Surface characteristics alteration by Magnesium iron silicate hydroxide.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Iron Silicate Hydroxide Background

Magnesium iron silicate hydroxide, also known as serpentine, is a group of minerals that play a significant role in various geological processes and industrial applications. This mineral group is characterized by its layered structure, consisting of alternating sheets of silica tetrahedra and magnesium-rich octahedra. The presence of iron in the crystal lattice contributes to its unique properties and coloration, ranging from pale green to dark olive.

The formation of magnesium iron silicate hydroxide is primarily associated with the hydrothermal alteration of ultramafic rocks, particularly in oceanic crust and upper mantle environments. This process, known as serpentinization, involves the reaction of olivine and pyroxene minerals with water at elevated temperatures and pressures. The resulting serpentine minerals play a crucial role in the Earth's water cycle and have implications for plate tectonics and mantle dynamics.

Historically, the study of magnesium iron silicate hydroxide has been of great interest to geologists and materials scientists due to its widespread occurrence and diverse applications. Early research focused on understanding its mineralogical structure and formation mechanisms. As analytical techniques advanced, researchers gained deeper insights into the mineral's chemical composition, crystal structure, and physical properties.

In recent decades, the focus of research has shifted towards exploring the potential applications of magnesium iron silicate hydroxide in various fields. Its unique surface characteristics have attracted attention in areas such as catalysis, environmental remediation, and nanotechnology. The mineral's ability to adsorb and immobilize heavy metals and organic pollutants has made it a promising candidate for water and soil treatment applications.

The surface characteristics of magnesium iron silicate hydroxide are of particular interest due to their potential for alteration and modification. The mineral's layered structure and high surface area provide numerous active sites for chemical reactions and interactions. These properties can be exploited to tailor the mineral's surface for specific applications, such as enhancing its catalytic activity or improving its adsorption capacity.

Recent advancements in surface modification techniques have opened up new possibilities for altering the characteristics of magnesium iron silicate hydroxide. Methods such as acid treatment, thermal activation, and chemical functionalization have been explored to enhance the mineral's properties for various applications. These modifications can lead to changes in surface area, pore structure, and surface chemistry, ultimately influencing the mineral's performance in different contexts.

The growing interest in sustainable and environmentally friendly materials has further propelled research into magnesium iron silicate hydroxide. Its natural abundance, low toxicity, and potential for surface alteration make it an attractive candidate for developing green technologies and eco-friendly products. As a result, ongoing research continues to explore novel applications and innovative approaches to harnessing the unique properties of this versatile mineral group.

The formation of magnesium iron silicate hydroxide is primarily associated with the hydrothermal alteration of ultramafic rocks, particularly in oceanic crust and upper mantle environments. This process, known as serpentinization, involves the reaction of olivine and pyroxene minerals with water at elevated temperatures and pressures. The resulting serpentine minerals play a crucial role in the Earth's water cycle and have implications for plate tectonics and mantle dynamics.

Historically, the study of magnesium iron silicate hydroxide has been of great interest to geologists and materials scientists due to its widespread occurrence and diverse applications. Early research focused on understanding its mineralogical structure and formation mechanisms. As analytical techniques advanced, researchers gained deeper insights into the mineral's chemical composition, crystal structure, and physical properties.

In recent decades, the focus of research has shifted towards exploring the potential applications of magnesium iron silicate hydroxide in various fields. Its unique surface characteristics have attracted attention in areas such as catalysis, environmental remediation, and nanotechnology. The mineral's ability to adsorb and immobilize heavy metals and organic pollutants has made it a promising candidate for water and soil treatment applications.

The surface characteristics of magnesium iron silicate hydroxide are of particular interest due to their potential for alteration and modification. The mineral's layered structure and high surface area provide numerous active sites for chemical reactions and interactions. These properties can be exploited to tailor the mineral's surface for specific applications, such as enhancing its catalytic activity or improving its adsorption capacity.

Recent advancements in surface modification techniques have opened up new possibilities for altering the characteristics of magnesium iron silicate hydroxide. Methods such as acid treatment, thermal activation, and chemical functionalization have been explored to enhance the mineral's properties for various applications. These modifications can lead to changes in surface area, pore structure, and surface chemistry, ultimately influencing the mineral's performance in different contexts.

