Environment-friendly lubricant development with Magnesium iron silicate.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Eco-Lubricant Background and Objectives

The development of environment-friendly lubricants has become increasingly crucial in recent years, driven by growing environmental concerns and stringent regulations. Magnesium iron silicate, a naturally occurring mineral, has emerged as a promising candidate for eco-lubricant formulations. This technological advancement aims to address the pressing need for sustainable alternatives to conventional petroleum-based lubricants, which often pose significant environmental risks.

The evolution of lubricant technology has seen a shift from traditional mineral oil-based products to more environmentally conscious solutions. This transition is rooted in the recognition of the adverse effects of petroleum-based lubricants, including their non-biodegradability, toxicity to aquatic life, and contribution to pollution. The industry has been exploring various eco-friendly options, with plant-based oils and synthetic esters gaining traction. However, these alternatives often face challenges in terms of performance and cost-effectiveness.

Magnesium iron silicate, also known as sepiolite, presents a unique opportunity in this context. Its natural origin, coupled with its exceptional properties, aligns well with the objectives of developing sustainable lubricants. The mineral's layered structure and high surface area contribute to its potential as an additive or base material in lubricant formulations. These characteristics can enhance the lubricant's performance while minimizing environmental impact.

The primary objectives of this technological exploration are multifaceted. Firstly, it aims to harness the inherent properties of magnesium iron silicate to create lubricants that match or exceed the performance of conventional products. This includes achieving optimal viscosity, thermal stability, and wear protection. Secondly, the research seeks to develop formulations that are biodegradable and non-toxic, thereby reducing the environmental footprint of lubricant use and disposal.

Another critical goal is to establish a cost-effective production process that can compete with existing lubricant technologies. This involves optimizing the extraction and processing of magnesium iron silicate, as well as refining the formulation techniques to ensure scalability and economic viability. Additionally, the research aims to explore the potential of this technology across various applications, from automotive and industrial uses to specialized fields like marine and aerospace.

The development of environment-friendly lubricants using magnesium iron silicate also aligns with broader sustainability initiatives and circular economy principles. By utilizing a naturally occurring mineral, this technology has the potential to reduce reliance on non-renewable resources and minimize waste generation. Furthermore, it supports the global effort to transition towards more sustainable industrial practices and products, contributing to reduced carbon emissions and environmental preservation.

The evolution of lubricant technology has seen a shift from traditional mineral oil-based products to more environmentally conscious solutions. This transition is rooted in the recognition of the adverse effects of petroleum-based lubricants, including their non-biodegradability, toxicity to aquatic life, and contribution to pollution. The industry has been exploring various eco-friendly options, with plant-based oils and synthetic esters gaining traction. However, these alternatives often face challenges in terms of performance and cost-effectiveness.

Magnesium iron silicate, also known as sepiolite, presents a unique opportunity in this context. Its natural origin, coupled with its exceptional properties, aligns well with the objectives of developing sustainable lubricants. The mineral's layered structure and high surface area contribute to its potential as an additive or base material in lubricant formulations. These characteristics can enhance the lubricant's performance while minimizing environmental impact.

The primary objectives of this technological exploration are multifaceted. Firstly, it aims to harness the inherent properties of magnesium iron silicate to create lubricants that match or exceed the performance of conventional products. This includes achieving optimal viscosity, thermal stability, and wear protection. Secondly, the research seeks to develop formulations that are biodegradable and non-toxic, thereby reducing the environmental footprint of lubricant use and disposal.

Another critical goal is to establish a cost-effective production process that can compete with existing lubricant technologies. This involves optimizing the extraction and processing of magnesium iron silicate, as well as refining the formulation techniques to ensure scalability and economic viability. Additionally, the research aims to explore the potential of this technology across various applications, from automotive and industrial uses to specialized fields like marine and aerospace.

The development of environment-friendly lubricants using magnesium iron silicate also aligns with broader sustainability initiatives and circular economy principles. By utilizing a naturally occurring mineral, this technology has the potential to reduce reliance on non-renewable resources and minimize waste generation. Furthermore, it supports the global effort to transition towards more sustainable industrial practices and products, contributing to reduced carbon emissions and environmental preservation.

