Fast charging protocols for next generation sodium ion batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Fast Charging Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of fast charging protocols for SIBs represents a critical frontier in energy storage technology, addressing the growing demand for rapid energy replenishment in various applications from consumer electronics to electric vehicles and grid-scale storage systems.

The evolution of SIB technology has progressed significantly over the past decade, transitioning from conceptual research to practical prototypes. Early SIB designs suffered from limited cycle life, low energy density, and particularly slow charging capabilities compared to their lithium counterparts. However, recent advancements in electrode materials, electrolyte formulations, and battery management systems have substantially improved performance metrics, bringing SIBs closer to commercial viability.

Fast charging capabilities represent a particularly challenging aspect of SIB development due to the larger ionic radius of sodium (1.02Å) compared to lithium (0.76Å), which inherently slows ion diffusion processes. This fundamental limitation has necessitated innovative approaches to electrode design, focusing on materials with expanded interlayer spacing, optimized porosity, and enhanced conductivity to facilitate rapid sodium ion insertion and extraction.

The technical objectives for next-generation fast-charging SIBs center around achieving charging rates comparable to advanced lithium-ion systems (80% capacity in under 15 minutes) while maintaining cycle stability and safety. This requires addressing several interconnected challenges: minimizing structural degradation during rapid charging, preventing dendrite formation, managing heat generation, and ensuring uniform ion distribution throughout electrode materials.

Current research trends indicate growing interest in hierarchical electrode architectures, novel electrolyte additives that form optimized solid-electrolyte interphases, and advanced charging algorithms that adapt to battery state and environmental conditions. These developments aim to push charging rates beyond 5C (full charge in 12 minutes) without compromising the 2000+ cycle life necessary for commercial applications.

The technological trajectory suggests that fast-charging SIBs could reach performance parity with lithium-ion batteries in specific applications by 2025-2027, potentially disrupting energy storage markets where raw material costs and charging speed are prioritized over absolute energy density. This timeline aligns with global sustainability initiatives and the increasing pressure to develop energy storage solutions less dependent on geographically concentrated resources.

The evolution of SIB technology has progressed significantly over the past decade, transitioning from conceptual research to practical prototypes. Early SIB designs suffered from limited cycle life, low energy density, and particularly slow charging capabilities compared to their lithium counterparts. However, recent advancements in electrode materials, electrolyte formulations, and battery management systems have substantially improved performance metrics, bringing SIBs closer to commercial viability.

Fast charging capabilities represent a particularly challenging aspect of SIB development due to the larger ionic radius of sodium (1.02Å) compared to lithium (0.76Å), which inherently slows ion diffusion processes. This fundamental limitation has necessitated innovative approaches to electrode design, focusing on materials with expanded interlayer spacing, optimized porosity, and enhanced conductivity to facilitate rapid sodium ion insertion and extraction.

The technical objectives for next-generation fast-charging SIBs center around achieving charging rates comparable to advanced lithium-ion systems (80% capacity in under 15 minutes) while maintaining cycle stability and safety. This requires addressing several interconnected challenges: minimizing structural degradation during rapid charging, preventing dendrite formation, managing heat generation, and ensuring uniform ion distribution throughout electrode materials.

Current research trends indicate growing interest in hierarchical electrode architectures, novel electrolyte additives that form optimized solid-electrolyte interphases, and advanced charging algorithms that adapt to battery state and environmental conditions. These developments aim to push charging rates beyond 5C (full charge in 12 minutes) without compromising the 2000+ cycle life necessary for commercial applications.

The technological trajectory suggests that fast-charging SIBs could reach performance parity with lithium-ion batteries in specific applications by 2025-2027, potentially disrupting energy storage markets where raw material costs and charging speed are prioritized over absolute energy density. This timeline aligns with global sustainability initiatives and the increasing pressure to develop energy storage solutions less dependent on geographically concentrated resources.

Market Analysis for Rapid Charging Energy Storage Solutions

The rapid charging energy storage market is experiencing unprecedented growth, driven by increasing demand for electric vehicles (EVs), renewable energy integration, and portable electronics. The global fast-charging battery market reached $15.3 billion in 2022 and is projected to grow at a CAGR of 18.7% through 2030, with sodium-ion battery technologies representing an emerging segment poised for significant expansion.

