Exploring high-capacity submersible pump designs.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution and Objectives

Submersible pumps have undergone significant evolution since their inception in the early 20th century. Initially designed for dewatering applications in mines and construction sites, these pumps have transformed into versatile tools capable of handling a wide range of fluids in various industries. The progression of submersible pump technology has been driven by the increasing demand for efficient and reliable fluid handling solutions in challenging environments.

The early submersible pumps were limited in their capacity and efficiency, often struggling with issues such as overheating and seal failures. However, advancements in materials science, motor technology, and hydraulic design have led to substantial improvements in pump performance and reliability. The introduction of variable frequency drives (VFDs) in the 1980s marked a significant milestone, allowing for precise control of pump speed and energy consumption.

In recent years, the focus has shifted towards developing high-capacity submersible pumps capable of handling larger volumes of fluid at greater depths. This trend is particularly evident in industries such as offshore oil and gas, deep-sea mining, and large-scale water management projects. The push for higher capacities has necessitated innovations in impeller design, motor cooling systems, and pump housing materials to withstand increased pressures and temperatures.

The objectives of current high-capacity submersible pump designs are multifaceted. Primarily, there is a drive to increase flow rates and head capabilities while maintaining or improving energy efficiency. This involves optimizing hydraulic passages, reducing internal friction, and enhancing motor performance. Additionally, there is a strong emphasis on improving the durability and reliability of these pumps, particularly in harsh operating conditions such as abrasive or corrosive environments.

Another key objective is the integration of smart technologies and IoT capabilities into submersible pump systems. This includes the development of advanced sensors and monitoring systems that can provide real-time data on pump performance, predict maintenance needs, and optimize operation based on changing conditions. The goal is to create more autonomous and self-regulating pump systems that can adapt to varying demands and environmental factors.

Environmental considerations also play a crucial role in shaping the objectives of high-capacity submersible pump designs. There is a growing focus on developing pumps that are more environmentally friendly, with reduced energy consumption, lower noise levels, and minimal impact on aquatic ecosystems. This includes research into alternative materials and lubricants that are less harmful to the environment.

As we look to the future, the evolution of high-capacity submersible pumps is likely to continue along these trajectories, with an increased emphasis on sustainability, efficiency, and intelligent operation. The integration of advanced materials, such as composites and nanomaterials, may lead to further improvements in pump performance and longevity. Additionally, the development of modular and scalable designs could provide greater flexibility in meeting diverse application requirements across various industries.

The early submersible pumps were limited in their capacity and efficiency, often struggling with issues such as overheating and seal failures. However, advancements in materials science, motor technology, and hydraulic design have led to substantial improvements in pump performance and reliability. The introduction of variable frequency drives (VFDs) in the 1980s marked a significant milestone, allowing for precise control of pump speed and energy consumption.

In recent years, the focus has shifted towards developing high-capacity submersible pumps capable of handling larger volumes of fluid at greater depths. This trend is particularly evident in industries such as offshore oil and gas, deep-sea mining, and large-scale water management projects. The push for higher capacities has necessitated innovations in impeller design, motor cooling systems, and pump housing materials to withstand increased pressures and temperatures.

The objectives of current high-capacity submersible pump designs are multifaceted. Primarily, there is a drive to increase flow rates and head capabilities while maintaining or improving energy efficiency. This involves optimizing hydraulic passages, reducing internal friction, and enhancing motor performance. Additionally, there is a strong emphasis on improving the durability and reliability of these pumps, particularly in harsh operating conditions such as abrasive or corrosive environments.

Another key objective is the integration of smart technologies and IoT capabilities into submersible pump systems. This includes the development of advanced sensors and monitoring systems that can provide real-time data on pump performance, predict maintenance needs, and optimize operation based on changing conditions. The goal is to create more autonomous and self-regulating pump systems that can adapt to varying demands and environmental factors.

Environmental considerations also play a crucial role in shaping the objectives of high-capacity submersible pump designs. There is a growing focus on developing pumps that are more environmentally friendly, with reduced energy consumption, lower noise levels, and minimal impact on aquatic ecosystems. This includes research into alternative materials and lubricants that are less harmful to the environment.

As we look to the future, the evolution of high-capacity submersible pumps is likely to continue along these trajectories, with an increased emphasis on sustainability, efficiency, and intelligent operation. The integration of advanced materials, such as composites and nanomaterials, may lead to further improvements in pump performance and longevity. Additionally, the development of modular and scalable designs could provide greater flexibility in meeting diverse application requirements across various industries.