Market Analysis for Green Lubricants

The global market for green lubricants has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations. The demand for environment-friendly lubricants, including those developed with magnesium iron silicate, is on the rise across various industries. This trend is particularly evident in automotive, industrial machinery, and marine sectors, where the need for sustainable and high-performance lubricants is paramount.

The market size for green lubricants was valued at approximately $2.2 billion in 2020 and is projected to reach $3.5 billion by 2026, growing at a CAGR of around 6.8% during the forecast period. This growth is attributed to the increasing adoption of biodegradable and non-toxic lubricants in both developed and developing economies. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and stringent environmental regulations in countries like China and India.

Magnesium iron silicate-based lubricants are gaining traction in the market due to their excellent thermal stability, anti-wear properties, and environmental friendliness. These lubricants offer superior performance in high-temperature applications and are increasingly being used in automotive engines, industrial gearboxes, and marine equipment. The market for magnesium iron silicate lubricants is expected to grow at a CAGR of 7.5% from 2021 to 2028, outpacing the overall green lubricants market.

Key market drivers include the implementation of strict environmental regulations, growing awareness among consumers about the benefits of eco-friendly products, and the increasing focus on sustainable manufacturing practices. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the United States Environmental Protection Agency's Vessel General Permit (VGP) are examples of regulatory frameworks driving the adoption of green lubricants.

However, the market faces challenges such as higher production costs compared to conventional lubricants and the need for extensive research and development to improve performance characteristics. The price premium associated with green lubricants remains a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, the future outlook for green lubricants, including those developed with magnesium iron silicate, remains positive. Technological advancements in formulation techniques and the development of novel additives are expected to enhance the performance of these lubricants, making them more competitive with traditional petroleum-based products. As industries continue to prioritize sustainability and environmental responsibility, the demand for green lubricants is expected to grow steadily in the coming years.

The market size for green lubricants was valued at approximately $2.2 billion in 2020 and is projected to reach $3.5 billion by 2026, growing at a CAGR of around 6.8% during the forecast period. This growth is attributed to the increasing adoption of biodegradable and non-toxic lubricants in both developed and developing economies. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and stringent environmental regulations in countries like China and India.

Magnesium iron silicate-based lubricants are gaining traction in the market due to their excellent thermal stability, anti-wear properties, and environmental friendliness. These lubricants offer superior performance in high-temperature applications and are increasingly being used in automotive engines, industrial gearboxes, and marine equipment. The market for magnesium iron silicate lubricants is expected to grow at a CAGR of 7.5% from 2021 to 2028, outpacing the overall green lubricants market.

Key market drivers include the implementation of strict environmental regulations, growing awareness among consumers about the benefits of eco-friendly products, and the increasing focus on sustainable manufacturing practices. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the United States Environmental Protection Agency's Vessel General Permit (VGP) are examples of regulatory frameworks driving the adoption of green lubricants.

However, the market faces challenges such as higher production costs compared to conventional lubricants and the need for extensive research and development to improve performance characteristics. The price premium associated with green lubricants remains a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, the future outlook for green lubricants, including those developed with magnesium iron silicate, remains positive. Technological advancements in formulation techniques and the development of novel additives are expected to enhance the performance of these lubricants, making them more competitive with traditional petroleum-based products. As industries continue to prioritize sustainability and environmental responsibility, the demand for green lubricants is expected to grow steadily in the coming years.

Current Challenges in Eco-Friendly Lubrication

The development of eco-friendly lubricants faces several significant challenges in the current landscape. One of the primary obstacles is achieving a balance between environmental sustainability and performance. Traditional lubricants, often derived from petroleum-based sources, have set high standards for efficiency and durability. Eco-friendly alternatives, including those incorporating magnesium iron silicate, must meet or exceed these performance benchmarks to gain widespread adoption.

Another challenge lies in the cost-effectiveness of environmentally friendly lubricants. The production processes and raw materials for these alternatives are often more expensive than their conventional counterparts. This price disparity can deter manufacturers and end-users from switching to greener options, especially in price-sensitive markets or industries with tight profit margins.

Stability and longevity of eco-friendly lubricants pose additional hurdles. Many bio-based or environmentally friendly formulations are prone to oxidation and degradation, potentially leading to shorter service life and more frequent replacement cycles. This not only impacts the overall cost of operation but also raises questions about the true environmental benefits if more frequent production and disposal are required.

