HEV Ecosystem: Impact of Digital Twin Technologies

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV and Digital Twin Background

Hybrid Electric Vehicles (HEVs) represent a significant advancement in automotive technology, combining traditional internal combustion engines with electric propulsion systems. This innovative approach aims to improve fuel efficiency and reduce emissions while maintaining the range and convenience of conventional vehicles. HEVs have gained substantial market traction over the past two decades, evolving from niche products to mainstream offerings across various vehicle segments.

Concurrently, the concept of Digital Twins has emerged as a transformative technology in the realm of industrial and product design. A Digital Twin is a virtual representation of a physical object or system, continuously updated with real-time data to mirror its real-world counterpart. This technology enables enhanced monitoring, predictive maintenance, and optimization of complex systems throughout their lifecycle.

The convergence of HEV technology and Digital Twin concepts presents a compelling opportunity for the automotive industry. By creating digital replicas of HEV components and systems, manufacturers can gain unprecedented insights into vehicle performance, energy management, and overall efficiency. This integration allows for real-time monitoring of critical parameters such as battery health, powertrain efficiency, and energy flow between the electric and combustion systems.

The evolution of HEV technology has been marked by continuous improvements in battery capacity, power electronics, and energy management algorithms. Digital Twin technologies have similarly progressed, benefiting from advancements in sensors, data analytics, and cloud computing. The synergy between these two domains has the potential to accelerate innovation in vehicle design, manufacturing processes, and after-sales services.

As the automotive industry faces increasing pressure to reduce carbon emissions and improve sustainability, the HEV ecosystem, enhanced by Digital Twin technologies, offers a promising pathway. This combination enables more precise control over vehicle operations, optimizing the balance between electric and combustion power sources in real-time. Furthermore, it facilitates the development of predictive maintenance strategies, potentially extending the lifespan of HEV components and reducing overall environmental impact.

The integration of Digital Twins in the HEV ecosystem also aligns with broader trends in connected and autonomous vehicles. By leveraging real-time data and advanced analytics, manufacturers can create more intelligent and adaptive vehicle systems, paving the way for enhanced safety features, improved energy management, and a more personalized driving experience.

Concurrently, the concept of Digital Twins has emerged as a transformative technology in the realm of industrial and product design. A Digital Twin is a virtual representation of a physical object or system, continuously updated with real-time data to mirror its real-world counterpart. This technology enables enhanced monitoring, predictive maintenance, and optimization of complex systems throughout their lifecycle.

The convergence of HEV technology and Digital Twin concepts presents a compelling opportunity for the automotive industry. By creating digital replicas of HEV components and systems, manufacturers can gain unprecedented insights into vehicle performance, energy management, and overall efficiency. This integration allows for real-time monitoring of critical parameters such as battery health, powertrain efficiency, and energy flow between the electric and combustion systems.

The evolution of HEV technology has been marked by continuous improvements in battery capacity, power electronics, and energy management algorithms. Digital Twin technologies have similarly progressed, benefiting from advancements in sensors, data analytics, and cloud computing. The synergy between these two domains has the potential to accelerate innovation in vehicle design, manufacturing processes, and after-sales services.

As the automotive industry faces increasing pressure to reduce carbon emissions and improve sustainability, the HEV ecosystem, enhanced by Digital Twin technologies, offers a promising pathway. This combination enables more precise control over vehicle operations, optimizing the balance between electric and combustion power sources in real-time. Furthermore, it facilitates the development of predictive maintenance strategies, potentially extending the lifespan of HEV components and reducing overall environmental impact.

The integration of Digital Twins in the HEV ecosystem also aligns with broader trends in connected and autonomous vehicles. By leveraging real-time data and advanced analytics, manufacturers can create more intelligent and adaptive vehicle systems, paving the way for enhanced safety features, improved energy management, and a more personalized driving experience.