Market Demand Analysis for High-Capacity Pumps

The market demand for high-capacity submersible pumps has been steadily increasing across various industries, driven by the growing need for efficient water management and resource extraction. In the oil and gas sector, deep-sea exploration and production activities require robust submersible pumps capable of handling high volumes of fluids at extreme depths. The offshore industry, in particular, has seen a surge in demand for pumps that can operate reliably in harsh underwater environments.

The mining industry represents another significant market for high-capacity submersible pumps. As surface mineral deposits become depleted, mining operations are moving deeper underground, necessitating more powerful dewatering solutions. These pumps are crucial for maintaining dry working conditions and ensuring the safety and productivity of mining operations.

In the water and wastewater treatment sector, urbanization and stricter environmental regulations have led to an increased demand for high-capacity pumps in large-scale treatment plants. These pumps are essential for handling the growing volumes of wastewater generated by expanding urban populations and industrial activities.

The agriculture sector also contributes to the market demand, particularly in regions facing water scarcity. Large-scale irrigation projects and water distribution systems require high-capacity submersible pumps to efficiently move water from underground aquifers or surface water sources to agricultural lands.

Emerging markets in developing countries present significant growth opportunities for high-capacity submersible pump manufacturers. Rapid industrialization, infrastructure development, and increasing investments in water management projects are driving the demand for these pumps in regions such as Asia-Pacific and Africa.

The global submersible pumps market is expected to experience substantial growth in the coming years. Factors such as increasing urbanization, rising energy demand, and the need for efficient water management solutions are likely to fuel this growth. Additionally, the trend towards smart pumping systems and the integration of IoT technologies are creating new opportunities for innovation in high-capacity submersible pump designs.

However, the market also faces challenges, including the high initial investment costs associated with advanced pump technologies and the need for specialized maintenance. Manufacturers are focusing on developing more energy-efficient and durable pump designs to address these concerns and meet the evolving needs of various industries.

The mining industry represents another significant market for high-capacity submersible pumps. As surface mineral deposits become depleted, mining operations are moving deeper underground, necessitating more powerful dewatering solutions. These pumps are crucial for maintaining dry working conditions and ensuring the safety and productivity of mining operations.

In the water and wastewater treatment sector, urbanization and stricter environmental regulations have led to an increased demand for high-capacity pumps in large-scale treatment plants. These pumps are essential for handling the growing volumes of wastewater generated by expanding urban populations and industrial activities.

The agriculture sector also contributes to the market demand, particularly in regions facing water scarcity. Large-scale irrigation projects and water distribution systems require high-capacity submersible pumps to efficiently move water from underground aquifers or surface water sources to agricultural lands.

Emerging markets in developing countries present significant growth opportunities for high-capacity submersible pump manufacturers. Rapid industrialization, infrastructure development, and increasing investments in water management projects are driving the demand for these pumps in regions such as Asia-Pacific and Africa.

The global submersible pumps market is expected to experience substantial growth in the coming years. Factors such as increasing urbanization, rising energy demand, and the need for efficient water management solutions are likely to fuel this growth. Additionally, the trend towards smart pumping systems and the integration of IoT technologies are creating new opportunities for innovation in high-capacity submersible pump designs.

However, the market also faces challenges, including the high initial investment costs associated with advanced pump technologies and the need for specialized maintenance. Manufacturers are focusing on developing more energy-efficient and durable pump designs to address these concerns and meet the evolving needs of various industries.

Current Challenges in Submersible Pump Technology

Submersible pump technology has made significant strides in recent years, yet several challenges persist in the development of high-capacity designs. One of the primary obstacles is the management of heat generation and dissipation. As pump capacity increases, so does the amount of heat produced during operation. This heat can lead to premature component failure, reduced efficiency, and shortened pump lifespan if not adequately addressed.

Another significant challenge lies in the materials used for pump construction. High-capacity submersible pumps often operate in harsh environments, exposed to corrosive fluids, abrasive particles, and extreme pressures. Developing materials that can withstand these conditions while maintaining performance and longevity remains a key focus area for researchers and engineers.

