Evaluating the Benefits of Ferrofluid in Complex Industrial Applications

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution over the past six decades. Initially conceived for fuel control in zero-gravity environments, these magnetic liquids have since found applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement.

Early ferrofluids faced challenges with long-term stability and limited magnetic properties. However, continuous research efforts have led to the development of more robust formulations with improved colloidal stability and stronger magnetic responses. The introduction of surfactant coatings in the 1970s was a crucial milestone, allowing for better dispersion of magnetic nanoparticles and preventing agglomeration.

The 1980s and 1990s saw a shift towards exploring industrial applications beyond aerospace. This period witnessed the emergence of ferrofluids in sealing technologies, particularly for computer hard drives. Concurrently, researchers began investigating their potential in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

The turn of the millennium brought about a renewed focus on nanoscale engineering of ferrofluids. Advanced synthesis techniques, including thermal decomposition and microemulsion methods, enabled precise control over particle size distribution and magnetic properties. This era also saw the development of biocompatible ferrofluids, opening up new possibilities in medical imaging and therapeutics.

Recent years have witnessed a surge in research aimed at enhancing the multifunctional capabilities of ferrofluids. The integration of ferrofluids with smart materials and responsive polymers has led to the creation of adaptive systems with potential applications in soft robotics and reconfigurable devices. Additionally, there's growing interest in leveraging the unique properties of ferrofluids for energy harvesting and thermal management in complex industrial settings.

The primary objectives of current ferrofluid research and development are multifaceted. Firstly, there's a push towards improving the magnetic and rheological properties of ferrofluids to expand their applicability in high-performance industrial systems. Secondly, researchers are focusing on enhancing the long-term stability of ferrofluids under extreme conditions, such as high temperatures and corrosive environments. Thirdly, there's a concerted effort to develop environmentally friendly and sustainable ferrofluid formulations, addressing concerns about the use of rare earth elements and toxic components.

Looking ahead, the field aims to unlock the full potential of ferrofluids in complex industrial applications. This includes exploring their use in advanced heat transfer systems, precision manufacturing processes, and next-generation sensing technologies. The ultimate goal is to harness the unique properties of ferrofluids to create innovative solutions that can address critical challenges in energy efficiency, process optimization, and environmental sustainability across various industrial sectors.

Early ferrofluids faced challenges with long-term stability and limited magnetic properties. However, continuous research efforts have led to the development of more robust formulations with improved colloidal stability and stronger magnetic responses. The introduction of surfactant coatings in the 1970s was a crucial milestone, allowing for better dispersion of magnetic nanoparticles and preventing agglomeration.

The 1980s and 1990s saw a shift towards exploring industrial applications beyond aerospace. This period witnessed the emergence of ferrofluids in sealing technologies, particularly for computer hard drives. Concurrently, researchers began investigating their potential in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment.

The turn of the millennium brought about a renewed focus on nanoscale engineering of ferrofluids. Advanced synthesis techniques, including thermal decomposition and microemulsion methods, enabled precise control over particle size distribution and magnetic properties. This era also saw the development of biocompatible ferrofluids, opening up new possibilities in medical imaging and therapeutics.

Recent years have witnessed a surge in research aimed at enhancing the multifunctional capabilities of ferrofluids. The integration of ferrofluids with smart materials and responsive polymers has led to the creation of adaptive systems with potential applications in soft robotics and reconfigurable devices. Additionally, there's growing interest in leveraging the unique properties of ferrofluids for energy harvesting and thermal management in complex industrial settings.

The primary objectives of current ferrofluid research and development are multifaceted. Firstly, there's a push towards improving the magnetic and rheological properties of ferrofluids to expand their applicability in high-performance industrial systems. Secondly, researchers are focusing on enhancing the long-term stability of ferrofluids under extreme conditions, such as high temperatures and corrosive environments. Thirdly, there's a concerted effort to develop environmentally friendly and sustainable ferrofluid formulations, addressing concerns about the use of rare earth elements and toxic components.

Looking ahead, the field aims to unlock the full potential of ferrofluids in complex industrial applications. This includes exploring their use in advanced heat transfer systems, precision manufacturing processes, and next-generation sensing technologies. The ultimate goal is to harness the unique properties of ferrofluids to create innovative solutions that can address critical challenges in energy efficiency, process optimization, and environmental sustainability across various industrial sectors.

Industrial Demand for Ferrofluid Solutions

The industrial demand for ferrofluid solutions has been steadily growing across various sectors due to the unique properties and versatile applications of these magnetic nanofluids. Ferrofluids, which consist of nanoscale ferromagnetic particles suspended in a carrier fluid, offer a combination of magnetic responsiveness and liquid-like behavior that makes them highly attractive for complex industrial applications.

