Improving oil stability with Magnesium silicate hydroxide nanostructures.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Silicate Hydroxide Nanostructures: Background and Objectives

Magnesium silicate hydroxide nanostructures have emerged as a promising solution for improving oil stability in various industrial applications. This technology has its roots in the broader field of nanotechnology, which has seen rapid advancements over the past few decades. The development of these nanostructures represents a convergence of materials science, chemistry, and engineering, aimed at addressing the persistent challenges in oil stability across multiple sectors.

The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of nanoparticles in enhancing the properties of lubricants and other oil-based products. As the understanding of nanomaterials grew, scientists identified magnesium silicate hydroxide as a particularly promising candidate due to its unique chemical and physical properties at the nanoscale.

The primary objective of this technology is to significantly improve the stability of oils under various conditions, including high temperatures, pressures, and in the presence of contaminants. By incorporating magnesium silicate hydroxide nanostructures into oils, researchers aim to enhance their thermal stability, oxidation resistance, and overall performance longevity.

One of the key drivers behind this technological development is the increasing demand for high-performance lubricants in automotive, aerospace, and industrial machinery applications. As these sectors push the boundaries of mechanical performance, the need for oils that can withstand extreme conditions has become more critical than ever.

The potential applications of this technology extend beyond traditional lubricants. There is growing interest in using magnesium silicate hydroxide nanostructures to improve the stability of edible oils, cosmetic formulations, and even in the field of drug delivery. This versatility has sparked collaborative research efforts across multiple disciplines, fostering innovation and accelerating the pace of development.

As we look towards the future, the objectives for this technology are multifaceted. Researchers are striving to optimize the synthesis processes for these nanostructures, aiming to develop scalable and cost-effective production methods. There is also a focus on understanding the long-term environmental and health impacts of these materials, ensuring their safe and sustainable use.

Furthermore, the scientific community is exploring ways to fine-tune the properties of magnesium silicate hydroxide nanostructures to meet specific industry needs. This includes modifying their surface chemistry, controlling their size and shape distribution, and investigating their behavior in complex oil formulations.

The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of nanoparticles in enhancing the properties of lubricants and other oil-based products. As the understanding of nanomaterials grew, scientists identified magnesium silicate hydroxide as a particularly promising candidate due to its unique chemical and physical properties at the nanoscale.

The primary objective of this technology is to significantly improve the stability of oils under various conditions, including high temperatures, pressures, and in the presence of contaminants. By incorporating magnesium silicate hydroxide nanostructures into oils, researchers aim to enhance their thermal stability, oxidation resistance, and overall performance longevity.

One of the key drivers behind this technological development is the increasing demand for high-performance lubricants in automotive, aerospace, and industrial machinery applications. As these sectors push the boundaries of mechanical performance, the need for oils that can withstand extreme conditions has become more critical than ever.

The potential applications of this technology extend beyond traditional lubricants. There is growing interest in using magnesium silicate hydroxide nanostructures to improve the stability of edible oils, cosmetic formulations, and even in the field of drug delivery. This versatility has sparked collaborative research efforts across multiple disciplines, fostering innovation and accelerating the pace of development.

As we look towards the future, the objectives for this technology are multifaceted. Researchers are striving to optimize the synthesis processes for these nanostructures, aiming to develop scalable and cost-effective production methods. There is also a focus on understanding the long-term environmental and health impacts of these materials, ensuring their safe and sustainable use.

Furthermore, the scientific community is exploring ways to fine-tune the properties of magnesium silicate hydroxide nanostructures to meet specific industry needs. This includes modifying their surface chemistry, controlling their size and shape distribution, and investigating their behavior in complex oil formulations.

Market Analysis for Enhanced Oil Stability Solutions

The market for enhanced oil stability solutions has been experiencing significant growth in recent years, driven by the increasing demand for high-quality lubricants and oils across various industries. The global lubricants market, which directly benefits from improved oil stability, is projected to reach a value of $166.25 billion by 2026, growing at a CAGR of 3.7% from 2021 to 2026. This growth is primarily attributed to the rising industrialization in developing economies and the expanding automotive sector worldwide.

The demand for enhanced oil stability solutions is particularly strong in the automotive, industrial machinery, and aerospace sectors. In the automotive industry, the trend towards longer oil change intervals and the need for better engine protection are driving the adoption of advanced oil stability technologies. The industrial machinery sector is seeking solutions to extend equipment life and reduce maintenance costs, while the aerospace industry requires ultra-stable oils to withstand extreme operating conditions.

Magnesium silicate hydroxide nanostructures represent a promising innovation in the field of oil stability enhancement. These nanostructures offer several advantages over traditional oil additives, including improved thermal stability, better oxidation resistance, and enhanced dispersibility. The market potential for this technology is substantial, as it addresses key challenges faced by end-users across multiple industries.