Power transmission and motor efficiency present additional hurdles. As pump capacities increase, so do the power requirements. Designing compact, efficient motors that can deliver the necessary power while operating reliably underwater is a complex task. This challenge is compounded by the need for effective insulation and sealing to protect electrical components from water ingress.

Hydraulic design optimization continues to be a critical area of focus. Achieving high flow rates and pressures while minimizing energy consumption requires sophisticated computational fluid dynamics modeling and innovative impeller designs. Balancing these factors with the physical constraints of submersible pump housings adds another layer of complexity to the design process.

Maintenance and serviceability pose unique challenges for high-capacity submersible pumps. Given their often remote or difficult-to-access locations, designing pumps that can be easily maintained or repaired in situ is crucial. This includes developing modular components, improving seal designs to reduce the frequency of maintenance, and incorporating advanced monitoring systems for predictive maintenance.

The increasing demand for smart and connected pumping systems introduces new challenges in integrating sensors, control systems, and communication technologies into submersible pump designs. Ensuring the reliability and durability of these electronic components in underwater environments while providing valuable operational data and remote control capabilities is an ongoing area of development.

Lastly, environmental considerations and energy efficiency standards are driving the need for more sustainable pump designs. Reducing the environmental impact of high-capacity submersible pumps, both in terms of energy consumption and potential fluid leakage, remains a significant challenge for manufacturers and researchers in the field.

Another significant challenge lies in the materials used for pump construction. High-capacity submersible pumps often operate in harsh environments, exposed to corrosive fluids, abrasive particles, and extreme pressures. Developing materials that can withstand these conditions while maintaining performance and longevity remains a key focus area for researchers and engineers.

Power transmission and motor efficiency present additional hurdles. As pump capacities increase, so do the power requirements. Designing compact, efficient motors that can deliver the necessary power while operating reliably underwater is a complex task. This challenge is compounded by the need for effective insulation and sealing to protect electrical components from water ingress.

Hydraulic design optimization continues to be a critical area of focus. Achieving high flow rates and pressures while minimizing energy consumption requires sophisticated computational fluid dynamics modeling and innovative impeller designs. Balancing these factors with the physical constraints of submersible pump housings adds another layer of complexity to the design process.

Maintenance and serviceability pose unique challenges for high-capacity submersible pumps. Given their often remote or difficult-to-access locations, designing pumps that can be easily maintained or repaired in situ is crucial. This includes developing modular components, improving seal designs to reduce the frequency of maintenance, and incorporating advanced monitoring systems for predictive maintenance.

The increasing demand for smart and connected pumping systems introduces new challenges in integrating sensors, control systems, and communication technologies into submersible pump designs. Ensuring the reliability and durability of these electronic components in underwater environments while providing valuable operational data and remote control capabilities is an ongoing area of development.

Lastly, environmental considerations and energy efficiency standards are driving the need for more sustainable pump designs. Reducing the environmental impact of high-capacity submersible pumps, both in terms of energy consumption and potential fluid leakage, remains a significant challenge for manufacturers and researchers in the field.

Existing High-Capacity Pump Solutions

01 Pump capacity optimization

Submersible pumps can be designed with optimized capacity through various methods, including improved impeller designs, advanced motor technology, and efficient hydraulic systems. These enhancements allow for increased flow rates and higher pressure capabilities, making the pumps suitable for a wide range of applications in different industries.- Pump capacity optimization: Submersible pumps can be designed with optimized capacity through various methods, including improved impeller designs, motor efficiency enhancements, and advanced flow control systems. These optimizations allow for increased fluid handling capabilities while maintaining or reducing power consumption.

- Multi-stage submersible pumps: Multi-stage submersible pumps utilize a series of impellers and diffusers to increase the overall pumping capacity. This design allows for higher head pressures and flow rates, making them suitable for deep well applications and high-demand industrial processes.

- Variable frequency drive integration: Incorporating variable frequency drives (VFDs) into submersible pump systems allows for precise control of pump speed and capacity. This integration enables energy-efficient operation across a wide range of flow requirements and adapts to changing system demands.

- Hydraulic design improvements: Advancements in hydraulic design, such as optimized volute geometry, improved suction inlet configurations, and enhanced diffuser designs, contribute to increased pump capacity. These improvements reduce internal losses and improve overall pump efficiency.

- Intelligent pump control systems: Smart control systems incorporating sensors, data analytics, and automation algorithms can optimize submersible pump capacity. These systems can adjust pump performance based on real-time conditions, predict maintenance needs, and ensure optimal operation across various scenarios.