The growing interest in sustainable and environmentally friendly materials has further propelled research into magnesium iron silicate hydroxide. Its natural abundance, low toxicity, and potential for surface alteration make it an attractive candidate for developing green technologies and eco-friendly products. As a result, ongoing research continues to explore novel applications and innovative approaches to harnessing the unique properties of this versatile mineral group.

Market Analysis for Surface Modification

The market for surface modification technologies has been experiencing significant growth, driven by increasing demand across various industries such as automotive, aerospace, electronics, and medical devices. The global surface modification market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that reflects the industry's robust expansion.

Magnesium iron silicate hydroxide, a naturally occurring mineral also known as attapulgite, has gained attention in the surface modification sector due to its unique properties. This material offers excellent adsorption capabilities, high surface area, and thermal stability, making it particularly attractive for applications in coatings, catalysts, and environmental remediation.

In the automotive industry, surface modification using magnesium iron silicate hydroxide has shown promise in enhancing the durability and corrosion resistance of vehicle components. The aerospace sector has also expressed interest in this technology for improving the performance of aircraft materials under extreme conditions. Additionally, the electronics industry is exploring the potential of magnesium iron silicate hydroxide for creating advanced surface coatings that can enhance the functionality and lifespan of electronic devices.

The environmental sector represents another significant market opportunity for surface modification using magnesium iron silicate hydroxide. Its ability to adsorb pollutants and heavy metals makes it valuable in water treatment applications and soil remediation projects. This aligns with the growing global focus on sustainability and environmental protection, potentially driving further market expansion.

Geographically, Asia-Pacific is expected to be a key growth region for surface modification technologies, including those utilizing magnesium iron silicate hydroxide. This is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in research and development. North America and Europe are also significant markets, particularly in high-tech industries and environmental applications.

However, the market faces challenges such as the need for standardization of surface modification processes and the potential environmental impact of certain modification techniques. These factors may influence market dynamics and require ongoing research and development efforts to address.

As industries continue to seek innovative solutions for enhancing material properties and performance, the market for surface modification using magnesium iron silicate hydroxide is poised for continued growth. The technology's versatility and potential applications across multiple sectors suggest a promising future, with opportunities for further market penetration and technological advancements.

Magnesium iron silicate hydroxide, a naturally occurring mineral also known as attapulgite, has gained attention in the surface modification sector due to its unique properties. This material offers excellent adsorption capabilities, high surface area, and thermal stability, making it particularly attractive for applications in coatings, catalysts, and environmental remediation.

In the automotive industry, surface modification using magnesium iron silicate hydroxide has shown promise in enhancing the durability and corrosion resistance of vehicle components. The aerospace sector has also expressed interest in this technology for improving the performance of aircraft materials under extreme conditions. Additionally, the electronics industry is exploring the potential of magnesium iron silicate hydroxide for creating advanced surface coatings that can enhance the functionality and lifespan of electronic devices.

The environmental sector represents another significant market opportunity for surface modification using magnesium iron silicate hydroxide. Its ability to adsorb pollutants and heavy metals makes it valuable in water treatment applications and soil remediation projects. This aligns with the growing global focus on sustainability and environmental protection, potentially driving further market expansion.

Geographically, Asia-Pacific is expected to be a key growth region for surface modification technologies, including those utilizing magnesium iron silicate hydroxide. This is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in research and development. North America and Europe are also significant markets, particularly in high-tech industries and environmental applications.

However, the market faces challenges such as the need for standardization of surface modification processes and the potential environmental impact of certain modification techniques. These factors may influence market dynamics and require ongoing research and development efforts to address.

As industries continue to seek innovative solutions for enhancing material properties and performance, the market for surface modification using magnesium iron silicate hydroxide is poised for continued growth. The technology's versatility and potential applications across multiple sectors suggest a promising future, with opportunities for further market penetration and technological advancements.

Current Challenges in Surface Alteration

The alteration of surface characteristics using Magnesium iron silicate hydroxide (MISH) presents several significant challenges in the current technological landscape. One of the primary obstacles is achieving uniform and controlled deposition of MISH on various substrate materials. The heterogeneous nature of surfaces and the complex chemistry of MISH make it difficult to ensure consistent coverage and adhesion across different applications.

Another major challenge lies in the stability and durability of MISH-altered surfaces under diverse environmental conditions. Exposure to varying temperatures, humidity levels, and chemical environments can potentially degrade the altered surface properties over time. This necessitates the development of robust stabilization techniques to maintain the desired surface characteristics for extended periods.

