Smart Piezoelectric Sensors with AI Integration

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Piezo-AI Sensors: Background and Objectives

Smart piezoelectric sensors integrated with artificial intelligence represent a cutting-edge technological advancement that combines the precision of piezoelectric materials with the analytical power of AI. This fusion has emerged as a response to the growing demand for more intelligent and responsive sensing systems across various industries.

The development of smart piezo-AI sensors can be traced back to the discovery of the piezoelectric effect in the late 19th century. Since then, piezoelectric materials have been widely used in sensors for their ability to convert mechanical stress into electrical signals. However, the integration of AI with these sensors marks a significant leap forward in their capabilities and potential applications.

The primary objective of research in this field is to create sensors that not only detect and measure physical phenomena but also interpret and act upon the data they collect in real-time. This integration aims to enhance the accuracy, reliability, and adaptability of sensing systems, making them more responsive to complex and dynamic environments.

One of the key drivers behind this technological evolution is the increasing need for autonomous and self-optimizing systems in industries such as manufacturing, healthcare, and automotive. Smart piezo-AI sensors have the potential to revolutionize predictive maintenance, structural health monitoring, and process control by providing more intelligent and context-aware sensing capabilities.

The convergence of piezoelectric technology and AI also aligns with broader trends in the Internet of Things (IoT) and edge computing. By embedding AI algorithms directly into sensor nodes, these smart sensors can perform local data processing and decision-making, reducing latency and bandwidth requirements while improving overall system efficiency.

Research in this area focuses on several key aspects, including the development of more sensitive and durable piezoelectric materials, the design of efficient energy harvesting mechanisms to power the AI components, and the creation of robust machine learning algorithms capable of operating within the constraints of embedded systems.

As the field progresses, researchers are exploring novel applications such as wearable health monitors that can detect and analyze subtle physiological changes, smart infrastructure systems that can assess and respond to structural stresses in real-time, and advanced robotics with enhanced tactile sensing capabilities.

The ultimate goal of this research is to create a new generation of sensors that can not only gather data but also understand and interpret it, leading to more intelligent and responsive systems across a wide range of applications. This fusion of piezoelectric sensing and AI promises to unlock new possibilities in fields ranging from industrial automation to personalized healthcare, driving innovation and improving the performance of countless systems and devices.

The development of smart piezo-AI sensors can be traced back to the discovery of the piezoelectric effect in the late 19th century. Since then, piezoelectric materials have been widely used in sensors for their ability to convert mechanical stress into electrical signals. However, the integration of AI with these sensors marks a significant leap forward in their capabilities and potential applications.

The primary objective of research in this field is to create sensors that not only detect and measure physical phenomena but also interpret and act upon the data they collect in real-time. This integration aims to enhance the accuracy, reliability, and adaptability of sensing systems, making them more responsive to complex and dynamic environments.

One of the key drivers behind this technological evolution is the increasing need for autonomous and self-optimizing systems in industries such as manufacturing, healthcare, and automotive. Smart piezo-AI sensors have the potential to revolutionize predictive maintenance, structural health monitoring, and process control by providing more intelligent and context-aware sensing capabilities.

The convergence of piezoelectric technology and AI also aligns with broader trends in the Internet of Things (IoT) and edge computing. By embedding AI algorithms directly into sensor nodes, these smart sensors can perform local data processing and decision-making, reducing latency and bandwidth requirements while improving overall system efficiency.

Research in this area focuses on several key aspects, including the development of more sensitive and durable piezoelectric materials, the design of efficient energy harvesting mechanisms to power the AI components, and the creation of robust machine learning algorithms capable of operating within the constraints of embedded systems.

As the field progresses, researchers are exploring novel applications such as wearable health monitors that can detect and analyze subtle physiological changes, smart infrastructure systems that can assess and respond to structural stresses in real-time, and advanced robotics with enhanced tactile sensing capabilities.