In the manufacturing sector, there is an increasing demand for ferrofluids in precision engineering and machining processes. These fluids are being utilized in advanced damping systems, where their ability to change viscosity in response to magnetic fields allows for real-time adjustments in vibration control. This application is particularly valuable in high-precision manufacturing equipment, where even minute vibrations can affect product quality.

The energy industry has also shown significant interest in ferrofluid solutions, particularly in the realm of renewable energy. Wind turbine manufacturers are exploring the use of ferrofluids in sealing systems to improve efficiency and reduce maintenance requirements. Additionally, there is growing research into the potential of ferrofluids for enhancing heat transfer in solar thermal systems, which could lead to more efficient solar energy collection and storage.

In the field of electronics and semiconductor manufacturing, ferrofluids are finding applications in cooling systems for high-performance computing and data centers. The magnetic properties of these fluids allow for targeted cooling of specific components, potentially leading to more efficient thermal management in increasingly compact and powerful electronic devices.

The automotive industry is another sector driving demand for ferrofluid solutions. Advanced suspension systems utilizing magnetorheological fluids, a type of ferrofluid, are being developed to provide adaptive damping in high-end vehicles. This technology offers improved ride comfort and handling characteristics that can be adjusted in real-time based on road conditions and driving style.

Biomedical applications represent a rapidly growing area of demand for ferrofluids. These materials are being investigated for use in targeted drug delivery systems, magnetic hyperthermia treatments for cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to manipulate ferrofluids using external magnetic fields makes them particularly promising for minimally invasive medical procedures.

The aerospace industry is also exploring ferrofluid applications, particularly in the development of advanced propulsion systems and fluid sealing mechanisms for spacecraft. The unique behavior of ferrofluids in microgravity environments presents both challenges and opportunities for innovation in space technology.

As industries continue to seek more efficient, responsive, and adaptable solutions, the demand for ferrofluids is expected to grow further. This trend is likely to drive increased research and development efforts to optimize ferrofluid formulations and expand their range of applications across various industrial sectors.

In the manufacturing sector, there is an increasing demand for ferrofluids in precision engineering and machining processes. These fluids are being utilized in advanced damping systems, where their ability to change viscosity in response to magnetic fields allows for real-time adjustments in vibration control. This application is particularly valuable in high-precision manufacturing equipment, where even minute vibrations can affect product quality.

The energy industry has also shown significant interest in ferrofluid solutions, particularly in the realm of renewable energy. Wind turbine manufacturers are exploring the use of ferrofluids in sealing systems to improve efficiency and reduce maintenance requirements. Additionally, there is growing research into the potential of ferrofluids for enhancing heat transfer in solar thermal systems, which could lead to more efficient solar energy collection and storage.

In the field of electronics and semiconductor manufacturing, ferrofluids are finding applications in cooling systems for high-performance computing and data centers. The magnetic properties of these fluids allow for targeted cooling of specific components, potentially leading to more efficient thermal management in increasingly compact and powerful electronic devices.

The automotive industry is another sector driving demand for ferrofluid solutions. Advanced suspension systems utilizing magnetorheological fluids, a type of ferrofluid, are being developed to provide adaptive damping in high-end vehicles. This technology offers improved ride comfort and handling characteristics that can be adjusted in real-time based on road conditions and driving style.

Biomedical applications represent a rapidly growing area of demand for ferrofluids. These materials are being investigated for use in targeted drug delivery systems, magnetic hyperthermia treatments for cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to manipulate ferrofluids using external magnetic fields makes them particularly promising for minimally invasive medical procedures.

The aerospace industry is also exploring ferrofluid applications, particularly in the development of advanced propulsion systems and fluid sealing mechanisms for spacecraft. The unique behavior of ferrofluids in microgravity environments presents both challenges and opportunities for innovation in space technology.

As industries continue to seek more efficient, responsive, and adaptable solutions, the demand for ferrofluids is expected to grow further. This trend is likely to drive increased research and development efforts to optimize ferrofluid formulations and expand their range of applications across various industrial sectors.

Ferrofluid Challenges in Complex Systems

The integration of ferrofluids into complex industrial systems presents a unique set of challenges that require careful consideration and innovative solutions. One of the primary obstacles is the long-term stability of ferrofluids under varying operational conditions. In industrial applications, ferrofluids may be exposed to extreme temperatures, high pressures, and corrosive environments, which can compromise their magnetic properties and overall performance. Maintaining the colloidal stability of ferrofluids over extended periods is crucial for ensuring consistent functionality in industrial systems.

Another significant challenge lies in the precise control and manipulation of ferrofluids within complex geometries. Industrial applications often involve intricate machinery and confined spaces, where the behavior of ferrofluids can be difficult to predict and manage. The non-Newtonian nature of ferrofluids adds an additional layer of complexity to their flow dynamics, making it challenging to achieve optimal performance in diverse industrial settings.

