Piezoelectric Sensors in Environmental Monitoring

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception in the early 20th century. Initially discovered by the Curie brothers in 1880, the piezoelectric effect has been harnessed for various applications, with environmental monitoring emerging as a crucial field in recent decades. The journey of piezoelectric sensors in environmental monitoring began in the 1960s, primarily focusing on seismic activity detection. As technology advanced, these sensors found broader applications in air quality monitoring, water pollution detection, and noise level measurement.

The evolution of piezoelectric sensors in environmental monitoring has been marked by several key milestones. In the 1980s, the development of more sensitive piezoelectric materials allowed for the detection of minute vibrations and pressure changes, enabling more accurate seismic monitoring. The 1990s saw the integration of piezoelectric sensors with microelectromechanical systems (MEMS), leading to miniaturization and increased sensitivity. This advancement opened up new possibilities for portable and distributed environmental monitoring systems.

The early 2000s brought about a shift towards multi-parameter sensing capabilities. Piezoelectric sensors were engineered to simultaneously detect various environmental factors, such as temperature, humidity, and chemical composition, alongside their traditional pressure and vibration sensing roles. This multi-functionality significantly enhanced the efficiency and comprehensiveness of environmental monitoring systems.

Recent years have witnessed a focus on improving the durability and reliability of piezoelectric sensors in harsh environmental conditions. Developments in materials science have led to sensors capable of withstanding extreme temperatures, corrosive environments, and high-pressure scenarios, making them suitable for a wider range of monitoring applications, including deep-sea and atmospheric research.

The primary objectives of current research on piezoelectric sensors in environmental monitoring are multifaceted. Firstly, there is a drive towards enhancing sensitivity and accuracy, aiming to detect even smaller changes in environmental parameters. This includes developing new piezoelectric materials and optimizing sensor designs to minimize noise and interference.

Secondly, researchers are focusing on expanding the range of detectable environmental factors. This involves creating sensors capable of identifying specific pollutants, measuring air quality parameters, and detecting subtle changes in ecosystem health. The goal is to provide more comprehensive and nuanced environmental data for better decision-making and policy formulation.

Another key objective is the integration of piezoelectric sensors with IoT and AI technologies. This aims to create smart, interconnected environmental monitoring networks capable of real-time data collection, analysis, and predictive modeling. Such systems could revolutionize our approach to environmental management and disaster prevention.

The evolution of piezoelectric sensors in environmental monitoring has been marked by several key milestones. In the 1980s, the development of more sensitive piezoelectric materials allowed for the detection of minute vibrations and pressure changes, enabling more accurate seismic monitoring. The 1990s saw the integration of piezoelectric sensors with microelectromechanical systems (MEMS), leading to miniaturization and increased sensitivity. This advancement opened up new possibilities for portable and distributed environmental monitoring systems.

The early 2000s brought about a shift towards multi-parameter sensing capabilities. Piezoelectric sensors were engineered to simultaneously detect various environmental factors, such as temperature, humidity, and chemical composition, alongside their traditional pressure and vibration sensing roles. This multi-functionality significantly enhanced the efficiency and comprehensiveness of environmental monitoring systems.

Recent years have witnessed a focus on improving the durability and reliability of piezoelectric sensors in harsh environmental conditions. Developments in materials science have led to sensors capable of withstanding extreme temperatures, corrosive environments, and high-pressure scenarios, making them suitable for a wider range of monitoring applications, including deep-sea and atmospheric research.

The primary objectives of current research on piezoelectric sensors in environmental monitoring are multifaceted. Firstly, there is a drive towards enhancing sensitivity and accuracy, aiming to detect even smaller changes in environmental parameters. This includes developing new piezoelectric materials and optimizing sensor designs to minimize noise and interference.

Secondly, researchers are focusing on expanding the range of detectable environmental factors. This involves creating sensors capable of identifying specific pollutants, measuring air quality parameters, and detecting subtle changes in ecosystem health. The goal is to provide more comprehensive and nuanced environmental data for better decision-making and policy formulation.

Another key objective is the integration of piezoelectric sensors with IoT and AI technologies. This aims to create smart, interconnected environmental monitoring networks capable of real-time data collection, analysis, and predictive modeling. Such systems could revolutionize our approach to environmental management and disaster prevention.

Environmental Monitoring Market Analysis

The environmental monitoring market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and stricter regulations worldwide. The global market for environmental monitoring solutions is expected to continue its upward trajectory, with piezoelectric sensors playing a crucial role in this expansion.

