Optimization of fast charging protocols for solid state batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Fast Charging Background and Objectives

Solid-state batteries (SSBs) represent a significant evolution in energy storage technology, promising higher energy density, improved safety, and longer lifespan compared to conventional lithium-ion batteries with liquid electrolytes. The development of SSBs dates back to the 1970s, but recent advancements in materials science and manufacturing techniques have accelerated their progress toward commercial viability.

The evolution of fast charging capabilities for batteries has been driven by consumer demand for reduced charging times across various applications, from consumer electronics to electric vehicles. While conventional lithium-ion batteries have seen substantial improvements in charging speeds, solid-state batteries present both unique opportunities and challenges in this domain due to their distinct material properties and ion transport mechanisms.

Current fast charging protocols for liquid electrolyte batteries cannot be directly applied to solid-state systems due to fundamental differences in ion transport dynamics, interfacial phenomena, and thermal behavior. The solid electrolytes in SSBs typically exhibit lower ionic conductivity at room temperature compared to liquid counterparts, creating a significant barrier to achieving competitive charging rates.

Research trends indicate growing interest in tailored charging protocols specifically designed for the unique characteristics of solid-state batteries. These efforts focus on understanding and optimizing the complex interplay between applied current profiles, temperature management, and the structural integrity of solid electrolytes and interfaces during rapid charging cycles.

The primary technical objectives for optimizing fast charging protocols for solid-state batteries include: reducing charging times to under 15 minutes for 80% capacity without compromising cycle life; developing temperature-adaptive charging algorithms that account for the temperature-dependent ionic conductivity of solid electrolytes; minimizing interfacial resistance growth during repeated fast charging cycles; and establishing standardized testing methodologies specific to solid-state battery fast charging performance.

Additionally, researchers aim to understand and mitigate dendrite formation mechanisms under high-rate charging conditions, as these can compromise both performance and safety even in solid electrolyte systems. Computational modeling approaches are increasingly being employed to predict optimal charging profiles based on fundamental material properties and cell architectures.

The ultimate goal of this technical domain is to enable solid-state batteries that combine their inherent safety and energy density advantages with charging speeds that match or exceed those of advanced liquid-electrolyte systems, thereby removing one of the final barriers to their widespread commercial adoption across multiple industries, particularly in electric mobility applications.

The evolution of fast charging capabilities for batteries has been driven by consumer demand for reduced charging times across various applications, from consumer electronics to electric vehicles. While conventional lithium-ion batteries have seen substantial improvements in charging speeds, solid-state batteries present both unique opportunities and challenges in this domain due to their distinct material properties and ion transport mechanisms.

Current fast charging protocols for liquid electrolyte batteries cannot be directly applied to solid-state systems due to fundamental differences in ion transport dynamics, interfacial phenomena, and thermal behavior. The solid electrolytes in SSBs typically exhibit lower ionic conductivity at room temperature compared to liquid counterparts, creating a significant barrier to achieving competitive charging rates.

Research trends indicate growing interest in tailored charging protocols specifically designed for the unique characteristics of solid-state batteries. These efforts focus on understanding and optimizing the complex interplay between applied current profiles, temperature management, and the structural integrity of solid electrolytes and interfaces during rapid charging cycles.

The primary technical objectives for optimizing fast charging protocols for solid-state batteries include: reducing charging times to under 15 minutes for 80% capacity without compromising cycle life; developing temperature-adaptive charging algorithms that account for the temperature-dependent ionic conductivity of solid electrolytes; minimizing interfacial resistance growth during repeated fast charging cycles; and establishing standardized testing methodologies specific to solid-state battery fast charging performance.

Additionally, researchers aim to understand and mitigate dendrite formation mechanisms under high-rate charging conditions, as these can compromise both performance and safety even in solid electrolyte systems. Computational modeling approaches are increasingly being employed to predict optimal charging profiles based on fundamental material properties and cell architectures.

