Exploring chemical uses of submersible pumps beyond water applications.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chemical Pump Evolution

The evolution of chemical pumps has been a journey marked by significant technological advancements and adaptations to meet the diverse needs of the chemical industry. Initially designed for water applications, these pumps have undergone substantial transformations to handle a wide array of chemical substances with varying properties and requirements.

In the early stages, chemical pumps were primarily modifications of water pumps, with basic corrosion-resistant materials and simple sealing mechanisms. As the chemical industry expanded and diversified, the demand for more specialized pumping solutions grew. This led to the development of pumps capable of handling aggressive chemicals, high-temperature fluids, and abrasive slurries.

The introduction of new materials played a crucial role in this evolution. The use of advanced alloys, ceramics, and polymers allowed pumps to withstand corrosive environments and extreme temperatures. Innovations in seal technology, such as mechanical seals and magnetic drive systems, significantly improved pump reliability and reduced the risk of leakage, addressing critical safety concerns in chemical processing.

The advent of computerized design and simulation tools revolutionized pump engineering. These technologies enabled the creation of more efficient impeller designs, optimized flow paths, and improved overall pump performance. Computational fluid dynamics (CFD) analysis became an integral part of pump development, allowing engineers to predict and mitigate potential issues before physical prototypes were built.

As environmental regulations became more stringent, chemical pump design evolved to meet these new standards. Sealless pump technologies gained prominence, offering zero-emission solutions for handling hazardous chemicals. Energy efficiency also became a key focus, with the development of variable speed drives and intelligent control systems that optimize pump operation based on process demands.

The integration of sensors and monitoring systems marked another significant milestone in chemical pump evolution. These advancements enabled real-time performance monitoring, predictive maintenance, and remote operation capabilities. Such features not only improved pump reliability but also contributed to overall plant efficiency and safety.

Recent years have seen a shift towards modular and customizable pump designs. This approach allows for greater flexibility in adapting pumps to specific chemical applications, reducing lead times and costs associated with specialized equipment. Additionally, the concept of "smart pumps" has emerged, incorporating IoT technologies for enhanced data collection, analysis, and process optimization.

In the early stages, chemical pumps were primarily modifications of water pumps, with basic corrosion-resistant materials and simple sealing mechanisms. As the chemical industry expanded and diversified, the demand for more specialized pumping solutions grew. This led to the development of pumps capable of handling aggressive chemicals, high-temperature fluids, and abrasive slurries.

The introduction of new materials played a crucial role in this evolution. The use of advanced alloys, ceramics, and polymers allowed pumps to withstand corrosive environments and extreme temperatures. Innovations in seal technology, such as mechanical seals and magnetic drive systems, significantly improved pump reliability and reduced the risk of leakage, addressing critical safety concerns in chemical processing.

The advent of computerized design and simulation tools revolutionized pump engineering. These technologies enabled the creation of more efficient impeller designs, optimized flow paths, and improved overall pump performance. Computational fluid dynamics (CFD) analysis became an integral part of pump development, allowing engineers to predict and mitigate potential issues before physical prototypes were built.

As environmental regulations became more stringent, chemical pump design evolved to meet these new standards. Sealless pump technologies gained prominence, offering zero-emission solutions for handling hazardous chemicals. Energy efficiency also became a key focus, with the development of variable speed drives and intelligent control systems that optimize pump operation based on process demands.

The integration of sensors and monitoring systems marked another significant milestone in chemical pump evolution. These advancements enabled real-time performance monitoring, predictive maintenance, and remote operation capabilities. Such features not only improved pump reliability but also contributed to overall plant efficiency and safety.

Recent years have seen a shift towards modular and customizable pump designs. This approach allows for greater flexibility in adapting pumps to specific chemical applications, reducing lead times and costs associated with specialized equipment. Additionally, the concept of "smart pumps" has emerged, incorporating IoT technologies for enhanced data collection, analysis, and process optimization.

