Probing Micro-movements with Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensing Evolution and Objectives

Piezoelectric sensing technology has undergone significant evolution since its discovery in the late 19th century. Initially utilized for basic pressure and force measurements, piezoelectric sensors have progressively advanced to detect and quantify micro-movements with remarkable precision. This technological progression has been driven by the increasing demand for high-sensitivity, non-invasive measurement tools across various industries.

The development of piezoelectric sensing can be traced through several key phases. Early applications focused on macroscopic measurements, such as pressure gauges and accelerometers. As material science and manufacturing techniques improved, piezoelectric sensors became more sensitive and compact, enabling their use in more delicate applications like ultrasound imaging and vibration analysis.

In recent years, the field has experienced a paradigm shift towards micro-scale sensing. This transition has been facilitated by advancements in nanotechnology, allowing for the fabrication of highly sensitive piezoelectric materials and structures. These innovations have opened up new possibilities for detecting minute movements and vibrations that were previously imperceptible.

The current frontier of piezoelectric sensing lies in probing micro-movements. This capability has far-reaching implications across multiple domains, including healthcare, robotics, and structural health monitoring. In medicine, for instance, micro-movement detection can aid in early diagnosis of neurological disorders or provide real-time feedback in minimally invasive surgeries.

The primary objectives of contemporary piezoelectric sensing research are multifaceted. Firstly, there is a push to enhance sensitivity and resolution, allowing for the detection of even smaller movements. This involves both material innovations and improvements in signal processing techniques. Secondly, researchers aim to expand the frequency range of piezoelectric sensors, enabling them to capture a wider spectrum of micro-movements.

Another crucial objective is the integration of piezoelectric sensors into compact, portable devices. This goal aligns with the broader trend of miniaturization in electronics and opens up new applications in wearable technology and Internet of Things (IoT) devices. Additionally, there is a focus on improving the durability and reliability of these sensors, particularly in harsh environments or for long-term monitoring applications.

As the field progresses, a key aim is to develop multi-modal sensing capabilities. By combining piezoelectric sensing with other technologies such as optical or electromagnetic sensing, researchers hope to create more comprehensive and accurate measurement systems. This synergistic approach could lead to breakthroughs in fields like biomechanics and structural engineering.

The development of piezoelectric sensing can be traced through several key phases. Early applications focused on macroscopic measurements, such as pressure gauges and accelerometers. As material science and manufacturing techniques improved, piezoelectric sensors became more sensitive and compact, enabling their use in more delicate applications like ultrasound imaging and vibration analysis.

In recent years, the field has experienced a paradigm shift towards micro-scale sensing. This transition has been facilitated by advancements in nanotechnology, allowing for the fabrication of highly sensitive piezoelectric materials and structures. These innovations have opened up new possibilities for detecting minute movements and vibrations that were previously imperceptible.

The current frontier of piezoelectric sensing lies in probing micro-movements. This capability has far-reaching implications across multiple domains, including healthcare, robotics, and structural health monitoring. In medicine, for instance, micro-movement detection can aid in early diagnosis of neurological disorders or provide real-time feedback in minimally invasive surgeries.

The primary objectives of contemporary piezoelectric sensing research are multifaceted. Firstly, there is a push to enhance sensitivity and resolution, allowing for the detection of even smaller movements. This involves both material innovations and improvements in signal processing techniques. Secondly, researchers aim to expand the frequency range of piezoelectric sensors, enabling them to capture a wider spectrum of micro-movements.

Another crucial objective is the integration of piezoelectric sensors into compact, portable devices. This goal aligns with the broader trend of miniaturization in electronics and opens up new applications in wearable technology and Internet of Things (IoT) devices. Additionally, there is a focus on improving the durability and reliability of these sensors, particularly in harsh environments or for long-term monitoring applications.

As the field progresses, a key aim is to develop multi-modal sensing capabilities. By combining piezoelectric sensing with other technologies such as optical or electromagnetic sensing, researchers hope to create more comprehensive and accurate measurement systems. This synergistic approach could lead to breakthroughs in fields like biomechanics and structural engineering.

Micro-movement Detection Market Analysis

The market for micro-movement detection using piezoelectric sensors has shown significant growth in recent years, driven by increasing demand across various industries. This technology's ability to detect minute movements and vibrations has found applications in sectors such as healthcare, automotive, aerospace, and consumer electronics.