Consumer demand for reduced charging times has become a critical market driver, with surveys indicating that 78% of potential EV buyers consider charging speed a decisive factor in purchase decisions. This trend extends beyond automotive applications into consumer electronics, grid storage, and industrial sectors, where minimizing downtime translates directly to operational efficiency and cost savings.

Sodium-ion batteries with advanced fast-charging protocols are positioned to capture substantial market share due to their cost advantages over lithium-ion alternatives. Raw material costs for sodium-ion batteries are approximately 30-40% lower than comparable lithium-ion systems, presenting a compelling value proposition as supply chains for critical battery materials face increasing constraints.

Regional market analysis reveals Asia-Pacific leading fast-charging technology development, with China accounting for 43% of global patents related to sodium-ion battery charging protocols. European markets show the fastest adoption growth rate at 22.3% annually, driven by stringent carbon reduction policies and substantial government investments in sustainable energy infrastructure.

Market segmentation indicates that transportation applications currently dominate demand for fast-charging solutions (52%), followed by grid storage (27%) and consumer electronics (15%). However, sodium-ion technologies are expected to initially gain strongest traction in stationary storage applications where energy density constraints are less critical than cost considerations.

Investor confidence in rapid charging technologies is evidenced by venture capital funding exceeding $4.2 billion in 2022 specifically targeting advanced charging protocols and battery management systems. Strategic partnerships between battery manufacturers, charging infrastructure providers, and automotive OEMs have increased by 65% over the past three years, indicating strong ecosystem development.

Customer willingness to pay premiums for faster charging capabilities varies significantly by application, with EV owners demonstrating acceptance of 15-20% price increases for vehicles offering sub-30-minute charging to 80% capacity. This price sensitivity data suggests viable commercialization pathways for sodium-ion technologies that can achieve competitive charging rates while maintaining their inherent cost advantages.

Consumer demand for reduced charging times has become a critical market driver, with surveys indicating that 78% of potential EV buyers consider charging speed a decisive factor in purchase decisions. This trend extends beyond automotive applications into consumer electronics, grid storage, and industrial sectors, where minimizing downtime translates directly to operational efficiency and cost savings.

Sodium-ion batteries with advanced fast-charging protocols are positioned to capture substantial market share due to their cost advantages over lithium-ion alternatives. Raw material costs for sodium-ion batteries are approximately 30-40% lower than comparable lithium-ion systems, presenting a compelling value proposition as supply chains for critical battery materials face increasing constraints.

Regional market analysis reveals Asia-Pacific leading fast-charging technology development, with China accounting for 43% of global patents related to sodium-ion battery charging protocols. European markets show the fastest adoption growth rate at 22.3% annually, driven by stringent carbon reduction policies and substantial government investments in sustainable energy infrastructure.

Market segmentation indicates that transportation applications currently dominate demand for fast-charging solutions (52%), followed by grid storage (27%) and consumer electronics (15%). However, sodium-ion technologies are expected to initially gain strongest traction in stationary storage applications where energy density constraints are less critical than cost considerations.

Investor confidence in rapid charging technologies is evidenced by venture capital funding exceeding $4.2 billion in 2022 specifically targeting advanced charging protocols and battery management systems. Strategic partnerships between battery manufacturers, charging infrastructure providers, and automotive OEMs have increased by 65% over the past three years, indicating strong ecosystem development.

Customer willingness to pay premiums for faster charging capabilities varies significantly by application, with EV owners demonstrating acceptance of 15-20% price increases for vehicles offering sub-30-minute charging to 80% capacity. This price sensitivity data suggests viable commercialization pathways for sodium-ion technologies that can achieve competitive charging rates while maintaining their inherent cost advantages.

Current Challenges in Na-ion Battery Fast Charging Technology

Despite significant advancements in sodium-ion battery technology, fast charging capabilities remain substantially limited compared to their lithium-ion counterparts. The primary challenge stems from the larger ionic radius of sodium ions (1.02Å) versus lithium ions (0.76Å), resulting in slower diffusion kinetics within electrode materials and across interfaces. This fundamental limitation creates significant barriers to achieving high-rate charging without compromising battery safety and longevity.