Chemical Industry Demands

The chemical industry's demand for submersible pumps extends far beyond traditional water applications, driven by the sector's need for efficient and reliable fluid handling solutions in various processes. These pumps are increasingly sought after for their ability to handle corrosive chemicals, high-temperature fluids, and abrasive slurries, making them indispensable in many chemical manufacturing and processing operations.

One of the primary drivers of demand is the growing emphasis on process efficiency and cost reduction in chemical production. Submersible pumps offer advantages in terms of space utilization, energy efficiency, and reduced maintenance requirements compared to conventional pump systems. This aligns well with the industry's focus on optimizing plant layouts and minimizing operational expenses.

The chemical industry's push towards more sustainable practices has also fueled the demand for submersible pumps. These pumps can be instrumental in wastewater treatment processes, chemical recovery systems, and closed-loop cooling applications, all of which contribute to reducing environmental impact and improving resource utilization in chemical plants.

Another significant factor driving demand is the increasing complexity of chemical processes. Many modern chemical manufacturing techniques involve multi-phase fluids, high-pressure environments, and precise flow control requirements. Submersible pumps, with their versatility and adaptability, are well-suited to handle these challenging conditions, making them a preferred choice for many specialized chemical applications.

The expansion of the specialty chemicals sector has created new opportunities for submersible pump applications. These pumps are particularly valuable in the production of high-purity chemicals, pharmaceuticals, and advanced materials, where contamination control and precise fluid handling are critical. Their ability to operate in sealed environments makes them ideal for maintaining the integrity of sensitive chemical processes.

Safety considerations in the chemical industry also contribute to the demand for submersible pumps. By eliminating the need for long shaft seals and reducing the risk of leaks, these pumps help minimize potential hazards associated with handling dangerous chemicals. This aspect is particularly important in the production and handling of volatile or toxic substances.

The trend towards modular and flexible manufacturing in the chemical industry has further boosted the appeal of submersible pumps. Their compact design and ease of installation make them well-suited for modular process units and pilot plants, allowing for greater flexibility in production setups and faster time-to-market for new chemical products.

One of the primary drivers of demand is the growing emphasis on process efficiency and cost reduction in chemical production. Submersible pumps offer advantages in terms of space utilization, energy efficiency, and reduced maintenance requirements compared to conventional pump systems. This aligns well with the industry's focus on optimizing plant layouts and minimizing operational expenses.

The chemical industry's push towards more sustainable practices has also fueled the demand for submersible pumps. These pumps can be instrumental in wastewater treatment processes, chemical recovery systems, and closed-loop cooling applications, all of which contribute to reducing environmental impact and improving resource utilization in chemical plants.

Another significant factor driving demand is the increasing complexity of chemical processes. Many modern chemical manufacturing techniques involve multi-phase fluids, high-pressure environments, and precise flow control requirements. Submersible pumps, with their versatility and adaptability, are well-suited to handle these challenging conditions, making them a preferred choice for many specialized chemical applications.

The expansion of the specialty chemicals sector has created new opportunities for submersible pump applications. These pumps are particularly valuable in the production of high-purity chemicals, pharmaceuticals, and advanced materials, where contamination control and precise fluid handling are critical. Their ability to operate in sealed environments makes them ideal for maintaining the integrity of sensitive chemical processes.

Safety considerations in the chemical industry also contribute to the demand for submersible pumps. By eliminating the need for long shaft seals and reducing the risk of leaks, these pumps help minimize potential hazards associated with handling dangerous chemicals. This aspect is particularly important in the production and handling of volatile or toxic substances.

The trend towards modular and flexible manufacturing in the chemical industry has further boosted the appeal of submersible pumps. Their compact design and ease of installation make them well-suited for modular process units and pilot plants, allowing for greater flexibility in production setups and faster time-to-market for new chemical products.