Market Demand for HEV Digital Twins

The market demand for digital twin technologies in the Hybrid Electric Vehicle (HEV) ecosystem is experiencing significant growth, driven by the automotive industry's push towards electrification and smart manufacturing. As HEVs become more complex and interconnected, digital twins offer a powerful tool for optimizing design, production, and maintenance processes.

In the design phase, digital twins enable manufacturers to create virtual prototypes of HEVs, allowing for extensive testing and simulation before physical production begins. This capability reduces development time and costs while improving the overall quality and performance of the final product. The demand for such tools is particularly high among major automotive manufacturers and their suppliers, who are constantly seeking ways to streamline their product development cycles.

During production, digital twins facilitate real-time monitoring and optimization of manufacturing processes. This is especially crucial for HEV production, where the integration of traditional combustion engines with electric powertrains requires precise coordination and quality control. The ability to simulate and optimize production lines virtually before implementation has led to increased demand from HEV manufacturers looking to enhance their operational efficiency and reduce production errors.

In the aftermarket and maintenance sector, digital twins are becoming increasingly valuable for predictive maintenance and performance optimization of HEVs. Fleet operators and service providers are showing growing interest in digital twin technologies that can monitor vehicle health, predict potential failures, and optimize maintenance schedules. This demand is driven by the need to maximize vehicle uptime and reduce operational costs associated with HEV fleets.

The market for HEV digital twins is also being propelled by the broader trend towards connected and autonomous vehicles. As HEVs incorporate more sensors and connectivity features, the volume of data generated creates new opportunities for digital twin applications. This data can be used to create highly accurate virtual models of individual vehicles, enabling personalized performance optimization and enhanced user experiences.

Government regulations and environmental concerns are further driving the demand for HEV digital twins. As emissions standards become stricter, manufacturers are turning to digital twin technologies to help optimize vehicle performance and reduce environmental impact. This includes simulating and fine-tuning hybrid powertrains to achieve the best balance between electric and combustion engine usage under various driving conditions.

The market demand is not limited to vehicle manufacturers alone. Suppliers of HEV components, such as battery manufacturers and electric motor producers, are also adopting digital twin technologies to improve their products and processes. This cascading effect is expanding the overall market for digital twins within the HEV ecosystem.

In the design phase, digital twins enable manufacturers to create virtual prototypes of HEVs, allowing for extensive testing and simulation before physical production begins. This capability reduces development time and costs while improving the overall quality and performance of the final product. The demand for such tools is particularly high among major automotive manufacturers and their suppliers, who are constantly seeking ways to streamline their product development cycles.

During production, digital twins facilitate real-time monitoring and optimization of manufacturing processes. This is especially crucial for HEV production, where the integration of traditional combustion engines with electric powertrains requires precise coordination and quality control. The ability to simulate and optimize production lines virtually before implementation has led to increased demand from HEV manufacturers looking to enhance their operational efficiency and reduce production errors.

In the aftermarket and maintenance sector, digital twins are becoming increasingly valuable for predictive maintenance and performance optimization of HEVs. Fleet operators and service providers are showing growing interest in digital twin technologies that can monitor vehicle health, predict potential failures, and optimize maintenance schedules. This demand is driven by the need to maximize vehicle uptime and reduce operational costs associated with HEV fleets.

The market for HEV digital twins is also being propelled by the broader trend towards connected and autonomous vehicles. As HEVs incorporate more sensors and connectivity features, the volume of data generated creates new opportunities for digital twin applications. This data can be used to create highly accurate virtual models of individual vehicles, enabling personalized performance optimization and enhanced user experiences.

Government regulations and environmental concerns are further driving the demand for HEV digital twins. As emissions standards become stricter, manufacturers are turning to digital twin technologies to help optimize vehicle performance and reduce environmental impact. This includes simulating and fine-tuning hybrid powertrains to achieve the best balance between electric and combustion engine usage under various driving conditions.

The market demand is not limited to vehicle manufacturers alone. Suppliers of HEV components, such as battery manufacturers and electric motor producers, are also adopting digital twin technologies to improve their products and processes. This cascading effect is expanding the overall market for digital twins within the HEV ecosystem.