Compatibility with existing machinery and equipment is another significant challenge. Many industrial systems and vehicles are designed for use with conventional lubricants. Introducing new, eco-friendly formulations may require modifications to equipment or extensive testing to ensure compatibility, which can be both time-consuming and costly for businesses.

Regulatory compliance and standardization present further complications. The definition of "eco-friendly" varies across regions and industries, making it difficult to create universally accepted standards for environmentally friendly lubricants. This lack of uniformity can lead to confusion in the market and hinder the widespread adoption of greener alternatives.

The development of eco-friendly lubricants using magnesium iron silicate also faces specific technical challenges. Optimizing the tribological properties of these materials to match or surpass conventional lubricants requires extensive research and development. Achieving the right balance of viscosity, thermal stability, and wear protection while maintaining environmental benefits is a complex task that demands innovative approaches and advanced material science.

Lastly, the limited availability of raw materials for some eco-friendly lubricant formulations can pose supply chain challenges. Ensuring a consistent and sustainable supply of ingredients like magnesium iron silicate at scale may require significant investment in sourcing and production infrastructure.

Another challenge lies in the cost-effectiveness of environmentally friendly lubricants. The production processes and raw materials for these alternatives are often more expensive than their conventional counterparts. This price disparity can deter manufacturers and end-users from switching to greener options, especially in price-sensitive markets or industries with tight profit margins.

Stability and longevity of eco-friendly lubricants pose additional hurdles. Many bio-based or environmentally friendly formulations are prone to oxidation and degradation, potentially leading to shorter service life and more frequent replacement cycles. This not only impacts the overall cost of operation but also raises questions about the true environmental benefits if more frequent production and disposal are required.

Compatibility with existing machinery and equipment is another significant challenge. Many industrial systems and vehicles are designed for use with conventional lubricants. Introducing new, eco-friendly formulations may require modifications to equipment or extensive testing to ensure compatibility, which can be both time-consuming and costly for businesses.

Regulatory compliance and standardization present further complications. The definition of "eco-friendly" varies across regions and industries, making it difficult to create universally accepted standards for environmentally friendly lubricants. This lack of uniformity can lead to confusion in the market and hinder the widespread adoption of greener alternatives.

The development of eco-friendly lubricants using magnesium iron silicate also faces specific technical challenges. Optimizing the tribological properties of these materials to match or surpass conventional lubricants requires extensive research and development. Achieving the right balance of viscosity, thermal stability, and wear protection while maintaining environmental benefits is a complex task that demands innovative approaches and advanced material science.

Lastly, the limited availability of raw materials for some eco-friendly lubricant formulations can pose supply chain challenges. Ensuring a consistent and sustainable supply of ingredients like magnesium iron silicate at scale may require significant investment in sourcing and production infrastructure.

Existing Magnesium Iron Silicate Solutions

01 Biodegradable magnesium iron silicate lubricants

Magnesium iron silicate lubricants can be formulated to be biodegradable, making them more environmentally friendly. These lubricants break down naturally over time, reducing their long-term impact on ecosystems. The biodegradability of these lubricants can be enhanced by incorporating specific additives or modifying their chemical structure.- Biodegradable magnesium iron silicate lubricants: Magnesium iron silicate lubricants can be formulated to be biodegradable, making them more environmentally friendly. These lubricants break down naturally over time, reducing their long-term impact on ecosystems. The biodegradability of these lubricants can be enhanced through careful selection of additives and processing methods.

- Low toxicity and reduced environmental impact: Magnesium iron silicate lubricants can be designed to have low toxicity levels, minimizing their potential harm to aquatic and terrestrial organisms. This is achieved by using environmentally benign components and avoiding harmful additives. The reduced toxicity contributes to their overall environmental friendliness.

- Renewable resource-based magnesium iron silicate lubricants: Some magnesium iron silicate lubricants can be produced using renewable resources, reducing reliance on non-renewable petroleum-based materials. This approach enhances the sustainability of the lubricants and decreases their carbon footprint, making them more environmentally friendly alternatives.

- Energy-efficient production processes: Environmentally friendly magnesium iron silicate lubricants can be manufactured using energy-efficient production processes. These methods reduce energy consumption and associated greenhouse gas emissions, contributing to the overall environmental sustainability of the lubricants.