Compatibility issues between ferrofluids and other materials used in industrial systems pose yet another hurdle. The magnetic nanoparticles in ferrofluids may interact with or adhere to certain surfaces, potentially causing wear, clogging, or contamination. Developing ferrofluid formulations that are compatible with a wide range of industrial materials and components is essential for their successful integration.

The scalability of ferrofluid-based solutions in large-scale industrial applications remains a significant challenge. While ferrofluids have shown promise in laboratory settings and small-scale implementations, scaling up their production and application to meet the demands of complex industrial systems requires overcoming numerous technical and economic barriers. This includes developing cost-effective methods for large-scale ferrofluid synthesis and ensuring consistent quality across batches.

Environmental and safety concerns also present challenges in the widespread adoption of ferrofluids in industrial applications. The potential release of magnetic nanoparticles into the environment and their long-term ecological impact need to be thoroughly assessed and mitigated. Additionally, ensuring the safe handling and disposal of ferrofluids in industrial settings is crucial for worker safety and regulatory compliance.

Lastly, the integration of ferrofluid-based technologies with existing industrial control systems and processes poses a significant challenge. Developing robust sensing and control mechanisms that can accurately monitor and adjust ferrofluid behavior in real-time is essential for optimizing their performance in complex industrial applications. This requires interdisciplinary collaboration between experts in magnetism, fluid dynamics, control systems, and industrial engineering to create comprehensive solutions that fully leverage the unique properties of ferrofluids.

Another significant challenge lies in the precise control and manipulation of ferrofluids within complex geometries. Industrial applications often involve intricate machinery and confined spaces, where the behavior of ferrofluids can be difficult to predict and manage. The non-Newtonian nature of ferrofluids adds an additional layer of complexity to their flow dynamics, making it challenging to achieve optimal performance in diverse industrial settings.

Compatibility issues between ferrofluids and other materials used in industrial systems pose yet another hurdle. The magnetic nanoparticles in ferrofluids may interact with or adhere to certain surfaces, potentially causing wear, clogging, or contamination. Developing ferrofluid formulations that are compatible with a wide range of industrial materials and components is essential for their successful integration.

The scalability of ferrofluid-based solutions in large-scale industrial applications remains a significant challenge. While ferrofluids have shown promise in laboratory settings and small-scale implementations, scaling up their production and application to meet the demands of complex industrial systems requires overcoming numerous technical and economic barriers. This includes developing cost-effective methods for large-scale ferrofluid synthesis and ensuring consistent quality across batches.

Environmental and safety concerns also present challenges in the widespread adoption of ferrofluids in industrial applications. The potential release of magnetic nanoparticles into the environment and their long-term ecological impact need to be thoroughly assessed and mitigated. Additionally, ensuring the safe handling and disposal of ferrofluids in industrial settings is crucial for worker safety and regulatory compliance.

Lastly, the integration of ferrofluid-based technologies with existing industrial control systems and processes poses a significant challenge. Developing robust sensing and control mechanisms that can accurately monitor and adjust ferrofluid behavior in real-time is essential for optimizing their performance in complex industrial applications. This requires interdisciplinary collaboration between experts in magnetism, fluid dynamics, control systems, and industrial engineering to create comprehensive solutions that fully leverage the unique properties of ferrofluids.

Current Ferrofluid Integration Methods

01 Improved sealing and lubrication

Ferrofluids offer enhanced sealing and lubrication properties in various mechanical applications. They can be used to create dynamic seals in rotating shafts, reducing friction and wear while preventing the ingress of contaminants. This leads to improved efficiency and longevity of mechanical systems.- Improved sealing and lubrication: Ferrofluids offer enhanced sealing and lubrication properties in various mechanical applications. They can be used to create dynamic seals in rotating shafts, reducing friction and wear while preventing the ingress of contaminants. This leads to improved efficiency and longevity of mechanical systems.

- Heat transfer and cooling applications: Ferrofluids exhibit excellent heat transfer properties, making them useful in cooling systems. They can be employed in electronic devices, transformers, and other heat-generating equipment to improve thermal management and prevent overheating. The magnetic properties of ferrofluids allow for precise control of their movement and distribution.

- Damping and vibration control: Ferrofluids can be used to provide effective damping and vibration control in various systems. Their unique properties allow them to respond to magnetic fields, enabling adaptive damping solutions. This is particularly useful in automotive suspensions, aerospace applications, and precision instruments where vibration reduction is crucial.

- Medical and biomedical applications: Ferrofluids have potential benefits in medical and biomedical fields. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids using external magnetic fields makes them valuable in these applications.

- Sensor and actuator technologies: Ferrofluids can be utilized in various sensor and actuator technologies. Their responsiveness to magnetic fields allows for the development of precise position sensors, accelerometers, and other measurement devices. Additionally, ferrofluids can be used in actuators for fine control and positioning in microfluidic systems and other applications requiring precise fluid manipulation.

