Novel lubrication formulations using Magnesium iron silicate hydroxide.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Iron Silicate Hydroxide Lubrication Background

Magnesium iron silicate hydroxide, also known as palygorskite or attapulgite, has emerged as a promising material in the field of lubrication. This naturally occurring clay mineral possesses unique structural and chemical properties that make it an excellent candidate for novel lubrication formulations. The exploration of magnesium iron silicate hydroxide in lubrication applications stems from the growing demand for more efficient and environmentally friendly lubricants across various industries.

The interest in magnesium iron silicate hydroxide for lubrication purposes can be traced back to the early 2000s when researchers began investigating its potential as an additive in lubricating oils. The mineral's fibrous structure, high surface area, and ability to form stable suspensions in various media caught the attention of tribology experts seeking to enhance the performance of conventional lubricants.

One of the key drivers behind the development of magnesium iron silicate hydroxide-based lubricants is the increasing focus on sustainability and environmental protection. Traditional lubricants often contain harmful additives and are derived from non-renewable resources. In contrast, magnesium iron silicate hydroxide is a naturally occurring mineral that can be sustainably sourced and offers biodegradability advantages.

The evolution of magnesium iron silicate hydroxide in lubrication technology has been marked by several significant milestones. Initial studies focused on its use as a rheology modifier and thickening agent in greases and oils. Subsequent research revealed its potential as a friction reducer and wear inhibitor, particularly in boundary lubrication conditions where conventional lubricants often fall short.

Recent advancements in nanotechnology have further expanded the possibilities for magnesium iron silicate hydroxide in lubrication. The development of nanostructured forms of the mineral has led to improved dispersion stability and enhanced tribological properties. These innovations have opened up new avenues for the creation of high-performance lubricants capable of operating under extreme conditions.

The current technological landscape surrounding magnesium iron silicate hydroxide lubrication is characterized by ongoing efforts to optimize its performance and expand its applications. Researchers are exploring various modification techniques, such as surface functionalization and composite formation, to tailor the mineral's properties for specific lubrication requirements. Additionally, there is a growing interest in combining magnesium iron silicate hydroxide with other advanced materials, such as graphene and carbon nanotubes, to create synergistic lubricant formulations.

The interest in magnesium iron silicate hydroxide for lubrication purposes can be traced back to the early 2000s when researchers began investigating its potential as an additive in lubricating oils. The mineral's fibrous structure, high surface area, and ability to form stable suspensions in various media caught the attention of tribology experts seeking to enhance the performance of conventional lubricants.

One of the key drivers behind the development of magnesium iron silicate hydroxide-based lubricants is the increasing focus on sustainability and environmental protection. Traditional lubricants often contain harmful additives and are derived from non-renewable resources. In contrast, magnesium iron silicate hydroxide is a naturally occurring mineral that can be sustainably sourced and offers biodegradability advantages.

The evolution of magnesium iron silicate hydroxide in lubrication technology has been marked by several significant milestones. Initial studies focused on its use as a rheology modifier and thickening agent in greases and oils. Subsequent research revealed its potential as a friction reducer and wear inhibitor, particularly in boundary lubrication conditions where conventional lubricants often fall short.

Recent advancements in nanotechnology have further expanded the possibilities for magnesium iron silicate hydroxide in lubrication. The development of nanostructured forms of the mineral has led to improved dispersion stability and enhanced tribological properties. These innovations have opened up new avenues for the creation of high-performance lubricants capable of operating under extreme conditions.

The current technological landscape surrounding magnesium iron silicate hydroxide lubrication is characterized by ongoing efforts to optimize its performance and expand its applications. Researchers are exploring various modification techniques, such as surface functionalization and composite formation, to tailor the mineral's properties for specific lubrication requirements. Additionally, there is a growing interest in combining magnesium iron silicate hydroxide with other advanced materials, such as graphene and carbon nanotubes, to create synergistic lubricant formulations.

Market Analysis for Novel Lubricants

The market for novel lubricants, particularly those incorporating Magnesium iron silicate hydroxide (MISH), is experiencing significant growth and transformation. This innovative formulation addresses several key challenges in the lubricant industry, driving its increasing demand across various sectors.

The global lubricants market is projected to expand steadily, with a growing emphasis on high-performance and environmentally friendly products. MISH-based lubricants are well-positioned to capitalize on this trend, offering improved thermal stability, wear resistance, and reduced environmental impact compared to traditional formulations.