Digital Twin Challenges in HEV Ecosystem

The implementation of digital twin technologies in the Hybrid Electric Vehicle (HEV) ecosystem presents several significant challenges that need to be addressed for successful integration and optimization. One of the primary obstacles is the complexity of data integration and synchronization across multiple systems within the HEV. The digital twin must accurately represent the physical vehicle, its powertrain components, and the intricate interactions between various subsystems, which requires seamless data flow and real-time updates.

Data security and privacy concerns pose another major challenge in the HEV digital twin ecosystem. As vehicles become more connected and data-driven, protecting sensitive information from cyber threats and unauthorized access becomes crucial. Ensuring robust encryption, secure communication protocols, and stringent access controls while maintaining the functionality and performance of the digital twin is a delicate balance to strike.

The scalability of digital twin solutions for HEVs is also a significant hurdle. As the number of vehicles and the complexity of simulations increase, the computational resources required to maintain and update digital twins in real-time grow exponentially. This scalability issue is further compounded by the need for edge computing capabilities to process data locally in vehicles, reducing latency and improving responsiveness.

Interoperability between different digital twin platforms, simulation tools, and vehicle systems presents another challenge. The HEV ecosystem involves multiple stakeholders, including manufacturers, suppliers, and service providers, each potentially using different technologies and standards. Establishing a common framework and protocols for seamless integration and data exchange is essential for the widespread adoption of digital twin technologies in the HEV sector.

The accuracy and fidelity of digital twin models are critical for their effectiveness in HEV applications. Developing high-fidelity models that can accurately predict vehicle performance, energy consumption, and component wear under various operating conditions is a complex task. It requires extensive validation and continuous refinement based on real-world data, which can be time-consuming and resource-intensive.

Furthermore, the dynamic nature of HEV technology poses a challenge for digital twin implementations. As new powertrain configurations, battery technologies, and control strategies emerge, digital twin models must be adaptable and easily updatable to reflect these advancements. This requires a flexible architecture and robust version control mechanisms to manage the evolution of digital twins over time.

Lastly, the integration of digital twin technologies with existing HEV development and manufacturing processes presents organizational and cultural challenges. It requires significant changes in workflows, skill sets, and decision-making processes. Overcoming resistance to change and fostering a data-driven culture across the entire HEV ecosystem is essential for realizing the full potential of digital twin technologies.

Data security and privacy concerns pose another major challenge in the HEV digital twin ecosystem. As vehicles become more connected and data-driven, protecting sensitive information from cyber threats and unauthorized access becomes crucial. Ensuring robust encryption, secure communication protocols, and stringent access controls while maintaining the functionality and performance of the digital twin is a delicate balance to strike.

The scalability of digital twin solutions for HEVs is also a significant hurdle. As the number of vehicles and the complexity of simulations increase, the computational resources required to maintain and update digital twins in real-time grow exponentially. This scalability issue is further compounded by the need for edge computing capabilities to process data locally in vehicles, reducing latency and improving responsiveness.

Interoperability between different digital twin platforms, simulation tools, and vehicle systems presents another challenge. The HEV ecosystem involves multiple stakeholders, including manufacturers, suppliers, and service providers, each potentially using different technologies and standards. Establishing a common framework and protocols for seamless integration and data exchange is essential for the widespread adoption of digital twin technologies in the HEV sector.

The accuracy and fidelity of digital twin models are critical for their effectiveness in HEV applications. Developing high-fidelity models that can accurately predict vehicle performance, energy consumption, and component wear under various operating conditions is a complex task. It requires extensive validation and continuous refinement based on real-world data, which can be time-consuming and resource-intensive.

Furthermore, the dynamic nature of HEV technology poses a challenge for digital twin implementations. As new powertrain configurations, battery technologies, and control strategies emerge, digital twin models must be adaptable and easily updatable to reflect these advancements. This requires a flexible architecture and robust version control mechanisms to manage the evolution of digital twins over time.