In the healthcare sector, micro-movement detection is being utilized for patient monitoring, sleep analysis, and early detection of neurological disorders. The aging population and the growing emphasis on preventive healthcare have contributed to the expansion of this market segment. Hospitals and care facilities are increasingly adopting these sensors for continuous patient monitoring, leading to improved patient outcomes and reduced healthcare costs.

The automotive industry has also embraced micro-movement detection technology for advanced driver assistance systems (ADAS) and autonomous vehicles. These sensors play a crucial role in detecting driver fatigue, enhancing safety features, and improving overall vehicle performance. As the automotive sector continues to evolve towards autonomous driving, the demand for high-precision micro-movement detection is expected to surge.

In the aerospace industry, piezoelectric sensors are used for structural health monitoring of aircraft and spacecraft. The ability to detect micro-movements allows for early identification of potential structural issues, enhancing safety and reducing maintenance costs. This application is particularly valuable in the growing commercial space industry, where reliability and safety are paramount.

The consumer electronics market has seen a rapid adoption of micro-movement detection technology in wearable devices, smartphones, and smart home applications. These sensors enable features such as gesture recognition, activity tracking, and enhanced user interfaces, driving innovation in the consumer technology sector.

Market analysis indicates that the global micro-movement detection market is poised for substantial growth. Factors such as technological advancements, increasing automation across industries, and the rising demand for high-precision sensing solutions are expected to fuel this growth. The market is characterized by intense competition among key players, with ongoing research and development efforts focused on improving sensor sensitivity, reducing power consumption, and enhancing integration capabilities.

Geographically, North America and Europe currently lead the market due to their advanced healthcare systems and strong presence in the automotive and aerospace industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, increasing adoption of IoT technologies, and growing investments in healthcare infrastructure.

As the technology continues to evolve, new applications are emerging in fields such as robotics, virtual reality, and smart manufacturing. These developments are expected to create new opportunities for market expansion and drive further innovation in micro-movement detection using piezoelectric sensors.

In the healthcare sector, micro-movement detection is being utilized for patient monitoring, sleep analysis, and early detection of neurological disorders. The aging population and the growing emphasis on preventive healthcare have contributed to the expansion of this market segment. Hospitals and care facilities are increasingly adopting these sensors for continuous patient monitoring, leading to improved patient outcomes and reduced healthcare costs.

The automotive industry has also embraced micro-movement detection technology for advanced driver assistance systems (ADAS) and autonomous vehicles. These sensors play a crucial role in detecting driver fatigue, enhancing safety features, and improving overall vehicle performance. As the automotive sector continues to evolve towards autonomous driving, the demand for high-precision micro-movement detection is expected to surge.

In the aerospace industry, piezoelectric sensors are used for structural health monitoring of aircraft and spacecraft. The ability to detect micro-movements allows for early identification of potential structural issues, enhancing safety and reducing maintenance costs. This application is particularly valuable in the growing commercial space industry, where reliability and safety are paramount.

The consumer electronics market has seen a rapid adoption of micro-movement detection technology in wearable devices, smartphones, and smart home applications. These sensors enable features such as gesture recognition, activity tracking, and enhanced user interfaces, driving innovation in the consumer technology sector.

Market analysis indicates that the global micro-movement detection market is poised for substantial growth. Factors such as technological advancements, increasing automation across industries, and the rising demand for high-precision sensing solutions are expected to fuel this growth. The market is characterized by intense competition among key players, with ongoing research and development efforts focused on improving sensor sensitivity, reducing power consumption, and enhancing integration capabilities.

Geographically, North America and Europe currently lead the market due to their advanced healthcare systems and strong presence in the automotive and aerospace industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, increasing adoption of IoT technologies, and growing investments in healthcare infrastructure.

As the technology continues to evolve, new applications are emerging in fields such as robotics, virtual reality, and smart manufacturing. These developments are expected to create new opportunities for market expansion and drive further innovation in micro-movement detection using piezoelectric sensors.

Piezoelectric Sensor Limitations and Challenges

Despite the numerous advantages of piezoelectric sensors in detecting micro-movements, several limitations and challenges persist in their application. One of the primary constraints is the inherent nonlinearity of piezoelectric materials, which can lead to distortions in the sensor output, especially when operating outside their optimal range. This nonlinearity complicates the interpretation of sensor data and necessitates complex calibration procedures to ensure accurate measurements.

Another significant challenge is the susceptibility of piezoelectric sensors to environmental factors. Temperature fluctuations, in particular, can greatly affect the sensor's performance, causing drift in the output signal and reducing measurement accuracy. This temperature sensitivity requires the implementation of compensation techniques or temperature-controlled environments, which can increase system complexity and cost.