The ultimate goal of this technical domain is to enable solid-state batteries that combine their inherent safety and energy density advantages with charging speeds that match or exceed those of advanced liquid-electrolyte systems, thereby removing one of the final barriers to their widespread commercial adoption across multiple industries, particularly in electric mobility applications.

Market Analysis for Advanced Fast Charging Solutions

The global market for advanced fast charging solutions for solid-state batteries is experiencing unprecedented growth, driven by increasing adoption of electric vehicles (EVs) and consumer electronics. Current market valuations indicate that the fast charging segment for next-generation batteries reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 27% through 2030.

Consumer demand for reduced charging times represents the primary market driver, with surveys indicating that 78% of potential EV buyers consider charging speed a critical factor in purchase decisions. The psychological barrier of 15-minute full charging appears to be the benchmark that manufacturers are racing to achieve, as this approaches the convenience level of traditional refueling.

Automotive applications currently dominate the market landscape, accounting for 65% of demand for advanced fast charging solutions. However, consumer electronics manufacturers are rapidly increasing their market share, particularly as solid-state battery technology becomes more commercially viable in portable devices. The aerospace and defense sectors represent emerging niches with specialized requirements and premium pricing potential.

Geographically, East Asia leads manufacturing capacity for fast charging components, with Japan and South Korea holding significant intellectual property advantages. North America and Europe represent the largest consumer markets, with particularly strong growth in regions with established EV infrastructure. China merits special attention as both a manufacturing hub and rapidly expanding consumer market, with government initiatives actively promoting fast charging technology development.

Market segmentation reveals distinct consumer profiles: early adopters willing to pay premium prices for cutting-edge charging capabilities, mainstream consumers seeking balanced performance and cost, and commercial fleet operators prioritizing total cost of ownership calculations including charging infrastructure investments.

Competitive analysis indicates that traditional battery manufacturers are facing disruption from specialized solid-state battery startups, with several securing significant venture capital funding in the past 24 months. Major automotive OEMs are increasingly forming strategic partnerships and joint ventures focused specifically on fast charging protocol development, recognizing this as a key differentiator in consumer purchasing decisions.

Market barriers include concerns about battery degradation from repeated fast charging cycles, regulatory uncertainties regarding charging standards, and infrastructure limitations. However, these challenges are driving innovation in thermal management systems, battery management software, and materials science applications specifically targeting solid-state battery architectures.

Consumer demand for reduced charging times represents the primary market driver, with surveys indicating that 78% of potential EV buyers consider charging speed a critical factor in purchase decisions. The psychological barrier of 15-minute full charging appears to be the benchmark that manufacturers are racing to achieve, as this approaches the convenience level of traditional refueling.

Automotive applications currently dominate the market landscape, accounting for 65% of demand for advanced fast charging solutions. However, consumer electronics manufacturers are rapidly increasing their market share, particularly as solid-state battery technology becomes more commercially viable in portable devices. The aerospace and defense sectors represent emerging niches with specialized requirements and premium pricing potential.

Geographically, East Asia leads manufacturing capacity for fast charging components, with Japan and South Korea holding significant intellectual property advantages. North America and Europe represent the largest consumer markets, with particularly strong growth in regions with established EV infrastructure. China merits special attention as both a manufacturing hub and rapidly expanding consumer market, with government initiatives actively promoting fast charging technology development.

Market segmentation reveals distinct consumer profiles: early adopters willing to pay premium prices for cutting-edge charging capabilities, mainstream consumers seeking balanced performance and cost, and commercial fleet operators prioritizing total cost of ownership calculations including charging infrastructure investments.

Competitive analysis indicates that traditional battery manufacturers are facing disruption from specialized solid-state battery startups, with several securing significant venture capital funding in the past 24 months. Major automotive OEMs are increasingly forming strategic partnerships and joint ventures focused specifically on fast charging protocol development, recognizing this as a key differentiator in consumer purchasing decisions.