Electrode degradation presents another critical challenge during fast charging. The rapid insertion of sodium ions causes substantial volume changes and mechanical stress in electrode materials, leading to particle cracking, pulverization, and eventual capacity fade. This issue is particularly pronounced in hard carbon anodes, where the disordered structure experiences severe strain during rapid sodium intercalation.

Electrolyte decomposition accelerates dramatically at high charging rates, forming unstable solid electrolyte interphase (SEI) layers that continuously consume active sodium and increase cell impedance. Current electrolyte formulations lack the stability required to withstand the elevated temperatures and voltage gradients associated with fast charging protocols, resulting in parasitic reactions that compromise both safety and cycle life.

Thermal management represents a significant engineering challenge specific to sodium-ion systems. The higher internal resistance compared to lithium-ion batteries generates more heat during fast charging, potentially triggering thermal runaway events. Existing cooling systems designed for lithium-ion batteries require substantial redesign to accommodate the unique thermal characteristics of sodium-ion cells.

The lack of standardized testing protocols for sodium-ion fast charging further complicates development efforts. Without established benchmarks and safety parameters, researchers employ inconsistent methodologies, making cross-study comparisons difficult and slowing industry-wide progress. This absence of standardization also hinders regulatory approval processes for commercial applications.

Current battery management systems (BMS) lack sodium-ion-specific algorithms to optimize fast charging while maintaining safety margins. The distinct voltage profiles, temperature responses, and aging mechanisms of sodium-ion cells render lithium-ion BMS solutions inadequate, necessitating fundamental algorithm redesign based on sodium-ion electrochemistry.

Manufacturing scalability presents additional challenges, as existing production lines optimized for lithium-ion cells require significant modification to accommodate sodium-ion battery components while maintaining the precision necessary for fast-charging capabilities. The cost-performance balance remains unfavorable compared to established lithium-ion technologies, creating market entry barriers despite sodium's inherent cost advantages.

Electrode degradation presents another critical challenge during fast charging. The rapid insertion of sodium ions causes substantial volume changes and mechanical stress in electrode materials, leading to particle cracking, pulverization, and eventual capacity fade. This issue is particularly pronounced in hard carbon anodes, where the disordered structure experiences severe strain during rapid sodium intercalation.

Electrolyte decomposition accelerates dramatically at high charging rates, forming unstable solid electrolyte interphase (SEI) layers that continuously consume active sodium and increase cell impedance. Current electrolyte formulations lack the stability required to withstand the elevated temperatures and voltage gradients associated with fast charging protocols, resulting in parasitic reactions that compromise both safety and cycle life.

Thermal management represents a significant engineering challenge specific to sodium-ion systems. The higher internal resistance compared to lithium-ion batteries generates more heat during fast charging, potentially triggering thermal runaway events. Existing cooling systems designed for lithium-ion batteries require substantial redesign to accommodate the unique thermal characteristics of sodium-ion cells.

The lack of standardized testing protocols for sodium-ion fast charging further complicates development efforts. Without established benchmarks and safety parameters, researchers employ inconsistent methodologies, making cross-study comparisons difficult and slowing industry-wide progress. This absence of standardization also hinders regulatory approval processes for commercial applications.

Current battery management systems (BMS) lack sodium-ion-specific algorithms to optimize fast charging while maintaining safety margins. The distinct voltage profiles, temperature responses, and aging mechanisms of sodium-ion cells render lithium-ion BMS solutions inadequate, necessitating fundamental algorithm redesign based on sodium-ion electrochemistry.

Manufacturing scalability presents additional challenges, as existing production lines optimized for lithium-ion cells require significant modification to accommodate sodium-ion battery components while maintaining the precision necessary for fast-charging capabilities. The cost-performance balance remains unfavorable compared to established lithium-ion technologies, creating market entry barriers despite sodium's inherent cost advantages.