In the automotive sector, stringent emissions regulations and the push for fuel efficiency are driving the adoption of advanced lubricants. MISH-based formulations can potentially enhance engine performance and longevity while contributing to reduced emissions, aligning with these industry goals.

The industrial machinery and equipment market presents another substantial opportunity for MISH lubricants. As manufacturers seek to optimize equipment efficiency and reduce maintenance costs, there is a growing demand for lubricants that can withstand extreme conditions and extend machinery lifespan.

The aerospace industry, known for its rigorous performance requirements, is also a promising market for MISH-based lubricants. The ability of these formulations to maintain stability under high temperatures and pressures makes them particularly attractive for aviation applications.

Environmental concerns are increasingly influencing lubricant choices across industries. MISH-based lubricants, with their potential for biodegradability and reduced toxicity, are well-positioned to meet the growing demand for eco-friendly alternatives.

Regionally, developed markets in North America and Europe are expected to be early adopters of MISH lubricants, driven by stringent environmental regulations and a focus on technological innovation. However, emerging economies in Asia-Pacific and Latin America present significant growth opportunities as their industrial sectors expand and modernize.

The market for MISH lubricants faces some challenges, including the need for extensive testing and certification to meet industry standards. Additionally, the higher initial cost compared to conventional lubricants may slow adoption in price-sensitive markets.

Despite these challenges, the long-term outlook for MISH-based lubricants remains positive. As research continues to demonstrate their performance benefits and environmental advantages, these novel formulations are likely to gain increasing market share across multiple industries.

The global lubricants market is projected to expand steadily, with a growing emphasis on high-performance and environmentally friendly products. MISH-based lubricants are well-positioned to capitalize on this trend, offering improved thermal stability, wear resistance, and reduced environmental impact compared to traditional formulations.

In the automotive sector, stringent emissions regulations and the push for fuel efficiency are driving the adoption of advanced lubricants. MISH-based formulations can potentially enhance engine performance and longevity while contributing to reduced emissions, aligning with these industry goals.

The industrial machinery and equipment market presents another substantial opportunity for MISH lubricants. As manufacturers seek to optimize equipment efficiency and reduce maintenance costs, there is a growing demand for lubricants that can withstand extreme conditions and extend machinery lifespan.

The aerospace industry, known for its rigorous performance requirements, is also a promising market for MISH-based lubricants. The ability of these formulations to maintain stability under high temperatures and pressures makes them particularly attractive for aviation applications.

Environmental concerns are increasingly influencing lubricant choices across industries. MISH-based lubricants, with their potential for biodegradability and reduced toxicity, are well-positioned to meet the growing demand for eco-friendly alternatives.

Regionally, developed markets in North America and Europe are expected to be early adopters of MISH lubricants, driven by stringent environmental regulations and a focus on technological innovation. However, emerging economies in Asia-Pacific and Latin America present significant growth opportunities as their industrial sectors expand and modernize.

The market for MISH lubricants faces some challenges, including the need for extensive testing and certification to meet industry standards. Additionally, the higher initial cost compared to conventional lubricants may slow adoption in price-sensitive markets.

Despite these challenges, the long-term outlook for MISH-based lubricants remains positive. As research continues to demonstrate their performance benefits and environmental advantages, these novel formulations are likely to gain increasing market share across multiple industries.

Current Challenges in Lubrication Technology

The lubrication industry faces several significant challenges in the current technological landscape. One of the primary issues is the increasing demand for high-performance lubricants that can withstand extreme conditions. As machinery and equipment become more sophisticated, they require lubricants that can operate under higher temperatures, pressures, and speeds. This puts immense stress on traditional lubricant formulations, often leading to premature breakdown and reduced efficiency.

Another critical challenge is the growing emphasis on environmental sustainability. Conventional lubricants, often derived from petroleum-based sources, pose significant environmental risks due to their non-biodegradability and potential toxicity. The industry is under pressure to develop eco-friendly alternatives that maintain or exceed the performance of traditional lubricants while minimizing environmental impact.

The need for energy efficiency is also driving innovation in lubrication technology. As global energy demands rise and environmental regulations tighten, there is a growing need for lubricants that can reduce friction and wear more effectively, thereby improving overall system efficiency and reducing energy consumption. This challenge is particularly acute in automotive and industrial applications, where even small improvements in efficiency can lead to significant energy savings.