Market barriers include concerns about battery degradation from repeated fast charging cycles, regulatory uncertainties regarding charging standards, and infrastructure limitations. However, these challenges are driving innovation in thermal management systems, battery management software, and materials science applications specifically targeting solid-state battery architectures.

Current Limitations and Technical Barriers in SSB Fast Charging

Despite the promising advantages of solid-state batteries (SSBs) over conventional lithium-ion batteries, their fast charging capabilities face significant technical barriers. One of the primary limitations is the high interfacial resistance between the solid electrolyte and electrodes. Unlike liquid electrolytes that can easily conform to electrode surfaces, solid electrolytes create imperfect contact interfaces, resulting in increased resistance and hindered ion transport during high-rate charging processes.

The ionic conductivity of solid electrolytes, while improving, still lags behind that of liquid counterparts at room temperature. Most solid electrolytes achieve optimal conductivity only at elevated temperatures (60-80°C), creating a significant challenge for fast charging under ambient conditions. This temperature dependency necessitates complex thermal management systems that add weight, cost, and complexity to battery systems.

Mechanical stress during fast charging represents another critical barrier. The rapid lithium insertion/extraction during high-rate charging causes significant volume changes in electrode materials. In conventional batteries, liquid electrolytes can accommodate these changes, but solid electrolytes lack this flexibility, leading to contact loss, crack formation, and mechanical degradation at interfaces. These mechanical failures accelerate capacity fade and reduce cycle life, particularly under fast charging conditions.

Lithium dendrite formation remains problematic even in SSBs, contrary to early expectations. During fast charging, uneven lithium deposition can occur at the anode interface, creating pathways that can penetrate certain solid electrolytes. This phenomenon is exacerbated by local current density variations and defects at interfaces, presenting significant safety concerns even in supposedly dendrite-resistant systems.

The limited understanding of charge transfer kinetics at solid-solid interfaces presents both a scientific and engineering challenge. The mechanisms governing ion transport across these interfaces during high current operations are not fully characterized, making it difficult to design optimal fast charging protocols. Current models often fail to accurately predict performance under various charging conditions.

Manufacturing challenges further complicate fast charging optimization. Producing SSBs with consistent interfacial properties at scale remains difficult, resulting in cell-to-cell variations that make universal fast charging protocols ineffective. The lack of standardized production methods creates inconsistencies in electrochemical performance, particularly under high-rate operations.

Finally, diagnostic limitations hinder progress in this field. Real-time monitoring of internal processes during fast charging is challenging due to the solid nature of all components. Conventional electrochemical techniques provide limited insight into degradation mechanisms occurring at buried interfaces, making it difficult to develop targeted solutions for fast charging optimization.

The ionic conductivity of solid electrolytes, while improving, still lags behind that of liquid counterparts at room temperature. Most solid electrolytes achieve optimal conductivity only at elevated temperatures (60-80°C), creating a significant challenge for fast charging under ambient conditions. This temperature dependency necessitates complex thermal management systems that add weight, cost, and complexity to battery systems.

Mechanical stress during fast charging represents another critical barrier. The rapid lithium insertion/extraction during high-rate charging causes significant volume changes in electrode materials. In conventional batteries, liquid electrolytes can accommodate these changes, but solid electrolytes lack this flexibility, leading to contact loss, crack formation, and mechanical degradation at interfaces. These mechanical failures accelerate capacity fade and reduce cycle life, particularly under fast charging conditions.

Lithium dendrite formation remains problematic even in SSBs, contrary to early expectations. During fast charging, uneven lithium deposition can occur at the anode interface, creating pathways that can penetrate certain solid electrolytes. This phenomenon is exacerbated by local current density variations and defects at interfaces, presenting significant safety concerns even in supposedly dendrite-resistant systems.

The limited understanding of charge transfer kinetics at solid-solid interfaces presents both a scientific and engineering challenge. The mechanisms governing ion transport across these interfaces during high current operations are not fully characterized, making it difficult to design optimal fast charging protocols. Current models often fail to accurately predict performance under various charging conditions.