Current Fast Charging Protocol Solutions for Na-ion Batteries

01 Advanced charging protocols for sodium-ion batteries

Various charging protocols have been developed specifically for sodium-ion batteries to enable fast charging while maintaining battery life. These protocols typically involve multi-stage charging processes with controlled current and voltage profiles. By optimizing charging parameters such as current density, voltage limits, and charging time at different stages, these protocols can significantly reduce charging time while minimizing degradation mechanisms specific to sodium-ion chemistry.- Advanced charging protocols for sodium-ion batteries: Various charging protocols have been developed specifically for sodium-ion batteries to enable fast charging while maintaining battery life. These protocols include multi-stage charging methods that adjust current and voltage parameters during different charging phases. By implementing sophisticated charging algorithms that consider the unique electrochemical properties of sodium-ion batteries, these protocols can significantly reduce charging time while minimizing degradation mechanisms such as sodium plating and structural changes in electrode materials.

- Temperature-controlled fast charging strategies: Temperature management plays a crucial role in fast charging of sodium-ion batteries. These strategies involve monitoring and controlling the battery temperature during charging to optimize charging speed and safety. Some approaches include preheating the battery to an optimal temperature range before fast charging, active cooling systems during high-current charging phases, and temperature-dependent current modulation. These methods help prevent thermal runaway while allowing for higher charging rates than would otherwise be possible.

- Electrode material optimization for fast charging: The development of electrode materials specifically designed to support fast charging in sodium-ion batteries is critical. These materials feature enhanced sodium ion diffusion pathways, optimized particle sizes and morphologies, and structural stability under high current conditions. Novel anode and cathode materials with large interstitial spaces, high electronic conductivity, and minimal volume change during sodium insertion/extraction enable rapid charge transfer without significant degradation, thereby supporting fast charging protocols.

- Electrolyte formulations for rapid ion transport: Specialized electrolyte formulations have been developed to enhance sodium ion transport during fast charging. These electrolytes feature optimized salt concentrations, solvent mixtures, and additives that reduce interfacial resistance and improve ionic conductivity. Some formulations incorporate flame-retardant components to address safety concerns associated with fast charging. Advanced electrolytes also help form stable solid electrolyte interphase (SEI) layers that protect electrode surfaces during high-rate charging while facilitating rapid sodium ion movement.

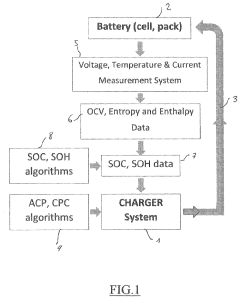

- Battery management systems for fast charging: Sophisticated battery management systems (BMS) have been designed specifically for sodium-ion batteries to enable safe and efficient fast charging. These systems incorporate real-time monitoring of cell voltage, current, and temperature, along with predictive models that estimate state of charge and state of health. Advanced BMS solutions use machine learning algorithms to continuously optimize charging parameters based on battery condition and usage patterns. They also implement safety protocols that can immediately adjust or terminate charging if abnormal conditions are detected.

02 Temperature-controlled fast charging strategies

Temperature management is crucial for fast charging of sodium-ion batteries. Advanced protocols incorporate temperature monitoring and control systems that adjust charging parameters based on battery temperature. These strategies often include preheating the battery to an optimal temperature range before fast charging and active cooling during the charging process to prevent overheating. By maintaining optimal temperature conditions, these protocols enable faster charging rates without compromising safety or cycle life.Expand Specific Solutions03 Electrode material optimization for fast charging

The development of specialized electrode materials is essential for enabling fast charging in sodium-ion batteries. Materials with enhanced sodium ion diffusion pathways, improved electrical conductivity, and structural stability under high current densities are particularly valuable. These materials include modified hard carbons, layered transition metal oxides, and various nanostructured composites that can accommodate rapid sodium ion insertion/extraction without significant structural degradation or capacity loss.Expand Specific Solutions04 Electrolyte formulations for rapid ion transport

Specialized electrolyte formulations play a critical role in enabling fast charging of sodium-ion batteries. These formulations typically include optimized salt concentrations, solvent mixtures, and additives that enhance sodium ion conductivity and reduce interfacial resistance. Some advanced electrolytes incorporate ionic liquids or solid-state components that improve ion transport kinetics while maintaining electrochemical stability at high charging rates, thereby facilitating faster charging without compromising safety.Expand Specific Solutions05 Battery management systems for optimized fast charging

