanical stimuli in the environment. This dual functionality – power generation and sensing – makes piezoelectric networks particularly attractive for applications in structural health monitoring, where the energy harvesting capability can serve as an indicator of structural stress or vibration.

The energy harvesting potential of piezoelectric networks is particularly promising in environments with abundant mechanical energy, such as industrial settings, transportation infrastructure, and urban areas. For instance, in smart city applications, piezoelectric sensors embedded in roads or sidewalks can capture energy from vehicular and pedestrian traffic. This harvested energy can then be used to power various sensing and communication functions within the network.

One of the key advantages of piezoelectric energy harvesting in large-scale networks is its scalability. As the network expands, the cumulative energy harvesting capacity increases proportionally, potentially leading to a self-sustaining system. This scalability is particularly valuable in applications where traditional power infrastructure is challenging to implement or maintain, such as in remote environmental monitoring or structural health monitoring of large structures.

The efficiency of energy harvesting in piezoelectric networks depends on several factors, including the type and quality of piezoelectric materials used, the design of the energy harvesting circuitry, and the nature of the mechanical energy source. Recent advancements in piezoelectric materials, such as the development of high-performance ceramics and polymers, have significantly improved the energy conversion efficiency of these systems.

Furthermore, the integration of energy storage technologies, such as supercapacitors or thin-film batteries, with piezoelectric harvesters can enhance the overall energy management of the network. These storage solutions allow for the accumulation of harvested energy during periods of high mechanical activity, ensuring a stable power supply during low-activity periods.

The potential applications of energy harvesting in piezoelectric networks extend beyond mere power generation. The harvested energy can be used as a sensing mechanism itself, providing valuable data on the intensity and frequency of mechanical stimuli in the environment. This dual functionality – power generation and sensing – makes piezoelectric networks particularly attractive for applications in structural health monitoring, where the energy harvesting capability can serve as an indicator of structural stress or vibration.

Data Management and Security in Sensor Networks

In large-scale networks of piezoelectric sensors, effective data management and robust security measures are crucial for ensuring the integrity, confidentiality, and availability of collected information. The sheer volume of data generated by these networks necessitates sophisticated data management strategies to handle storage, processing, and retrieval efficiently.

Distributed data storage systems are often employed to manage the vast amounts of sensor data. These systems distribute data across multiple nodes in the network, improving scalability and fault tolerance. Techniques such as data compression and aggregation are utilized to reduce storage requirements and network traffic. Time-series databases, optimized for handling time-stamped data, are particularly well-suited for storing and querying sensor readings.

Data processing in piezoelectric sensor networks often involves edge computing, where initial data analysis is performed at or near the sensor nodes. This approach reduces the amount of raw data transmitted to central servers, conserving bandwidth and energy. Machine learning algorithms can be deployed at the edge to detect anomalies or patterns in real-time, enabling rapid response to critical events.

Security in piezoelectric sensor networks is paramount, given the potential sensitivity of the data collected. Encryption is essential for protecting data both in transit and at rest. Public key infrastructure (PKI) can be implemented to manage cryptographic keys and digital certificates, ensuring secure communication between nodes and central systems.

Access control mechanisms are crucial for preventing unauthorized access to sensor data and network resources. Role-based access control (RBAC) systems can be employed to manage user permissions effectively. Additionally, intrusion detection systems (IDS) should be deployed to monitor network traffic for suspicious activities and potential security breaches.

Data integrity is another critical aspect of security in sensor networks. Digital signatures and hash functions can be used to verify the authenticity and integrity of sensor readings. Blockchain technology is emerging as a promising solution for creating tamper-evident logs of sensor data, providing an immutable record of measurements and events.

Privacy considerations must also be addressed, especially when sensor networks are deployed in public spaces. Data anonymization techniques can be applied to protect individual privacy while still allowing for meaningful analysis of aggregate data. Differential privacy methods can be used to add controlled noise to data outputs, preventing the identification of individuals from query results.

Distributed data storage systems are often employed to manage the vast amounts of sensor data. These systems distribute data across multiple nodes in the network, improving scalability and fault tolerance. Techniques such as data compression and aggregation are utilized to reduce storage requirements and network traffic. Time-series databases, optimized for handling time-stamped data, are particularly well-suited for storing and querying sensor readings.

Data processing in piezoelectric sensor networks often involves edge computing, where initial data analysis is performed at or near the sensor nodes. This approach reduces the amount of raw data transmitted to central servers, conserving bandwidth and energy. Machine learning algorithms can be deployed at the edge to detect anomalies or patterns in real-time, enabling rapid response to critical events.

Security in piezoelectric sensor networks is paramount, given the potential sensitivity of the data collected. Encryption is essential for protecting data both in transit and at rest. Public key infrastructure (PKI) can be implemented to manage cryptographic keys and digital certificates, ensuring secure communication between nodes and central systems.

Access control mechanisms are crucial for preventing unauthorized access to sensor data and network resources. Role-based access control (RBAC) systems can be employed to manage user permissions effectively. Additionally, intrusion detection systems (IDS) should be deployed to monitor network traffic for suspicious activities and potential security breaches.

Data integrity is another critical aspect of security in sensor networks. Digital signatures and hash functions can be used to verify the authenticity and integrity of sensor readings. Blockchain technology is emerging as a promising solution for creating tamper-evident logs of sensor data, providing an immutable record of measurements and events.

Privacy considerations must also be addressed, especially when sensor networks are deployed in public spaces. Data anonymization techniques can be applied to protect individual privacy while still allowing for meaningful analysis of aggregate data. Differential privacy methods can be used to add controlled noise to data outputs, preventing the identification of individuals from query results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!