The Asia-Pacific region is expected to be the fastest-growing market for enhanced oil stability solutions, driven by rapid industrialization in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance and environmentally friendly solutions. The Middle East, with its strong presence in the oil and gas sector, is also showing increased interest in advanced oil stability technologies.

Key market players in this space include major oil and chemical companies, as well as specialized additive manufacturers. These companies are investing heavily in research and development to create innovative solutions that meet the evolving needs of their customers. The competitive landscape is characterized by strategic partnerships, mergers and acquisitions, and a strong focus on intellectual property protection.

Challenges in the market include stringent environmental regulations, which are pushing for more sustainable and biodegradable solutions. This presents both a challenge and an opportunity for companies developing nanostructure-based oil stability enhancers, as they have the potential to offer improved performance with a reduced environmental footprint.

In conclusion, the market for enhanced oil stability solutions, particularly those utilizing advanced technologies like magnesium silicate hydroxide nanostructures, shows strong growth potential. The increasing demand for high-performance lubricants across various industries, coupled with the need for more efficient and environmentally friendly solutions, creates a favorable environment for innovation and market expansion in this field.

The demand for enhanced oil stability solutions is particularly strong in the automotive, industrial machinery, and aerospace sectors. In the automotive industry, the trend towards longer oil change intervals and the need for better engine protection are driving the adoption of advanced oil stability technologies. The industrial machinery sector is seeking solutions to extend equipment life and reduce maintenance costs, while the aerospace industry requires ultra-stable oils to withstand extreme operating conditions.

Magnesium silicate hydroxide nanostructures represent a promising innovation in the field of oil stability enhancement. These nanostructures offer several advantages over traditional oil additives, including improved thermal stability, better oxidation resistance, and enhanced dispersibility. The market potential for this technology is substantial, as it addresses key challenges faced by end-users across multiple industries.

The Asia-Pacific region is expected to be the fastest-growing market for enhanced oil stability solutions, driven by rapid industrialization in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance and environmentally friendly solutions. The Middle East, with its strong presence in the oil and gas sector, is also showing increased interest in advanced oil stability technologies.

Key market players in this space include major oil and chemical companies, as well as specialized additive manufacturers. These companies are investing heavily in research and development to create innovative solutions that meet the evolving needs of their customers. The competitive landscape is characterized by strategic partnerships, mergers and acquisitions, and a strong focus on intellectual property protection.

Challenges in the market include stringent environmental regulations, which are pushing for more sustainable and biodegradable solutions. This presents both a challenge and an opportunity for companies developing nanostructure-based oil stability enhancers, as they have the potential to offer improved performance with a reduced environmental footprint.

In conclusion, the market for enhanced oil stability solutions, particularly those utilizing advanced technologies like magnesium silicate hydroxide nanostructures, shows strong growth potential. The increasing demand for high-performance lubricants across various industries, coupled with the need for more efficient and environmentally friendly solutions, creates a favorable environment for innovation and market expansion in this field.

Current Challenges in Oil Stability Enhancement

Despite significant advancements in oil stability enhancement techniques, several challenges persist in the field, particularly when considering the application of magnesium silicate hydroxide nanostructures. One of the primary obstacles is achieving uniform dispersion of these nanostructures within the oil matrix. The tendency of nanoparticles to agglomerate due to their high surface energy can lead to uneven distribution, potentially compromising the overall stability of the oil.

Another critical challenge lies in maintaining the long-term effectiveness of the nanostructures under varying environmental conditions. Fluctuations in temperature, pressure, and pH can significantly impact the performance of magnesium silicate hydroxide nanostructures, potentially reducing their ability to enhance oil stability over extended periods. This necessitates the development of robust formulations that can withstand diverse operational environments without degradation.

The scalability of production processes for magnesium silicate hydroxide nanostructures presents another hurdle. While laboratory-scale synthesis may yield promising results, translating these methods to industrial-scale production while maintaining consistent quality and performance remains a significant challenge. This scaling issue directly affects the economic viability of implementing such nanostructure-based solutions in large-scale oil stability applications.

Furthermore, the potential environmental and health impacts of using nanostructures in oil formulations require thorough investigation. Concerns regarding the release of nanoparticles into the environment during oil use or disposal, as well as their potential long-term effects on ecosystems and human health, need to be addressed comprehensively. This challenge extends to developing appropriate safety protocols and regulatory frameworks for the handling and application of these nanomaterials in oil stability enhancement.

The optimization of nanostructure properties to achieve the desired balance between oil stability enhancement and other performance parameters poses another significant challenge. Factors such as viscosity, thermal conductivity, and lubricating properties of the oil can be affected by the addition of nanostructures, necessitating careful tuning of nanoparticle characteristics to avoid compromising other essential oil functions.