Sophisticated battery management systems (BMS) are essential for implementing safe and efficient fast charging protocols for sodium-ion batteries. These systems employ real-time monitoring of cell parameters including voltage, current, temperature, and state of charge to dynamically adjust charging profiles. Advanced BMS may incorporate machine learning algorithms that adapt charging strategies based on battery aging, usage patterns, and environmental conditions, maximizing charging speed while preserving battery health and safety.Expand Specific Solutions

Leading Companies in Na-ion Battery Fast Charging Development

The sodium ion battery fast charging protocols market is in an early growth phase, characterized by increasing R&D investments as companies seek alternatives to lithium-ion technologies. The market is projected to expand significantly as sodium's abundance and lower cost drive adoption in grid storage and electric vehicles. Leading players demonstrate varying levels of technical maturity: StoreDot and CATL are pioneering commercial-ready solutions, while established automotive manufacturers like Toyota, Hyundai, and BMW are integrating these technologies into their electrification strategies. Research institutions like Southwest Research Institute and battery specialists including SK On and LG Energy Solution are advancing fundamental charging protocol innovations, creating a competitive landscape where collaboration between academic research and industrial application is accelerating technology development.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced fast charging protocol for sodium-ion batteries that utilizes a multi-stage charging approach. Their technology employs a variable current charging method that adapts to the battery's state of charge, applying higher currents during the initial charging phase and gradually reducing current as the battery approaches full capacity. This protocol incorporates real-time temperature monitoring and control systems to prevent overheating during rapid charging. CATL's approach includes proprietary electrolyte formulations specifically designed to enhance Na+ ion transport at interfaces, reducing the formation of solid-electrolyte interphase layers that typically impede fast charging. Their system also features advanced battery management algorithms that continuously optimize charging parameters based on battery health, temperature, and usage patterns to maximize both charging speed and battery longevity.

Strengths: Superior thermal management during fast charging, reducing degradation risks; integrated battery management system that adapts to battery aging; scalable technology applicable to various battery sizes. Weaknesses: Requires specialized charging infrastructure; potential higher manufacturing costs due to advanced materials; performance may vary significantly with ambient temperature conditions.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive fast charging protocol for sodium-ion batteries that focuses on electrode interface optimization. Their approach utilizes pulse charging techniques with variable frequency and amplitude to enhance ion diffusion rates at the electrode-electrolyte interface. The system incorporates predictive thermal modeling that anticipates temperature rises during fast charging and proactively adjusts charging parameters to prevent thermal runaway. Bosch's protocol employs a dual-layer electrode design that facilitates rapid sodium ion intercalation while minimizing structural stress. Their technology also features adaptive impedance matching that continuously optimizes the power delivery based on the battery's internal resistance changes during charging. This is complemented by a sophisticated battery management system that uses machine learning algorithms to predict optimal charging profiles based on battery age, temperature, and previous charging cycles.

Strengths: Highly adaptive charging profiles that maximize speed while preserving battery health; sophisticated thermal management system; integration with existing automotive electrical architectures. Weaknesses: Complex implementation requiring advanced control systems; higher initial development and integration costs; potential compatibility issues with some sodium-ion battery chemistries.

Key Patents and Research in Na-ion Fast Charging Mechanisms

A high-power density sodium-ion battery

PatentActiveIN201921007799A

Innovation

- A high-power density sodium-ion battery design featuring a carbon-coated Sodium Vanadium Phosphate cathode and a pre-treated anode with a tailored mass balance and porosity, along with a pre-alkalization/presodiation process to form a stable SEI, enabling charging at higher rates and extending cycle life to 5000 cycles.

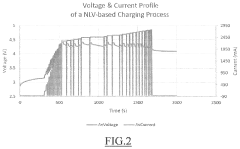

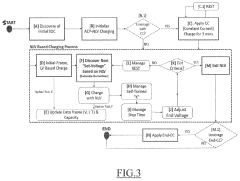

Adaptive charging protocol for fast charging of batteries and fast charging system implementing this protocol

PatentActiveUS20210167620A1

Innovation

- An adaptive charging protocol (ACP) that detects historical data and state of charge variations to optimize charging, using Non-Linear Voltammetry (NLV) and Inverse of Polarization (IP) methods, dynamically adjusting charging parameters to balance charging speed and safety, applicable to various battery types.