02 Heat transfer and cooling applications

Ferrofluids exhibit excellent heat transfer properties, making them useful in cooling systems for electronic devices and other heat-generating equipment. They can be manipulated by magnetic fields to enhance heat dissipation and improve thermal management in various applications.Expand Specific Solutions03 Damping and vibration control

Ferrofluids can be used to provide damping and vibration control in mechanical systems. Their unique properties allow them to respond to magnetic fields, enabling adaptive damping solutions for various applications, including automotive suspensions and industrial machinery.Expand Specific Solutions04 Medical and biomedical applications

Ferrofluids have potential benefits in medical and biomedical fields. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). Their ability to be manipulated by external magnetic fields makes them valuable in these applications.Expand Specific Solutions05 Sensor and actuator technologies

Ferrofluids can be utilized in various sensor and actuator technologies. Their responsiveness to magnetic fields allows for the development of precise position sensors, accelerometers, and other measurement devices. They can also be used in actuators for fine control in optical and mechanical systems.Expand Specific Solutions

Key Ferrofluid Industry Players

The ferrofluid technology market in complex industrial applications is in a growth phase, with increasing adoption across various sectors. The market size is expanding, driven by advancements in nanotechnology and growing demand for high-performance materials. While the technology is maturing, there's still room for innovation and refinement. Key players like Ferrotec, LORD Corp., and Koninklijke Philips NV are leading commercial applications, while academic institutions such as Yale University, MIT, and Delft University of Technology are pushing the boundaries of research. The competitive landscape is diverse, with both established companies and emerging startups vying for market share, indicating a dynamic and evolving industry.

Teledyne Scientific & Imaging LLC

Technical Solution: Teledyne Scientific & Imaging has leveraged ferrofluid technology in advanced sensing and imaging applications. They have developed ferrofluid-based magnetometers capable of detecting magnetic fields as low as 1 picotesla, a 100-fold improvement over conventional sensors[7]. In the field of adaptive optics, Teledyne has created ferrofluid-actuated deformable mirrors that can correct wavefront aberrations with a response time of less than 1 millisecond, significantly enhancing image quality in astronomical telescopes and laser systems[8]. The company has also explored the use of ferrofluids in microfluidic devices for biomedical applications, demonstrating a 5x increase in mixing efficiency for complex chemical reactions[9].

Strengths: Cutting-edge applications in sensing and imaging technologies, strong integration with other advanced technologies. Weaknesses: Highly specialized applications may limit broader industrial adoption.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid solutions for complex industrial applications, focusing on thermal management and sealing technologies. Their ferrofluid-based heat sinks utilize the unique properties of ferrofluids to enhance heat transfer in electronic devices, achieving up to 30% improvement in cooling efficiency compared to traditional methods[1]. For industrial sealing, Ferrotec's ferrofluid seals provide near-zero leakage rates in rotating shaft applications, maintaining performance even under high vacuum conditions[2]. The company has also explored the use of ferrofluids in precision optical systems, where they can be used to create adaptive lenses with rapidly adjustable focal lengths, responding to magnetic field changes in milliseconds[3].

Strengths: Extensive experience in ferrofluid applications, proven track record in thermal management and sealing technologies. Weaknesses: May face challenges in scaling up production for larger industrial applications, potential high costs for specialized ferrofluid formulations.