The high impedance output of piezoelectric sensors presents another hurdle. This characteristic makes them prone to electromagnetic interference and noise, potentially compromising the integrity of the micro-movement data. Shielding and proper signal conditioning are essential but can add to the overall system complexity and cost.

Piezoelectric sensors also face limitations in detecting static or very low-frequency movements. Due to their inherent charge leakage, these sensors struggle to maintain a stable output for prolonged periods under constant stress, making them less suitable for applications requiring long-term static measurements.

The fragility of certain piezoelectric materials poses challenges in rugged or high-stress environments. Some piezoelectric crystals can be brittle and susceptible to damage from excessive force or shock, limiting their applicability in harsh industrial settings or high-impact scenarios.

Hysteresis effects in piezoelectric materials can lead to measurement inaccuracies, particularly in applications requiring precise bidirectional movement detection. This phenomenon can result in different sensor outputs for the same input depending on the previous state, complicating data interpretation and control algorithms.

Lastly, the integration of piezoelectric sensors into compact or flexible systems presents significant engineering challenges. Miniaturization while maintaining sensitivity and robustness is an ongoing area of research, particularly for applications in wearable technology and micro-electromechanical systems (MEMS).

Addressing these limitations and challenges requires ongoing research and development in materials science, signal processing, and sensor design. Innovations in composite piezoelectric materials, advanced signal conditioning techniques, and novel sensor architectures are crucial for expanding the capabilities and applications of piezoelectric sensors in micro-movement detection.

Another significant challenge is the susceptibility of piezoelectric sensors to environmental factors. Temperature fluctuations, in particular, can greatly affect the sensor's performance, causing drift in the output signal and reducing measurement accuracy. This temperature sensitivity requires the implementation of compensation techniques or temperature-controlled environments, which can increase system complexity and cost.

The high impedance output of piezoelectric sensors presents another hurdle. This characteristic makes them prone to electromagnetic interference and noise, potentially compromising the integrity of the micro-movement data. Shielding and proper signal conditioning are essential but can add to the overall system complexity and cost.

Piezoelectric sensors also face limitations in detecting static or very low-frequency movements. Due to their inherent charge leakage, these sensors struggle to maintain a stable output for prolonged periods under constant stress, making them less suitable for applications requiring long-term static measurements.

The fragility of certain piezoelectric materials poses challenges in rugged or high-stress environments. Some piezoelectric crystals can be brittle and susceptible to damage from excessive force or shock, limiting their applicability in harsh industrial settings or high-impact scenarios.

Hysteresis effects in piezoelectric materials can lead to measurement inaccuracies, particularly in applications requiring precise bidirectional movement detection. This phenomenon can result in different sensor outputs for the same input depending on the previous state, complicating data interpretation and control algorithms.

Lastly, the integration of piezoelectric sensors into compact or flexible systems presents significant engineering challenges. Miniaturization while maintaining sensitivity and robustness is an ongoing area of research, particularly for applications in wearable technology and micro-electromechanical systems (MEMS).

Addressing these limitations and challenges requires ongoing research and development in materials science, signal processing, and sensor design. Innovations in composite piezoelectric materials, advanced signal conditioning techniques, and novel sensor architectures are crucial for expanding the capabilities and applications of piezoelectric sensors in micro-movement detection.

Current Micro-movement Detection Solutions

01 Piezoelectric sensors for detecting micro-movements

Piezoelectric sensors are utilized to detect and measure micro-movements in various applications. These sensors convert mechanical stress or vibration into electrical signals, allowing for precise measurement of small displacements or movements. The high sensitivity of piezoelectric materials makes them ideal for detecting subtle changes in position or motion.- Piezoelectric sensors for detecting micro-movements: Piezoelectric sensors are utilized to detect and measure micro-movements in various applications. These sensors convert mechanical stress or vibration into electrical signals, allowing for precise measurement of small-scale movements. The high sensitivity of piezoelectric materials makes them ideal for detecting minute displacements and vibrations in micro-scale applications.

- Micro-actuators using piezoelectric elements: Piezoelectric elements are employed in micro-actuators to generate controlled micro-movements. These actuators can produce precise displacements in response to applied electrical signals, making them suitable for applications requiring fine positioning or vibration control. The ability to generate micro-movements with high precision allows for improved performance in various devices and systems.