Lastly, the integration of digital twin technologies with existing HEV development and manufacturing processes presents organizational and cultural challenges. It requires significant changes in workflows, skill sets, and decision-making processes. Overcoming resistance to change and fostering a data-driven culture across the entire HEV ecosystem is essential for realizing the full potential of digital twin technologies.

Current HEV Digital Twin Solutions

01 Digital Twin Creation and Modeling

Digital twin technologies involve creating virtual representations of physical assets or systems. This includes developing detailed models that accurately reflect the real-world counterpart, incorporating data from sensors and other sources to maintain a real-time digital replica. These models can be used for simulation, analysis, and optimization of the physical asset's performance and behavior.- Digital Twin Creation and Modeling: Digital twin technologies involve creating virtual representations of physical assets or systems. This includes developing detailed models that accurately reflect the real-world counterpart, incorporating data from sensors and other sources to maintain a real-time digital replica. These models can be used for simulation, analysis, and optimization of the physical asset's performance and behavior.

- Data Integration and Real-time Monitoring: Digital twins rely on continuous data integration from various sources, including IoT sensors, historical databases, and real-time operational data. This allows for real-time monitoring of the physical asset's condition, performance, and environment. Advanced data processing techniques are used to analyze this information and provide actionable insights.

- Predictive Maintenance and Optimization: Digital twin technologies enable predictive maintenance by analyzing patterns and trends in the data collected from the physical asset. This allows for early detection of potential issues, optimizing maintenance schedules, and reducing downtime. Additionally, digital twins can be used to optimize operational parameters and processes, improving overall efficiency and performance.

- Simulation and Testing: Digital twins provide a platform for simulating various scenarios and testing different configurations without risking the physical asset. This capability is particularly valuable in product development, process optimization, and risk assessment. It allows for rapid prototyping, virtual commissioning, and performance evaluation under different conditions.

- Integration with AI and Machine Learning: Digital twin technologies are increasingly being integrated with artificial intelligence and machine learning algorithms. This combination enhances the predictive capabilities of digital twins, enabling more accurate forecasting, anomaly detection, and autonomous decision-making. It also facilitates the development of self-learning systems that can continuously improve their performance based on accumulated data and experiences.

02 Data Integration and Real-time Monitoring

Digital twins rely on continuous data integration from various sources, including IoT sensors, historical databases, and real-time monitoring systems. This allows for up-to-date representation of the physical asset's state and enables predictive maintenance, performance optimization, and anomaly detection. Advanced data processing techniques are employed to handle large volumes of data and extract meaningful insights.Expand Specific Solutions03 Simulation and Predictive Analytics

Digital twin technologies incorporate simulation capabilities to predict future states and behaviors of physical assets. This includes running various scenarios, testing different parameters, and forecasting outcomes. Machine learning and AI algorithms are often employed to enhance predictive capabilities, enabling proactive decision-making and risk management in complex systems.Expand Specific Solutions04 Visualization and User Interaction

Advanced visualization techniques are crucial in digital twin technologies, allowing users to interact with and manipulate the digital representation. This includes 3D modeling, augmented reality (AR), and virtual reality (VR) interfaces that provide intuitive ways to explore and analyze the digital twin. These visualization tools enhance understanding of complex systems and facilitate collaborative decision-making.Expand Specific Solutions05 Cross-domain Integration and Interoperability

Digital twin technologies often require integration across multiple domains and systems. This involves developing standardized protocols and interfaces to ensure interoperability between different digital twin models, as well as with existing enterprise systems. Cloud-based platforms and edge computing solutions are frequently employed to facilitate seamless data exchange and collaboration across various stakeholders and systems.Expand Specific Solutions