The ultimate goal of this research is to create a new generation of sensors that can not only gather data but also understand and interpret it, leading to more intelligent and responsive systems across a wide range of applications. This fusion of piezoelectric sensing and AI promises to unlock new possibilities in fields ranging from industrial automation to personalized healthcare, driving innovation and improving the performance of countless systems and devices.

Market Analysis for AI-Enhanced Piezoelectric Sensors

The market for AI-enhanced piezoelectric sensors is experiencing rapid growth, driven by increasing demand for smart sensing technologies across various industries. These advanced sensors, which combine the precision of piezoelectric materials with the intelligence of artificial intelligence, are finding applications in sectors such as healthcare, automotive, aerospace, and industrial automation.

In the healthcare sector, AI-enhanced piezoelectric sensors are revolutionizing patient monitoring and diagnostics. These sensors can provide real-time, accurate measurements of vital signs, enabling early detection of health issues and personalized treatment plans. The global market for smart healthcare devices, including AI-enhanced sensors, is projected to grow significantly in the coming years.

The automotive industry is another key market for AI-enhanced piezoelectric sensors. These sensors are crucial for developing advanced driver assistance systems (ADAS) and autonomous vehicles. They provide precise measurements of pressure, acceleration, and vibration, which are essential for vehicle safety and performance. As the automotive industry continues to move towards electrification and autonomy, the demand for these sensors is expected to surge.

In the aerospace sector, AI-enhanced piezoelectric sensors are being utilized for structural health monitoring of aircraft and spacecraft. These sensors can detect minute changes in stress and strain, allowing for predictive maintenance and improved safety. The growing emphasis on lightweight materials and fuel efficiency in aerospace is driving the adoption of these advanced sensing technologies.

Industrial automation is another significant market for AI-enhanced piezoelectric sensors. These sensors are being integrated into smart manufacturing systems to monitor equipment health, optimize production processes, and enhance quality control. The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) is expected to fuel the demand for these sensors in the coming years.

The market for AI-enhanced piezoelectric sensors is characterized by intense competition and rapid technological advancements. Key players in this market include established sensor manufacturers, AI technology companies, and startups focusing on innovative sensing solutions. Collaborations between sensor manufacturers and AI companies are becoming increasingly common, as they seek to develop more sophisticated and integrated solutions.

In the healthcare sector, AI-enhanced piezoelectric sensors are revolutionizing patient monitoring and diagnostics. These sensors can provide real-time, accurate measurements of vital signs, enabling early detection of health issues and personalized treatment plans. The global market for smart healthcare devices, including AI-enhanced sensors, is projected to grow significantly in the coming years.

The automotive industry is another key market for AI-enhanced piezoelectric sensors. These sensors are crucial for developing advanced driver assistance systems (ADAS) and autonomous vehicles. They provide precise measurements of pressure, acceleration, and vibration, which are essential for vehicle safety and performance. As the automotive industry continues to move towards electrification and autonomy, the demand for these sensors is expected to surge.

In the aerospace sector, AI-enhanced piezoelectric sensors are being utilized for structural health monitoring of aircraft and spacecraft. These sensors can detect minute changes in stress and strain, allowing for predictive maintenance and improved safety. The growing emphasis on lightweight materials and fuel efficiency in aerospace is driving the adoption of these advanced sensing technologies.

Industrial automation is another significant market for AI-enhanced piezoelectric sensors. These sensors are being integrated into smart manufacturing systems to monitor equipment health, optimize production processes, and enhance quality control. The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) is expected to fuel the demand for these sensors in the coming years.

The market for AI-enhanced piezoelectric sensors is characterized by intense competition and rapid technological advancements. Key players in this market include established sensor manufacturers, AI technology companies, and startups focusing on innovative sensing solutions. Collaborations between sensor manufacturers and AI companies are becoming increasingly common, as they seek to develop more sophisticated and integrated solutions.