Piezoelectric sensors have gained traction in environmental monitoring applications due to their unique ability to convert mechanical stress into electrical signals. This characteristic makes them particularly suitable for detecting and measuring various environmental parameters, such as air and water quality, soil conditions, and seismic activity. The versatility of piezoelectric sensors has led to their widespread adoption across different sectors of environmental monitoring.

In the air quality monitoring segment, piezoelectric sensors are increasingly being utilized for particulate matter detection and gas sensing. These sensors offer high sensitivity and rapid response times, making them ideal for real-time air pollution monitoring in urban areas and industrial settings. The growing concern over air pollution in major cities worldwide has fueled the demand for advanced monitoring systems, thereby driving the market for piezoelectric sensor-based solutions.

Water quality monitoring represents another significant market opportunity for piezoelectric sensors. These sensors can detect various contaminants and measure parameters such as pH, turbidity, and dissolved oxygen levels with high precision. The increasing need for clean water resources and stringent water quality regulations have boosted the adoption of piezoelectric sensor technologies in this sector.

Soil monitoring applications have also seen a rise in the use of piezoelectric sensors. These sensors can measure soil moisture, compaction, and nutrient levels, providing valuable data for agriculture and land management. The growing emphasis on precision agriculture and sustainable land use practices has created a favorable market environment for piezoelectric sensor-based soil monitoring systems.

The market for piezoelectric sensors in seismic monitoring has expanded due to the rising demand for early warning systems in earthquake-prone regions. These sensors can detect minute ground vibrations, enabling more accurate prediction and monitoring of seismic events. The increasing investment in infrastructure protection and disaster preparedness has further propelled the growth of this market segment.

As environmental concerns continue to escalate globally, the demand for more sophisticated and accurate monitoring solutions is expected to rise. This trend presents significant opportunities for piezoelectric sensor manufacturers and environmental monitoring solution providers. The integration of piezoelectric sensors with IoT and AI technologies is likely to open up new avenues for market growth, enabling more comprehensive and intelligent environmental monitoring systems.

Piezoelectric sensors have gained traction in environmental monitoring applications due to their unique ability to convert mechanical stress into electrical signals. This characteristic makes them particularly suitable for detecting and measuring various environmental parameters, such as air and water quality, soil conditions, and seismic activity. The versatility of piezoelectric sensors has led to their widespread adoption across different sectors of environmental monitoring.

In the air quality monitoring segment, piezoelectric sensors are increasingly being utilized for particulate matter detection and gas sensing. These sensors offer high sensitivity and rapid response times, making them ideal for real-time air pollution monitoring in urban areas and industrial settings. The growing concern over air pollution in major cities worldwide has fueled the demand for advanced monitoring systems, thereby driving the market for piezoelectric sensor-based solutions.

Water quality monitoring represents another significant market opportunity for piezoelectric sensors. These sensors can detect various contaminants and measure parameters such as pH, turbidity, and dissolved oxygen levels with high precision. The increasing need for clean water resources and stringent water quality regulations have boosted the adoption of piezoelectric sensor technologies in this sector.

Soil monitoring applications have also seen a rise in the use of piezoelectric sensors. These sensors can measure soil moisture, compaction, and nutrient levels, providing valuable data for agriculture and land management. The growing emphasis on precision agriculture and sustainable land use practices has created a favorable market environment for piezoelectric sensor-based soil monitoring systems.

The market for piezoelectric sensors in seismic monitoring has expanded due to the rising demand for early warning systems in earthquake-prone regions. These sensors can detect minute ground vibrations, enabling more accurate prediction and monitoring of seismic events. The increasing investment in infrastructure protection and disaster preparedness has further propelled the growth of this market segment.

As environmental concerns continue to escalate globally, the demand for more sophisticated and accurate monitoring solutions is expected to rise. This trend presents significant opportunities for piezoelectric sensor manufacturers and environmental monitoring solution providers. The integration of piezoelectric sensors with IoT and AI technologies is likely to open up new avenues for market growth, enabling more comprehensive and intelligent environmental monitoring systems.

Piezoelectric Sensor Challenges in Environmental Applications

Piezoelectric sensors face several significant challenges when applied to environmental monitoring. One of the primary issues is their sensitivity to temperature fluctuations, which can lead to inaccurate readings in outdoor environments where temperatures can vary widely. This temperature dependence necessitates complex compensation mechanisms, adding to the overall system complexity and cost.