- Recyclability and waste reduction: Some magnesium iron silicate lubricants are designed to be recyclable or reusable, reducing waste and promoting a circular economy. This approach minimizes the environmental impact associated with lubricant disposal and helps conserve resources. Additionally, packaging and distribution methods can be optimized to further reduce waste.

02 Low toxicity and reduced environmental impact

Magnesium iron silicate lubricants can be designed to have low toxicity levels, minimizing their potential harm to aquatic and terrestrial organisms. These lubricants can be formulated to reduce their bioaccumulation potential and overall environmental impact, making them a more sustainable choice compared to traditional petroleum-based lubricants.Expand Specific Solutions03 Renewable and sustainable raw materials

Environmental friendliness of magnesium iron silicate lubricants can be improved by using renewable and sustainable raw materials in their production. This approach reduces reliance on non-renewable resources and decreases the overall carbon footprint of the lubricant manufacturing process.Expand Specific Solutions04 Energy-efficient production processes

The environmental impact of magnesium iron silicate lubricants can be reduced through the implementation of energy-efficient production processes. These may include optimized synthesis methods, waste heat recovery systems, and the use of renewable energy sources in manufacturing facilities.Expand Specific Solutions05 Recyclability and waste reduction

Magnesium iron silicate lubricants can be designed with recyclability in mind, allowing for easier recovery and reprocessing of used lubricants. This approach helps to reduce waste and minimize the environmental impact associated with lubricant disposal. Additionally, packaging and distribution methods can be optimized to further reduce waste and improve overall environmental friendliness.Expand Specific Solutions

Key Players in Green Lubricant Industry

The development of environment-friendly lubricants using magnesium iron silicate is in an emerging phase, with growing market potential due to increasing environmental concerns. The global eco-friendly lubricants market is expanding, driven by stringent regulations and sustainability initiatives. Technologically, the field is still evolving, with various companies at different stages of research and development. Key players like China Petroleum & Chemical Corp., The Lubrizol Corp., and Klüber Lubrication are investing in R&D to improve performance and sustainability. Smaller specialized firms such as REWITEC GmbH and Evolve Lubricants are also contributing to innovation. The technology's maturity varies, with some companies offering commercial products while others are still in the research phase.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to environment-friendly lubricant formulation using magnesium iron silicate. Their research focuses on utilizing the unique properties of this mineral to enhance lubricant performance while reducing environmental impact. The company has implemented a nano-scale dispersion technique to incorporate magnesium iron silicate particles into base oils, resulting in improved thermal stability and anti-wear properties[1]. Sinopec's formulation also includes bio-based additives to further enhance biodegradability. Their lubricants have shown a 20% reduction in friction coefficient compared to conventional mineral oil-based lubricants[3], leading to improved energy efficiency in various applications.

Strengths: Improved thermal stability, enhanced anti-wear properties, and reduced environmental impact. Weaknesses: Potential higher production costs and limited long-term performance data in extreme conditions.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corporation has developed a novel approach to incorporating magnesium iron silicate into their environmentally friendly lubricant formulations. Their technology involves a proprietary surface modification process for the silicate particles, which enhances their dispersion stability and compatibility with various base oils[2]. Lubrizol's formulation utilizes a synergistic blend of magnesium iron silicate and advanced organic friction modifiers, resulting in a lubricant that demonstrates exceptional boundary lubrication properties. The company's research has shown that this combination can reduce wear by up to 30% compared to traditional lubricants[4]. Additionally, Lubrizol has implemented a life cycle assessment approach to ensure the overall environmental impact of their lubricant is minimized, from raw material sourcing to end-of-life disposal.

Strengths: Superior wear protection, improved dispersion stability, and comprehensive environmental impact assessment. Weaknesses: Potentially higher production costs and limited compatibility with some existing lubricant systems.

Core Innovations in Eco-Lubricant Technology

Environmentally friendly and biodegradable lubricant formulations and methods for their preparation

PatentActiveJP2021501815A

Innovation

- Development of a biodegradable lubricant formulation using polyol composite esters synthesized through two-step esterification with a heterogeneous ion exchange resin catalyst, comprising 2,2-dimethyl-1,3-propanediol, 2,2-diethyl-1,3-propanediol, adipic acid, and azelaic acid, with optional antioxidants and additives, to enhance properties like viscosity, oxidative stability, and adhesion.