The scalability of MISH-based surface alteration processes also poses a considerable challenge. While laboratory-scale experiments may yield promising results, translating these outcomes to industrial-scale applications often encounters unforeseen complications. Issues such as process control, quality assurance, and cost-effectiveness become more pronounced when scaling up the technology.

Furthermore, the environmental impact and safety considerations of MISH-based surface treatments require careful evaluation. The potential release of nanoparticles or chemical byproducts during the alteration process or throughout the lifecycle of treated materials raises concerns about long-term ecological effects and human health risks.

Characterization and measurement of MISH-altered surfaces present another set of challenges. Developing accurate and reliable methods to quantify the changes in surface properties, such as wettability, roughness, and chemical composition, is crucial for quality control and performance optimization. However, the complex nature of MISH interactions with surfaces often complicates these analytical processes.

Additionally, the integration of MISH-based surface alteration with existing manufacturing processes and materials poses compatibility challenges. Ensuring that the altered surfaces maintain their desired properties while not compromising the overall performance or functionality of the final product requires extensive research and development efforts.

Lastly, the cost-effectiveness of MISH-based surface alteration techniques compared to alternative methods remains a significant hurdle. While the technology offers unique advantages, the economic viability of large-scale implementation needs to be carefully assessed against competing surface modification approaches.

Another major challenge lies in the stability and durability of MISH-altered surfaces under diverse environmental conditions. Exposure to varying temperatures, humidity levels, and chemical environments can potentially degrade the altered surface properties over time. This necessitates the development of robust stabilization techniques to maintain the desired surface characteristics for extended periods.

The scalability of MISH-based surface alteration processes also poses a considerable challenge. While laboratory-scale experiments may yield promising results, translating these outcomes to industrial-scale applications often encounters unforeseen complications. Issues such as process control, quality assurance, and cost-effectiveness become more pronounced when scaling up the technology.

Furthermore, the environmental impact and safety considerations of MISH-based surface treatments require careful evaluation. The potential release of nanoparticles or chemical byproducts during the alteration process or throughout the lifecycle of treated materials raises concerns about long-term ecological effects and human health risks.

Characterization and measurement of MISH-altered surfaces present another set of challenges. Developing accurate and reliable methods to quantify the changes in surface properties, such as wettability, roughness, and chemical composition, is crucial for quality control and performance optimization. However, the complex nature of MISH interactions with surfaces often complicates these analytical processes.

Additionally, the integration of MISH-based surface alteration with existing manufacturing processes and materials poses compatibility challenges. Ensuring that the altered surfaces maintain their desired properties while not compromising the overall performance or functionality of the final product requires extensive research and development efforts.

Lastly, the cost-effectiveness of MISH-based surface alteration techniques compared to alternative methods remains a significant hurdle. While the technology offers unique advantages, the economic viability of large-scale implementation needs to be carefully assessed against competing surface modification approaches.

Existing Surface Alteration Methods

01 Surface modification of magnesium iron silicate hydroxide

Various methods are employed to modify the surface characteristics of magnesium iron silicate hydroxide. These modifications can include coating, functionalization, or chemical treatment to alter properties such as hydrophobicity, dispersibility, or reactivity. Such modifications can enhance the material's performance in specific applications.- Surface modification of magnesium iron silicate hydroxide: Various methods are employed to modify the surface characteristics of magnesium iron silicate hydroxide. These modifications can include coating, functionalization, or chemical treatment to alter properties such as hydrophobicity, dispersibility, or reactivity. Such modifications can enhance the material's performance in specific applications.

- Particle size control and surface area optimization: Techniques are developed to control the particle size and optimize the surface area of magnesium iron silicate hydroxide. This can involve milling, grinding, or specific synthesis methods to achieve desired particle dimensions and surface characteristics, which can significantly impact the material's properties and applications.

- Surface charge and zeta potential manipulation: Methods are explored to manipulate the surface charge and zeta potential of magnesium iron silicate hydroxide particles. This can involve pH adjustment, ion exchange, or surface treatments to alter the electrical properties of the material's surface, affecting its stability in suspensions and interactions with other substances.

- Porosity and adsorption characteristics: Research focuses on understanding and modifying the porosity and adsorption characteristics of magnesium iron silicate hydroxide surfaces. This includes creating or enhancing porous structures, controlling pore size distribution, and modifying surface chemistry to improve adsorption capacity for various applications.