Current Challenges in Smart Piezoelectric Sensing

Smart piezoelectric sensors integrated with AI face several significant challenges in their development and implementation. One of the primary obstacles is the complexity of signal processing and interpretation. Piezoelectric sensors generate complex electrical signals in response to mechanical stress, and these signals can be influenced by various environmental factors. Integrating AI to accurately interpret these signals in real-time requires sophisticated algorithms capable of handling high-dimensional data and filtering out noise.

Another challenge lies in the power consumption of AI-integrated sensors. Traditional piezoelectric sensors are often passive devices with low power requirements. However, the addition of AI processing capabilities significantly increases the energy demand. This poses difficulties in applications where long-term, autonomous operation is required, such as in remote monitoring systems or wearable devices.

The durability and reliability of smart piezoelectric sensors also present ongoing challenges. Piezoelectric materials can degrade over time, especially when subjected to repeated stress or extreme environmental conditions. Ensuring the long-term stability of both the sensing element and the integrated AI components is crucial for maintaining accurate and consistent performance.

Miniaturization is another area of concern. While piezoelectric sensors can be made quite small, integrating AI capabilities often requires additional hardware, which can increase the overall size and weight of the sensor system. This limitation can be particularly problematic in applications where space is at a premium, such as in medical implants or aerospace systems.

Data security and privacy issues also pose significant challenges, especially in IoT applications. Smart sensors often collect and process sensitive data, and ensuring the security of this information from collection to transmission and storage is critical. This requires robust encryption methods and secure communication protocols, which can further complicate the design and increase power consumption.

Calibration and standardization of AI-integrated piezoelectric sensors present additional hurdles. The performance of these sensors can vary based on manufacturing processes, environmental conditions, and the specific AI algorithms used. Developing standardized calibration methods and ensuring consistency across different sensor units and applications is essential for widespread adoption.

Finally, the integration of AI with piezoelectric sensing technology faces challenges in terms of cost-effectiveness and scalability. While the potential benefits of smart sensors are significant, the increased complexity and manufacturing costs can limit their adoption in price-sensitive markets. Balancing advanced capabilities with affordability remains a key challenge for researchers and manufacturers in this field.

Another challenge lies in the power consumption of AI-integrated sensors. Traditional piezoelectric sensors are often passive devices with low power requirements. However, the addition of AI processing capabilities significantly increases the energy demand. This poses difficulties in applications where long-term, autonomous operation is required, such as in remote monitoring systems or wearable devices.

The durability and reliability of smart piezoelectric sensors also present ongoing challenges. Piezoelectric materials can degrade over time, especially when subjected to repeated stress or extreme environmental conditions. Ensuring the long-term stability of both the sensing element and the integrated AI components is crucial for maintaining accurate and consistent performance.

Miniaturization is another area of concern. While piezoelectric sensors can be made quite small, integrating AI capabilities often requires additional hardware, which can increase the overall size and weight of the sensor system. This limitation can be particularly problematic in applications where space is at a premium, such as in medical implants or aerospace systems.

Data security and privacy issues also pose significant challenges, especially in IoT applications. Smart sensors often collect and process sensitive data, and ensuring the security of this information from collection to transmission and storage is critical. This requires robust encryption methods and secure communication protocols, which can further complicate the design and increase power consumption.

Calibration and standardization of AI-integrated piezoelectric sensors present additional hurdles. The performance of these sensors can vary based on manufacturing processes, environmental conditions, and the specific AI algorithms used. Developing standardized calibration methods and ensuring consistency across different sensor units and applications is essential for widespread adoption.

Finally, the integration of AI with piezoelectric sensing technology faces challenges in terms of cost-effectiveness and scalability. While the potential benefits of smart sensors are significant, the increased complexity and manufacturing costs can limit their adoption in price-sensitive markets. Balancing advanced capabilities with affordability remains a key challenge for researchers and manufacturers in this field.