- Integration of piezoelectric sensors in MEMS devices: Piezoelectric sensors are integrated into Micro-Electro-Mechanical Systems (MEMS) devices to enable micro-movement detection and measurement. This integration allows for the development of compact and highly sensitive devices capable of detecting and responding to small-scale movements. MEMS devices with integrated piezoelectric sensors find applications in various fields, including accelerometers, gyroscopes, and pressure sensors.

- Piezoelectric sensors for touch and gesture recognition: Piezoelectric sensors are used in touch and gesture recognition systems to detect micro-movements of fingers or objects on surfaces. These sensors can accurately measure the pressure and movement applied to a surface, enabling the development of responsive touch interfaces and gesture-based control systems. The high sensitivity of piezoelectric sensors allows for the detection of subtle movements and pressure changes.

- Energy harvesting from micro-movements using piezoelectric materials: Piezoelectric materials are utilized to harvest energy from micro-movements and vibrations in the environment. This approach enables the conversion of small-scale mechanical energy into electrical energy, which can be used to power low-power devices or charge batteries. Energy harvesting from micro-movements using piezoelectric materials has applications in self-powered sensors, wearable devices, and IoT systems.

02 Integration of piezoelectric sensors in electronic devices

Piezoelectric sensors are integrated into electronic devices such as smartphones, tablets, and wearables to enable gesture recognition, touch sensitivity, and motion detection. These sensors can be incorporated into displays, buttons, or other components to enhance user interaction and provide new input methods based on micro-movements.Expand Specific Solutions03 Micro-electromechanical systems (MEMS) with piezoelectric elements

MEMS devices incorporating piezoelectric elements are developed for various sensing applications. These miniaturized systems combine mechanical and electrical components to detect and measure micro-movements with high precision. MEMS-based piezoelectric sensors offer advantages such as small size, low power consumption, and high sensitivity.Expand Specific Solutions04 Piezoelectric actuators for micro-positioning

Piezoelectric materials are used to create actuators capable of precise micro-positioning. These actuators can generate small displacements with high accuracy, making them suitable for applications in optics, microscopy, and precision manufacturing. The ability to control micro-movements allows for fine adjustments and improved performance in various systems.Expand Specific Solutions05 Energy harvesting from micro-movements using piezoelectric materials

Piezoelectric materials are employed to harvest energy from micro-movements and vibrations in the environment. This technology can be used to power small electronic devices or sensors by converting mechanical energy from subtle movements into electrical energy. Energy harvesting from micro-movements offers potential for self-powered systems and IoT applications.Expand Specific Solutions

Key Piezoelectric Sensor Manufacturers

The field of probing micro-movements with piezoelectric sensors is in a growth phase, with increasing market size and technological advancements. The global market for piezoelectric sensors is expanding, driven by applications in various industries. Technologically, the field is progressing rapidly, with companies like Murata Manufacturing, Yamaha Corp., and Samsung Electronics leading innovation. These firms are developing more sensitive and miniaturized sensors, enhancing their capabilities for detecting micro-movements. Academic institutions such as California Institute of Technology and Tsinghua University are contributing to fundamental research, pushing the boundaries of sensor technology. The collaboration between industry and academia is accelerating the maturation of this technology, promising significant improvements in precision and applicability across diverse sectors.

California Institute of Technology

Technical Solution: Caltech researchers have developed a novel approach to piezoelectric sensing for micro-movements using nanoscale materials. Their method involves creating arrays of piezoelectric nanowires, typically made of zinc oxide or lead zirconate titanate, with diameters as small as 20 nanometers[1]. These nanowire arrays can detect movements on the scale of individual molecules, with a sensitivity approaching 1 picometer[2]. The team has also developed a unique signal amplification technique that uses resonant coupling between adjacent nanowires to enhance the detection of weak signals[3]. This technology has been applied to create ultra-sensitive seismometers and to study the mechanics of individual biological cells[4].

Strengths: Extremely high sensitivity, potential for molecular-scale sensing. Weaknesses: Complex fabrication process, may be challenging to scale up for commercial applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric sensors for micro-movement detection, utilizing their expertise in ceramic materials. Their sensors employ multi-layer piezoelectric elements to enhance sensitivity and reduce noise[1]. The company has implemented a proprietary signal processing algorithm that can detect movements as small as 1 micron[2]. Murata's sensors are designed with a compact form factor, typically less than 5mm in thickness, allowing for integration into various devices[3]. They have also developed a wireless version of their sensors, enabling remote monitoring of micro-movements in structural health monitoring applications[4].

Strengths: High sensitivity, compact size, and wireless capabilities. Weaknesses: May be more expensive than simpler piezoelectric sensors, and could require specialized knowledge for integration.