02 Variable capacity control

Incorporating variable frequency drives and intelligent control systems allows submersible pumps to adjust their capacity based on demand. This feature enables energy-efficient operation, extends pump life, and provides flexibility in handling varying flow requirements in different operating conditions.Expand Specific Solutions03 High-capacity submersible pumps for oil and gas

Specialized submersible pumps designed for the oil and gas industry can handle high capacities of fluid extraction from deep wells. These pumps often incorporate advanced materials and designs to withstand harsh downhole conditions while maintaining high flow rates and efficiency.Expand Specific Solutions04 Multi-stage pump designs for increased capacity

Multi-stage submersible pump configurations allow for increased capacity and higher head pressures. By stacking multiple impellers in series, these pumps can achieve greater lift and flow rates, making them suitable for deep well applications and high-pressure water supply systems.Expand Specific Solutions05 Capacity enhancement through innovative materials and manufacturing

The use of advanced materials, such as composite polymers and high-strength alloys, combined with innovative manufacturing techniques like 3D printing, allows for the creation of submersible pumps with improved capacity. These advancements result in lighter, more durable, and higher-performing pump components that can handle increased flow rates and pressures.Expand Specific Solutions

Key Players in Submersible Pump Industry

The high-capacity submersible pump market is in a mature growth phase, characterized by steady demand and technological advancements. The global market size is substantial, driven by applications in various industries such as oil and gas, water management, and mining. Key players like Baker Hughes Co., Schlumberger Technologies, Inc., and KSB SE & Co. KGaA are at the forefront of innovation, focusing on improving pump efficiency, durability, and performance in challenging environments. Emerging companies from China, such as Jiangsu Best Pump Making Co., Ltd. and Zhejiang Doyin Technology Co. Ltd., are also making significant strides in the market, particularly in cost-effective solutions. The technology maturity level is high, with ongoing research and development efforts aimed at enhancing pump capabilities and addressing specific industry needs.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced high-capacity submersible pump designs utilizing innovative materials and hydraulic engineering. Their REDA Maximus ESP system incorporates a high-efficiency motor and advanced gas-handling capabilities, allowing for operation in challenging downhole environments with gas volume fractions up to 70%[1]. The pump features a modular design with specialized impellers and diffusers that optimize flow paths and reduce turbulence, resulting in improved efficiency and reduced power consumption. Schlumberger's pumps also integrate real-time monitoring and control systems, enabling adaptive operation based on changing well conditions[2]. This technology allows for remote adjustments to pump speed and performance, maximizing production while minimizing downtime and maintenance requirements.

Strengths: Superior gas-handling capabilities, high efficiency in challenging environments, and advanced monitoring systems. Weaknesses: Higher initial cost and complexity compared to conventional pumps, potentially requiring specialized maintenance.

Grundfos Management A/S

Technical Solution: Grundfos has pioneered high-capacity submersible pump designs with a focus on energy efficiency and reliability. Their SP submersible pumps utilize advanced hydraulic designs and high-grade materials such as stainless steel and composite components to withstand corrosive environments[3]. The pumps feature a unique floating stack design that reduces axial thrust, minimizing wear and extending operational life. Grundfos has also integrated intelligent control systems, such as their SmartFlo technology, which optimizes pump performance based on demand and system conditions[4]. This results in energy savings of up to 50% compared to conventional fixed-speed pumps. Additionally, Grundfos has developed innovative motor cooling systems that allow for higher horsepower ratings in smaller diameter wells, increasing installation flexibility and reducing overall system costs.

Strengths: High energy efficiency, advanced materials for durability, and intelligent control systems. Weaknesses: May have limitations in extremely high-temperature or high-solid content applications.

Core Innovations in Pump Design

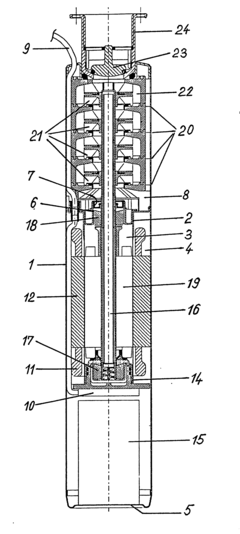

An electrical submersible pump

PatentInactiveCA2608538A1

Innovation

- The design features ceramic impellers and diffusers with metal spacers, spring sleeves for thermal expansion compensation, and elastomer layers for damping, along with an alternative torque transmission mechanism to address erosion, thermal expansion, and impact loads, ensuring robustness and longevity.

