How to Enhance HEV Powertrain Integration?

AUG 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Powertrain Evolution

The evolution of Hybrid Electric Vehicle (HEV) powertrains has been a journey of continuous innovation and refinement. Initially, HEV powertrains were simple parallel configurations, combining an internal combustion engine (ICE) with an electric motor. This basic setup allowed for improved fuel efficiency and reduced emissions compared to conventional vehicles.

As technology advanced, more sophisticated powertrain architectures emerged. Series-parallel hybrid systems, such as Toyota's Hybrid Synergy Drive, became popular. These systems offered greater flexibility in power distribution between the ICE and electric motor, leading to improved overall efficiency and performance.

The next significant step in HEV powertrain evolution was the introduction of plug-in hybrid electric vehicles (PHEVs). This technology allowed for extended electric-only driving ranges and further reduced reliance on fossil fuels. PHEVs represented a bridge between traditional hybrids and fully electric vehicles, offering consumers the benefits of both technologies.

Recent years have seen a focus on optimizing power electronics and control systems. Advanced power inverters and DC-DC converters have improved energy conversion efficiency, while sophisticated control algorithms have enhanced the coordination between the ICE and electric motor. These developments have led to smoother power delivery and improved fuel economy.

Battery technology has also played a crucial role in HEV powertrain evolution. The shift from nickel-metal hydride (NiMH) to lithium-ion batteries has resulted in increased energy density, faster charging times, and longer battery life. This has enabled automakers to reduce the size and weight of battery packs while improving vehicle performance and range.

Integration of regenerative braking systems has become more refined, capturing a higher percentage of kinetic energy during deceleration and converting it into usable electrical energy. This has further improved overall system efficiency and extended the electric-only driving range of HEVs.

The latest trend in HEV powertrain evolution is the development of modular and scalable architectures. These designs allow automakers to easily adapt their hybrid systems across different vehicle models and sizes, reducing development costs and time-to-market. Additionally, the integration of artificial intelligence and machine learning algorithms is enabling more predictive and adaptive energy management strategies, further optimizing powertrain performance based on driving conditions and patterns.

As HEV powertrains continue to evolve, the focus is shifting towards seamless integration with advanced driver assistance systems (ADAS) and connected vehicle technologies. This integration aims to create more intelligent and efficient powertrains that can anticipate and respond to traffic conditions, road topography, and even weather patterns to maximize energy efficiency and performance.

As technology advanced, more sophisticated powertrain architectures emerged. Series-parallel hybrid systems, such as Toyota's Hybrid Synergy Drive, became popular. These systems offered greater flexibility in power distribution between the ICE and electric motor, leading to improved overall efficiency and performance.

The next significant step in HEV powertrain evolution was the introduction of plug-in hybrid electric vehicles (PHEVs). This technology allowed for extended electric-only driving ranges and further reduced reliance on fossil fuels. PHEVs represented a bridge between traditional hybrids and fully electric vehicles, offering consumers the benefits of both technologies.

Recent years have seen a focus on optimizing power electronics and control systems. Advanced power inverters and DC-DC converters have improved energy conversion efficiency, while sophisticated control algorithms have enhanced the coordination between the ICE and electric motor. These developments have led to smoother power delivery and improved fuel economy.

Battery technology has also played a crucial role in HEV powertrain evolution. The shift from nickel-metal hydride (NiMH) to lithium-ion batteries has resulted in increased energy density, faster charging times, and longer battery life. This has enabled automakers to reduce the size and weight of battery packs while improving vehicle performance and range.

Integration of regenerative braking systems has become more refined, capturing a higher percentage of kinetic energy during deceleration and converting it into usable electrical energy. This has further improved overall system efficiency and extended the electric-only driving range of HEVs.

The latest trend in HEV powertrain evolution is the development of modular and scalable architectures. These designs allow automakers to easily adapt their hybrid systems across different vehicle models and sizes, reducing development costs and time-to-market. Additionally, the integration of artificial intelligence and machine learning algorithms is enabling more predictive and adaptive energy management strategies, further optimizing powertrain performance based on driving conditions and patterns.

As HEV powertrains continue to evolve, the focus is shifting towards seamless integration with advanced driver assistance systems (ADAS) and connected vehicle technologies. This integration aims to create more intelligent and efficient powertrains that can anticipate and respond to traffic conditions, road topography, and even weather patterns to maximize energy efficiency and performance.