Existing AI Integration Solutions for Piezoelectric Sensors

01 Intelligent piezoelectric sensor systems

Advanced piezoelectric sensor systems incorporating smart features for enhanced data collection, processing, and analysis. These systems may include machine learning algorithms, real-time monitoring capabilities, and adaptive sensing technologies to improve accuracy and efficiency in various applications.- Intelligent piezoelectric sensor systems: Advanced piezoelectric sensor systems incorporating smart features for enhanced data collection, processing, and analysis. These systems may include machine learning algorithms, real-time monitoring capabilities, and adaptive sensing technologies to improve accuracy and efficiency in various applications.

- Energy harvesting and self-powered sensors: Development of piezoelectric sensors capable of harvesting energy from ambient vibrations or mechanical stress, enabling self-powered operation. These sensors may incorporate energy storage mechanisms and power management systems to optimize energy usage and extend operational lifetimes.

- Miniaturization and flexible sensor designs: Advancements in fabrication techniques and materials science to create ultra-thin, flexible, and stretchable piezoelectric sensors. These innovations enable integration into wearable devices, soft robotics, and other applications requiring conformable and unobtrusive sensing solutions.

- Multi-modal sensing and sensor fusion: Integration of piezoelectric sensors with other sensing modalities, such as optical, chemical, or thermal sensors, to create multi-functional smart sensing platforms. These systems may employ sensor fusion algorithms to combine data from multiple sources for improved accuracy and comprehensive environmental monitoring.

- Wireless connectivity and IoT integration: Implementation of wireless communication protocols and Internet of Things (IoT) capabilities in piezoelectric sensor systems. This enables remote monitoring, data transmission, and integration with cloud-based analytics platforms for real-time decision-making and predictive maintenance applications.

02 Energy harvesting and self-powered sensors

Development of piezoelectric sensors capable of harvesting energy from ambient vibrations or mechanical stress, enabling self-powered operation. These sensors may incorporate energy storage mechanisms and power management systems to optimize energy usage and extend operational lifetimes.Expand Specific Solutions03 Miniaturization and integration of piezoelectric sensors

Advancements in miniaturization techniques and integration of piezoelectric sensors into compact, multifunctional devices. This may include the development of MEMS-based piezoelectric sensors, flexible or stretchable sensor arrays, and integration with other sensing modalities for comprehensive data collection.Expand Specific Solutions04 Wireless and IoT-enabled piezoelectric sensor networks

Integration of piezoelectric sensors with wireless communication technologies and Internet of Things (IoT) platforms. This enables the creation of large-scale sensor networks for distributed sensing, remote monitoring, and data-driven decision-making in various industries and smart city applications.Expand Specific Solutions05 Advanced signal processing and data analytics

Implementation of sophisticated signal processing techniques and data analytics algorithms for piezoelectric sensor systems. This may include noise reduction methods, feature extraction, pattern recognition, and predictive analytics to enhance sensor performance and enable intelligent decision-making based on sensor data.Expand Specific Solutions

Key Players in Smart Sensor Industry

The research on Smart Piezoelectric Sensors with AI Integration is in a nascent stage, characterized by rapid technological advancements and growing market potential. The industry is transitioning from traditional piezoelectric sensors to AI-integrated smart solutions, indicating an early growth phase. Market size is expanding, driven by increasing demand in automotive, healthcare, and industrial applications. Technologically, companies like Murata Manufacturing, Robert Bosch, and Texas Instruments are leading the development, leveraging their expertise in sensor technology and AI. Academic institutions such as Chongqing University and research organizations like Fraunhofer-Gesellschaft are contributing significantly to technological advancements, fostering industry-academia collaborations and accelerating innovation in this field.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed smart piezoelectric sensors with integrated AI capabilities. Their approach combines high-performance piezoelectric materials with advanced machine learning algorithms. The sensors utilize a multi-layer structure, incorporating piezoelectric elements, signal processing circuits, and AI chips in a compact package[1]. This integration allows for real-time data analysis and decision-making at the edge. Murata's sensors employ deep learning models optimized for low-power operation, enabling continuous monitoring and adaptive responses to environmental changes[3]. The company has also implemented federated learning techniques to improve sensor performance while maintaining data privacy[5].