Compatibility with new materials and technologies presents another hurdle. As industries adopt advanced materials like composites and new metal alloys, lubricants must be formulated to work effectively with these materials without causing degradation or adverse reactions. Additionally, the rise of electric vehicles and renewable energy technologies introduces new lubrication requirements that differ significantly from those of traditional combustion engines.

The challenge of extending lubricant life and reducing maintenance frequency is also at the forefront. Industries are seeking lubricants that can perform consistently over longer periods, reducing the need for frequent oil changes and system downtime. This demand is driving research into more stable formulations and additives that can maintain lubricant properties over extended periods under various operating conditions.

Lastly, the industry faces the challenge of balancing performance with cost-effectiveness. While high-performance lubricants offer superior protection and efficiency, they often come at a premium price. Developing advanced lubricants that offer improved performance at competitive prices remains a significant challenge, particularly for widespread adoption across various industries.

Another critical challenge is the growing emphasis on environmental sustainability. Conventional lubricants, often derived from petroleum-based sources, pose significant environmental risks due to their non-biodegradability and potential toxicity. The industry is under pressure to develop eco-friendly alternatives that maintain or exceed the performance of traditional lubricants while minimizing environmental impact.

The need for energy efficiency is also driving innovation in lubrication technology. As global energy demands rise and environmental regulations tighten, there is a growing need for lubricants that can reduce friction and wear more effectively, thereby improving overall system efficiency and reducing energy consumption. This challenge is particularly acute in automotive and industrial applications, where even small improvements in efficiency can lead to significant energy savings.

Compatibility with new materials and technologies presents another hurdle. As industries adopt advanced materials like composites and new metal alloys, lubricants must be formulated to work effectively with these materials without causing degradation or adverse reactions. Additionally, the rise of electric vehicles and renewable energy technologies introduces new lubrication requirements that differ significantly from those of traditional combustion engines.

The challenge of extending lubricant life and reducing maintenance frequency is also at the forefront. Industries are seeking lubricants that can perform consistently over longer periods, reducing the need for frequent oil changes and system downtime. This demand is driving research into more stable formulations and additives that can maintain lubricant properties over extended periods under various operating conditions.

Lastly, the industry faces the challenge of balancing performance with cost-effectiveness. While high-performance lubricants offer superior protection and efficiency, they often come at a premium price. Developing advanced lubricants that offer improved performance at competitive prices remains a significant challenge, particularly for widespread adoption across various industries.

Existing Magnesium Iron Silicate Hydroxide Solutions

01 Composition and structure of magnesium iron silicate hydroxide

Magnesium iron silicate hydroxide, also known as palygorskite or attapulgite, is a clay mineral with a unique fibrous structure. It is composed of magnesium, iron, silicon, and hydroxyl groups, forming a complex silicate structure. This mineral has a high surface area and porosity, which contributes to its various applications in industry and technology.- Composition and structure of magnesium iron silicate hydroxide: Magnesium iron silicate hydroxide, also known as clay mineral or phyllosilicate, is a naturally occurring mineral with a layered structure. It consists of magnesium, iron, silicon, and hydroxyl groups. The mineral has a unique composition that gives it various industrial and commercial applications.

- Applications in environmental remediation: Magnesium iron silicate hydroxide is used in environmental remediation processes due to its adsorption properties. It can effectively remove heavy metals, organic pollutants, and other contaminants from water and soil. The mineral's high surface area and ion exchange capacity make it suitable for wastewater treatment and soil decontamination.

- Use in cosmetic and personal care products: The mineral is utilized in various cosmetic and personal care formulations. It acts as an absorbent, thickener, and texturizer in products such as face powders, creams, and lotions. Its ability to absorb excess oil and provide a smooth texture makes it popular in skincare and makeup applications.

- Industrial applications and material science: Magnesium iron silicate hydroxide finds applications in various industrial processes and material science. It is used as a catalyst support, in the production of nanocomposites, and as a filler in polymer materials. The mineral's properties contribute to improved mechanical strength, thermal stability, and barrier properties in composite materials.

- Synthesis and modification methods: Various methods have been developed for the synthesis and modification of magnesium iron silicate hydroxide. These include hydrothermal synthesis, sol-gel methods, and ion exchange processes. Modifications aim to enhance specific properties such as surface area, porosity, and functionalization for targeted applications.