Key Players in HEV Digital Twin Market

The HEV Ecosystem and Digital Twin Technologies market is in a growth phase, with increasing adoption across the automotive industry. The market size is expanding rapidly as major players like Hyundai Motor, Kia, Ford, and Toyota invest heavily in digital twin solutions for hybrid electric vehicles. Technology maturity varies, with established automakers like Hyundai and Ford leading in implementation, while newer entrants like BYD are rapidly advancing their capabilities. Universities and research institutes such as Beihang University and Electronics & Telecommunications Research Institute are contributing to technological advancements. The competitive landscape is diverse, including traditional automakers, tech companies like Siemens and NTT, and specialized firms like Sensia, indicating a complex and evolving ecosystem.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive Digital Twin platform for their HEV ecosystem, focusing on holistic vehicle performance optimization and user experience enhancement. Their approach integrates advanced AI algorithms with real-time data from vehicle sensors to create dynamic digital representations of HEV systems. This enables precise simulation of vehicle behavior under various conditions, optimizing energy management strategies and powertrain efficiency. Hyundai's Digital Twin technology also facilitates predictive maintenance, reducing downtime and improving vehicle reliability. The company has implemented this technology in their design and production processes, creating virtual prototypes to accelerate development cycles and improve manufacturing efficiency [13][14]. Hyundai's Digital Twin platform also enables personalized driving experiences by analyzing individual driving patterns and adapting vehicle performance accordingly [15].

Strengths: Holistic approach to HEV ecosystem optimization. Strong focus on user experience and personalization. Weaknesses: Potential challenges in balancing complexity with user-friendliness.

Ford Global Technologies LLC

Technical Solution: Ford has developed a robust Digital Twin platform for their HEV ecosystem, focusing on real-time performance monitoring and optimization. Their approach leverages advanced sensor technology and edge computing to create accurate digital representations of HEV powertrains and components. This allows for continuous analysis of vehicle performance, enabling predictive maintenance and adaptive energy management strategies. Ford's Digital Twin technology also facilitates rapid prototyping and virtual testing of new HEV designs, significantly reducing development time and costs. The company has implemented this technology in their manufacturing processes, creating virtual replicas of production lines to enhance efficiency and quality control [7][8]. Ford's Digital Twin platform also enables personalized driving experiences by analyzing individual driving patterns and optimizing vehicle performance accordingly [9].

Strengths: Strong focus on real-time data analysis and personalization. Extensive integration with existing vehicle telematics systems. Weaknesses: Potential challenges in scaling the technology across diverse vehicle models and markets.

Core Digital Twin Technologies for HEVs

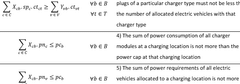

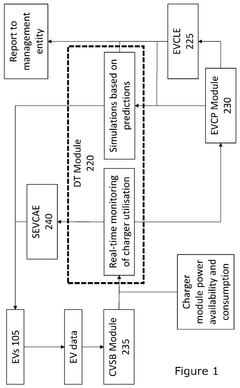

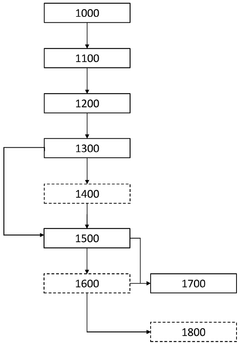

Electric vehicles platform for new charge infrastructure risk, tactical, and operational planning

PatentWO2025131518A1

Innovation

- A method utilizing a digital twin of the EV charging network to monitor and manage charger module utilization, predict future demands, simulate scenarios, and generate reports for optimized charger deployment and EV allocation, ensuring efficient power usage and minimizing risks like power crashes or shortages.

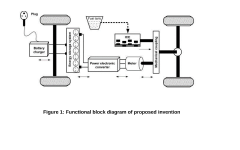

Hybrid electric vehicle with electric motor providing strategic power assist to load balance internal combustion engine

PatentPendingIN202441000035A

Innovation

- A Hybrid Electric Vehicle (HEV) system with an electric motor providing strategic power assist to the internal combustion engine, optimizing power distribution and energy management through advanced control algorithms.

Environmental Impact of HEV Digital Twins

The integration of digital twin technologies in the Hybrid Electric Vehicle (HEV) ecosystem has significant implications for environmental sustainability. By creating virtual replicas of physical HEVs, digital twins enable manufacturers and operators to optimize vehicle performance, reduce emissions, and enhance overall efficiency throughout the vehicle lifecycle.