Manufacturing challenges further complicate fast charging optimization. Producing SSBs with consistent interfacial properties at scale remains difficult, resulting in cell-to-cell variations that make universal fast charging protocols ineffective. The lack of standardized production methods creates inconsistencies in electrochemical performance, particularly under high-rate operations.

Finally, diagnostic limitations hinder progress in this field. Real-time monitoring of internal processes during fast charging is challenging due to the solid nature of all components. Conventional electrochemical techniques provide limited insight into degradation mechanisms occurring at buried interfaces, making it difficult to develop targeted solutions for fast charging optimization.

Current Fast Charging Protocols and Methodologies for SSBs

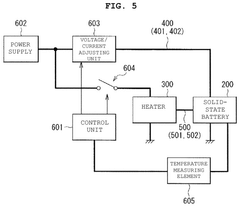

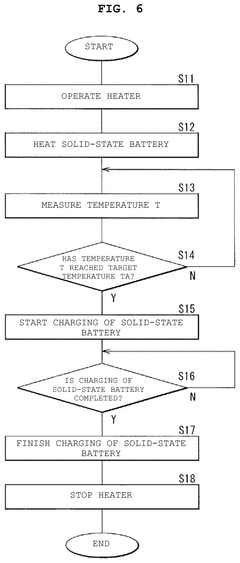

01 Temperature-controlled fast charging protocols for solid-state batteries

Temperature management is crucial for fast charging of solid-state batteries. These protocols monitor and control battery temperature during charging to prevent damage to the solid electrolyte interface and maintain battery integrity. Advanced thermal management systems can optimize charging rates based on real-time temperature data, allowing for maximum charging speed while preventing overheating that could lead to degradation of the solid electrolyte or electrode materials.- Temperature-controlled fast charging protocols for solid-state batteries: Temperature management is crucial for fast charging of solid-state batteries. These protocols monitor and control battery temperature during charging to prevent damage to the solid electrolyte interface and maintain battery integrity. Advanced thermal management systems can optimize charging rates based on real-time temperature data, allowing for maximum charging speed while preventing overheating that could lead to degradation of the solid electrolyte.

- Pulse charging techniques for solid-state batteries: Pulse charging applies intermittent current pulses rather than continuous current to solid-state batteries. This technique allows for faster ion movement through the solid electrolyte while providing relaxation periods that prevent dendrite formation and reduce internal resistance. The pulse parameters (amplitude, duration, frequency) can be dynamically adjusted based on the battery's state of charge and health to optimize charging speed and efficiency.

- Multi-stage charging algorithms for solid-state batteries: Multi-stage charging algorithms implement different charging rates at various states of charge to optimize the charging process for solid-state batteries. These protocols typically begin with a high-current constant current phase, followed by a constant voltage phase, and may include additional stages tailored to the specific chemistry of the solid electrolyte. This approach balances fast charging capabilities with battery longevity by adapting to the changing electrochemical behavior during the charging process.

- Adaptive charging systems with battery health monitoring: Adaptive charging systems continuously monitor battery health parameters and adjust charging protocols accordingly for solid-state batteries. These systems collect data on impedance, voltage response, and other electrochemical indicators to detect early signs of degradation or stress. Machine learning algorithms can analyze this data to optimize charging parameters in real-time, extending battery lifespan while maintaining fast charging capabilities by adapting to the unique characteristics of each battery.

- Interface engineering for improved fast charging: Interface engineering focuses on optimizing the contact between solid electrolytes and electrodes to enhance ion transport during fast charging. This approach involves developing specialized coatings, buffer layers, or dopants that reduce interfacial resistance and improve ion conductivity across material boundaries. By addressing the unique challenges of solid-state interfaces, these techniques enable higher charging currents without compromising safety or triggering degradation mechanisms that would otherwise limit charging speeds.