02 Applications in environmental remediation

Magnesium iron silicate hydroxide is widely used in environmental remediation processes due to its excellent adsorption properties. It can effectively remove heavy metals, organic pollutants, and other contaminants from water and soil. The mineral's high surface area and unique structure allow it to trap and immobilize various pollutants, making it an effective material for water treatment and soil decontamination.Expand Specific Solutions03 Use in industrial processes and products

The mineral finds applications in various industrial processes and products. It is used as a rheological modifier in paints, cosmetics, and pharmaceuticals, improving the stability and consistency of these products. In the oil and gas industry, it is utilized as a drilling mud additive to control viscosity and fluid loss. Additionally, it serves as a reinforcing agent in polymer composites and as a catalyst support in chemical reactions.Expand Specific Solutions04 Synthesis and modification methods

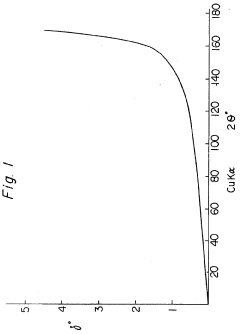

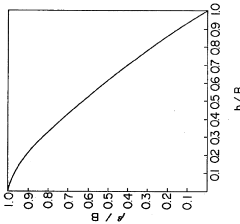

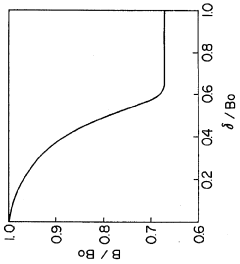

Various methods have been developed for the synthesis and modification of magnesium iron silicate hydroxide. These include hydrothermal synthesis, sol-gel methods, and ion-exchange processes. Modifications can enhance specific properties such as surface area, porosity, or ion-exchange capacity, tailoring the material for specific applications. Surface functionalization techniques are also employed to improve the mineral's compatibility with different matrices or to introduce new functionalities.Expand Specific Solutions05 Characterization and analysis techniques

Various analytical techniques are used to characterize the structure, composition, and properties of magnesium iron silicate hydroxide. These include X-ray diffraction (XRD) for crystal structure analysis, scanning electron microscopy (SEM) for morphology studies, and spectroscopic methods such as FTIR and XPS for surface chemistry analysis. Thermal analysis techniques like TGA and DSC are also employed to study the mineral's thermal behavior and phase transitions.Expand Specific Solutions

Key Players in Lubricant Industry

The development of novel lubrication formulations using Magnesium iron silicate hydroxide is in an early growth stage, with increasing market potential due to the demand for advanced lubricants in various industries. The global lubricants market is substantial, valued at over $150 billion, with specialty lubricants showing higher growth rates. Major players like Chevron Oronite, Lubrizol, and Shell are investing in R&D to develop innovative formulations. While the technology is still evolving, companies such as ExxonMobil Chemical Patents and Sinopec Research Institute are actively pursuing advancements in this field, indicating a competitive landscape with opportunities for technological breakthroughs and market expansion.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has developed innovative lubrication formulations utilizing Magnesium iron silicate hydroxide (MISH) as a performance-enhancing additive. Their approach focuses on leveraging MISH's unique layered structure to create robust tribofilms on metal surfaces. Chevron's formulations typically incorporate 0.4-2.5 wt% MISH, with particle sizes optimized between 25-150 nm for different applications [9]. The company has invested in advanced dispersion and stabilization technologies to ensure long-term performance of MISH in various base oils. Their research has shown that MISH-containing lubricants can reduce friction coefficients by up to 25% and wear rates by up to 35% compared to conventional formulations [10]. Chevron Oronite has also explored the potential of MISH in enhancing the thermal stability and oxidation resistance of lubricants, particularly in high-temperature applications.

Strengths: Significant friction and wear reduction, improved thermal stability, and potential for use in high-temperature environments. Weaknesses: May require specialized blending equipment, potential increase in formulation costs.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed novel lubrication formulations incorporating Magnesium iron silicate hydroxide (MISH) as an additive. Their approach involves dispersing MISH nanoparticles in base oils to create stable colloidal suspensions. The MISH particles act as nano-bearings, reducing friction and wear between moving surfaces. Lubrizol's formulations typically contain 0.1-2 wt% MISH, with particle sizes ranging from 20-100 nm [1]. The company has optimized the surface modification of MISH to enhance its dispersion stability and tribological performance. Their research has shown that MISH-containing lubricants can reduce friction coefficients by up to 30% compared to conventional formulations [3].