Strengths: Compact integration of sensing and AI processing, low-power operation, and advanced data privacy features. Weaknesses: Potential complexity in manufacturing and higher initial costs compared to traditional sensors.

Robert Bosch GmbH

Technical Solution: Bosch has developed smart piezoelectric sensors with AI integration for various applications, including automotive and industrial sectors. Their approach combines high-precision piezoelectric sensing elements with embedded AI processors. The sensors utilize advanced signal processing techniques and machine learning algorithms to enhance sensitivity and reduce noise[2]. Bosch's smart sensors incorporate edge AI capabilities, allowing for real-time data analysis and decision-making directly on the sensor node. The company has implemented transfer learning techniques to adapt pre-trained AI models to specific application requirements, improving efficiency and reducing development time[4]. Bosch's sensors also feature self-calibration and predictive maintenance capabilities powered by AI algorithms[6].

Strengths: Versatile applications across multiple industries, robust edge AI capabilities, and advanced self-optimization features. Weaknesses: May require significant computational resources for complex AI models, potentially increasing power consumption.

Core Innovations in Smart Piezoelectric Sensing

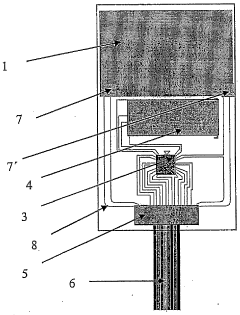

Device for measuring pressure, sound and vibration and method for analyzing flow on surfaces of structural parts

PatentInactiveEP1183512A1

Innovation

- A device with a sensor module integrated inside or on the rear of the component structure, using piezoelectric sensors and AI for signal evaluation, which protects the sensors from damage and minimizes interference with the flow, allowing for accurate measurement of flow characteristics without surface modifications.

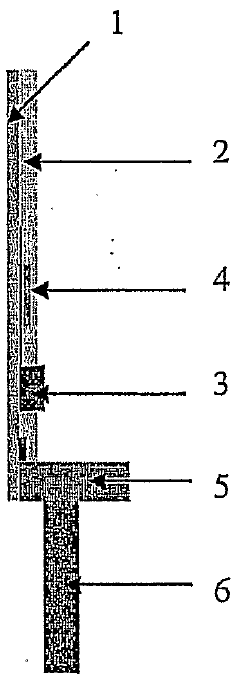

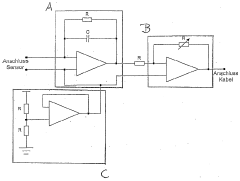

Piezoelectric sensor comprising a thermal sensor and an amplifier circuit

PatentWO2006084767A1

Innovation

- Integration of a thermal sensor and a temperature-compensated amplifier circuit within a miniaturized piezoelectric sensor system, utilizing semiconductor technology to ensure mechanical flexibility and cost-effectiveness, allowing the sensor to operate under different temperature conditions without significant mechanical or shape influence on the measurement object.

Standardization and Interoperability Considerations

In the rapidly evolving field of smart piezoelectric sensors with AI integration, standardization and interoperability considerations play a crucial role in ensuring widespread adoption and seamless integration across various applications. The development of common standards and protocols is essential for enabling different sensor systems to communicate effectively and share data across platforms.

One of the primary challenges in this domain is the lack of unified standards for data formats and communication protocols. Different manufacturers often use proprietary systems, making it difficult for sensors from various sources to work together seamlessly. To address this issue, industry stakeholders are collaborating to establish common data exchange formats and APIs that can facilitate interoperability between different sensor systems and AI platforms.