Another challenge is the durability of piezoelectric materials in harsh environmental conditions. Exposure to moisture, chemicals, and extreme temperatures can degrade the sensor's performance over time, potentially leading to reduced sensitivity or complete failure. This is particularly problematic in long-term environmental monitoring applications where sensors may need to operate unattended for extended periods.

The limited frequency range of some piezoelectric sensors can also be a constraint in environmental monitoring. While they excel at detecting high-frequency vibrations, they may struggle to accurately measure low-frequency phenomena common in natural environments, such as slow ground movements or gradual changes in air pressure.

Power consumption is another significant concern, especially for remote or off-grid monitoring stations. Although piezoelectric sensors themselves are passive devices, the associated signal conditioning and data transmission electronics can drain batteries quickly, necessitating frequent maintenance or limiting deployment duration.

Interference from electromagnetic fields and mechanical vibrations unrelated to the target environmental parameters can also compromise measurement accuracy. This is particularly challenging in urban or industrial environments where various sources of electromagnetic noise and vibration are present.

The need for high-impedance signal conditioning circuitry presents another hurdle. Such circuits are susceptible to noise and can be affected by cable capacitance, limiting the distance between the sensor and the data acquisition system. This can complicate sensor placement in expansive environmental monitoring networks.

Lastly, the inherent non-linearity of piezoelectric materials can make calibration and data interpretation complex, especially when measuring a wide range of environmental parameters. Sophisticated signal processing algorithms are often required to compensate for these non-linearities, adding to the computational demands of the monitoring system.

Another challenge is the durability of piezoelectric materials in harsh environmental conditions. Exposure to moisture, chemicals, and extreme temperatures can degrade the sensor's performance over time, potentially leading to reduced sensitivity or complete failure. This is particularly problematic in long-term environmental monitoring applications where sensors may need to operate unattended for extended periods.

The limited frequency range of some piezoelectric sensors can also be a constraint in environmental monitoring. While they excel at detecting high-frequency vibrations, they may struggle to accurately measure low-frequency phenomena common in natural environments, such as slow ground movements or gradual changes in air pressure.

Power consumption is another significant concern, especially for remote or off-grid monitoring stations. Although piezoelectric sensors themselves are passive devices, the associated signal conditioning and data transmission electronics can drain batteries quickly, necessitating frequent maintenance or limiting deployment duration.

Interference from electromagnetic fields and mechanical vibrations unrelated to the target environmental parameters can also compromise measurement accuracy. This is particularly challenging in urban or industrial environments where various sources of electromagnetic noise and vibration are present.

The need for high-impedance signal conditioning circuitry presents another hurdle. Such circuits are susceptible to noise and can be affected by cable capacitance, limiting the distance between the sensor and the data acquisition system. This can complicate sensor placement in expansive environmental monitoring networks.

Lastly, the inherent non-linearity of piezoelectric materials can make calibration and data interpretation complex, especially when measuring a wide range of environmental parameters. Sophisticated signal processing algorithms are often required to compensate for these non-linearities, adding to the computational demands of the monitoring system.

Current Piezoelectric Sensor Solutions for Environmental Monitoring

01 Piezoelectric sensor design and fabrication

This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.- Piezoelectric sensor design and fabrication: This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.

- Applications of piezoelectric sensors: Piezoelectric sensors find diverse applications across multiple industries. This category explores their use in areas such as automotive systems, consumer electronics, industrial monitoring, and medical devices. The versatility of these sensors allows for precise measurement of pressure, acceleration, and vibration in various environments.

- Signal processing and data analysis for piezoelectric sensors: This category covers techniques for processing and analyzing signals from piezoelectric sensors. It includes methods for noise reduction, signal amplification, and data interpretation to extract meaningful information from sensor outputs. Advanced algorithms and software solutions are developed to enhance the accuracy and reliability of measurements.

- Integration of piezoelectric sensors in smart systems: The integration of piezoelectric sensors into smart systems and Internet of Things (IoT) devices is a growing trend. This category explores how these sensors are incorporated into larger networks for real-time monitoring, data collection, and automated decision-making. It includes developments in sensor interfaces, wireless communication, and energy harvesting for self-powered operation.