Market Demand Analysis

The market demand for enhanced HEV powertrain integration is driven by several key factors, including stringent emissions regulations, consumer preferences for fuel efficiency, and the automotive industry's push towards electrification. As governments worldwide implement stricter CO2 emission standards, automakers are increasingly turning to hybrid electric vehicles (HEVs) as a transitional technology between conventional internal combustion engines and fully electric vehicles.

The global HEV market has been experiencing significant growth, with a compound annual growth rate (CAGR) projected to exceed 8% between 2021 and 2026. This growth is particularly strong in regions with supportive policies and incentives for low-emission vehicles, such as Europe, China, and Japan. In these markets, consumers are showing a growing preference for vehicles that offer improved fuel economy without the range anxiety associated with pure electric vehicles.

Automotive manufacturers are responding to this demand by expanding their HEV product lines and investing heavily in powertrain integration technologies. The focus is on developing more efficient, compact, and cost-effective hybrid systems that can be easily integrated into various vehicle platforms. This trend is evident in the increasing number of HEV models being introduced across different vehicle segments, from compact cars to SUVs and even light commercial vehicles.

One of the primary drivers for enhanced powertrain integration is the need to optimize the overall vehicle performance while minimizing additional costs. Consumers expect HEVs to deliver improved fuel efficiency and reduced emissions without compromising on driving dynamics or interior space. This has led to a growing demand for more sophisticated powertrain control systems, advanced power electronics, and innovative packaging solutions that can seamlessly integrate electric motors, batteries, and internal combustion engines.

The market is also seeing increased demand for plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving ranges. This segment is particularly attractive to consumers who want the flexibility of both electric and conventional driving modes. As a result, there is a strong market pull for powertrain integration solutions that can effectively manage the complexities of dual power sources and optimize their operation based on driving conditions and user preferences.

Furthermore, the automotive supply chain is adapting to meet the growing demand for HEV components and systems. Tier 1 suppliers are investing in research and development to provide more integrated powertrain solutions, while new players are entering the market with innovative technologies. This competitive landscape is driving innovation and cost reduction in HEV powertrain integration, making hybrid vehicles more accessible to a broader range of consumers.

In conclusion, the market demand for enhanced HEV powertrain integration is robust and growing, driven by regulatory pressures, consumer preferences, and industry competition. As the technology continues to evolve, we can expect to see further innovations in powertrain integration that will improve the performance, efficiency, and affordability of hybrid electric vehicles.

The global HEV market has been experiencing significant growth, with a compound annual growth rate (CAGR) projected to exceed 8% between 2021 and 2026. This growth is particularly strong in regions with supportive policies and incentives for low-emission vehicles, such as Europe, China, and Japan. In these markets, consumers are showing a growing preference for vehicles that offer improved fuel economy without the range anxiety associated with pure electric vehicles.

Automotive manufacturers are responding to this demand by expanding their HEV product lines and investing heavily in powertrain integration technologies. The focus is on developing more efficient, compact, and cost-effective hybrid systems that can be easily integrated into various vehicle platforms. This trend is evident in the increasing number of HEV models being introduced across different vehicle segments, from compact cars to SUVs and even light commercial vehicles.

One of the primary drivers for enhanced powertrain integration is the need to optimize the overall vehicle performance while minimizing additional costs. Consumers expect HEVs to deliver improved fuel efficiency and reduced emissions without compromising on driving dynamics or interior space. This has led to a growing demand for more sophisticated powertrain control systems, advanced power electronics, and innovative packaging solutions that can seamlessly integrate electric motors, batteries, and internal combustion engines.

The market is also seeing increased demand for plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving ranges. This segment is particularly attractive to consumers who want the flexibility of both electric and conventional driving modes. As a result, there is a strong market pull for powertrain integration solutions that can effectively manage the complexities of dual power sources and optimize their operation based on driving conditions and user preferences.

Furthermore, the automotive supply chain is adapting to meet the growing demand for HEV components and systems. Tier 1 suppliers are investing in research and development to provide more integrated powertrain solutions, while new players are entering the market with innovative technologies. This competitive landscape is driving innovation and cost reduction in HEV powertrain integration, making hybrid vehicles more accessible to a broader range of consumers.

In conclusion, the market demand for enhanced HEV powertrain integration is robust and growing, driven by regulatory pressures, consumer preferences, and industry competition. As the technology continues to evolve, we can expect to see further innovations in powertrain integration that will improve the performance, efficiency, and affordability of hybrid electric vehicles.