Innovative Piezoelectric Sensing Techniques

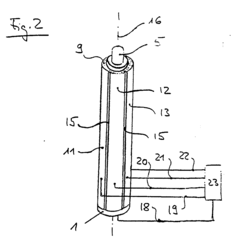

Device for micro-movement of objects

PatentInactiveEP0239085A3

Innovation

- A movement device utilizing piezoelectric material with hollow cylindrical elements and electrically conductive coatings, allowing for precise control of object movement through varying voltages, providing high mechanical rigidity, low susceptibility to vibration, and minimal temperature drift, enabling precise translational, rotational, and tilting movements.

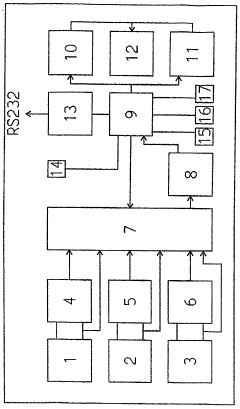

Method for recording motions of a person and device for carrying out said method

PatentWO2005104946A1

Innovation

- A microcontroller-based system using piezoelectric sensors to measure angular displacements along three perpendicular axes, recording signals in non-volatile memory and processing data for efficient movement registration without external illumination, reducing costs and increasing accuracy.

Miniaturization and Integration Strategies

The miniaturization and integration of piezoelectric sensors for probing micro-movements present both challenges and opportunities in advancing this technology. As devices become smaller and more compact, integrating these sensors seamlessly into various applications becomes increasingly feasible. One key strategy involves the development of thin-film piezoelectric materials, which can be deposited on flexible substrates, allowing for conformal integration into curved or irregular surfaces.

Advances in microfabrication techniques have enabled the production of piezoelectric sensors on the microscale, with some reaching dimensions of just a few micrometers. These miniaturized sensors can be arranged in dense arrays, significantly enhancing spatial resolution for detecting micro-movements. The integration of such arrays with microelectronic circuits on a single chip has led to the creation of highly sensitive and compact sensing systems.

Another important aspect of miniaturization is the reduction of power consumption. By optimizing the sensor design and employing efficient energy harvesting techniques, it is possible to create self-powered piezoelectric sensors that can operate autonomously for extended periods. This is particularly valuable for applications in remote or inaccessible locations.

Integration strategies also focus on combining piezoelectric sensors with other sensing modalities, such as accelerometers or gyroscopes, to create multi-functional sensing platforms. This approach not only saves space but also enables more comprehensive movement analysis by correlating data from different sensor types.

The development of flexible and stretchable piezoelectric materials has opened up new possibilities for integration into wearable devices and soft robotics. These materials can conform to complex shapes and withstand deformation while maintaining their sensing capabilities, making them ideal for applications in healthcare monitoring and human-machine interfaces.

Advancements in packaging technologies play a crucial role in miniaturization and integration efforts. Techniques such as wafer-level packaging and through-silicon vias (TSVs) allow for vertical integration of sensors and electronics, significantly reducing the overall footprint of the sensing system. Additionally, the use of biocompatible materials in sensor packaging enables direct integration with biological systems for medical applications.

As miniaturization progresses, addressing challenges related to signal-to-noise ratio and cross-talk between closely packed sensors becomes increasingly important. Novel signal processing algorithms and shielding techniques are being developed to mitigate these issues and maintain high sensing performance in miniaturized systems.

Advances in microfabrication techniques have enabled the production of piezoelectric sensors on the microscale, with some reaching dimensions of just a few micrometers. These miniaturized sensors can be arranged in dense arrays, significantly enhancing spatial resolution for detecting micro-movements. The integration of such arrays with microelectronic circuits on a single chip has led to the creation of highly sensitive and compact sensing systems.

Another important aspect of miniaturization is the reduction of power consumption. By optimizing the sensor design and employing efficient energy harvesting techniques, it is possible to create self-powered piezoelectric sensors that can operate autonomously for extended periods. This is particularly valuable for applications in remote or inaccessible locations.

Integration strategies also focus on combining piezoelectric sensors with other sensing modalities, such as accelerometers or gyroscopes, to create multi-functional sensing platforms. This approach not only saves space but also enables more comprehensive movement analysis by correlating data from different sensor types.

The development of flexible and stretchable piezoelectric materials has opened up new possibilities for integration into wearable devices and soft robotics. These materials can conform to complex shapes and withstand deformation while maintaining their sensing capabilities, making them ideal for applications in healthcare monitoring and human-machine interfaces.