The IEEE has been at the forefront of developing standards for smart sensor technologies, including those related to piezoelectric sensors. The IEEE 2700-2017 standard, for instance, provides guidelines for sensor performance parameter definitions, which can be applied to smart piezoelectric sensors. Additionally, efforts are underway to create specific standards for AI-integrated sensor systems, focusing on data representation, sensor fusion, and edge computing protocols.

Interoperability considerations extend beyond data formats to include hardware interfaces and power management. The development of standardized connectors and power supply specifications can greatly enhance the plug-and-play capabilities of smart piezoelectric sensors, allowing for easier integration into existing systems and reducing implementation costs.

Security and privacy standards are another critical aspect of standardization efforts. As smart sensors collect and process sensitive data, it is essential to establish robust encryption and authentication protocols to protect against unauthorized access and data breaches. The development of standardized security frameworks specifically tailored for AI-integrated sensor networks is an ongoing area of research and development.

Cloud integration standards are also being developed to ensure that data from smart piezoelectric sensors can be seamlessly uploaded, processed, and analyzed in cloud environments. This includes standardizing data storage formats, query languages, and APIs for cloud-based AI analytics platforms.

As the field continues to evolve, ongoing collaboration between industry leaders, academic institutions, and standardization bodies will be crucial in developing and refining standards that can keep pace with technological advancements. The ultimate goal is to create a cohesive ecosystem where smart piezoelectric sensors with AI integration can operate seamlessly across different applications and industries, maximizing their potential impact and driving innovation in sensor technologies.

One of the primary challenges in this domain is the lack of unified standards for data formats and communication protocols. Different manufacturers often use proprietary systems, making it difficult for sensors from various sources to work together seamlessly. To address this issue, industry stakeholders are collaborating to establish common data exchange formats and APIs that can facilitate interoperability between different sensor systems and AI platforms.

The IEEE has been at the forefront of developing standards for smart sensor technologies, including those related to piezoelectric sensors. The IEEE 2700-2017 standard, for instance, provides guidelines for sensor performance parameter definitions, which can be applied to smart piezoelectric sensors. Additionally, efforts are underway to create specific standards for AI-integrated sensor systems, focusing on data representation, sensor fusion, and edge computing protocols.

Interoperability considerations extend beyond data formats to include hardware interfaces and power management. The development of standardized connectors and power supply specifications can greatly enhance the plug-and-play capabilities of smart piezoelectric sensors, allowing for easier integration into existing systems and reducing implementation costs.

Security and privacy standards are another critical aspect of standardization efforts. As smart sensors collect and process sensitive data, it is essential to establish robust encryption and authentication protocols to protect against unauthorized access and data breaches. The development of standardized security frameworks specifically tailored for AI-integrated sensor networks is an ongoing area of research and development.

Cloud integration standards are also being developed to ensure that data from smart piezoelectric sensors can be seamlessly uploaded, processed, and analyzed in cloud environments. This includes standardizing data storage formats, query languages, and APIs for cloud-based AI analytics platforms.

As the field continues to evolve, ongoing collaboration between industry leaders, academic institutions, and standardization bodies will be crucial in developing and refining standards that can keep pace with technological advancements. The ultimate goal is to create a cohesive ecosystem where smart piezoelectric sensors with AI integration can operate seamlessly across different applications and industries, maximizing their potential impact and driving innovation in sensor technologies.

Environmental Impact and Sustainability Aspects

The integration of smart piezoelectric sensors with AI has significant implications for environmental sustainability. These advanced sensing systems offer enhanced monitoring capabilities that can contribute to more efficient resource management and reduced environmental impact across various industries.

One of the primary environmental benefits of smart piezoelectric sensors with AI integration is their potential to optimize energy consumption. By providing real-time, high-precision data on structural health, vibrations, and pressure changes, these sensors enable more targeted and efficient energy use in applications such as smart buildings, industrial processes, and transportation systems. This improved energy efficiency can lead to substantial reductions in greenhouse gas emissions and overall carbon footprint.