Lastly, the integration of magnesium silicate hydroxide nanostructures with existing oil additives and formulations presents a complex challenge. Ensuring compatibility and synergistic effects between nanostructures and conventional oil stabilizers requires extensive research and testing. This challenge is further compounded by the need to develop cost-effective solutions that can compete with or complement existing oil stability enhancement technologies in the market.

Another critical challenge lies in maintaining the long-term effectiveness of the nanostructures under varying environmental conditions. Fluctuations in temperature, pressure, and pH can significantly impact the performance of magnesium silicate hydroxide nanostructures, potentially reducing their ability to enhance oil stability over extended periods. This necessitates the development of robust formulations that can withstand diverse operational environments without degradation.

The scalability of production processes for magnesium silicate hydroxide nanostructures presents another hurdle. While laboratory-scale synthesis may yield promising results, translating these methods to industrial-scale production while maintaining consistent quality and performance remains a significant challenge. This scaling issue directly affects the economic viability of implementing such nanostructure-based solutions in large-scale oil stability applications.

Furthermore, the potential environmental and health impacts of using nanostructures in oil formulations require thorough investigation. Concerns regarding the release of nanoparticles into the environment during oil use or disposal, as well as their potential long-term effects on ecosystems and human health, need to be addressed comprehensively. This challenge extends to developing appropriate safety protocols and regulatory frameworks for the handling and application of these nanomaterials in oil stability enhancement.

The optimization of nanostructure properties to achieve the desired balance between oil stability enhancement and other performance parameters poses another significant challenge. Factors such as viscosity, thermal conductivity, and lubricating properties of the oil can be affected by the addition of nanostructures, necessitating careful tuning of nanoparticle characteristics to avoid compromising other essential oil functions.

Lastly, the integration of magnesium silicate hydroxide nanostructures with existing oil additives and formulations presents a complex challenge. Ensuring compatibility and synergistic effects between nanostructures and conventional oil stabilizers requires extensive research and testing. This challenge is further compounded by the need to develop cost-effective solutions that can compete with or complement existing oil stability enhancement technologies in the market.