02 Pulse charging techniques for solid-state batteries

Pulse charging involves applying current in controlled pulses rather than continuously, which can enhance charging efficiency in solid-state batteries. This technique allows ions to redistribute within the solid electrolyte between pulses, reducing internal resistance and preventing dendrite formation. By optimizing pulse width, frequency, and amplitude, these protocols can significantly reduce charging time while extending battery lifespan and maintaining safety.Expand Specific Solutions03 Multi-stage charging algorithms for solid-state batteries

Multi-stage charging protocols implement different charging rates at various states of charge to optimize the charging process for solid-state batteries. These algorithms typically begin with a high-current phase for rapid initial charging, followed by progressively lower current stages as the battery approaches full capacity. This approach addresses the unique characteristics of solid electrolytes, which may have different ion transport properties at different charge states, enabling faster overall charging while preserving battery health.Expand Specific Solutions04 Interface management for fast charging of solid-state batteries

Managing the electrode-electrolyte interface is essential for enabling fast charging in solid-state batteries. These protocols focus on reducing interfacial resistance and preventing degradation during high-rate charging. Techniques include applying specific voltage profiles that minimize stress at the interfaces, controlling ion flux to prevent dendrite formation, and implementing strategies to maintain good contact between solid components during thermal expansion and contraction that occurs during fast charging cycles.Expand Specific Solutions05 Adaptive charging systems for solid-state batteries

Adaptive charging systems use real-time feedback from battery monitoring systems to dynamically adjust charging parameters for solid-state batteries. These intelligent protocols analyze multiple parameters including voltage, current, temperature, and internal resistance to optimize the charging process. Machine learning algorithms can be employed to predict battery behavior and adjust charging strategies accordingly, enabling faster charging while accounting for battery aging, environmental conditions, and variations in solid electrolyte properties.Expand Specific Solutions

Leading Companies and Research Institutions in SSB Charging

The solid-state battery fast charging optimization market is in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The global market is projected to expand rapidly as solid-state technology matures, driven by electric vehicle adoption and energy storage demands. Key players demonstrate varying technological maturity: established battery manufacturers like CATL, LG Energy Solution, and Samsung Electronics possess advanced research capabilities and manufacturing infrastructure, while specialized innovators such as StoreDot and Factorial focus on breakthrough charging protocols. Automotive companies including Tesla, BMW, and OPPO are actively developing proprietary solutions to gain competitive advantages. Academic-industry partnerships with institutions like Université Libre de Bruxelles and University of Michigan are accelerating innovation in this field, indicating a collaborative yet competitive landscape poised for significant advancement in the next 3-5 years.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered an advanced fast charging protocol for solid-state batteries centered around their "cell-to-pack" technology integration. Their approach utilizes a gradient charging methodology that applies varying current densities across different sections of the battery simultaneously, leveraging the higher thermal stability of solid electrolytes. The protocol incorporates real-time electrochemical impedance spectroscopy to monitor internal resistance changes during charging, allowing for precise current adjustments that prevent localized overheating and mechanical stress at the electrode-electrolyte interfaces. CATL's system employs proprietary algorithms that account for the unique ion transport mechanisms in solid electrolytes, enabling charging rates up to 3C while maintaining temperature gradients below critical thresholds. Their technology has demonstrated the ability to achieve 80% charge in approximately 20 minutes while preserving cycle life beyond 1200 cycles, representing a significant improvement over conventional liquid electrolyte systems.

Strengths: Excellent balance between charging speed and battery longevity; sophisticated thermal management integration; scalable implementation across various vehicle platforms. Weaknesses: Higher manufacturing complexity; requires specialized charging equipment; performance advantages diminish at extreme temperature conditions.

StoreDot Ltd.