In the context of environmental monitoring, AI-enhanced piezoelectric sensors offer unprecedented capabilities for detecting and analyzing pollution, air quality, and water contamination. The sensitivity and adaptability of these sensors, combined with AI's data processing power, allow for more accurate and timely identification of environmental threats. This can facilitate rapid response to potential hazards and support long-term environmental protection strategies.

The durability and longevity of piezoelectric materials contribute to the sustainability of these sensing systems. Unlike traditional sensors that may require frequent replacement, piezoelectric sensors have a longer operational lifespan, reducing waste generation and the need for resource-intensive manufacturing of replacement components. Additionally, the self-powering nature of piezoelectric sensors minimizes the need for external power sources or battery replacements, further reducing environmental impact.

However, the environmental impact of manufacturing and disposing of these advanced sensors must also be considered. The production of piezoelectric materials and associated electronic components may involve the use of rare earth elements and other resources with potentially significant environmental footprints. As such, the development of more sustainable manufacturing processes and materials for these sensors remains an important area for ongoing research and innovation.

Looking towards the future, the integration of AI with smart piezoelectric sensors holds promise for advancing circular economy principles. These sensors can play a crucial role in predictive maintenance systems, extending the lifespan of equipment and infrastructure, and minimizing waste through timely repairs and optimized resource allocation. Furthermore, the data gathered by these sensors can inform more sustainable design practices and lifecycle management strategies across various industries.

In conclusion, while smart piezoelectric sensors with AI integration offer substantial environmental benefits through improved monitoring, efficiency, and resource management, their full potential for sustainability can only be realized through careful consideration of their entire lifecycle impact and continued efforts to enhance their eco-friendly attributes.

One of the primary environmental benefits of smart piezoelectric sensors with AI integration is their potential to optimize energy consumption. By providing real-time, high-precision data on structural health, vibrations, and pressure changes, these sensors enable more targeted and efficient energy use in applications such as smart buildings, industrial processes, and transportation systems. This improved energy efficiency can lead to substantial reductions in greenhouse gas emissions and overall carbon footprint.

In the context of environmental monitoring, AI-enhanced piezoelectric sensors offer unprecedented capabilities for detecting and analyzing pollution, air quality, and water contamination. The sensitivity and adaptability of these sensors, combined with AI's data processing power, allow for more accurate and timely identification of environmental threats. This can facilitate rapid response to potential hazards and support long-term environmental protection strategies.

The durability and longevity of piezoelectric materials contribute to the sustainability of these sensing systems. Unlike traditional sensors that may require frequent replacement, piezoelectric sensors have a longer operational lifespan, reducing waste generation and the need for resource-intensive manufacturing of replacement components. Additionally, the self-powering nature of piezoelectric sensors minimizes the need for external power sources or battery replacements, further reducing environmental impact.

However, the environmental impact of manufacturing and disposing of these advanced sensors must also be considered. The production of piezoelectric materials and associated electronic components may involve the use of rare earth elements and other resources with potentially significant environmental footprints. As such, the development of more sustainable manufacturing processes and materials for these sensors remains an important area for ongoing research and innovation.

Looking towards the future, the integration of AI with smart piezoelectric sensors holds promise for advancing circular economy principles. These sensors can play a crucial role in predictive maintenance systems, extending the lifespan of equipment and infrastructure, and minimizing waste through timely repairs and optimized resource allocation. Furthermore, the data gathered by these sensors can inform more sustainable design practices and lifecycle management strategies across various industries.

In conclusion, while smart piezoelectric sensors with AI integration offer substantial environmental benefits through improved monitoring, efficiency, and resource management, their full potential for sustainability can only be realized through careful consideration of their entire lifecycle impact and continued efforts to enhance their eco-friendly attributes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!