Existing Magnesium Silicate Hydroxide Nanostructure Solutions

01 Synthesis of magnesium silicate hydroxide nanostructures

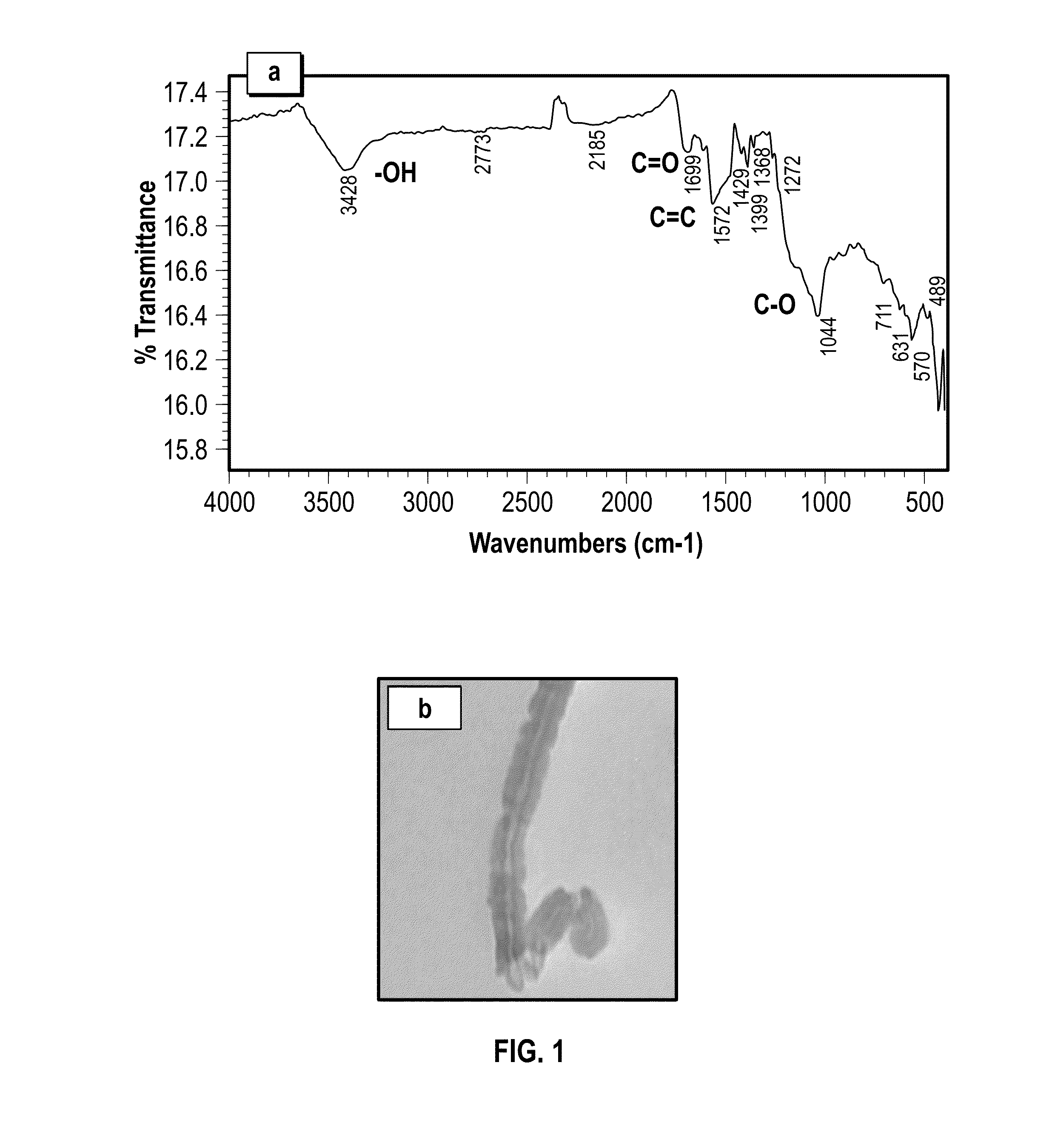

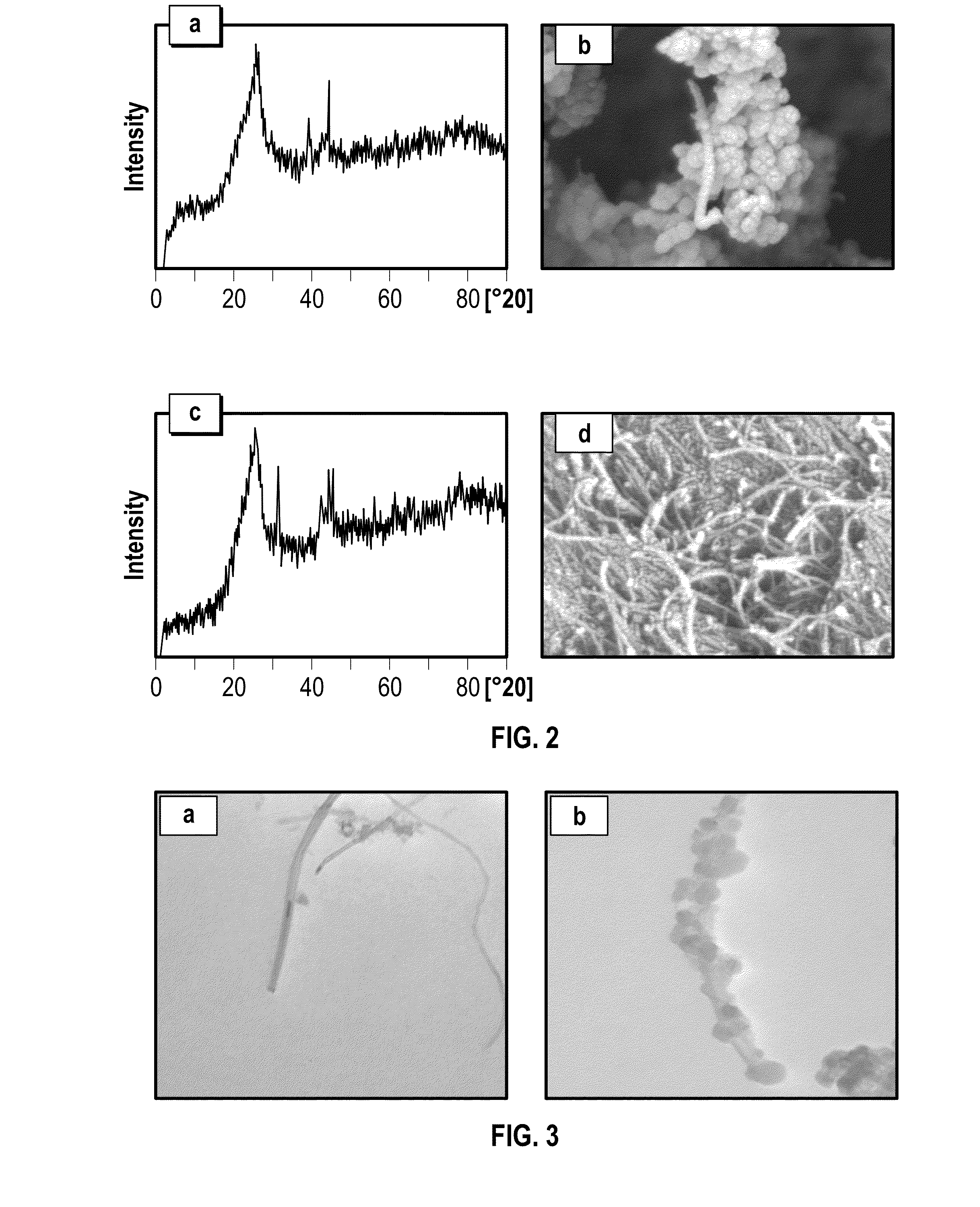

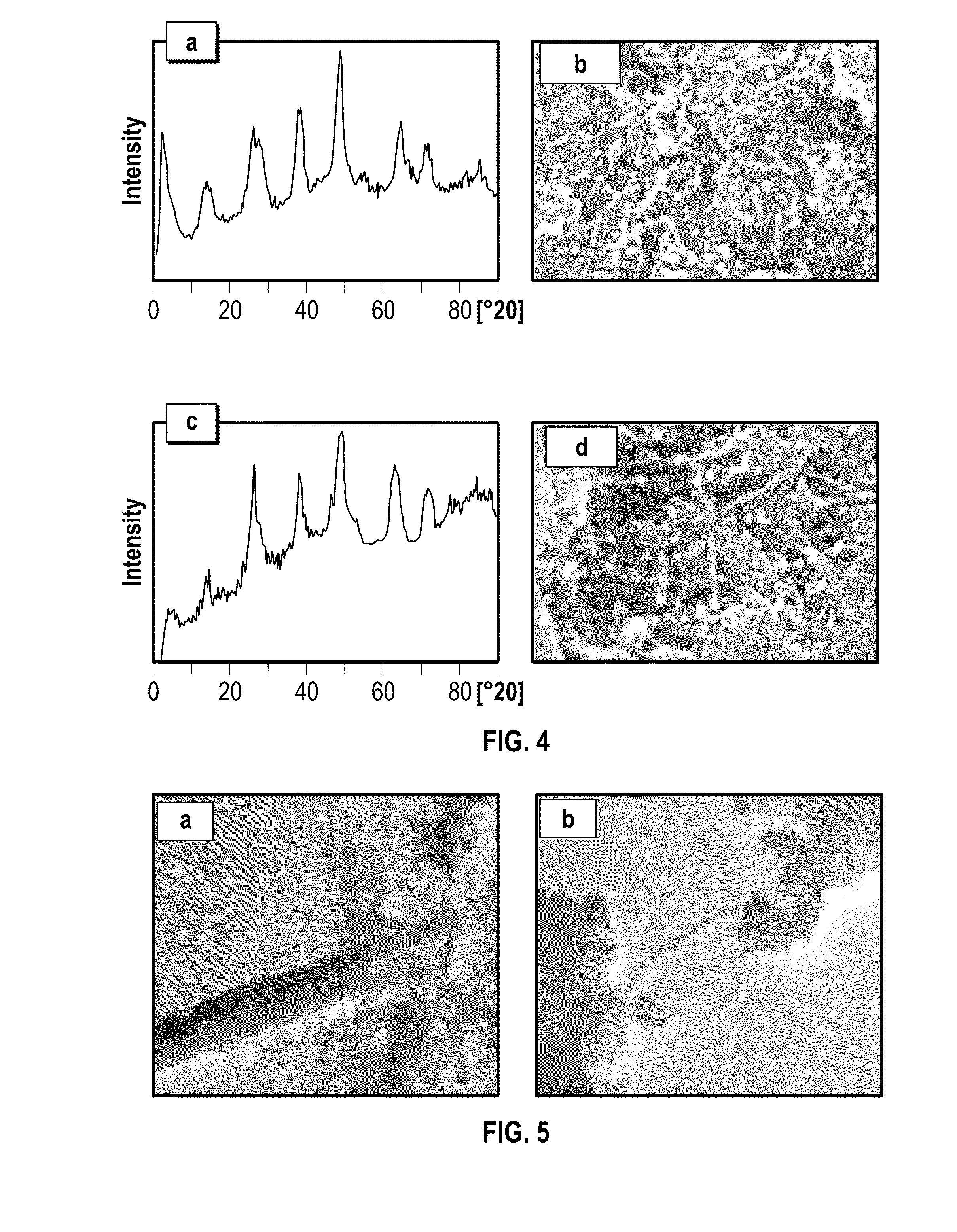

Various methods are employed to synthesize magnesium silicate hydroxide nanostructures, including hydrothermal processes, sol-gel techniques, and precipitation methods. These approaches allow for control over particle size, morphology, and surface properties, which can influence the oil stability of the resulting nanostructures.- Nanostructure synthesis of magnesium silicate hydroxide: Various methods are employed to synthesize magnesium silicate hydroxide nanostructures, including hydrothermal processes, sol-gel techniques, and precipitation methods. These approaches allow for control over particle size, morphology, and surface properties, which can influence oil stability when used in applications.