Advancements in packaging technologies play a crucial role in miniaturization and integration efforts. Techniques such as wafer-level packaging and through-silicon vias (TSVs) allow for vertical integration of sensors and electronics, significantly reducing the overall footprint of the sensing system. Additionally, the use of biocompatible materials in sensor packaging enables direct integration with biological systems for medical applications.

As miniaturization progresses, addressing challenges related to signal-to-noise ratio and cross-talk between closely packed sensors becomes increasingly important. Novel signal processing algorithms and shielding techniques are being developed to mitigate these issues and maintain high sensing performance in miniaturized systems.

Applications Across Various Industries

Piezoelectric sensors have found applications across a wide range of industries due to their ability to detect micro-movements with high precision. In the healthcare sector, these sensors are revolutionizing patient monitoring systems. They can be integrated into hospital beds to track vital signs such as heart rate and respiratory rate without the need for invasive equipment. This technology also enables early detection of patient movement, which is crucial for preventing falls and pressure ulcers in bedridden patients.

In the automotive industry, piezoelectric sensors are enhancing safety and comfort features. They are used in advanced driver assistance systems (ADAS) to detect minute vibrations and movements, improving the accuracy of collision avoidance systems and adaptive cruise control. These sensors also play a role in developing more responsive suspension systems, providing real-time adjustments based on road conditions and vehicle dynamics.

The aerospace sector has embraced piezoelectric sensors for structural health monitoring of aircraft. By detecting micro-movements and vibrations in critical components, these sensors can identify potential structural weaknesses or damage before they become serious issues. This proactive approach to maintenance significantly enhances flight safety and reduces downtime for inspections.

In manufacturing and industrial settings, piezoelectric sensors are integral to quality control processes. They can detect minute deviations in product dimensions or surface irregularities, ensuring high precision in manufacturing operations. These sensors are particularly valuable in industries requiring nanometer-level accuracy, such as semiconductor fabrication and precision machining.

The field of robotics has also benefited from piezoelectric sensor technology. By incorporating these sensors into robotic arms and grippers, engineers have developed systems capable of ultra-precise movements and force feedback. This has enabled advancements in areas such as microsurgery robots and automated assembly lines for delicate electronic components.

In the consumer electronics market, piezoelectric sensors are enhancing user interfaces and device functionality. They are used in touchscreens to provide haptic feedback and in wearable devices to track physical activity with greater accuracy. Some smartphones now incorporate these sensors for improved gesture recognition and pressure-sensitive inputs.

The energy sector is exploring piezoelectric sensors for structural health monitoring of wind turbines and oil pipelines. By detecting micro-movements indicative of stress or fatigue, these sensors can predict potential failures and optimize maintenance schedules, leading to increased operational efficiency and reduced downtime.

In the automotive industry, piezoelectric sensors are enhancing safety and comfort features. They are used in advanced driver assistance systems (ADAS) to detect minute vibrations and movements, improving the accuracy of collision avoidance systems and adaptive cruise control. These sensors also play a role in developing more responsive suspension systems, providing real-time adjustments based on road conditions and vehicle dynamics.

The aerospace sector has embraced piezoelectric sensors for structural health monitoring of aircraft. By detecting micro-movements and vibrations in critical components, these sensors can identify potential structural weaknesses or damage before they become serious issues. This proactive approach to maintenance significantly enhances flight safety and reduces downtime for inspections.

In manufacturing and industrial settings, piezoelectric sensors are integral to quality control processes. They can detect minute deviations in product dimensions or surface irregularities, ensuring high precision in manufacturing operations. These sensors are particularly valuable in industries requiring nanometer-level accuracy, such as semiconductor fabrication and precision machining.

The field of robotics has also benefited from piezoelectric sensor technology. By incorporating these sensors into robotic arms and grippers, engineers have developed systems capable of ultra-precise movements and force feedback. This has enabled advancements in areas such as microsurgery robots and automated assembly lines for delicate electronic components.

In the consumer electronics market, piezoelectric sensors are enhancing user interfaces and device functionality. They are used in touchscreens to provide haptic feedback and in wearable devices to track physical activity with greater accuracy. Some smartphones now incorporate these sensors for improved gesture recognition and pressure-sensitive inputs.

The energy sector is exploring piezoelectric sensors for structural health monitoring of wind turbines and oil pipelines. By detecting micro-movements indicative of stress or fatigue, these sensors can predict potential failures and optimize maintenance schedules, leading to increased operational efficiency and reduced downtime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!