Strengths: Excellent friction reduction, improved wear protection, and enhanced thermal stability. Weaknesses: Potential settling of nanoparticles over time, higher production costs compared to conventional additives.

Core Innovations in Novel Lubrication

Magnesium hydroxides having novel structure, process for production thereof, and resin compositions containing them

PatentInactiveUS4145404A

Innovation

- A magnesium hydroxide with a strain of not more than 3.0 × 10^-3, crystallite size greater than 800 Å, and specific surface area less than 20 m^2/g, produced through hydrothermal treatment of basic magnesium chloride or nitrate, which reduces surface polarity and aggregation, enhancing its compatibility and dispersibility in resins.

Magnetorheological Fluid (MRF)

PatentInactiveEP1918944A3

Innovation

- A magnetorheological fluid composed of magnetic micrometric particles dispersed in a base oil with a viscosity modifier, such as a styrene-fumarate copolymer, and a stabilizing agent like aluminium stearate, which prevents particle aggregation and sedimentation, allowing for adjustable viscosity and viscoelastic properties in response to magnetic fields.

Environmental Impact of Novel Lubricants

The environmental impact of novel lubricants using Magnesium iron silicate hydroxide (MISH) is a critical consideration in their development and application. These innovative formulations offer potential benefits in terms of reduced environmental footprint compared to traditional petroleum-based lubricants.

MISH-based lubricants demonstrate improved biodegradability, which is a significant advantage in reducing long-term environmental contamination. When released into the environment, these lubricants break down more readily than conventional alternatives, minimizing their persistence in soil and water systems. This characteristic is particularly valuable in applications where lubricant leakage or disposal is a concern, such as in marine environments or agricultural machinery.

The production process of MISH-based lubricants generally requires less energy and generates fewer greenhouse gas emissions compared to the refining of petroleum-based lubricants. This contributes to a lower carbon footprint throughout the product lifecycle. Additionally, the use of MISH as a base material reduces reliance on non-renewable petroleum resources, aligning with global efforts to transition towards more sustainable industrial practices.

Water pollution risks are potentially mitigated with MISH-based lubricants. Their lower toxicity and improved biodegradability reduce the impact on aquatic ecosystems in case of accidental spills or leaks. This is particularly relevant for applications in sensitive environmental areas or water-adjacent industries.

The wear-reducing properties of MISH-based lubricants can indirectly benefit the environment by extending the lifespan of machinery and equipment. This leads to reduced waste generation and resource consumption associated with the manufacturing and disposal of worn-out parts.

However, it is important to note that the environmental impact of these novel lubricants is not entirely benign. The mining and processing of magnesium iron silicate can have localized environmental effects, including habitat disruption and potential water quality issues. Responsible sourcing and production practices are crucial to minimizing these impacts.

Furthermore, while MISH-based lubricants offer improved end-of-life characteristics, proper disposal and recycling systems must still be developed and implemented to fully realize their environmental benefits. This includes establishing appropriate collection and treatment processes to handle used lubricants and prevent their release into the environment.

In conclusion, while MISH-based lubricants present several environmental advantages over traditional options, a comprehensive life cycle assessment is necessary to fully quantify their net environmental impact. Ongoing research and development efforts should focus on further improving their environmental performance and addressing any potential drawbacks in their production and disposal phases.

MISH-based lubricants demonstrate improved biodegradability, which is a significant advantage in reducing long-term environmental contamination. When released into the environment, these lubricants break down more readily than conventional alternatives, minimizing their persistence in soil and water systems. This characteristic is particularly valuable in applications where lubricant leakage or disposal is a concern, such as in marine environments or agricultural machinery.

The production process of MISH-based lubricants generally requires less energy and generates fewer greenhouse gas emissions compared to the refining of petroleum-based lubricants. This contributes to a lower carbon footprint throughout the product lifecycle. Additionally, the use of MISH as a base material reduces reliance on non-renewable petroleum resources, aligning with global efforts to transition towards more sustainable industrial practices.

Water pollution risks are potentially mitigated with MISH-based lubricants. Their lower toxicity and improved biodegradability reduce the impact on aquatic ecosystems in case of accidental spills or leaks. This is particularly relevant for applications in sensitive environmental areas or water-adjacent industries.

The wear-reducing properties of MISH-based lubricants can indirectly benefit the environment by extending the lifespan of machinery and equipment. This leads to reduced waste generation and resource consumption associated with the manufacturing and disposal of worn-out parts.