- Miniaturization and performance enhancement of piezoelectric sensors: This category focuses on efforts to miniaturize piezoelectric sensors while improving their performance. It includes research into new piezoelectric materials, nanostructured sensors, and advanced packaging techniques. These developments aim to create smaller, more sensitive sensors capable of operating in challenging environments and with reduced power consumption.

02 Applications in automotive and transportation

Piezoelectric sensors find extensive use in automotive and transportation systems. They are employed for various purposes such as tire pressure monitoring, engine diagnostics, and vehicle safety systems. These sensors help in improving vehicle performance, safety, and efficiency by providing real-time data on various parameters.Expand Specific Solutions03 Integration with electronic devices and user interfaces

This category covers the integration of piezoelectric sensors into electronic devices and user interfaces. It includes applications in touchscreens, haptic feedback systems, and gesture recognition technologies. These integrations enhance user experience and enable more intuitive interactions with electronic devices.Expand Specific Solutions04 Environmental and industrial monitoring

Piezoelectric sensors play a crucial role in environmental and industrial monitoring applications. They are used for detecting and measuring various parameters such as pressure, vibration, and acoustic emissions. These sensors contribute to improved process control, predictive maintenance, and environmental safety in industrial settings.Expand Specific Solutions05 Advancements in signal processing and data analysis

This category focuses on improvements in signal processing and data analysis techniques for piezoelectric sensors. It includes innovations in noise reduction, signal amplification, and data interpretation algorithms. These advancements enhance the accuracy and reliability of measurements obtained from piezoelectric sensors across various applications.Expand Specific Solutions

Key Players in Piezoelectric Environmental Sensors

The research on piezoelectric sensors in environmental monitoring is in a growth phase, with increasing market size and technological advancements. The global market for these sensors is expanding due to rising environmental concerns and stringent regulations. Technologically, piezoelectric sensors are maturing, with companies like PCB Piezotronics and Nihon Dempa Kogyo leading in sensor development. Universities such as Tsinghua and Shanghai Jiao Tong are contributing to research advancements. Emerging players like Ionix Advanced Technologies are innovating with new materials and designs, while established firms like Jabil and HELLA are integrating these sensors into broader environmental monitoring systems. The competitive landscape is diverse, with a mix of specialized sensor manufacturers, large electronics companies, and academic institutions driving progress in this field.

Beijing Titan Technology Co., Ltd.

Technical Solution: Beijing Titan Technology specializes in piezoelectric sensor solutions for environmental monitoring. Their approach focuses on developing multi-parameter sensors that can simultaneously measure various environmental factors. The company has introduced a novel piezoelectric composite material that enhances sensitivity while reducing cross-axis interference[4]. Titan's sensors incorporate advanced signal processing algorithms to filter out noise and improve measurement accuracy in complex environmental conditions[5]. They have also developed a wireless sensor network platform that enables real-time data transmission and remote monitoring capabilities for large-scale environmental studies[6].

Strengths: Multi-parameter sensing capabilities, advanced signal processing, and integrated wireless networking. Weaknesses: Limited global market presence compared to some international competitors, and potential challenges in scaling production for large-scale deployments.

PCB Piezotronics, Inc.

Technical Solution: PCB Piezotronics has developed advanced piezoelectric sensors for environmental monitoring applications. Their sensors utilize quartz crystals and ceramics to convert mechanical stress into electrical signals. The company's ICP (Integrated Circuit Piezoelectric) technology incorporates built-in microelectronics for improved signal quality and reduced noise[1]. Their sensors can measure various environmental parameters such as vibration, pressure, and acoustic emissions with high sensitivity and wide frequency range[2]. PCB's sensors are designed to withstand harsh environments, featuring hermetic sealing and robust construction for long-term stability in outdoor applications[3].

Strengths: High sensitivity, wide frequency range, and durability in harsh environments. Weaknesses: Relatively high cost compared to some alternative sensing technologies, and potential temperature sensitivity requiring compensation.

Innovative Piezoelectric Sensing Techniques for Environment

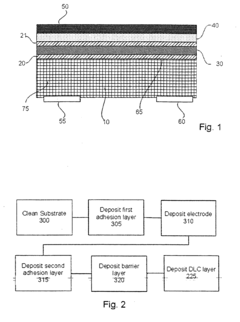

Coating for harsh environments and sensors using same

PatentInactiveEP1891429B1

Innovation

- A coating system comprising a thin Diamond-Like Carbon (DLC) layer with a thicker adhesion/barrier metal system, including niobium or tantalum, and a conductive electrode layer, optimized for smoothness and stability, applied to piezoelectric sensors to enhance durability and operational reliability in extreme conditions.