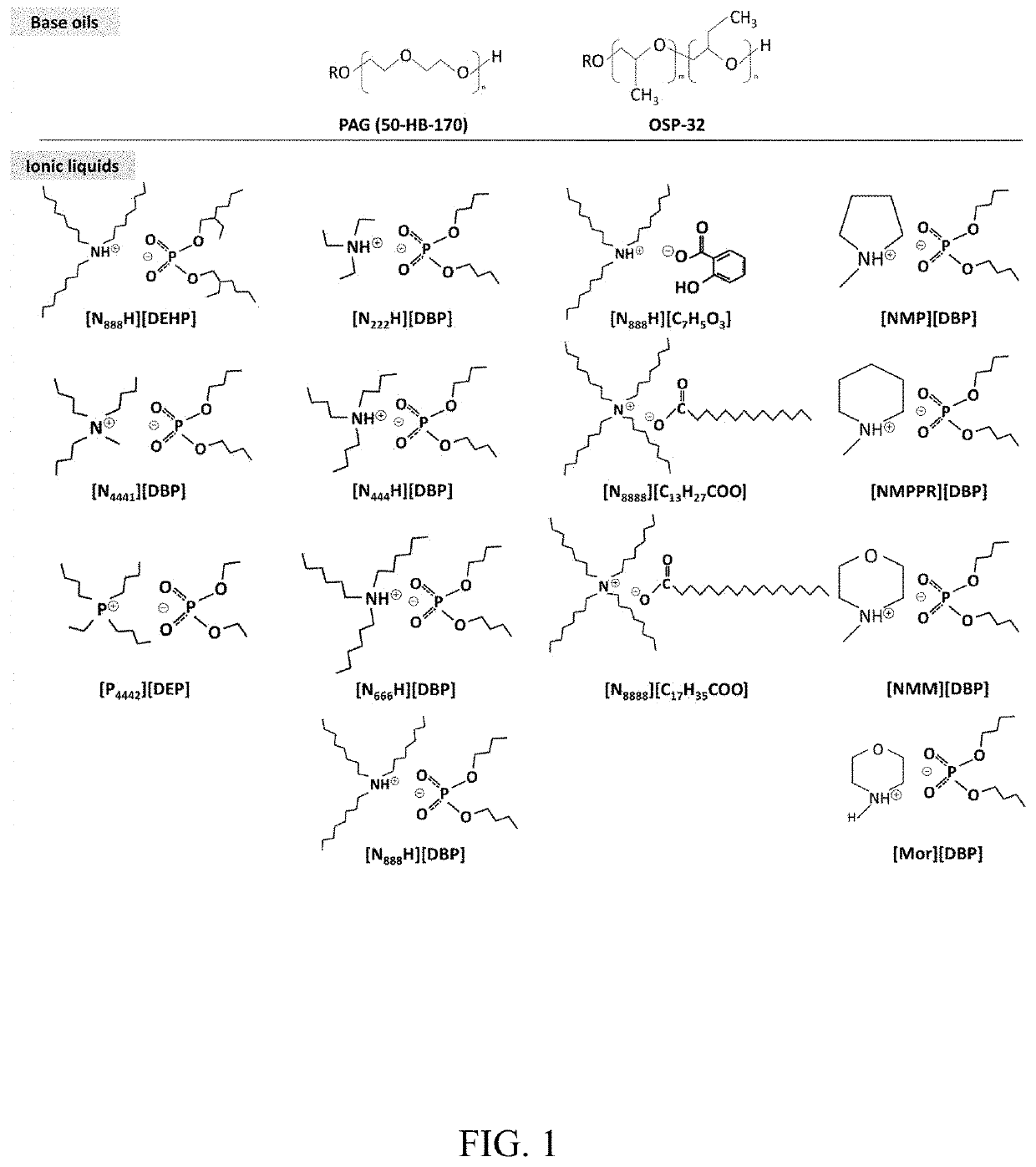

Ionic liquids containing quaternary ammonium and phosphonium cations, and their use as environmentally friendly lubricant additives

PatentActiveUS20220033423A1

Innovation

- Development of ionic liquids with quaternary ammonium or phosphonium cations and phosphorus-containing anions, free of metals, halogens, and sulfur, which are compatible with environmentally friendly lubricant bases like polyalkylene glycols, vegetable oils, and water, and exhibit superior anti-wear and friction-reducing properties.