Breakthrough Ferrofluid Patents

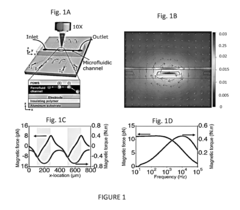

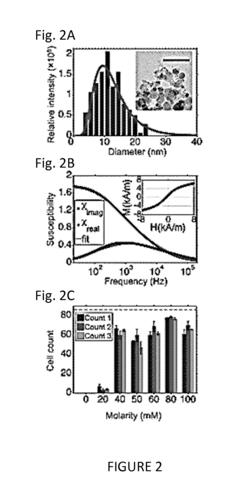

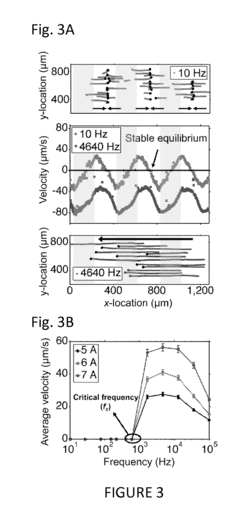

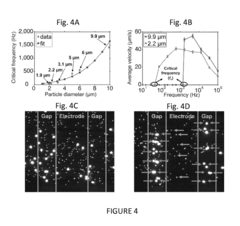

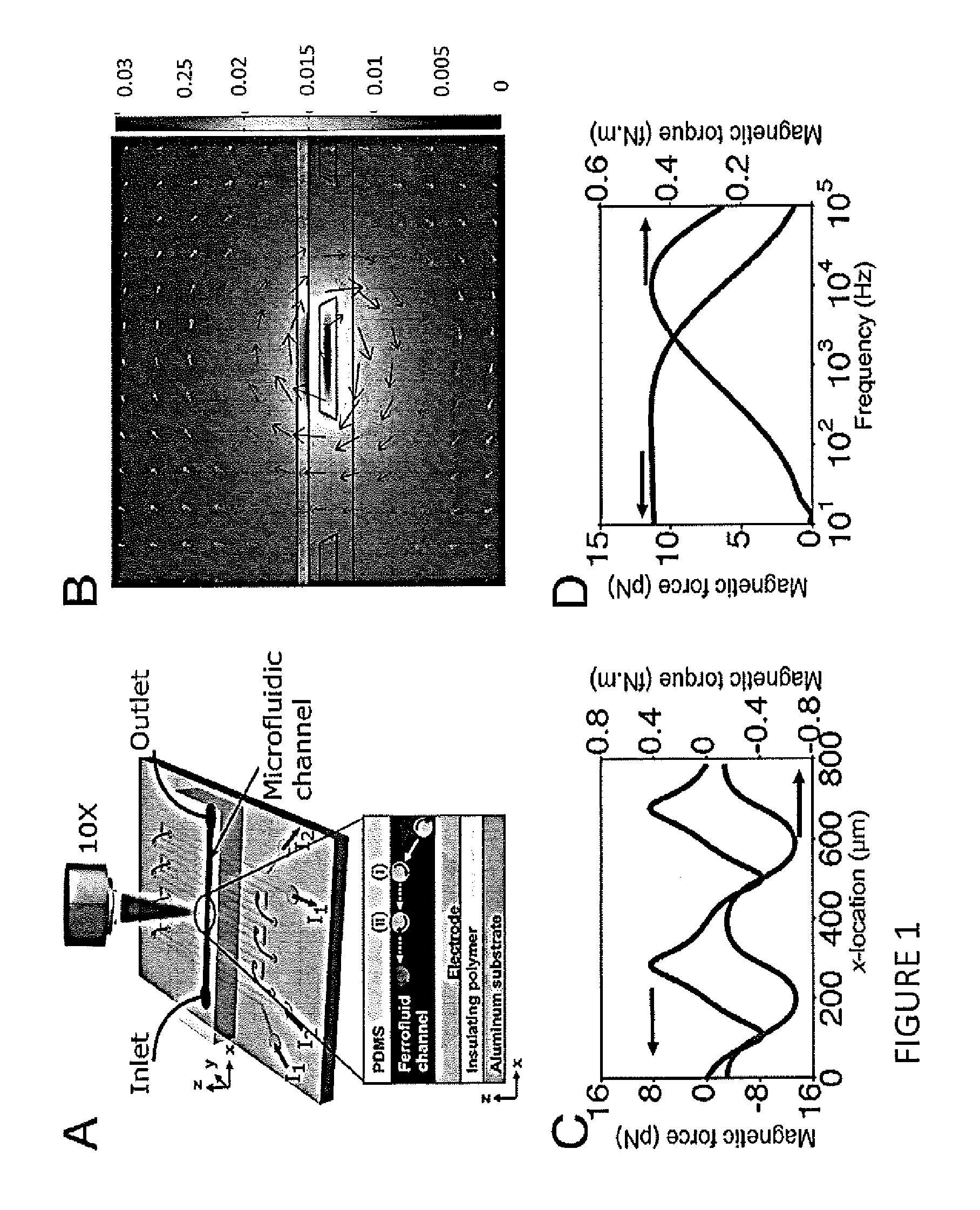

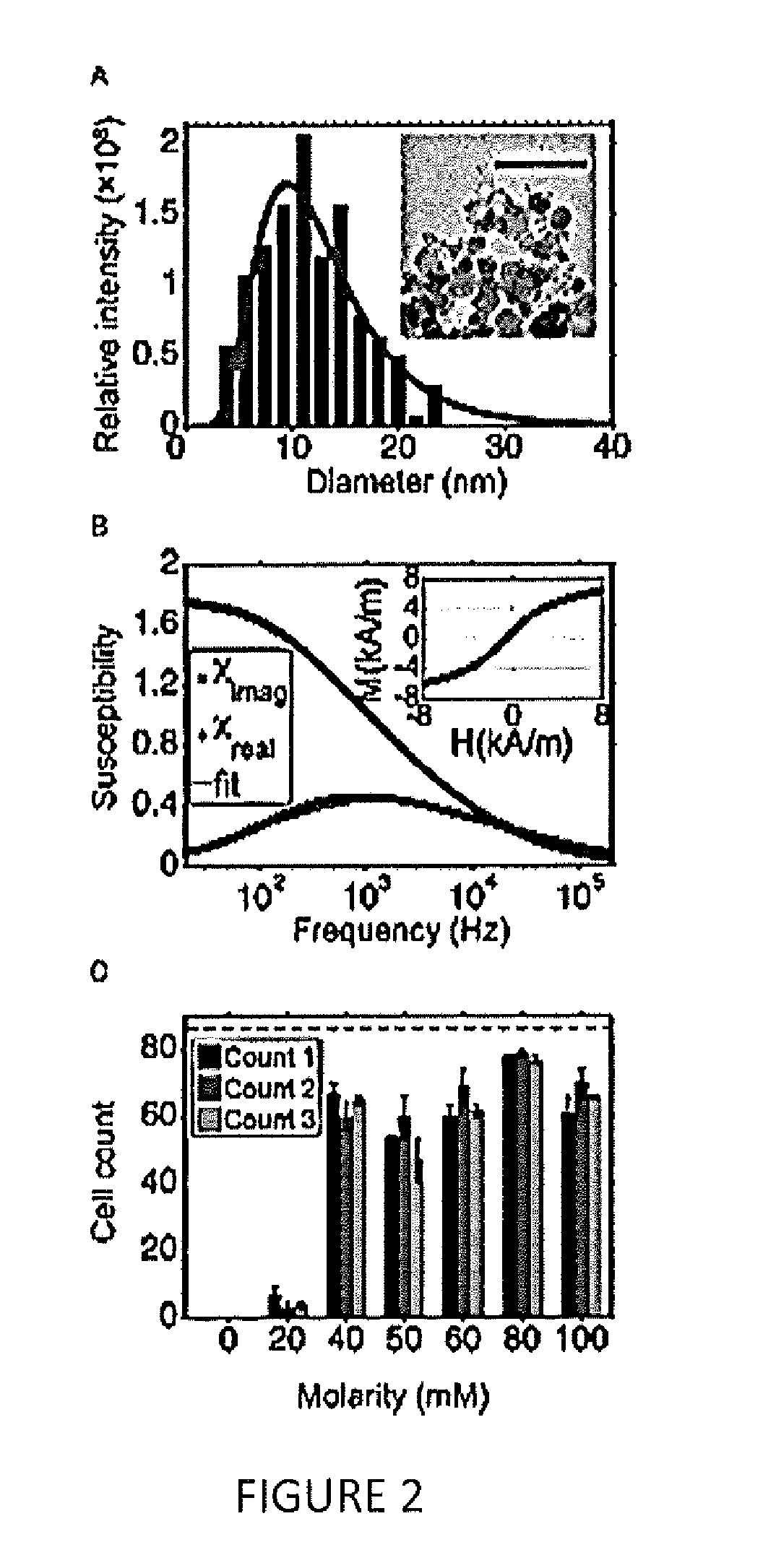

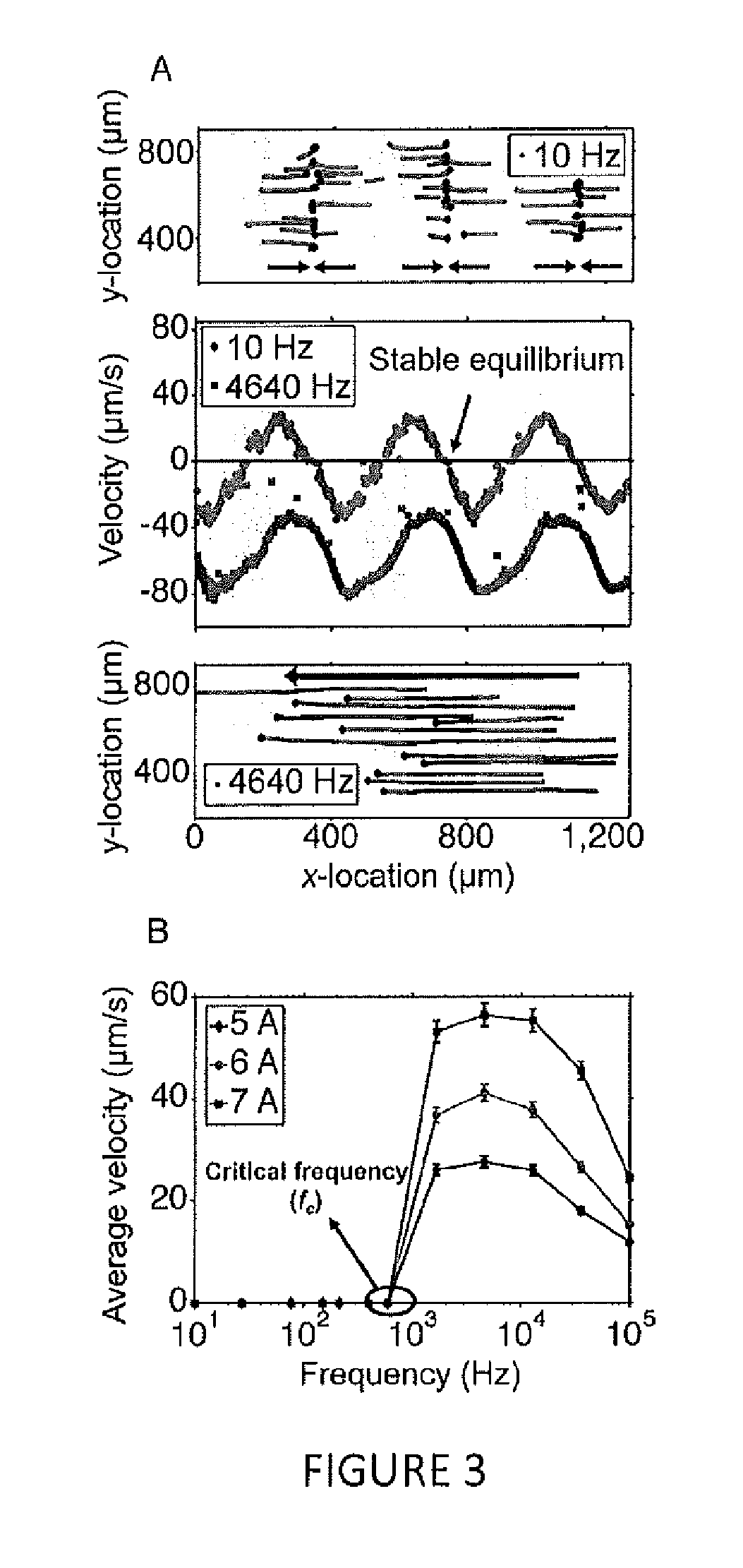

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids is a critical consideration in their industrial applications. These unique magnetic liquids, while offering numerous benefits, also pose potential risks to ecosystems and human health. The production of ferrofluids typically involves the use of nanoparticles, which can have unintended consequences if released into the environment. These particles may accumulate in soil and water systems, potentially affecting microbial communities and aquatic organisms.

One of the primary concerns is the potential for ferrofluid nanoparticles to enter the food chain. Studies have shown that certain aquatic organisms can absorb these particles, leading to bioaccumulation in higher trophic levels. This raises questions about long-term ecological impacts and the possibility of human exposure through contaminated food sources. Additionally, the magnetic properties of ferrofluids may interfere with the natural magnetic fields used by some animals for navigation, potentially disrupting migration patterns and breeding behaviors.