Submersible Pump Challenges

While submersible pumps have proven highly effective in water applications, their adaptation for chemical uses presents several significant challenges. The primary obstacle lies in the material compatibility between the pump components and various chemical substances. Many chemicals are corrosive or reactive, potentially damaging standard pump materials and compromising the integrity of seals, impellers, and casings. This necessitates the development of specialized materials and coatings capable of withstanding harsh chemical environments without degradation or contamination.

Another major challenge is the need for precise flow control and metering in chemical processes. Unlike water applications, chemical pumping often requires extremely accurate dosing and flow rates to maintain proper reactions and product quality. Achieving this level of precision with submersible pumps, especially in varying viscosities and densities of different chemicals, demands advanced control systems and potentially redesigned impeller geometries.

The risk of chemical leakage poses a significant safety and environmental concern. Submersible pumps operating in chemical applications must incorporate fail-safe mechanisms and robust sealing technologies to prevent any potential leaks, which could be hazardous or environmentally damaging. This challenge is compounded by the need for easy maintenance and repair, as accessing submerged pumps in chemical tanks or vessels can be complex and potentially dangerous.

Heat management presents another hurdle in adapting submersible pumps for chemical use. Many chemical processes involve high temperatures or exothermic reactions, which can affect pump performance and longevity. Developing effective cooling systems or heat-resistant materials that can operate reliably in these conditions is crucial.

The diversity of chemical properties also complicates pump design. Viscosity, specific gravity, and gas content can vary widely among different chemicals, affecting pump efficiency and performance. Creating versatile pump designs that can handle a broad range of chemical properties without compromising effectiveness is a significant engineering challenge.

Lastly, ensuring explosion-proof designs for pumps used with flammable or volatile chemicals adds another layer of complexity. This requires not only appropriate material selection but also specialized electrical components and intrinsically safe designs to prevent any potential ignition sources.

Addressing these challenges requires a multidisciplinary approach, combining materials science, fluid dynamics, chemical engineering, and safety engineering. Overcoming these hurdles will open new possibilities for submersible pumps in various chemical industries, potentially revolutionizing processes in sectors such as petrochemicals, pharmaceuticals, and specialty chemicals.

Another major challenge is the need for precise flow control and metering in chemical processes. Unlike water applications, chemical pumping often requires extremely accurate dosing and flow rates to maintain proper reactions and product quality. Achieving this level of precision with submersible pumps, especially in varying viscosities and densities of different chemicals, demands advanced control systems and potentially redesigned impeller geometries.

The risk of chemical leakage poses a significant safety and environmental concern. Submersible pumps operating in chemical applications must incorporate fail-safe mechanisms and robust sealing technologies to prevent any potential leaks, which could be hazardous or environmentally damaging. This challenge is compounded by the need for easy maintenance and repair, as accessing submerged pumps in chemical tanks or vessels can be complex and potentially dangerous.

Heat management presents another hurdle in adapting submersible pumps for chemical use. Many chemical processes involve high temperatures or exothermic reactions, which can affect pump performance and longevity. Developing effective cooling systems or heat-resistant materials that can operate reliably in these conditions is crucial.

The diversity of chemical properties also complicates pump design. Viscosity, specific gravity, and gas content can vary widely among different chemicals, affecting pump efficiency and performance. Creating versatile pump designs that can handle a broad range of chemical properties without compromising effectiveness is a significant engineering challenge.

Lastly, ensuring explosion-proof designs for pumps used with flammable or volatile chemicals adds another layer of complexity. This requires not only appropriate material selection but also specialized electrical components and intrinsically safe designs to prevent any potential ignition sources.

Addressing these challenges requires a multidisciplinary approach, combining materials science, fluid dynamics, chemical engineering, and safety engineering. Overcoming these hurdles will open new possibilities for submersible pumps in various chemical industries, potentially revolutionizing processes in sectors such as petrochemicals, pharmaceuticals, and specialty chemicals.