Safety Standards and Thermal Management Considerations

The rapid development of sodium-ion battery technology necessitates comprehensive safety standards and thermal management strategies, particularly for fast charging protocols. Current safety standards for lithium-ion batteries provide a foundation, but sodium-ion batteries present unique safety considerations that require specific regulatory frameworks. Organizations such as IEC, UL, and ISO are actively developing standards that address the distinct chemical properties and thermal behaviors of sodium-ion systems during fast charging operations.

Temperature control represents a critical challenge in fast charging protocols for sodium-ion batteries. During rapid charging, these batteries can experience significant temperature increases due to increased internal resistance and accelerated electrochemical reactions. Research indicates that sodium-ion cells typically operate optimally between 15-35°C, with performance degradation and safety risks emerging beyond this range. Fast charging protocols must therefore incorporate dynamic thermal management systems that can respond to temperature fluctuations in real-time.

Advanced cooling technologies are emerging as essential components for next-generation sodium-ion battery systems. These include phase change materials, liquid cooling circuits, and advanced heat sink designs specifically optimized for the thermal characteristics of sodium-ion chemistry. Computational fluid dynamics modeling suggests that sodium-ion batteries may require 15-20% greater cooling capacity during fast charging compared to equivalent lithium-ion systems due to differences in thermal conductivity and heat generation patterns.

Safety monitoring systems for fast-charging sodium-ion batteries must integrate multiple sensor types to track critical parameters. These include distributed temperature sensors, pressure monitors, and gas detection systems capable of identifying early warning signs of thermal runaway. Machine learning algorithms are increasingly being deployed to analyze sensor data patterns and predict potential safety issues before they manifest as dangerous conditions, enabling preemptive adjustments to charging protocols.

Cell design considerations significantly impact thermal management during fast charging. Recent innovations include thermally conductive electrode materials, optimized electrolyte formulations with flame-retardant additives, and novel cell geometries that facilitate more efficient heat dissipation. These design elements work synergistically with external thermal management systems to maintain safe operating conditions even under aggressive charging regimes.

Industry testing protocols are evolving to address the specific requirements of sodium-ion battery safety during fast charging. These include accelerated aging tests under various charging rates, thermal abuse testing, and nail penetration tests modified to account for the different failure modes of sodium-ion chemistry. Such comprehensive testing frameworks are essential for establishing reliable safety certifications for commercial deployment of fast-charging sodium-ion battery systems.

Temperature control represents a critical challenge in fast charging protocols for sodium-ion batteries. During rapid charging, these batteries can experience significant temperature increases due to increased internal resistance and accelerated electrochemical reactions. Research indicates that sodium-ion cells typically operate optimally between 15-35°C, with performance degradation and safety risks emerging beyond this range. Fast charging protocols must therefore incorporate dynamic thermal management systems that can respond to temperature fluctuations in real-time.

Advanced cooling technologies are emerging as essential components for next-generation sodium-ion battery systems. These include phase change materials, liquid cooling circuits, and advanced heat sink designs specifically optimized for the thermal characteristics of sodium-ion chemistry. Computational fluid dynamics modeling suggests that sodium-ion batteries may require 15-20% greater cooling capacity during fast charging compared to equivalent lithium-ion systems due to differences in thermal conductivity and heat generation patterns.

Safety monitoring systems for fast-charging sodium-ion batteries must integrate multiple sensor types to track critical parameters. These include distributed temperature sensors, pressure monitors, and gas detection systems capable of identifying early warning signs of thermal runaway. Machine learning algorithms are increasingly being deployed to analyze sensor data patterns and predict potential safety issues before they manifest as dangerous conditions, enabling preemptive adjustments to charging protocols.

Cell design considerations significantly impact thermal management during fast charging. Recent innovations include thermally conductive electrode materials, optimized electrolyte formulations with flame-retardant additives, and novel cell geometries that facilitate more efficient heat dissipation. These design elements work synergistically with external thermal management systems to maintain safe operating conditions even under aggressive charging regimes.

Industry testing protocols are evolving to address the specific requirements of sodium-ion battery safety during fast charging. These include accelerated aging tests under various charging rates, thermal abuse testing, and nail penetration tests modified to account for the different failure modes of sodium-ion chemistry. Such comprehensive testing frameworks are essential for establishing reliable safety certifications for commercial deployment of fast-charging sodium-ion battery systems.