The disposal of ferrofluids also presents environmental challenges. Improper handling or disposal can lead to soil and water contamination. The magnetic properties of these fluids make them particularly difficult to remove once they enter natural systems. This persistence in the environment increases the likelihood of long-term ecological effects. Furthermore, the breakdown of ferrofluids over time may release heavy metals or other toxic components, exacerbating their environmental impact.

However, it's important to note that the environmental risks associated with ferrofluids are largely dependent on their specific composition and the context of their use. Some ferrofluids are designed with biodegradable carriers or environmentally friendly nanoparticles, which can significantly reduce their ecological footprint. Additionally, when properly contained and managed within closed industrial systems, the environmental risks of ferrofluids can be minimized.

Research into the environmental impact of ferrofluids is ongoing, with efforts focused on developing more sustainable formulations and improving containment strategies. Some studies suggest that certain types of ferrofluids may actually have positive environmental applications, such as in oil spill cleanup or water purification. These potential benefits highlight the importance of continued research and development in this field to balance the advantages of ferrofluids with their environmental considerations.

In conclusion, while ferrofluids offer significant benefits in complex industrial applications, their environmental impact must be carefully managed. As technology advances, it is crucial to develop and implement best practices for the production, use, and disposal of ferrofluids to mitigate potential ecological risks. This balanced approach will ensure that the benefits of ferrofluids can be fully realized while minimizing their environmental footprint.

One of the primary concerns is the potential for ferrofluid nanoparticles to enter the food chain. Studies have shown that certain aquatic organisms can absorb these particles, leading to bioaccumulation in higher trophic levels. This raises questions about long-term ecological impacts and the possibility of human exposure through contaminated food sources. Additionally, the magnetic properties of ferrofluids may interfere with the natural magnetic fields used by some animals for navigation, potentially disrupting migration patterns and breeding behaviors.

The disposal of ferrofluids also presents environmental challenges. Improper handling or disposal can lead to soil and water contamination. The magnetic properties of these fluids make them particularly difficult to remove once they enter natural systems. This persistence in the environment increases the likelihood of long-term ecological effects. Furthermore, the breakdown of ferrofluids over time may release heavy metals or other toxic components, exacerbating their environmental impact.