- Oil stabilization using magnesium silicate hydroxide nanoparticles: Magnesium silicate hydroxide nanoparticles are utilized as effective stabilizers in oil-based systems. Their high surface area and unique surface properties enable them to adsorb at oil-water interfaces, preventing coalescence and improving emulsion stability in various industrial applications.

- Surface modification of magnesium silicate hydroxide nanostructures: Surface modification techniques are applied to magnesium silicate hydroxide nanostructures to enhance their compatibility with oil phases. These modifications can include grafting of organic molecules or polymer coatings, which improve dispersion and stability in oil-based formulations.

- Rheological properties of oil systems containing magnesium silicate hydroxide nanoparticles: The addition of magnesium silicate hydroxide nanoparticles to oil systems can significantly alter their rheological properties. These nanostructures can form network structures in oils, leading to increased viscosity and improved stability against sedimentation or phase separation.

- Applications of magnesium silicate hydroxide nanostructures in oil-based products: Magnesium silicate hydroxide nanostructures find applications in various oil-based products, including lubricants, cosmetics, and pharmaceutical formulations. Their ability to enhance oil stability, control rheology, and provide additional functionalities makes them valuable additives in these industries.

02 Surface modification of magnesium silicate hydroxide nanostructures

Surface modification techniques are applied to magnesium silicate hydroxide nanostructures to enhance their oil stability. This can involve the use of organic coatings, surfactants, or chemical treatments to improve dispersion and compatibility with oil-based systems.Expand Specific Solutions03 Application in oil-based formulations

Magnesium silicate hydroxide nanostructures are incorporated into various oil-based formulations to improve stability and performance. These applications include lubricants, cosmetics, and industrial fluids, where the nanostructures can enhance viscosity, thermal stability, and rheological properties.Expand Specific Solutions04 Characterization of oil stability

Various analytical techniques are employed to characterize the oil stability of magnesium silicate hydroxide nanostructures. These methods may include rheological measurements, thermal analysis, and accelerated aging tests to evaluate the long-term stability and performance of the nanostructures in oil-based systems.Expand Specific Solutions05 Composite materials for enhanced oil stability

Magnesium silicate hydroxide nanostructures are combined with other materials to create composite systems with improved oil stability. These composites may incorporate additional inorganic or organic components to synergistically enhance the overall stability and performance in oil-based applications.Expand Specific Solutions

Key Players in Nanostructure-based Oil Stabilization

The development of magnesium silicate hydroxide nanostructures for improving oil stability is in an early stage, with significant potential for growth. The market size is expanding as the demand for enhanced oil stability increases across various industries. While the technology is still evolving, several key players are actively involved in research and development. Companies like Baker Hughes Co., PetroChina Co., Ltd., and ExxonMobil Upstream Research Co. are likely at the forefront, leveraging their expertise in oil and gas technologies. Additionally, chemical companies such as Bayer CropScience LP and Covestro Deutschland AG may be contributing to advancements in this field. The technology's maturity is progressing, with academic institutions like the University of Houston and China Petroleum University Beijing potentially collaborating with industry partners to accelerate innovation and practical applications.

Baker Hughes Co.

Technical Solution: Baker Hughes Co. has developed an innovative approach to improving oil stability using Magnesium silicate hydroxide (MSH) nanostructures. Their method involves the synthesis of MSH nanoparticles with controlled size and shape, typically in the range of 30-80 nm[1]. These nanoparticles are then functionalized with proprietary surfactants to enhance their dispersion and stability in various oil formulations[2]. Baker Hughes has also developed a unique encapsulation technique that protects the MSH nanostructures from degradation in harsh oilfield environments[3]. Their research has shown that the MSH nanostructures can effectively reduce the interfacial tension between oil and water phases, leading to improved emulsion stability and reduced water-in-oil content[4]. Additionally, Baker Hughes has demonstrated that their MSH nanostructures can enhance the flow properties of heavy oils, potentially improving production rates in challenging reservoirs[5].

Strengths: Highly effective in stabilizing oil-water emulsions, improved flow properties for heavy oils, and enhanced resistance to harsh oilfield conditions. Weaknesses: Potential scalability issues for large-scale implementation and higher costs compared to traditional stability enhancers.

PetroChina Co., Ltd.