Technical Solution: StoreDot has developed an innovative extreme fast charging (XFC) protocol specifically optimized for solid-state batteries incorporating their silicon-dominant anode technology. Their approach utilizes a proprietary "stress-relaxation" charging methodology that applies carefully timed current pulses interspersed with rest periods, allowing for controlled lithium-ion diffusion through the solid electrolyte while minimizing mechanical stress. The protocol employs advanced battery sensing technology that monitors minute changes in internal resistance and temperature distribution across the cell in real-time, enabling dynamic adjustment of charging parameters. StoreDot's system incorporates a multi-phase charging algorithm that begins with a specialized conditioning phase designed to optimize the solid-electrolyte interface before transitioning to higher power delivery phases. Their technology has demonstrated charging capabilities of up to 5C rates (achieving 80% charge in approximately 10 minutes) while maintaining over 1000 cycles before significant capacity degradation, representing a breakthrough in solid-state battery charging performance.

Strengths: Industry-leading charging speeds; proprietary silicon-dominant anode technology optimized for solid electrolytes; sophisticated battery health monitoring system. Weaknesses: Higher initial manufacturing costs; requires specialized charging infrastructure; potential challenges with scaling production to mass-market volumes.

Key Patents and Research on SSB Fast Charging Optimization

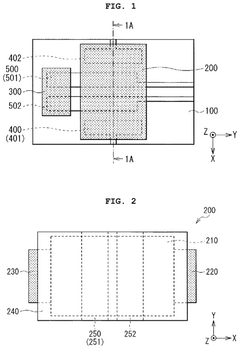

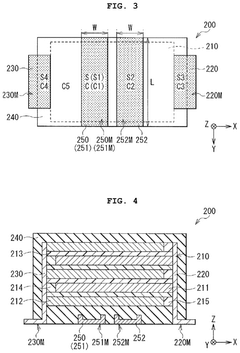

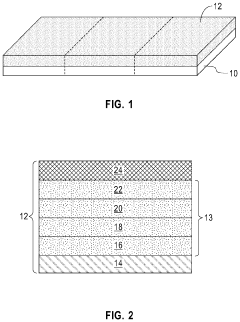

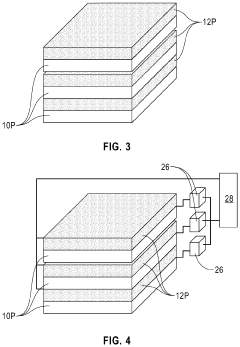

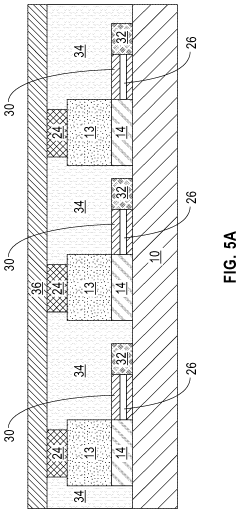

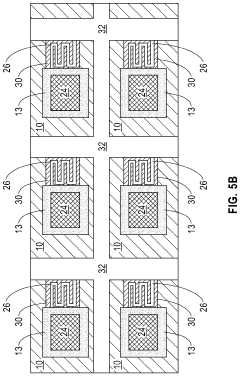

Solid-state battery having a heat receiving member embedded in an insulating coating, battery module, and charging method of solid-state battery

PatentActiveUS12119468B2

Innovation

- A solid-state battery configuration with alternating positive and negative electrode layers separated by solid electrolyte layers, a heat receiving member with higher thermal conductivity than the insulating coating, and a heating source thermally connected to the battery via a heat transfer member, allowing for controlled heating and charging based on temperature, heating time, charge rate, or voltage.

High charge rate, large capacity, solid-state battery

PatentActiveUS10673097B2

Innovation

- The development of solid-state battery structures featuring vertically stacked or arrayed thin-film batteries with fuse elements and via-filled contact structures, utilizing non-toxic materials and a solid-state electrolyte, to enhance charging speed and capacity beyond 3C and 1 Ah, respectively.