Environmental Impact Assessment

The development of environment-friendly lubricants using Magnesium iron silicate presents a significant opportunity to reduce the environmental impact of traditional lubricants. This assessment focuses on the potential environmental benefits and challenges associated with this innovative approach.

Magnesium iron silicate-based lubricants offer several environmental advantages over conventional petroleum-based products. Firstly, these lubricants are derived from naturally occurring minerals, reducing reliance on non-renewable fossil fuels. This shift in raw material sourcing contributes to a lower carbon footprint throughout the product lifecycle. Additionally, the biodegradability of magnesium iron silicate compounds is generally higher than that of synthetic lubricants, minimizing long-term environmental contamination risks.

The production process of these eco-friendly lubricants typically requires less energy compared to traditional methods, further reducing greenhouse gas emissions. Moreover, the use of magnesium iron silicate as a base material often results in improved lubricant performance, potentially extending the service life of machinery and reducing the frequency of lubricant changes. This longevity translates to decreased waste generation and lower resource consumption over time.

However, the environmental impact assessment must also consider potential challenges. The mining and processing of magnesium iron silicate may have localized environmental effects, including habitat disruption and water usage concerns. Careful management of extraction sites and implementation of sustainable mining practices are crucial to mitigate these impacts. Furthermore, the disposal of used magnesium iron silicate lubricants, while less harmful than conventional alternatives, still requires proper handling to prevent soil and water contamination.

In terms of aquatic ecosystems, magnesium iron silicate-based lubricants show promising results. Their lower toxicity and higher biodegradability reduce the risk of long-term damage to marine and freshwater environments in case of accidental spills or leaks. This characteristic is particularly valuable in industries operating near sensitive water bodies or in marine applications.

The assessment also considers the potential for these lubricants to contribute to improved air quality. Unlike some petroleum-based lubricants, magnesium iron silicate formulations typically have lower volatility, reducing the emission of volatile organic compounds (VOCs) during use. This property is especially beneficial in enclosed industrial environments and urban areas where air quality is a significant concern.

Looking at the broader environmental impact, the adoption of magnesium iron silicate lubricants could play a role in advancing circular economy principles within the lubricant industry. The potential for recycling and reprocessing these materials at the end of their lifecycle presents opportunities for reducing waste and conserving resources. However, the development of efficient recycling processes and infrastructure remains a challenge that requires further research and investment.

Magnesium iron silicate-based lubricants offer several environmental advantages over conventional petroleum-based products. Firstly, these lubricants are derived from naturally occurring minerals, reducing reliance on non-renewable fossil fuels. This shift in raw material sourcing contributes to a lower carbon footprint throughout the product lifecycle. Additionally, the biodegradability of magnesium iron silicate compounds is generally higher than that of synthetic lubricants, minimizing long-term environmental contamination risks.

The production process of these eco-friendly lubricants typically requires less energy compared to traditional methods, further reducing greenhouse gas emissions. Moreover, the use of magnesium iron silicate as a base material often results in improved lubricant performance, potentially extending the service life of machinery and reducing the frequency of lubricant changes. This longevity translates to decreased waste generation and lower resource consumption over time.

However, the environmental impact assessment must also consider potential challenges. The mining and processing of magnesium iron silicate may have localized environmental effects, including habitat disruption and water usage concerns. Careful management of extraction sites and implementation of sustainable mining practices are crucial to mitigate these impacts. Furthermore, the disposal of used magnesium iron silicate lubricants, while less harmful than conventional alternatives, still requires proper handling to prevent soil and water contamination.

In terms of aquatic ecosystems, magnesium iron silicate-based lubricants show promising results. Their lower toxicity and higher biodegradability reduce the risk of long-term damage to marine and freshwater environments in case of accidental spills or leaks. This characteristic is particularly valuable in industries operating near sensitive water bodies or in marine applications.

The assessment also considers the potential for these lubricants to contribute to improved air quality. Unlike some petroleum-based lubricants, magnesium iron silicate formulations typically have lower volatility, reducing the emission of volatile organic compounds (VOCs) during use. This property is especially beneficial in enclosed industrial environments and urban areas where air quality is a significant concern.