Current Chemical Solutions

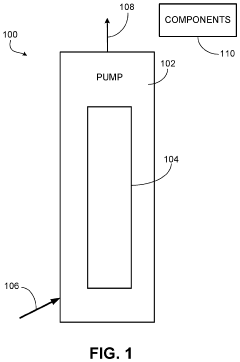

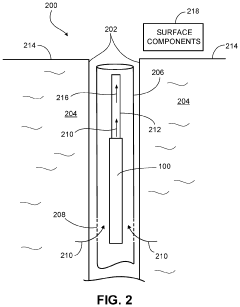

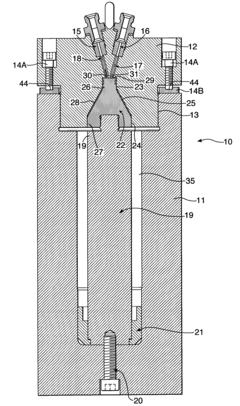

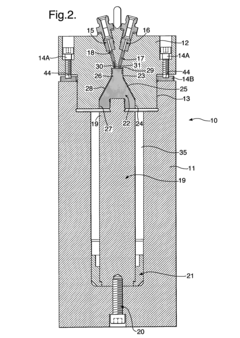

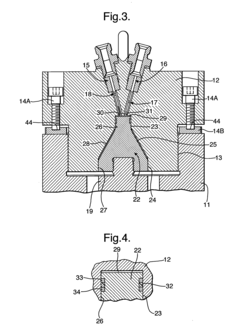

01 Design and construction of submersible pumps

Submersible pumps are designed to operate while fully submerged in liquid. Their construction typically includes a sealed motor directly coupled to the pump body, allowing for efficient operation in underwater environments. These pumps are engineered to withstand the pressure and corrosive effects of the liquid they are immersed in, making them suitable for various applications such as well pumping, wastewater management, and offshore operations.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically feature a sealed motor closely coupled to the pump body, ensuring efficient operation in underwater environments. The construction often includes corrosion-resistant materials and specialized sealing techniques to prevent liquid ingress into sensitive components.

- Control systems for submersible pumps: Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring pump conditions, variable frequency drives for adjusting motor speed, and remote monitoring capabilities. Such controls enhance efficiency, prevent damage, and allow for automated operation in various applications.

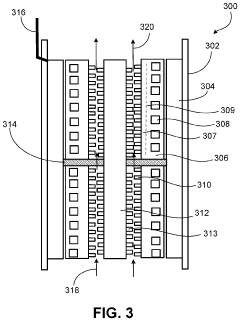

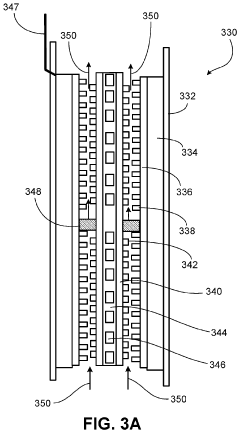

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on improving energy efficiency. This includes the development of high-efficiency motors, optimized impeller designs, and the use of advanced materials to reduce friction and wear. These improvements result in reduced power consumption and increased operational lifespan of the pumps.

- Application-specific submersible pump designs: Submersible pumps are engineered for specific applications such as wastewater treatment, oil and gas extraction, and deep-sea operations. These specialized designs may incorporate features like self-cleaning mechanisms, abrasion-resistant components, or the ability to handle high-temperature or high-pressure environments.

- Maintenance and reliability enhancements: Innovations in submersible pump technology aim to improve reliability and ease of maintenance. This includes the development of modular designs for easy component replacement, self-diagnostic systems for predictive maintenance, and the use of wear-resistant materials to extend the operational life of critical components.