One of the primary environmental benefits of HEV digital twins is the potential for improved energy management. Through real-time data collection and analysis, digital twins can optimize the interplay between electric and combustion power sources, maximizing fuel efficiency and minimizing emissions. This dynamic adjustment of power distribution can lead to substantial reductions in greenhouse gas emissions, particularly in urban environments where HEVs frequently switch between power modes.

Digital twins also contribute to more sustainable manufacturing processes for HEVs. By simulating production lines and supply chains, manufacturers can identify inefficiencies, reduce waste, and optimize resource utilization. This results in a lower environmental footprint during the production phase, aligning with circular economy principles and reducing the overall carbon footprint of HEV manufacturing.

In the realm of vehicle maintenance and longevity, digital twins play a crucial role in predictive maintenance strategies. By continuously monitoring vehicle components and systems, digital twins can predict potential failures before they occur, enabling proactive maintenance. This approach not only extends the lifespan of HEVs but also reduces the need for replacement parts and minimizes the environmental impact associated with vehicle repairs and premature replacements.

The application of digital twins in HEV battery management systems is particularly noteworthy from an environmental perspective. These virtual models can accurately predict battery degradation, optimize charging cycles, and extend battery life. This not only improves the overall efficiency of HEVs but also addresses one of the most significant environmental concerns associated with electric vehicles – battery lifecycle and disposal.

Furthermore, digital twins facilitate the development of more efficient recycling and end-of-life processes for HEVs. By providing detailed information about the composition and condition of vehicle components, digital twins enable more targeted and effective recycling strategies. This approach maximizes the recovery of valuable materials and minimizes waste, contributing to a more sustainable automotive ecosystem.

In urban planning and infrastructure development, HEV digital twins can inform the optimal placement of charging stations and the design of smart grid systems. This integration of vehicle data with urban infrastructure planning can lead to more efficient energy distribution and reduced environmental impact of HEV charging networks.

One of the primary environmental benefits of HEV digital twins is the potential for improved energy management. Through real-time data collection and analysis, digital twins can optimize the interplay between electric and combustion power sources, maximizing fuel efficiency and minimizing emissions. This dynamic adjustment of power distribution can lead to substantial reductions in greenhouse gas emissions, particularly in urban environments where HEVs frequently switch between power modes.

Digital twins also contribute to more sustainable manufacturing processes for HEVs. By simulating production lines and supply chains, manufacturers can identify inefficiencies, reduce waste, and optimize resource utilization. This results in a lower environmental footprint during the production phase, aligning with circular economy principles and reducing the overall carbon footprint of HEV manufacturing.

In the realm of vehicle maintenance and longevity, digital twins play a crucial role in predictive maintenance strategies. By continuously monitoring vehicle components and systems, digital twins can predict potential failures before they occur, enabling proactive maintenance. This approach not only extends the lifespan of HEVs but also reduces the need for replacement parts and minimizes the environmental impact associated with vehicle repairs and premature replacements.

The application of digital twins in HEV battery management systems is particularly noteworthy from an environmental perspective. These virtual models can accurately predict battery degradation, optimize charging cycles, and extend battery life. This not only improves the overall efficiency of HEVs but also addresses one of the most significant environmental concerns associated with electric vehicles – battery lifecycle and disposal.

Furthermore, digital twins facilitate the development of more efficient recycling and end-of-life processes for HEVs. By providing detailed information about the composition and condition of vehicle components, digital twins enable more targeted and effective recycling strategies. This approach maximizes the recovery of valuable materials and minimizes waste, contributing to a more sustainable automotive ecosystem.

In urban planning and infrastructure development, HEV digital twins can inform the optimal placement of charging stations and the design of smart grid systems. This integration of vehicle data with urban infrastructure planning can lead to more efficient energy distribution and reduced environmental impact of HEV charging networks.