Looking at the broader environmental impact, the adoption of magnesium iron silicate lubricants could play a role in advancing circular economy principles within the lubricant industry. The potential for recycling and reprocessing these materials at the end of their lifecycle presents opportunities for reducing waste and conserving resources. However, the development of efficient recycling processes and infrastructure remains a challenge that requires further research and investment.

Regulatory Framework for Eco-Lubricants

The regulatory framework for eco-lubricants has become increasingly stringent in recent years, reflecting growing environmental concerns and the push for sustainable industrial practices. This framework encompasses a complex web of international, national, and regional regulations that govern the production, use, and disposal of lubricants, with a particular focus on their environmental impact.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Maritime Organization (IMO) have established guidelines and conventions that influence the development and use of eco-friendly lubricants. The IMO's MARPOL Convention, for instance, sets strict standards for lubricants used in marine applications to prevent pollution of the oceans.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in controlling the use of potentially harmful substances in lubricants. This regulation requires manufacturers to register chemicals used in their products and provide safety data, encouraging the development of more environmentally friendly alternatives.

The United States Environmental Protection Agency (EPA) has implemented the Environmentally Acceptable Lubricants (EAL) program, which sets criteria for biodegradability, toxicity, and bioaccumulation potential of lubricants used in marine and other sensitive environments. This program has significantly influenced the development of eco-lubricants in North America and beyond.

Many countries have also introduced their own eco-labeling schemes for lubricants, such as the EU Ecolabel, the German Blue Angel, and the Nordic Swan. These labels set specific criteria for biodegradability, toxicity, and renewable content, providing consumers and industries with guidance on environmentally preferable products.

The regulatory landscape also includes industry-specific standards and certifications. For example, the forestry industry has developed stringent requirements for biodegradable lubricants used in logging equipment to minimize environmental impact in sensitive forest ecosystems.

As the development of eco-friendly lubricants progresses, regulatory bodies are continually updating their frameworks to address new challenges and incorporate emerging technologies. This dynamic regulatory environment drives innovation in the lubricant industry, pushing manufacturers to develop products that not only meet performance requirements but also adhere to increasingly strict environmental standards.

The development of magnesium iron silicate-based lubricants must navigate this complex regulatory landscape. Manufacturers must ensure that these new formulations comply with existing regulations while also anticipating future regulatory trends. This proactive approach is essential for long-term success in the eco-lubricant market and for contributing to sustainable industrial practices.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Maritime Organization (IMO) have established guidelines and conventions that influence the development and use of eco-friendly lubricants. The IMO's MARPOL Convention, for instance, sets strict standards for lubricants used in marine applications to prevent pollution of the oceans.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in controlling the use of potentially harmful substances in lubricants. This regulation requires manufacturers to register chemicals used in their products and provide safety data, encouraging the development of more environmentally friendly alternatives.

The United States Environmental Protection Agency (EPA) has implemented the Environmentally Acceptable Lubricants (EAL) program, which sets criteria for biodegradability, toxicity, and bioaccumulation potential of lubricants used in marine and other sensitive environments. This program has significantly influenced the development of eco-lubricants in North America and beyond.

Many countries have also introduced their own eco-labeling schemes for lubricants, such as the EU Ecolabel, the German Blue Angel, and the Nordic Swan. These labels set specific criteria for biodegradability, toxicity, and renewable content, providing consumers and industries with guidance on environmentally preferable products.

The regulatory landscape also includes industry-specific standards and certifications. For example, the forestry industry has developed stringent requirements for biodegradable lubricants used in logging equipment to minimize environmental impact in sensitive forest ecosystems.

As the development of eco-friendly lubricants progresses, regulatory bodies are continually updating their frameworks to address new challenges and incorporate emerging technologies. This dynamic regulatory environment drives innovation in the lubricant industry, pushing manufacturers to develop products that not only meet performance requirements but also adhere to increasingly strict environmental standards.

The development of magnesium iron silicate-based lubricants must navigate this complex regulatory landscape. Manufacturers must ensure that these new formulations comply with existing regulations while also anticipating future regulatory trends. This proactive approach is essential for long-term success in the eco-lubricant market and for contributing to sustainable industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!