Integration Challenges

The integration of hybrid electric vehicle (HEV) powertrains presents several significant challenges that must be addressed to enhance overall system performance and efficiency. One of the primary obstacles is the complex coordination between multiple power sources, including the internal combustion engine, electric motor, and battery pack. Achieving seamless power delivery and optimal energy management requires sophisticated control algorithms and advanced electronic control units (ECUs) capable of real-time decision-making.

Space constraints within the vehicle pose another critical challenge. The addition of electric components, such as motors, batteries, and power electronics, demands innovative packaging solutions to maintain vehicle ergonomics and safety standards. Engineers must optimize the layout of these components while considering factors like weight distribution, thermal management, and accessibility for maintenance.

Thermal management is a crucial aspect of HEV powertrain integration. The diverse operating temperatures of various components necessitate an integrated cooling system that can efficiently regulate temperatures across the entire powertrain. This system must account for the heat generated by the internal combustion engine, electric motor, power electronics, and battery pack, while minimizing energy consumption and maintaining optimal performance.

The integration of regenerative braking systems with traditional friction brakes presents another challenge. Balancing the distribution of braking force between these two systems requires precise control to maximize energy recovery without compromising vehicle stability or driver comfort. This integration must also comply with safety regulations and provide consistent brake feel under various driving conditions.

Electromagnetic compatibility (EMC) is a significant concern in HEV powertrain integration. The high-voltage electrical systems and power electronics can generate electromagnetic interference, potentially affecting other vehicle systems and nearby electronic devices. Shielding and isolation techniques must be implemented to ensure the reliable operation of all vehicle components and compliance with EMC regulations.

Cost optimization remains a persistent challenge in HEV powertrain integration. The addition of electric components increases the overall system complexity and manufacturing costs. Striking a balance between performance, efficiency, and affordability requires careful component selection, design optimization, and consideration of economies of scale in production.

Lastly, the integration of HEV powertrains must address the challenge of serviceability and maintenance. The complex nature of these systems demands specialized diagnostic tools, training for service technicians, and considerations for component accessibility. Designing for ease of maintenance and repair is crucial to ensure the long-term viability and customer acceptance of HEV technologies.

Space constraints within the vehicle pose another critical challenge. The addition of electric components, such as motors, batteries, and power electronics, demands innovative packaging solutions to maintain vehicle ergonomics and safety standards. Engineers must optimize the layout of these components while considering factors like weight distribution, thermal management, and accessibility for maintenance.

Thermal management is a crucial aspect of HEV powertrain integration. The diverse operating temperatures of various components necessitate an integrated cooling system that can efficiently regulate temperatures across the entire powertrain. This system must account for the heat generated by the internal combustion engine, electric motor, power electronics, and battery pack, while minimizing energy consumption and maintaining optimal performance.

The integration of regenerative braking systems with traditional friction brakes presents another challenge. Balancing the distribution of braking force between these two systems requires precise control to maximize energy recovery without compromising vehicle stability or driver comfort. This integration must also comply with safety regulations and provide consistent brake feel under various driving conditions.

Electromagnetic compatibility (EMC) is a significant concern in HEV powertrain integration. The high-voltage electrical systems and power electronics can generate electromagnetic interference, potentially affecting other vehicle systems and nearby electronic devices. Shielding and isolation techniques must be implemented to ensure the reliable operation of all vehicle components and compliance with EMC regulations.

Cost optimization remains a persistent challenge in HEV powertrain integration. The addition of electric components increases the overall system complexity and manufacturing costs. Striking a balance between performance, efficiency, and affordability requires careful component selection, design optimization, and consideration of economies of scale in production.

Lastly, the integration of HEV powertrains must address the challenge of serviceability and maintenance. The complex nature of these systems demands specialized diagnostic tools, training for service technicians, and considerations for component accessibility. Designing for ease of maintenance and repair is crucial to ensure the long-term viability and customer acceptance of HEV technologies.

Current Integration Solutions

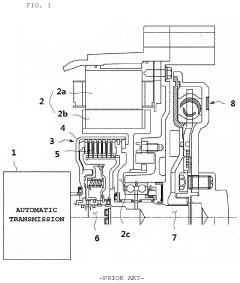

01 Integration of electric and combustion powertrains

HEV powertrain integration involves combining electric motors with internal combustion engines to create a hybrid system. This integration aims to improve fuel efficiency and reduce emissions while maintaining performance. The system typically includes power electronics, battery management, and control strategies to optimize the interaction between the two power sources.- Electric motor integration in HEV powertrains: Integration of electric motors into hybrid electric vehicle (HEV) powertrains, focusing on optimal placement and coupling with internal combustion engines. This includes strategies for power distribution, torque management, and efficiency optimization between the electric motor and conventional engine.