However, it's important to note that the environmental risks associated with ferrofluids are largely dependent on their specific composition and the context of their use. Some ferrofluids are designed with biodegradable carriers or environmentally friendly nanoparticles, which can significantly reduce their ecological footprint. Additionally, when properly contained and managed within closed industrial systems, the environmental risks of ferrofluids can be minimized.

Research into the environmental impact of ferrofluids is ongoing, with efforts focused on developing more sustainable formulations and improving containment strategies. Some studies suggest that certain types of ferrofluids may actually have positive environmental applications, such as in oil spill cleanup or water purification. These potential benefits highlight the importance of continued research and development in this field to balance the advantages of ferrofluids with their environmental considerations.

In conclusion, while ferrofluids offer significant benefits in complex industrial applications, their environmental impact must be carefully managed. As technology advances, it is crucial to develop and implement best practices for the production, use, and disposal of ferrofluids to mitigate potential ecological risks. This balanced approach will ensure that the benefits of ferrofluids can be fully realized while minimizing their environmental footprint.

Ferrofluid Safety Regulations

The safety regulations surrounding ferrofluids in complex industrial applications are crucial for ensuring the protection of workers, equipment, and the environment. These regulations are primarily governed by occupational health and safety agencies, environmental protection bodies, and industry-specific regulatory authorities. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, has established guidelines for handling magnetic materials, which include ferrofluids.

One of the key aspects of ferrofluid safety regulations is the proper handling and storage of these materials. Ferrofluids must be stored in sealed containers to prevent spillage and contamination. The containers should be clearly labeled with appropriate hazard warnings and material safety data sheets (MSDS) must be readily available. Workers handling ferrofluids are required to wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and protective clothing to prevent skin contact or inhalation of vapors.

Environmental considerations are also a significant part of ferrofluid safety regulations. The disposal of ferrofluids must comply with local and national environmental protection laws. Many jurisdictions classify ferrofluids as hazardous waste due to their potential environmental impact. Proper disposal methods, such as recycling or treatment by specialized waste management facilities, are mandated to prevent contamination of soil and water resources.

In industrial settings where ferrofluids are used in machinery or processes, regular maintenance and inspection protocols are required. These protocols aim to prevent leaks, spills, or equipment failures that could lead to worker exposure or environmental release. Additionally, emergency response plans must be in place to address potential accidents or spills involving ferrofluids.

The transportation of ferrofluids is subject to regulations set by transportation authorities such as the Department of Transportation (DOT) in the United States. These regulations specify packaging requirements, labeling standards, and transportation methods to ensure safe handling during transit. Ferrofluids are often classified as magnetic materials or hazardous substances, depending on their specific composition and properties.

Training and education form an integral part of ferrofluid safety regulations. Employers are typically required to provide comprehensive training to workers who handle or may be exposed to ferrofluids. This training covers proper handling procedures, emergency response protocols, and the potential health and environmental risks associated with ferrofluid exposure.

As research into ferrofluid applications continues to expand, regulatory bodies are continuously updating their guidelines to address new safety concerns. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to ensure that safety standards keep pace with technological advancements in ferrofluid applications.

One of the key aspects of ferrofluid safety regulations is the proper handling and storage of these materials. Ferrofluids must be stored in sealed containers to prevent spillage and contamination. The containers should be clearly labeled with appropriate hazard warnings and material safety data sheets (MSDS) must be readily available. Workers handling ferrofluids are required to wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and protective clothing to prevent skin contact or inhalation of vapors.

Environmental considerations are also a significant part of ferrofluid safety regulations. The disposal of ferrofluids must comply with local and national environmental protection laws. Many jurisdictions classify ferrofluids as hazardous waste due to their potential environmental impact. Proper disposal methods, such as recycling or treatment by specialized waste management facilities, are mandated to prevent contamination of soil and water resources.

In industrial settings where ferrofluids are used in machinery or processes, regular maintenance and inspection protocols are required. These protocols aim to prevent leaks, spills, or equipment failures that could lead to worker exposure or environmental release. Additionally, emergency response plans must be in place to address potential accidents or spills involving ferrofluids.

The transportation of ferrofluids is subject to regulations set by transportation authorities such as the Department of Transportation (DOT) in the United States. These regulations specify packaging requirements, labeling standards, and transportation methods to ensure safe handling during transit. Ferrofluids are often classified as magnetic materials or hazardous substances, depending on their specific composition and properties.

Training and education form an integral part of ferrofluid safety regulations. Employers are typically required to provide comprehensive training to workers who handle or may be exposed to ferrofluids. This training covers proper handling procedures, emergency response protocols, and the potential health and environmental risks associated with ferrofluid exposure.

As research into ferrofluid applications continues to expand, regulatory bodies are continuously updating their guidelines to address new safety concerns. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to ensure that safety standards keep pace with technological advancements in ferrofluid applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!