02 Control systems for submersible pumps

Advanced control systems are implemented in submersible pumps to optimize their performance and efficiency. These systems may include sensors for monitoring pump conditions, variable frequency drives for adjusting motor speed, and intelligent algorithms for predictive maintenance. Such control mechanisms enable remote operation, automatic adjustment to changing conditions, and improved energy efficiency in pump operations.Expand Specific Solutions03 Innovations in motor technology for submersible pumps

Recent advancements in motor technology have led to more efficient and reliable submersible pumps. These innovations include the development of high-performance electric motors, improved cooling systems, and the use of advanced materials that can withstand harsh underwater conditions. Such improvements result in pumps with higher power output, longer operational life, and reduced maintenance requirements.Expand Specific Solutions04 Application-specific submersible pump designs

Submersible pumps are often designed for specific applications, such as oil and gas extraction, deep-sea exploration, or municipal water supply. These specialized designs may incorporate features like multi-stage impellers for high-pressure applications, abrasion-resistant materials for handling slurries, or compact designs for installation in narrow boreholes. The tailored designs ensure optimal performance in diverse operational environments.Expand Specific Solutions05 Energy efficiency and environmental considerations

Modern submersible pump designs place a strong emphasis on energy efficiency and environmental sustainability. This includes the development of pumps with high hydraulic efficiency, the use of eco-friendly materials, and the integration of energy recovery systems. Additionally, some designs incorporate features to minimize the impact on aquatic ecosystems, such as fish-friendly impellers or reduced noise operation.Expand Specific Solutions

Key Chemical Pump Makers

The exploration of chemical uses for submersible pumps beyond water applications is in an emerging phase, with the market showing potential for significant growth. The global submersible pump market, valued at $11.68 billion in 2021, is expected to expand as industries seek innovative solutions for chemical handling. Technologically, the field is advancing, with companies like Schlumberger Technologies, Baker Hughes, and Xylem Europe leading research and development efforts. These firms are adapting existing pump technologies for diverse chemical applications, focusing on corrosion resistance, precision control, and safety features. The competitive landscape is intensifying as traditional pump manufacturers and oilfield service companies vie for market share in this specialized niche, driving innovation and expanding the range of chemical-compatible submersible pump solutions.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump technologies for chemical applications in the oil and gas industry. Their REDA Maximus ESP system utilizes corrosion-resistant materials and specialized impeller designs to handle aggressive chemicals and abrasive fluids in downhole environments[1]. The company has also introduced chemical injection systems integrated with submersible pumps, allowing precise dosing of chemicals directly into the production stream[2]. These innovations enable efficient chemical treatment of wells, enhancing production rates and reducing equipment failures due to scaling or corrosion[3].

Strengths: Extensive experience in harsh downhole environments, advanced materials science, and integrated chemical injection capabilities. Weaknesses: High costs associated with specialized equipment and potential limitations in non-oil and gas applications.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed the AutoTrak eXpress system, which incorporates submersible pump technology for chemical applications in drilling operations. This system allows for real-time adjustment of drilling fluid chemistry and properties while drilling, improving efficiency and reducing environmental impact[4]. The company has also introduced the Chemical Optimization Service, which uses submersible pumps to deliver tailored chemical solutions to optimize production in challenging well conditions[5]. Baker Hughes' focus on digitalization has led to the development of smart chemical management systems that use data analytics to optimize chemical usage in submersible pump applications[6].

Strengths: Integration of digital technologies, customized chemical solutions, and expertise in challenging well environments. Weaknesses: Potential over-reliance on oil and gas sector, which may limit diversification into other chemical applications.

Innovative Pump Designs

Motorized pump

PatentActiveUS20220243570A1

Innovation

- The integration of a motor and pump as a single unit without a shaft or protector section, utilizing magnetic coupling and an external-rotor motor design to enhance reliability and facilitate rigless deployment, allowing for higher motor torque and larger pump head generation capabilities.

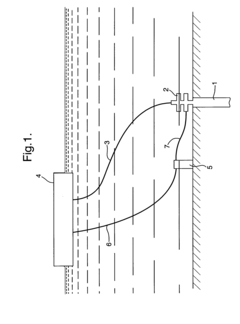

Subsea Chemical Injection System and Pumps Therefor

PatentActiveUS20100074776A1

Innovation

- An electrically-operated, solid-state pumping system using a piezoelectric actuator to reciprocate a plunger within a pumping chamber, minimizing moving parts and eliminating the need for rotating components, with a conduit system for chemical injection and a control system for precise pressure and flow control.