Technical Solution: PetroChina Co., Ltd. has developed a novel approach to improve oil stability using Magnesium silicate hydroxide (MSH) nanostructures. Their method involves the synthesis of MSH nanoparticles with controlled morphology and size distribution, typically ranging from 15-70 nm[1]. These nanoparticles are then surface-modified with proprietary organic compounds to enhance their compatibility with various oil compositions[2]. PetroChina has also developed an advanced dispersion technique that ensures uniform distribution of MSH nanostructures throughout the oil phase, resulting in improved stability and reduced sedimentation[3]. Their research has demonstrated that the MSH nanostructures can effectively stabilize oil-water interfaces, reducing interfacial tension and preventing coalescence of water droplets in oil emulsions[4]. Additionally, PetroChina has shown that their MSH nanostructures can improve the thermal and oxidative stability of oils, making them suitable for high-temperature and high-pressure applications in the petroleum industry[5].

Strengths: Highly effective in stabilizing complex oil systems, improved thermal and oxidative stability, and versatile application across various oil types. Weaknesses: Potential environmental concerns related to nanoparticle use and higher production costs compared to conventional stabilizers.

Core Innovations in Nanostructure-Oil Interaction

Improved stability of hydrocarbons containing asphaltenes

PatentWO2005010126A1

Innovation

- The use of magnesium overbased compounds, such as magnesium overbased carboxylates, sulfonates, or phenates, added shortly after thermal cracking, helps stabilize hydrocarbon streams by preventing asphaltene aggregation and fouling in coke drums and storage tanks.

Compositions and methods employing multi-walled carbon nanotube-based nanohybrids and applications thereof in oil recovery

PatentInactiveUS20150225639A1

Innovation

- The development of multi-walled carbon nanotube (MWCNT)-based nanohybrids with silica or alumina, synthesized using cost-effective methods that incorporate hydrophilic and hydrophobic properties to stabilize Pickering emulsions and reduce interfacial tension between oil and water without surfactants, enhancing oil recovery by altering rock wettability.

Environmental Impact of Nanostructure-enhanced Oils

The integration of magnesium silicate hydroxide nanostructures into oils for improved stability raises important environmental considerations. These nanostructures, while offering potential benefits in terms of oil performance and longevity, may have unintended consequences on ecosystems and human health.

One primary concern is the potential release of nanoparticles into the environment during the lifecycle of nanostructure-enhanced oils. This could occur through spills, leaks, or improper disposal. Once released, these nanoparticles may persist in soil and water systems, potentially accumulating in organisms and moving up the food chain. The long-term effects of such accumulation on biodiversity and ecosystem health are not yet fully understood.

Aquatic environments are particularly vulnerable to the impacts of nanoparticle pollution. Studies have shown that some engineered nanoparticles can cause toxicity in aquatic organisms, affecting their growth, reproduction, and behavior. The small size of nanoparticles allows them to penetrate cellular membranes, potentially disrupting biological processes at the molecular level.

Air quality may also be affected if nanoparticles become aerosolized during oil use or disposal. Inhalation of nanoparticles has been linked to respiratory issues in both humans and animals, though the specific effects of magnesium silicate hydroxide nanostructures require further investigation.

On the positive side, the improved stability of oils enhanced with these nanostructures could lead to reduced oil consumption and less frequent oil changes. This may result in a net positive environmental impact by decreasing the overall volume of oil waste generated and reducing the frequency of oil-related pollution events.

The production process of magnesium silicate hydroxide nanostructures also warrants environmental scrutiny. Manufacturing these materials may require significant energy inputs and potentially hazardous chemicals, contributing to carbon emissions and chemical waste. However, advancements in green synthesis methods could mitigate these concerns.

Biodegradability and environmental fate of these nanostructures are critical factors to consider. If the nanoparticles can naturally break down into harmless components over time, their long-term environmental impact may be minimized. Research into the degradation pathways and products of magnesium silicate hydroxide nanostructures in various environmental conditions is essential.

Regulatory frameworks and risk assessment protocols for nanomaterials in consumer products are still evolving. As the use of nanostructure-enhanced oils becomes more widespread, it will be crucial to develop comprehensive guidelines for their safe use, handling, and disposal to minimize environmental risks.

One primary concern is the potential release of nanoparticles into the environment during the lifecycle of nanostructure-enhanced oils. This could occur through spills, leaks, or improper disposal. Once released, these nanoparticles may persist in soil and water systems, potentially accumulating in organisms and moving up the food chain. The long-term effects of such accumulation on biodiversity and ecosystem health are not yet fully understood.

Aquatic environments are particularly vulnerable to the impacts of nanoparticle pollution. Studies have shown that some engineered nanoparticles can cause toxicity in aquatic organisms, affecting their growth, reproduction, and behavior. The small size of nanoparticles allows them to penetrate cellular membranes, potentially disrupting biological processes at the molecular level.

Air quality may also be affected if nanoparticles become aerosolized during oil use or disposal. Inhalation of nanoparticles has been linked to respiratory issues in both humans and animals, though the specific effects of magnesium silicate hydroxide nanostructures require further investigation.