- Surface reactivity and catalytic properties: Investigations are conducted on the surface reactivity and catalytic properties of magnesium iron silicate hydroxide. This involves studying and modifying the material's surface to enhance its catalytic activity, selectivity, or stability in various chemical reactions and processes.

02 Particle size control and surface area optimization

Techniques are developed to control the particle size and optimize the surface area of magnesium iron silicate hydroxide. This can involve milling, grinding, or specific synthesis methods to achieve desired particle dimensions and surface characteristics, which can significantly impact the material's properties and applications.Expand Specific Solutions03 Surface charge and zeta potential manipulation

Methods are explored to manipulate the surface charge and zeta potential of magnesium iron silicate hydroxide particles. This can involve pH adjustment, ion exchange, or surface treatments to alter the electrical properties of the material's surface, affecting its stability in suspensions and interactions with other substances.Expand Specific Solutions04 Porosity and adsorption characteristics

Research focuses on understanding and modifying the porosity and adsorption characteristics of magnesium iron silicate hydroxide. This includes studying pore size distribution, surface area, and adsorption capacity, which are crucial for applications in catalysis, filtration, and environmental remediation.Expand Specific Solutions05 Surface functionalization for specific applications

Techniques are developed to functionalize the surface of magnesium iron silicate hydroxide for specific applications. This can involve grafting organic molecules, attaching functional groups, or creating hybrid materials to tailor the surface properties for use in areas such as drug delivery, composite materials, or advanced coatings.Expand Specific Solutions

Key Players in Material Science Industry

The surface characteristics alteration by Magnesium iron silicate hydroxide technology is in a developing stage, with a growing market driven by increasing applications in various industries. The global market size is expanding, though exact figures are not readily available. Technologically, it's progressing from early to mid-maturity, with companies like Evonik Operations GmbH, Merck Patent GmbH, and Wacker Chemie AG leading research and development efforts. These firms are focusing on improving the efficiency and scalability of the technology, while also exploring new applications. Emerging players such as SilcoTek Corp and Ecopro BM Co., Ltd. are contributing to the competitive landscape by introducing innovative approaches and specialized solutions.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced surface modification techniques using magnesium iron silicate hydroxide (MISH) for various applications. Their approach involves controlled deposition of MISH nanoparticles onto substrate surfaces, creating a uniform coating with enhanced properties. The process utilizes a sol-gel method, allowing precise control over particle size and distribution[1]. This results in improved surface characteristics such as increased hydrophobicity, corrosion resistance, and thermal stability[2]. Evonik's technology also incorporates functionalization of MISH particles to tailor surface properties for specific applications, such as self-cleaning coatings or anti-fouling surfaces[3].

Strengths: Precise control over surface modification, versatility in applications, and ability to tailor properties. Weaknesses: Potential high cost of production and scalability challenges for large-scale applications.

Merck Patent GmbH

Technical Solution: Merck has pioneered a novel approach to surface alteration using MISH-based composites. Their technology involves the synthesis of hybrid MISH-polymer nanocomposites, which are then applied as thin films to modify surface characteristics. The process utilizes a proprietary emulsion polymerization technique, allowing for the incorporation of MISH nanoparticles into polymer matrices[4]. This results in surfaces with enhanced mechanical properties, improved chemical resistance, and unique optical characteristics[5]. Merck's method also allows for the incorporation of additional functional additives, enabling the creation of multifunctional surfaces with properties such as antimicrobial activity or electrical conductivity[6].

Strengths: Multifunctional surface properties, good compatibility with existing coating processes. Weaknesses: Potential limitations in durability for certain harsh environments, complexity in formulation.

Core Innovations in MISH Technology

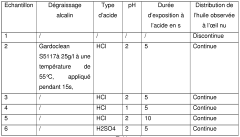

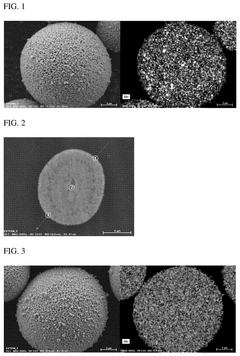

Method for producing a metal sheet having oiled zn-al-mg coatings, and corresponding metal sheet

PatentWO2013160871A1

Innovation

- Incorporating a step to alter the magnesium oxide or magnesium hydroxide layers on the outer surfaces of the coatings using mechanical forces or acid solutions before oil application, which can be combined with degreasing and surface treatment to improve oil distribution and corrosion resistance.