Material Compatibility

Material compatibility is a critical consideration when exploring chemical uses of submersible pumps beyond water applications. The diverse range of chemicals encountered in various industries necessitates careful selection of pump materials to ensure longevity, efficiency, and safety. Corrosion resistance is paramount, as many chemicals can rapidly degrade standard pump components, leading to premature failure and potential hazards.

Stainless steel alloys, such as 316L and duplex grades, are commonly employed for their excellent resistance to a wide array of chemicals. These materials offer superior protection against corrosion and pitting, making them suitable for applications involving acids, alkalis, and chlorides. However, for more aggressive chemicals, specialized alloys like Hastelloy or titanium may be required to withstand extreme conditions.

Polymeric materials also play a crucial role in chemical-resistant pump design. Fluoropolymers, such as PTFE and PVDF, exhibit exceptional chemical inertness and can be used for pump components that come into direct contact with corrosive fluids. These materials are particularly valuable in applications involving strong oxidizers or highly reactive substances.

Elastomers used in seals and gaskets must be carefully selected based on chemical compatibility. Fluoroelastomers like Viton offer broad chemical resistance, while EPDM is suitable for certain polar solvents and steam applications. Perfluoroelastomers provide the highest level of chemical resistance but at a premium cost.

Ceramic materials, such as silicon carbide and alumina, are often employed in mechanical seals and bearings due to their excellent wear resistance and chemical inertness. These materials can withstand abrasive slurries and corrosive environments that would quickly degrade metal components.

Coatings and surface treatments can enhance the chemical resistance of pump components. For instance, electroless nickel plating can improve the corrosion resistance of cast iron or steel parts, while specialized polymer coatings can protect against specific chemical attacks.

When selecting materials for chemical applications, it is essential to consider not only the primary chemical being pumped but also any potential contaminants or byproducts. Temperature, pressure, and concentration must also be factored into material selection, as these parameters can significantly affect chemical compatibility.

Manufacturers often provide chemical resistance charts to guide material selection, but it is crucial to conduct thorough testing and validation for specific applications. Long-term exposure tests and pilot studies can help identify potential material degradation issues that may not be apparent in short-term evaluations.

Stainless steel alloys, such as 316L and duplex grades, are commonly employed for their excellent resistance to a wide array of chemicals. These materials offer superior protection against corrosion and pitting, making them suitable for applications involving acids, alkalis, and chlorides. However, for more aggressive chemicals, specialized alloys like Hastelloy or titanium may be required to withstand extreme conditions.

Polymeric materials also play a crucial role in chemical-resistant pump design. Fluoropolymers, such as PTFE and PVDF, exhibit exceptional chemical inertness and can be used for pump components that come into direct contact with corrosive fluids. These materials are particularly valuable in applications involving strong oxidizers or highly reactive substances.

Elastomers used in seals and gaskets must be carefully selected based on chemical compatibility. Fluoroelastomers like Viton offer broad chemical resistance, while EPDM is suitable for certain polar solvents and steam applications. Perfluoroelastomers provide the highest level of chemical resistance but at a premium cost.

Ceramic materials, such as silicon carbide and alumina, are often employed in mechanical seals and bearings due to their excellent wear resistance and chemical inertness. These materials can withstand abrasive slurries and corrosive environments that would quickly degrade metal components.

Coatings and surface treatments can enhance the chemical resistance of pump components. For instance, electroless nickel plating can improve the corrosion resistance of cast iron or steel parts, while specialized polymer coatings can protect against specific chemical attacks.

When selecting materials for chemical applications, it is essential to consider not only the primary chemical being pumped but also any potential contaminants or byproducts. Temperature, pressure, and concentration must also be factored into material selection, as these parameters can significantly affect chemical compatibility.