Thermal Management Strategies for SSB Fast Charging

Effective thermal management is critical for the successful implementation of fast charging protocols in solid-state batteries (SSBs). Unlike conventional lithium-ion batteries with liquid electrolytes that can dissipate heat more readily, SSBs face unique thermal challenges during rapid charging due to their solid-state architecture and different thermal conductivity properties.

Temperature distribution within SSBs during fast charging is often non-uniform, creating thermal gradients that can lead to mechanical stress, accelerated degradation, and reduced cycle life. Advanced thermal modeling techniques have been developed to predict these temperature profiles, enabling more precise thermal management system design. These models incorporate the anisotropic thermal conductivity characteristics of solid electrolytes and account for interfacial thermal resistance between battery components.

Active cooling systems represent a promising approach for SSB thermal management during fast charging. These systems utilize liquid cooling channels, thermoelectric coolers, or phase change materials strategically positioned to extract heat efficiently from critical battery regions. Recent innovations include microchannel cooling plates that can be integrated directly into battery modules, providing high cooling power density while minimizing additional weight and volume.

Passive thermal management strategies also play an important role, particularly in applications where system simplicity is valued. These include the incorporation of high thermal conductivity materials within battery components, optimized cell geometry to facilitate heat dissipation, and the use of thermally conductive adhesives at interfaces to reduce thermal bottlenecks. Some researchers have explored graphene-enhanced solid electrolytes that simultaneously improve ionic conductivity and thermal transport properties.

Adaptive thermal management systems that respond dynamically to changing conditions show particular promise for SSB fast charging. These systems utilize real-time temperature monitoring through embedded sensors and adjust cooling intensity based on charging state, ambient conditions, and battery temperature. Machine learning algorithms are increasingly being employed to predict thermal behavior and proactively adjust thermal management parameters before critical temperature thresholds are reached.

The integration of thermal management with battery management systems (BMS) represents the state-of-the-art approach. This holistic strategy enables charging protocols that are continuously optimized based on thermal feedback, ensuring maximum charging speed while maintaining safe operating temperatures. Such systems can implement variable charging current profiles that adapt to the thermal response of the battery, preventing localized hotspots while minimizing overall charging time.

Temperature distribution within SSBs during fast charging is often non-uniform, creating thermal gradients that can lead to mechanical stress, accelerated degradation, and reduced cycle life. Advanced thermal modeling techniques have been developed to predict these temperature profiles, enabling more precise thermal management system design. These models incorporate the anisotropic thermal conductivity characteristics of solid electrolytes and account for interfacial thermal resistance between battery components.

Active cooling systems represent a promising approach for SSB thermal management during fast charging. These systems utilize liquid cooling channels, thermoelectric coolers, or phase change materials strategically positioned to extract heat efficiently from critical battery regions. Recent innovations include microchannel cooling plates that can be integrated directly into battery modules, providing high cooling power density while minimizing additional weight and volume.

Passive thermal management strategies also play an important role, particularly in applications where system simplicity is valued. These include the incorporation of high thermal conductivity materials within battery components, optimized cell geometry to facilitate heat dissipation, and the use of thermally conductive adhesives at interfaces to reduce thermal bottlenecks. Some researchers have explored graphene-enhanced solid electrolytes that simultaneously improve ionic conductivity and thermal transport properties.

Adaptive thermal management systems that respond dynamically to changing conditions show particular promise for SSB fast charging. These systems utilize real-time temperature monitoring through embedded sensors and adjust cooling intensity based on charging state, ambient conditions, and battery temperature. Machine learning algorithms are increasingly being employed to predict thermal behavior and proactively adjust thermal management parameters before critical temperature thresholds are reached.

The integration of thermal management with battery management systems (BMS) represents the state-of-the-art approach. This holistic strategy enables charging protocols that are continuously optimized based on thermal feedback, ensuring maximum charging speed while maintaining safe operating temperatures. Such systems can implement variable charging current profiles that adapt to the thermal response of the battery, preventing localized hotspots while minimizing overall charging time.