Positive electrode active material and lithium secondary battery comprising the same

PatentPendingUS20250140809A1

Innovation

- Surface modification of lithium manganese-based oxide using molybdenum to reduce surface resistance, stabilize the surface, and form a spinel phase, thereby improving the electrochemical properties and stability of the positive electrode active material.

Environmental Impact Assessment

The environmental impact assessment of surface characteristics alteration by magnesium iron silicate hydroxide (MISH) is a critical aspect of evaluating the technology's sustainability and ecological footprint. MISH, a naturally occurring mineral, has gained attention for its potential applications in various industries, including water treatment, soil remediation, and material science. However, its widespread use necessitates a thorough examination of its environmental implications.

One of the primary environmental considerations is the potential release of MISH particles into aquatic ecosystems. While MISH is generally considered non-toxic, the alteration of surface characteristics may lead to changes in particle size and reactivity. These modifications could affect the mineral's behavior in water bodies, potentially impacting aquatic organisms and altering sediment composition. Long-term studies are needed to assess the potential bioaccumulation and biomagnification of MISH-derived particles in aquatic food chains.

The use of MISH for soil remediation presents both opportunities and challenges from an environmental perspective. On one hand, its ability to adsorb heavy metals and organic pollutants can contribute to the restoration of contaminated soils. However, the large-scale application of MISH may alter soil pH, mineral composition, and microbial communities. These changes could have cascading effects on plant growth, nutrient cycling, and overall ecosystem functioning. Careful monitoring and site-specific assessments are essential to ensure that the benefits of MISH application outweigh any potential negative impacts on soil health.

Air quality is another important consideration in the environmental impact assessment of MISH-based technologies. The production and handling of MISH may generate dust particles, which could contribute to local air pollution if not properly managed. Additionally, the potential for MISH to act as a carrier for other pollutants in the atmosphere needs to be evaluated, particularly in urban and industrial settings where it may interact with existing air contaminants.

The life cycle assessment of MISH production and application is crucial for understanding its overall environmental footprint. This includes evaluating the energy requirements and greenhouse gas emissions associated with mining, processing, and transporting the mineral. Furthermore, the potential for recycling and reuse of MISH after its primary application should be explored to minimize waste and promote circular economy principles.

Lastly, the environmental impact assessment must consider the potential long-term effects of MISH on ecosystem services and biodiversity. While short-term studies may show promising results, the cumulative impact of widespread MISH use on various habitats and species interactions remains uncertain. Comprehensive ecological monitoring programs and adaptive management strategies are necessary to detect and mitigate any unforeseen environmental consequences of MISH-based surface alteration technologies.

One of the primary environmental considerations is the potential release of MISH particles into aquatic ecosystems. While MISH is generally considered non-toxic, the alteration of surface characteristics may lead to changes in particle size and reactivity. These modifications could affect the mineral's behavior in water bodies, potentially impacting aquatic organisms and altering sediment composition. Long-term studies are needed to assess the potential bioaccumulation and biomagnification of MISH-derived particles in aquatic food chains.

The use of MISH for soil remediation presents both opportunities and challenges from an environmental perspective. On one hand, its ability to adsorb heavy metals and organic pollutants can contribute to the restoration of contaminated soils. However, the large-scale application of MISH may alter soil pH, mineral composition, and microbial communities. These changes could have cascading effects on plant growth, nutrient cycling, and overall ecosystem functioning. Careful monitoring and site-specific assessments are essential to ensure that the benefits of MISH application outweigh any potential negative impacts on soil health.

Air quality is another important consideration in the environmental impact assessment of MISH-based technologies. The production and handling of MISH may generate dust particles, which could contribute to local air pollution if not properly managed. Additionally, the potential for MISH to act as a carrier for other pollutants in the atmosphere needs to be evaluated, particularly in urban and industrial settings where it may interact with existing air contaminants.

The life cycle assessment of MISH production and application is crucial for understanding its overall environmental footprint. This includes evaluating the energy requirements and greenhouse gas emissions associated with mining, processing, and transporting the mineral. Furthermore, the potential for recycling and reuse of MISH after its primary application should be explored to minimize waste and promote circular economy principles.