Manufacturers often provide chemical resistance charts to guide material selection, but it is crucial to conduct thorough testing and validation for specific applications. Long-term exposure tests and pilot studies can help identify potential material degradation issues that may not be apparent in short-term evaluations.

Safety and Regulations

When exploring chemical uses of submersible pumps beyond water applications, safety and regulatory considerations are paramount. The handling of various chemicals introduces unique risks that must be carefully managed. Regulatory bodies such as OSHA, EPA, and industry-specific organizations have established stringent guidelines for the use of submersible pumps in chemical environments.

Material compatibility is a critical safety concern. Pumps must be constructed from materials that can withstand the corrosive or reactive nature of the chemicals being handled. This often requires the use of specialized alloys, polymers, or coatings to ensure the integrity of the pump components. Failure to address material compatibility can lead to pump degradation, chemical leaks, and potential environmental hazards.

Explosion-proof certifications are essential for pumps operating in environments with flammable or explosive chemicals. These certifications ensure that the pump's electrical components and motor are designed to prevent ignition sources, reducing the risk of fire or explosion. Compliance with standards such as ATEX in Europe or UL in North America is mandatory for such applications.

Containment and leak prevention systems are crucial regulatory requirements. Double-walled pump casings, advanced sealing technologies, and leak detection systems are often mandated to minimize the risk of chemical spills. These systems must be regularly inspected and maintained to ensure their effectiveness and compliance with environmental regulations.

Proper training and operational procedures are vital for personnel safety. Operators must be well-versed in the specific hazards associated with the chemicals being pumped and the proper use of personal protective equipment. Emergency response plans and regular safety drills are typically required by regulations to prepare for potential incidents.

Environmental impact assessments and monitoring are often mandated when using submersible pumps for chemical applications. This may involve regular testing of surrounding soil and water sources to detect any potential contamination. Compliance with local, national, and international environmental regulations is essential to maintain operational licenses and avoid hefty fines.

Disposal and decontamination procedures for pumps and associated equipment must adhere to strict guidelines. Proper cleaning and disposal of pumps that have been in contact with hazardous chemicals are critical to prevent environmental contamination and ensure worker safety during maintenance or replacement activities.

Material compatibility is a critical safety concern. Pumps must be constructed from materials that can withstand the corrosive or reactive nature of the chemicals being handled. This often requires the use of specialized alloys, polymers, or coatings to ensure the integrity of the pump components. Failure to address material compatibility can lead to pump degradation, chemical leaks, and potential environmental hazards.

Explosion-proof certifications are essential for pumps operating in environments with flammable or explosive chemicals. These certifications ensure that the pump's electrical components and motor are designed to prevent ignition sources, reducing the risk of fire or explosion. Compliance with standards such as ATEX in Europe or UL in North America is mandatory for such applications.

Containment and leak prevention systems are crucial regulatory requirements. Double-walled pump casings, advanced sealing technologies, and leak detection systems are often mandated to minimize the risk of chemical spills. These systems must be regularly inspected and maintained to ensure their effectiveness and compliance with environmental regulations.

Proper training and operational procedures are vital for personnel safety. Operators must be well-versed in the specific hazards associated with the chemicals being pumped and the proper use of personal protective equipment. Emergency response plans and regular safety drills are typically required by regulations to prepare for potential incidents.

Environmental impact assessments and monitoring are often mandated when using submersible pumps for chemical applications. This may involve regular testing of surrounding soil and water sources to detect any potential contamination. Compliance with local, national, and international environmental regulations is essential to maintain operational licenses and avoid hefty fines.

Disposal and decontamination procedures for pumps and associated equipment must adhere to strict guidelines. Proper cleaning and disposal of pumps that have been in contact with hazardous chemicals are critical to prevent environmental contamination and ensure worker safety during maintenance or replacement activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!