HEV Digital Twin Data Security

Data security is a critical concern in the implementation of digital twin technologies for Hybrid Electric Vehicles (HEVs). As these virtual replicas collect, process, and analyze vast amounts of sensitive information, protecting this data from unauthorized access, breaches, and potential misuse becomes paramount.

The HEV digital twin ecosystem involves multiple stakeholders, including vehicle manufacturers, component suppliers, service providers, and end-users. Each entity contributes and accesses different levels of data, necessitating a robust security framework. This framework must address data encryption, access control, authentication mechanisms, and secure data transmission protocols.

One of the primary challenges in HEV digital twin data security is ensuring end-to-end protection throughout the data lifecycle. This includes safeguarding data during collection from various sensors and systems, secure transmission to cloud or edge computing platforms, protected storage, and controlled access for analysis and decision-making processes.

Implementing strong encryption algorithms is essential to protect data both at rest and in transit. Advanced encryption standards, such as AES-256, should be employed to secure sensitive information, including vehicle performance data, user behavior patterns, and proprietary algorithms used in the digital twin models.

Access control and authentication mechanisms play a crucial role in maintaining data integrity and confidentiality. Multi-factor authentication, role-based access control, and regular security audits should be implemented to ensure that only authorized personnel can access and manipulate the digital twin data.

Another critical aspect of HEV digital twin data security is the protection against cyber threats and attacks. As these systems become more interconnected and reliant on cloud infrastructure, they become potential targets for malicious actors. Implementing robust firewalls, intrusion detection systems, and regular security updates is essential to mitigate these risks.

Data privacy regulations, such as GDPR and CCPA, also play a significant role in shaping the security landscape for HEV digital twins. Compliance with these regulations requires careful consideration of data collection practices, storage duration, and user consent mechanisms. Implementing privacy-by-design principles in the development of digital twin systems can help address these regulatory requirements.

As the HEV ecosystem continues to evolve, emerging technologies like blockchain and federated learning present new opportunities for enhancing data security. Blockchain can provide immutable records of data transactions and access logs, while federated learning allows for collaborative model training without sharing raw data, thereby reducing the risk of data breaches.

The HEV digital twin ecosystem involves multiple stakeholders, including vehicle manufacturers, component suppliers, service providers, and end-users. Each entity contributes and accesses different levels of data, necessitating a robust security framework. This framework must address data encryption, access control, authentication mechanisms, and secure data transmission protocols.

One of the primary challenges in HEV digital twin data security is ensuring end-to-end protection throughout the data lifecycle. This includes safeguarding data during collection from various sensors and systems, secure transmission to cloud or edge computing platforms, protected storage, and controlled access for analysis and decision-making processes.

Implementing strong encryption algorithms is essential to protect data both at rest and in transit. Advanced encryption standards, such as AES-256, should be employed to secure sensitive information, including vehicle performance data, user behavior patterns, and proprietary algorithms used in the digital twin models.

Access control and authentication mechanisms play a crucial role in maintaining data integrity and confidentiality. Multi-factor authentication, role-based access control, and regular security audits should be implemented to ensure that only authorized personnel can access and manipulate the digital twin data.

Another critical aspect of HEV digital twin data security is the protection against cyber threats and attacks. As these systems become more interconnected and reliant on cloud infrastructure, they become potential targets for malicious actors. Implementing robust firewalls, intrusion detection systems, and regular security updates is essential to mitigate these risks.

Data privacy regulations, such as GDPR and CCPA, also play a significant role in shaping the security landscape for HEV digital twins. Compliance with these regulations requires careful consideration of data collection practices, storage duration, and user consent mechanisms. Implementing privacy-by-design principles in the development of digital twin systems can help address these regulatory requirements.

As the HEV ecosystem continues to evolve, emerging technologies like blockchain and federated learning present new opportunities for enhancing data security. Blockchain can provide immutable records of data transactions and access logs, while federated learning allows for collaborative model training without sharing raw data, thereby reducing the risk of data breaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!