Sustainability Impact and Resource Availability Analysis

The development of fast charging protocols for sodium-ion batteries presents significant sustainability advantages compared to conventional lithium-ion technology. Sodium resources are abundantly available in the earth's crust (2.6%) and oceans (1.1%), vastly exceeding lithium's global availability (0.002%). This abundance translates to lower extraction costs and reduced environmental impact, as sodium can be sourced from seawater through less invasive processes than lithium mining, which often requires extensive water usage and causes habitat disruption.

The carbon footprint analysis of sodium-ion battery manufacturing reveals approximately 20-30% lower greenhouse gas emissions compared to lithium-ion counterparts. This reduction stems primarily from simplified production processes and the elimination of cobalt and nickel in cathode materials, both of which present significant environmental and ethical concerns in their extraction. Fast charging protocols further enhance this sustainability profile by potentially extending battery lifespan through reduced degradation mechanisms.

Resource availability assessments indicate that sodium supply chains face significantly fewer geopolitical constraints than lithium. While over 80% of lithium production is concentrated in Australia, Chile, and China, sodium resources are geographically distributed more equitably across global regions. This distribution reduces supply chain vulnerabilities and promotes more stable pricing, which is crucial for widespread adoption of energy storage technologies.

Water consumption metrics for sodium extraction and processing show approximately 50-60% reduction compared to lithium production. This aspect is particularly significant in water-stressed regions where battery manufacturing facilities might be located. The development of fast charging protocols that utilize ambient temperature operation further reduces cooling requirements during charging, decreasing the overall water footprint of battery operation.

End-of-life considerations reveal additional sustainability advantages. Sodium-ion batteries contain fewer toxic materials than lithium-ion alternatives, simplifying recycling processes. Current research indicates recycling efficiency rates of up to 90% for sodium-ion batteries, compared to 50-70% for conventional lithium-ion technologies. Fast charging protocols that minimize degradation can extend useful life cycles, further improving lifecycle assessment metrics.

The transition to sodium-ion technology with advanced fast charging capabilities could potentially reduce critical material dependencies by eliminating the need for cobalt, nickel, and lithium. This shift aligns with circular economy principles and supports sustainable development goals related to responsible consumption and production, particularly SDG 12 and SDG 7 for affordable and clean energy.

The carbon footprint analysis of sodium-ion battery manufacturing reveals approximately 20-30% lower greenhouse gas emissions compared to lithium-ion counterparts. This reduction stems primarily from simplified production processes and the elimination of cobalt and nickel in cathode materials, both of which present significant environmental and ethical concerns in their extraction. Fast charging protocols further enhance this sustainability profile by potentially extending battery lifespan through reduced degradation mechanisms.

Resource availability assessments indicate that sodium supply chains face significantly fewer geopolitical constraints than lithium. While over 80% of lithium production is concentrated in Australia, Chile, and China, sodium resources are geographically distributed more equitably across global regions. This distribution reduces supply chain vulnerabilities and promotes more stable pricing, which is crucial for widespread adoption of energy storage technologies.

Water consumption metrics for sodium extraction and processing show approximately 50-60% reduction compared to lithium production. This aspect is particularly significant in water-stressed regions where battery manufacturing facilities might be located. The development of fast charging protocols that utilize ambient temperature operation further reduces cooling requirements during charging, decreasing the overall water footprint of battery operation.

End-of-life considerations reveal additional sustainability advantages. Sodium-ion batteries contain fewer toxic materials than lithium-ion alternatives, simplifying recycling processes. Current research indicates recycling efficiency rates of up to 90% for sodium-ion batteries, compared to 50-70% for conventional lithium-ion technologies. Fast charging protocols that minimize degradation can extend useful life cycles, further improving lifecycle assessment metrics.

The transition to sodium-ion technology with advanced fast charging capabilities could potentially reduce critical material dependencies by eliminating the need for cobalt, nickel, and lithium. This shift aligns with circular economy principles and supports sustainable development goals related to responsible consumption and production, particularly SDG 12 and SDG 7 for affordable and clean energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!