Submersible pump

PatentInactiveEP0346731A2

Innovation

- A submersible pump unit design where the motor, pump body, and frequency converter are arranged in series within a tubular jacket, with a thermally conductive base and heat-dissipating materials, and an internal cable routing to simplify production and reduce thermal resistance, along with a self-adjusting axial bearing for easier installation.

Environmental Impact Assessment

The environmental impact assessment of high-capacity submersible pump designs is a critical aspect of their development and implementation. These pumps, while essential for various industrial and municipal applications, can have significant effects on aquatic ecosystems and surrounding environments.

One of the primary concerns is the potential for habitat disruption. High-capacity submersible pumps often require large-scale installations, which can alter the physical structure of aquatic environments. This may lead to changes in water flow patterns, sedimentation rates, and the overall composition of benthic communities. The alteration of these habitats can have cascading effects on local flora and fauna, potentially impacting biodiversity and ecosystem functions.

Water quality is another crucial factor to consider. The operation of high-capacity submersible pumps can result in the resuspension of sediments, leading to increased turbidity and potential release of contaminants that were previously bound in the sediment. This can affect water clarity, light penetration, and dissolved oxygen levels, all of which are vital for aquatic life. Additionally, the pumps may introduce or redistribute pollutants, altering the chemical composition of the water body.

Energy consumption is a significant environmental concern associated with high-capacity submersible pumps. These systems often require substantial power to operate, contributing to increased energy demand and, consequently, greenhouse gas emissions if non-renewable energy sources are used. The development of more energy-efficient pump designs and the integration of renewable energy sources for pump operation are important considerations for minimizing the carbon footprint of these systems.

Noise pollution is another environmental impact that warrants attention. Underwater noise generated by high-capacity submersible pumps can disrupt marine life, affecting communication, navigation, and behavior patterns of various aquatic species. This is particularly concerning in sensitive ecosystems or areas with endangered species.

The potential for entrainment and impingement of aquatic organisms is a significant issue, especially in natural water bodies. High-capacity pumps can draw in small aquatic life, leading to injury or mortality. Implementing appropriate screening systems and designing pump intakes to minimize these risks is crucial for protecting local ecosystems.

Lastly, the disposal and management of waste products associated with pump operation and maintenance, such as lubricants and worn parts, must be carefully considered to prevent contamination of water sources and surrounding environments. Proper handling and disposal protocols are essential to mitigate these risks and ensure environmental compliance.

One of the primary concerns is the potential for habitat disruption. High-capacity submersible pumps often require large-scale installations, which can alter the physical structure of aquatic environments. This may lead to changes in water flow patterns, sedimentation rates, and the overall composition of benthic communities. The alteration of these habitats can have cascading effects on local flora and fauna, potentially impacting biodiversity and ecosystem functions.

Water quality is another crucial factor to consider. The operation of high-capacity submersible pumps can result in the resuspension of sediments, leading to increased turbidity and potential release of contaminants that were previously bound in the sediment. This can affect water clarity, light penetration, and dissolved oxygen levels, all of which are vital for aquatic life. Additionally, the pumps may introduce or redistribute pollutants, altering the chemical composition of the water body.

Energy consumption is a significant environmental concern associated with high-capacity submersible pumps. These systems often require substantial power to operate, contributing to increased energy demand and, consequently, greenhouse gas emissions if non-renewable energy sources are used. The development of more energy-efficient pump designs and the integration of renewable energy sources for pump operation are important considerations for minimizing the carbon footprint of these systems.

Noise pollution is another environmental impact that warrants attention. Underwater noise generated by high-capacity submersible pumps can disrupt marine life, affecting communication, navigation, and behavior patterns of various aquatic species. This is particularly concerning in sensitive ecosystems or areas with endangered species.

The potential for entrainment and impingement of aquatic organisms is a significant issue, especially in natural water bodies. High-capacity pumps can draw in small aquatic life, leading to injury or mortality. Implementing appropriate screening systems and designing pump intakes to minimize these risks is crucial for protecting local ecosystems.