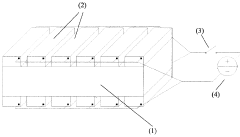

Piezoelectric shield for sensors used in environmental applications.

PatentActiveES2329533A1

Innovation

- A piezoelectric shield is applied to the sensor's active part, comprising alternating rows of piezoelectric material with a switch to control voltage application, preventing contact and saturation by expanding to isolate the sensor from excessive exposure.

Environmental Regulations Impact on Sensor Development

Environmental regulations have significantly influenced the development and deployment of piezoelectric sensors in environmental monitoring. These regulations, aimed at protecting human health and the environment, have created both challenges and opportunities for sensor manufacturers and researchers.

The increasing stringency of environmental standards has driven the demand for more accurate, sensitive, and reliable sensors. Piezoelectric sensors, known for their high sensitivity and fast response times, have become increasingly important in meeting these regulatory requirements. For instance, the Clean Air Act in the United States has necessitated the development of sensors capable of detecting minute concentrations of pollutants, pushing the boundaries of piezoelectric sensor technology.

Water quality regulations have also played a crucial role in shaping sensor development. The European Union's Water Framework Directive, for example, has set strict standards for water quality monitoring, leading to innovations in underwater piezoelectric sensors for detecting various contaminants and microorganisms.

Regulations concerning noise pollution have spurred advancements in acoustic piezoelectric sensors. Many countries have implemented noise level limits in urban areas, industrial zones, and transportation hubs, creating a market for high-performance sound and vibration monitoring devices.

The RoHS (Restriction of Hazardous Substances) directive has had a profound impact on the materials used in sensor manufacturing. This regulation has prompted research into lead-free piezoelectric materials, as traditional lead-based piezoceramics face restrictions due to their environmental impact.

Environmental regulations have also influenced the design of sensor systems for durability and longevity. Many environmental monitoring applications require sensors to operate in harsh conditions for extended periods. This has led to innovations in sensor packaging and protective coatings to ensure compliance with long-term monitoring requirements set by regulatory bodies.

The need for real-time data reporting to comply with environmental regulations has driven the integration of piezoelectric sensors with IoT (Internet of Things) technologies. This convergence has resulted in the development of smart sensor networks capable of continuous monitoring and instant alert systems for environmental parameter deviations.

As regulations evolve, so does the focus of sensor development. For instance, emerging concerns about microplastics have led to research into piezoelectric sensors capable of detecting these minute particles in water bodies, anticipating future regulatory requirements.

In conclusion, environmental regulations have been a significant driving force in the advancement of piezoelectric sensor technology for environmental monitoring. They have not only set the standards for sensor performance but have also shaped the direction of research and development in this field, leading to more sophisticated, efficient, and environmentally friendly sensor solutions.

The increasing stringency of environmental standards has driven the demand for more accurate, sensitive, and reliable sensors. Piezoelectric sensors, known for their high sensitivity and fast response times, have become increasingly important in meeting these regulatory requirements. For instance, the Clean Air Act in the United States has necessitated the development of sensors capable of detecting minute concentrations of pollutants, pushing the boundaries of piezoelectric sensor technology.

Water quality regulations have also played a crucial role in shaping sensor development. The European Union's Water Framework Directive, for example, has set strict standards for water quality monitoring, leading to innovations in underwater piezoelectric sensors for detecting various contaminants and microorganisms.

Regulations concerning noise pollution have spurred advancements in acoustic piezoelectric sensors. Many countries have implemented noise level limits in urban areas, industrial zones, and transportation hubs, creating a market for high-performance sound and vibration monitoring devices.

The RoHS (Restriction of Hazardous Substances) directive has had a profound impact on the materials used in sensor manufacturing. This regulation has prompted research into lead-free piezoelectric materials, as traditional lead-based piezoceramics face restrictions due to their environmental impact.

Environmental regulations have also influenced the design of sensor systems for durability and longevity. Many environmental monitoring applications require sensors to operate in harsh conditions for extended periods. This has led to innovations in sensor packaging and protective coatings to ensure compliance with long-term monitoring requirements set by regulatory bodies.

The need for real-time data reporting to comply with environmental regulations has driven the integration of piezoelectric sensors with IoT (Internet of Things) technologies. This convergence has resulted in the development of smart sensor networks capable of continuous monitoring and instant alert systems for environmental parameter deviations.