Lastly, the environmental impact assessment must consider the potential long-term effects of MISH on ecosystem services and biodiversity. While short-term studies may show promising results, the cumulative impact of widespread MISH use on various habitats and species interactions remains uncertain. Comprehensive ecological monitoring programs and adaptive management strategies are necessary to detect and mitigate any unforeseen environmental consequences of MISH-based surface alteration technologies.

Scalability and Industrial Applications

The scalability and industrial applications of surface characteristics alteration by Magnesium iron silicate hydroxide (MISH) present significant potential for various sectors. This technology's ability to modify surface properties offers wide-ranging implications for manufacturing processes and product development.

In terms of scalability, MISH-based surface alteration techniques have shown promising results in laboratory settings. However, transitioning from small-scale experiments to large-scale industrial applications requires careful consideration of several factors. The production of MISH in sufficient quantities for industrial use is a key challenge that needs to be addressed. Current synthesis methods may need to be optimized or entirely new approaches developed to meet the demand of large-scale applications.

The uniformity and consistency of surface alteration across large areas or high volumes of materials is another critical aspect of scalability. Ensuring that the MISH treatment produces consistent results on industrial-scale surfaces or batches of products is essential for maintaining quality control in manufacturing processes.

From an industrial applications perspective, MISH-based surface alteration technology shows promise in several sectors. In the automotive industry, it could be used to enhance the corrosion resistance of metal components or improve the adhesion of paints and coatings. The aerospace sector might benefit from MISH treatments to create more durable and heat-resistant surfaces on aircraft components.

In the field of electronics, MISH surface alteration could potentially improve the performance of various components. For instance, it might be used to modify the surface characteristics of semiconductor materials, enhancing their electrical or thermal properties. The technology could also find applications in the production of more efficient solar panels by altering the surface properties of photovoltaic cells.

The construction industry is another area where MISH-based surface alteration could have significant impact. It could be used to improve the durability and weather resistance of building materials, potentially extending the lifespan of structures and reducing maintenance costs.

Environmental applications are also worth considering. MISH surface treatments could be used to develop more effective filtration systems for water and air purification. The altered surface characteristics might enhance the adsorption or catalytic properties of filter materials, leading to more efficient removal of contaminants.

As research in this field progresses, new applications are likely to emerge. The versatility of MISH-based surface alteration techniques suggests that they could find use in a wide range of industries, from medical device manufacturing to textile production. However, realizing these potential applications will require continued research and development efforts to overcome current limitations and optimize the technology for specific industrial needs.

In terms of scalability, MISH-based surface alteration techniques have shown promising results in laboratory settings. However, transitioning from small-scale experiments to large-scale industrial applications requires careful consideration of several factors. The production of MISH in sufficient quantities for industrial use is a key challenge that needs to be addressed. Current synthesis methods may need to be optimized or entirely new approaches developed to meet the demand of large-scale applications.

The uniformity and consistency of surface alteration across large areas or high volumes of materials is another critical aspect of scalability. Ensuring that the MISH treatment produces consistent results on industrial-scale surfaces or batches of products is essential for maintaining quality control in manufacturing processes.

From an industrial applications perspective, MISH-based surface alteration technology shows promise in several sectors. In the automotive industry, it could be used to enhance the corrosion resistance of metal components or improve the adhesion of paints and coatings. The aerospace sector might benefit from MISH treatments to create more durable and heat-resistant surfaces on aircraft components.

In the field of electronics, MISH surface alteration could potentially improve the performance of various components. For instance, it might be used to modify the surface characteristics of semiconductor materials, enhancing their electrical or thermal properties. The technology could also find applications in the production of more efficient solar panels by altering the surface properties of photovoltaic cells.

The construction industry is another area where MISH-based surface alteration could have significant impact. It could be used to improve the durability and weather resistance of building materials, potentially extending the lifespan of structures and reducing maintenance costs.

Environmental applications are also worth considering. MISH surface treatments could be used to develop more effective filtration systems for water and air purification. The altered surface characteristics might enhance the adsorption or catalytic properties of filter materials, leading to more efficient removal of contaminants.

As research in this field progresses, new applications are likely to emerge. The versatility of MISH-based surface alteration techniques suggests that they could find use in a wide range of industries, from medical device manufacturing to textile production. However, realizing these potential applications will require continued research and development efforts to overcome current limitations and optimize the technology for specific industrial needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!