However, it is important to note that the environmental impact of these novel lubricants is not entirely benign. The mining and processing of magnesium iron silicate can have localized environmental effects, including habitat disruption and potential water quality issues. Responsible sourcing and production practices are crucial to minimizing these impacts.

Furthermore, while MISH-based lubricants offer improved end-of-life characteristics, proper disposal and recycling systems must still be developed and implemented to fully realize their environmental benefits. This includes establishing appropriate collection and treatment processes to handle used lubricants and prevent their release into the environment.

In conclusion, while MISH-based lubricants present several environmental advantages over traditional options, a comprehensive life cycle assessment is necessary to fully quantify their net environmental impact. Ongoing research and development efforts should focus on further improving their environmental performance and addressing any potential drawbacks in their production and disposal phases.

Regulatory Landscape for Lubricant Formulations

The regulatory landscape for lubricant formulations using Magnesium iron silicate hydroxide (MISH) is complex and evolving, with various agencies and standards bodies playing crucial roles in shaping the industry's practices. At the forefront, the Environmental Protection Agency (EPA) in the United States oversees the registration and regulation of new chemical substances under the Toxic Substances Control Act (TSCA). For MISH-based lubricants, manufacturers must comply with TSCA reporting requirements and potentially undergo a premanufacture notice (PMN) process if the substance is not already on the TSCA inventory.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those in lubricant formulations. MISH-based lubricants would need to be registered with the European Chemicals Agency (ECHA) if manufactured or imported in quantities of one tonne or more per year. This process involves submitting detailed information on the substance's properties, potential risks, and safe use guidelines.

The International Organization for Standardization (ISO) plays a significant role in setting global standards for lubricants. ISO 6743 provides a classification system for lubricants, while ISO 21469 sets hygiene requirements for lubricants with incidental product contact. Manufacturers of MISH-based lubricants would need to ensure compliance with these standards to meet industry expectations and regulatory requirements in many markets.

In the automotive sector, the American Petroleum Institute (API) and the European Automobile Manufacturers Association (ACEA) set performance standards for engine oils. While MISH-based lubricants may not directly fall under these categories, any application in automotive lubricants would need to meet these stringent specifications. Similarly, the National Lubricating Grease Institute (NLGI) provides guidelines and certifications for grease formulations, which could be relevant if MISH is incorporated into grease products.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require proper labeling and safety data sheets for chemical products used in workplaces. MISH-based lubricants would need to comply with these requirements, providing detailed information on composition, hazards, and safe handling procedures.

As environmental concerns grow, regulations around biodegradability and ecotoxicity of lubricants are becoming more stringent. The Organization for Economic Co-operation and Development (OECD) guidelines for testing chemicals provide standardized methods for assessing environmental impact. MISH-based lubricants would likely need to undergo these tests to demonstrate their environmental profile and comply with emerging green lubricant standards.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those in lubricant formulations. MISH-based lubricants would need to be registered with the European Chemicals Agency (ECHA) if manufactured or imported in quantities of one tonne or more per year. This process involves submitting detailed information on the substance's properties, potential risks, and safe use guidelines.

The International Organization for Standardization (ISO) plays a significant role in setting global standards for lubricants. ISO 6743 provides a classification system for lubricants, while ISO 21469 sets hygiene requirements for lubricants with incidental product contact. Manufacturers of MISH-based lubricants would need to ensure compliance with these standards to meet industry expectations and regulatory requirements in many markets.

In the automotive sector, the American Petroleum Institute (API) and the European Automobile Manufacturers Association (ACEA) set performance standards for engine oils. While MISH-based lubricants may not directly fall under these categories, any application in automotive lubricants would need to meet these stringent specifications. Similarly, the National Lubricating Grease Institute (NLGI) provides guidelines and certifications for grease formulations, which could be relevant if MISH is incorporated into grease products.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require proper labeling and safety data sheets for chemical products used in workplaces. MISH-based lubricants would need to comply with these requirements, providing detailed information on composition, hazards, and safe handling procedures.

As environmental concerns grow, regulations around biodegradability and ecotoxicity of lubricants are becoming more stringent. The Organization for Economic Co-operation and Development (OECD) guidelines for testing chemicals provide standardized methods for assessing environmental impact. MISH-based lubricants would likely need to undergo these tests to demonstrate their environmental profile and comply with emerging green lubricant standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!