As regulations evolve, so does the focus of sensor development. For instance, emerging concerns about microplastics have led to research into piezoelectric sensors capable of detecting these minute particles in water bodies, anticipating future regulatory requirements.

In conclusion, environmental regulations have been a significant driving force in the advancement of piezoelectric sensor technology for environmental monitoring. They have not only set the standards for sensor performance but have also shaped the direction of research and development in this field, leading to more sophisticated, efficient, and environmentally friendly sensor solutions.

Energy Harvesting Potential of Piezoelectric Sensors

Piezoelectric sensors have shown significant potential in energy harvesting applications, particularly in environmental monitoring contexts. These sensors can convert mechanical stress or vibrations into electrical energy, offering a sustainable power source for remote sensing devices. The energy harvesting capability of piezoelectric sensors is particularly valuable in environments where traditional power sources are impractical or costly to maintain.

In environmental monitoring, piezoelectric sensors can harness energy from various natural sources. Wind-induced vibrations, water flow, and even seismic activity can be converted into usable electrical power. This energy can then be used to power low-energy consumption devices such as wireless sensor nodes, data loggers, or small actuators. The amount of energy harvested depends on factors such as the piezoelectric material properties, device design, and the intensity and frequency of environmental stimuli.

Recent advancements in piezoelectric materials and energy harvesting circuits have significantly improved the efficiency of these systems. Novel materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) have demonstrated enhanced energy conversion rates. Additionally, optimized circuit designs incorporating power management systems and energy storage components have increased the overall system efficiency.

The integration of piezoelectric energy harvesters with environmental sensors offers several advantages. It reduces or eliminates the need for battery replacements, lowering maintenance costs and environmental impact. This is particularly beneficial in remote or hazardous locations where frequent human intervention is challenging. Furthermore, the self-powered nature of these systems enables long-term, continuous monitoring without the constraints of limited battery life.

However, challenges remain in maximizing the energy output of piezoelectric harvesters. Environmental conditions can be unpredictable, leading to fluctuations in energy generation. Researchers are exploring hybrid systems that combine piezoelectric harvesters with other energy sources like solar or thermal to ensure consistent power supply. Additionally, efforts are being made to develop more robust and durable piezoelectric materials that can withstand harsh environmental conditions while maintaining high energy conversion efficiency.

The future of piezoelectric energy harvesting in environmental monitoring looks promising. As sensor technologies become more energy-efficient and piezoelectric materials improve, the range of applications is expected to expand. Potential future developments include self-powered environmental monitoring networks, autonomous weather stations, and even large-scale energy harvesting systems integrated into infrastructure for urban environmental monitoring.

In environmental monitoring, piezoelectric sensors can harness energy from various natural sources. Wind-induced vibrations, water flow, and even seismic activity can be converted into usable electrical power. This energy can then be used to power low-energy consumption devices such as wireless sensor nodes, data loggers, or small actuators. The amount of energy harvested depends on factors such as the piezoelectric material properties, device design, and the intensity and frequency of environmental stimuli.

Recent advancements in piezoelectric materials and energy harvesting circuits have significantly improved the efficiency of these systems. Novel materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) have demonstrated enhanced energy conversion rates. Additionally, optimized circuit designs incorporating power management systems and energy storage components have increased the overall system efficiency.

The integration of piezoelectric energy harvesters with environmental sensors offers several advantages. It reduces or eliminates the need for battery replacements, lowering maintenance costs and environmental impact. This is particularly beneficial in remote or hazardous locations where frequent human intervention is challenging. Furthermore, the self-powered nature of these systems enables long-term, continuous monitoring without the constraints of limited battery life.

However, challenges remain in maximizing the energy output of piezoelectric harvesters. Environmental conditions can be unpredictable, leading to fluctuations in energy generation. Researchers are exploring hybrid systems that combine piezoelectric harvesters with other energy sources like solar or thermal to ensure consistent power supply. Additionally, efforts are being made to develop more robust and durable piezoelectric materials that can withstand harsh environmental conditions while maintaining high energy conversion efficiency.

The future of piezoelectric energy harvesting in environmental monitoring looks promising. As sensor technologies become more energy-efficient and piezoelectric materials improve, the range of applications is expected to expand. Potential future developments include self-powered environmental monitoring networks, autonomous weather stations, and even large-scale energy harvesting systems integrated into infrastructure for urban environmental monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!