Safety Standards and Certification Requirements for SSB Charging

The safety landscape for solid-state battery (SSB) fast charging protocols requires comprehensive standardization to ensure consumer protection and industry-wide adoption. Currently, international bodies such as IEC, ISO, and UL are developing specific standards for SSB charging, with IEC 62660-3 and ISO 6469-1 being adapted to address the unique characteristics of solid electrolytes. These standards focus on thermal runaway prevention, electrical safety parameters, and mechanical integrity during high-power charging scenarios.

Certification requirements for SSB fast charging systems are more stringent than those for conventional lithium-ion batteries due to the higher operating temperatures and voltage thresholds. Manufacturers must demonstrate compliance with thermal management specifications that account for the reduced thermal conductivity of solid electrolytes compared to liquid counterparts. Testing protocols typically include accelerated cycling under extreme charging conditions to verify long-term safety performance.

Regulatory frameworks across major markets show notable variations. The European Union, through its Battery Directive update, is implementing specific provisions for SSB charging infrastructure certification by 2025. Similarly, China's GB/T standards are being revised to incorporate SSB-specific safety parameters, while the United States relies on UL 1642 and UL 2580 adaptations pending specialized SSB standards development.

Risk assessment methodologies for SSB fast charging certification emphasize dendrite formation monitoring, interface stability verification, and pressure distribution analysis during rapid charging cycles. These assessments require specialized testing equipment capable of in-situ monitoring of solid-state interfaces under high current conditions. Certification bodies increasingly require real-time safety monitoring systems as part of the charging protocol design.

Insurance and liability considerations represent another critical dimension of SSB charging safety standards. Underwriters are developing specialized risk models for SSB technologies, with particular attention to fast charging scenarios where thermal gradients and mechanical stresses are maximized. These models inform both certification requirements and warranty structures for commercial SSB implementations.

The harmonization of global standards remains a significant challenge, with the International Electrotechnical Commission (IEC) leading efforts to establish a unified framework through its Technical Committee 21. Industry consortia such as the Solid-State Battery Consortium and the Global Battery Alliance are contributing to these standardization efforts by providing technical data from pre-commercial deployments and accelerated testing programs.

Certification requirements for SSB fast charging systems are more stringent than those for conventional lithium-ion batteries due to the higher operating temperatures and voltage thresholds. Manufacturers must demonstrate compliance with thermal management specifications that account for the reduced thermal conductivity of solid electrolytes compared to liquid counterparts. Testing protocols typically include accelerated cycling under extreme charging conditions to verify long-term safety performance.

Regulatory frameworks across major markets show notable variations. The European Union, through its Battery Directive update, is implementing specific provisions for SSB charging infrastructure certification by 2025. Similarly, China's GB/T standards are being revised to incorporate SSB-specific safety parameters, while the United States relies on UL 1642 and UL 2580 adaptations pending specialized SSB standards development.

Risk assessment methodologies for SSB fast charging certification emphasize dendrite formation monitoring, interface stability verification, and pressure distribution analysis during rapid charging cycles. These assessments require specialized testing equipment capable of in-situ monitoring of solid-state interfaces under high current conditions. Certification bodies increasingly require real-time safety monitoring systems as part of the charging protocol design.

Insurance and liability considerations represent another critical dimension of SSB charging safety standards. Underwriters are developing specialized risk models for SSB technologies, with particular attention to fast charging scenarios where thermal gradients and mechanical stresses are maximized. These models inform both certification requirements and warranty structures for commercial SSB implementations.

The harmonization of global standards remains a significant challenge, with the International Electrotechnical Commission (IEC) leading efforts to establish a unified framework through its Technical Committee 21. Industry consortia such as the Solid-State Battery Consortium and the Global Battery Alliance are contributing to these standardization efforts by providing technical data from pre-commercial deployments and accelerated testing programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!