Lastly, the disposal and management of waste products associated with pump operation and maintenance, such as lubricants and worn parts, must be carefully considered to prevent contamination of water sources and surrounding environments. Proper handling and disposal protocols are essential to mitigate these risks and ensure environmental compliance.

Materials and Manufacturing Advancements

Recent advancements in materials science and manufacturing technologies have significantly impacted the development of high-capacity submersible pump designs. The use of advanced materials, such as high-strength alloys and composite materials, has enabled the creation of pump components that are more resistant to corrosion, wear, and high-pressure environments. These materials offer improved durability and performance, allowing pumps to operate efficiently in harsh underwater conditions for extended periods.

Innovations in manufacturing processes have also played a crucial role in enhancing pump designs. Precision machining techniques, including computer numerical control (CNC) and electrical discharge machining (EDM), have enabled the production of complex pump geometries with tighter tolerances. This has resulted in improved hydraulic efficiency and reduced energy consumption. Additionally, additive manufacturing technologies, such as 3D printing, have opened up new possibilities for creating intricate internal structures and optimizing fluid flow paths within pump components.

Surface engineering techniques have further contributed to the advancement of submersible pump designs. Coatings and surface treatments, such as plasma nitriding and physical vapor deposition (PVD), have been employed to enhance the wear resistance and corrosion protection of pump components. These treatments extend the operational life of pumps and reduce maintenance requirements, particularly in abrasive or chemically aggressive environments.

The integration of smart materials and sensors into pump designs has led to the development of self-monitoring and self-adjusting systems. Shape memory alloys and piezoelectric materials have been incorporated to create adaptive components that can respond to changes in operating conditions, optimizing pump performance in real-time. This integration of smart materials has also facilitated the implementation of predictive maintenance strategies, reducing downtime and improving overall pump reliability.

Advancements in joining technologies have enabled the creation of more robust and efficient pump assemblies. Techniques such as friction stir welding and electron beam welding have allowed for the joining of dissimilar materials, expanding design possibilities and improving overall pump performance. These advanced joining methods have also contributed to the development of modular pump designs, facilitating easier maintenance and replacement of components.

The application of computational fluid dynamics (CFD) and finite element analysis (FEA) in the design process has led to optimized pump geometries and improved overall efficiency. These simulation tools have enabled engineers to predict and mitigate potential issues such as cavitation and vibration, resulting in more reliable and higher-performing pump designs. The integration of these advanced modeling techniques with modern manufacturing processes has accelerated the development cycle and reduced the need for extensive physical prototyping.

Innovations in manufacturing processes have also played a crucial role in enhancing pump designs. Precision machining techniques, including computer numerical control (CNC) and electrical discharge machining (EDM), have enabled the production of complex pump geometries with tighter tolerances. This has resulted in improved hydraulic efficiency and reduced energy consumption. Additionally, additive manufacturing technologies, such as 3D printing, have opened up new possibilities for creating intricate internal structures and optimizing fluid flow paths within pump components.

Surface engineering techniques have further contributed to the advancement of submersible pump designs. Coatings and surface treatments, such as plasma nitriding and physical vapor deposition (PVD), have been employed to enhance the wear resistance and corrosion protection of pump components. These treatments extend the operational life of pumps and reduce maintenance requirements, particularly in abrasive or chemically aggressive environments.

The integration of smart materials and sensors into pump designs has led to the development of self-monitoring and self-adjusting systems. Shape memory alloys and piezoelectric materials have been incorporated to create adaptive components that can respond to changes in operating conditions, optimizing pump performance in real-time. This integration of smart materials has also facilitated the implementation of predictive maintenance strategies, reducing downtime and improving overall pump reliability.

Advancements in joining technologies have enabled the creation of more robust and efficient pump assemblies. Techniques such as friction stir welding and electron beam welding have allowed for the joining of dissimilar materials, expanding design possibilities and improving overall pump performance. These advanced joining methods have also contributed to the development of modular pump designs, facilitating easier maintenance and replacement of components.

The application of computational fluid dynamics (CFD) and finite element analysis (FEA) in the design process has led to optimized pump geometries and improved overall efficiency. These simulation tools have enabled engineers to predict and mitigate potential issues such as cavitation and vibration, resulting in more reliable and higher-performing pump designs. The integration of these advanced modeling techniques with modern manufacturing processes has accelerated the development cycle and reduced the need for extensive physical prototyping.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!