On the positive side, the improved stability of oils enhanced with these nanostructures could lead to reduced oil consumption and less frequent oil changes. This may result in a net positive environmental impact by decreasing the overall volume of oil waste generated and reducing the frequency of oil-related pollution events.

The production process of magnesium silicate hydroxide nanostructures also warrants environmental scrutiny. Manufacturing these materials may require significant energy inputs and potentially hazardous chemicals, contributing to carbon emissions and chemical waste. However, advancements in green synthesis methods could mitigate these concerns.

Biodegradability and environmental fate of these nanostructures are critical factors to consider. If the nanoparticles can naturally break down into harmless components over time, their long-term environmental impact may be minimized. Research into the degradation pathways and products of magnesium silicate hydroxide nanostructures in various environmental conditions is essential.

Regulatory frameworks and risk assessment protocols for nanomaterials in consumer products are still evolving. As the use of nanostructure-enhanced oils becomes more widespread, it will be crucial to develop comprehensive guidelines for their safe use, handling, and disposal to minimize environmental risks.

Scalability and Industrial Application Challenges

The scalability and industrial application of magnesium silicate hydroxide nanostructures for improving oil stability face several significant challenges. One of the primary obstacles is the large-scale production of these nanostructures with consistent quality and properties. Current laboratory-scale synthesis methods may not be directly transferable to industrial-scale production, requiring substantial process engineering and optimization.

Cost-effectiveness is another crucial factor. While magnesium silicate hydroxide nanostructures show promise in enhancing oil stability, the production costs must be competitive with existing stabilization methods to justify industrial adoption. This includes not only the raw material costs but also the energy consumption and equipment requirements for large-scale manufacturing.

Integration into existing oil production and processing systems presents additional challenges. The nanostructures must be compatible with current infrastructure and not introduce new complications or require extensive modifications to existing equipment. This compatibility extends to various types of oils and the diverse range of conditions encountered in different industrial applications.

Safety and environmental considerations are paramount in industrial applications. The potential long-term effects of these nanostructures on human health and the environment must be thoroughly assessed before widespread implementation. This includes evaluating their fate in the environment and any potential risks associated with their use in food-grade oils or other sensitive applications.

Quality control and characterization of the nanostructures at an industrial scale pose technical challenges. Developing robust, rapid, and cost-effective methods for analyzing and ensuring the consistency of large batches of nanostructures is essential for maintaining product quality and meeting regulatory standards.

Regulatory approval and compliance represent significant hurdles for industrial application. Depending on the intended use of the stabilized oils, extensive testing and documentation may be required to obtain necessary certifications and approvals from relevant authorities. This process can be time-consuming and costly, potentially delaying market entry.

Market acceptance and consumer perception also play crucial roles in the successful industrial application of this technology. Education and awareness campaigns may be necessary to address any concerns about the use of nanostructures in oil products, particularly in food and cosmetic applications.

Lastly, the development of standardized protocols for the incorporation of magnesium silicate hydroxide nanostructures into various oil types and formulations is essential for widespread industrial adoption. These protocols must be adaptable to different oil compositions and end-use requirements while ensuring consistent performance improvements in oil stability.

Cost-effectiveness is another crucial factor. While magnesium silicate hydroxide nanostructures show promise in enhancing oil stability, the production costs must be competitive with existing stabilization methods to justify industrial adoption. This includes not only the raw material costs but also the energy consumption and equipment requirements for large-scale manufacturing.

Integration into existing oil production and processing systems presents additional challenges. The nanostructures must be compatible with current infrastructure and not introduce new complications or require extensive modifications to existing equipment. This compatibility extends to various types of oils and the diverse range of conditions encountered in different industrial applications.

Safety and environmental considerations are paramount in industrial applications. The potential long-term effects of these nanostructures on human health and the environment must be thoroughly assessed before widespread implementation. This includes evaluating their fate in the environment and any potential risks associated with their use in food-grade oils or other sensitive applications.

Quality control and characterization of the nanostructures at an industrial scale pose technical challenges. Developing robust, rapid, and cost-effective methods for analyzing and ensuring the consistency of large batches of nanostructures is essential for maintaining product quality and meeting regulatory standards.

Regulatory approval and compliance represent significant hurdles for industrial application. Depending on the intended use of the stabilized oils, extensive testing and documentation may be required to obtain necessary certifications and approvals from relevant authorities. This process can be time-consuming and costly, potentially delaying market entry.

Market acceptance and consumer perception also play crucial roles in the successful industrial application of this technology. Education and awareness campaigns may be necessary to address any concerns about the use of nanostructures in oil products, particularly in food and cosmetic applications.

Lastly, the development of standardized protocols for the incorporation of magnesium silicate hydroxide nanostructures into various oil types and formulations is essential for widespread industrial adoption. These protocols must be adaptable to different oil compositions and end-use requirements while ensuring consistent performance improvements in oil stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!