- Battery management and energy storage systems: Development of advanced battery management systems and energy storage solutions for HEVs. This encompasses battery pack design, thermal management, state-of-charge monitoring, and integration with the vehicle's power electronics to ensure efficient energy utilization and extended battery life.

- Power electronics and control systems: Design and integration of power electronics and control systems for HEV powertrains. This includes inverters, converters, and sophisticated control algorithms to manage power flow between different components of the hybrid system, ensuring smooth operation and optimal performance.

- Transmission and drivetrain integration: Innovative approaches to integrating hybrid powertrains with vehicle transmissions and drivetrains. This involves developing specialized gearboxes, clutch systems, and power split devices to effectively combine power from electric motors and internal combustion engines for improved efficiency and performance.

- Thermal management and cooling systems: Development of advanced thermal management and cooling systems for HEV powertrains. This includes strategies for managing heat generated by electric motors, batteries, and power electronics, as well as integrating these systems with the vehicle's overall thermal management to ensure optimal performance and longevity of components.

02 Power management and control systems

Advanced control systems are crucial for efficient HEV powertrain integration. These systems manage power distribution between the electric motor and combustion engine, optimize energy recuperation during braking, and control battery charging. Sophisticated algorithms and sensors are used to ensure seamless operation and maximize overall system efficiency.Expand Specific Solutions03 Thermal management in HEV powertrains

Effective thermal management is essential in HEV powertrain integration to maintain optimal operating temperatures for both the electric and combustion components. This includes cooling systems for batteries, power electronics, and electric motors, as well as managing heat dissipation from the internal combustion engine to improve overall efficiency and component longevity.Expand Specific Solutions04 Transmission and drivetrain integration

HEV powertrain integration involves designing specialized transmissions and drivetrains that can effectively manage power from both electric and combustion sources. This may include the development of hybrid-specific gearboxes, clutch systems, and power split devices to optimize power delivery and efficiency across various driving conditions.Expand Specific Solutions05 Lightweight materials and packaging optimization

To offset the additional weight of batteries and electric components in HEVs, lightweight materials and optimized packaging solutions are crucial. This includes the use of advanced composites, high-strength alloys, and innovative design strategies to integrate powertrain components efficiently within the vehicle architecture, minimizing weight and maximizing space utilization.Expand Specific Solutions

Key Industry Players

The competition landscape for enhancing HEV powertrain integration is characterized by a mature market with significant growth potential. Major players like Ford, BYD, Hyundai, and Toyota are investing heavily in this technology, reflecting its strategic importance. The market is experiencing rapid expansion due to increasing demand for fuel-efficient vehicles and stricter emissions regulations. Technologically, the field is advancing quickly, with companies like Cummins and Vitesco Technologies pushing boundaries in electrification and system integration. Universities such as Tsinghua and Zhejiang are contributing to R&D efforts, fostering innovation. As the industry moves towards more sophisticated hybrid systems, collaboration between automakers, suppliers, and research institutions is becoming increasingly crucial for success in this competitive arena.

BYD Co., Ltd.

Technical Solution: BYD's approach to HEV powertrain integration is centered around their DM-i (Dual Mode Intelligent) hybrid system. This system utilizes a highly efficient Blade Battery, which offers improved energy density and safety compared to traditional lithium-ion batteries[10]. BYD's hybrid powertrain incorporates a small displacement, high-efficiency engine specifically designed for hybrid applications, coupled with an advanced electric drive system. The DM-i system can achieve fuel consumption as low as 3.8L/100km, with the ability to operate in pure electric mode for short distances[11]. BYD has also developed an intelligent power distribution system that optimizes energy flow between the engine, battery, and electric motors based on driving conditions and battery state of charge[12].

Strengths: Advanced battery technology, high system efficiency, and strong integration of electric and combustion components. Weaknesses: Limited global market presence compared to some competitors and potential concerns about long-term reliability in diverse markets.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's strategy for enhancing HEV powertrain integration focuses on their Active Shift Control (ASC) technology and modular hybrid transmission systems. ASC uses the electric motor to precisely control transmission shaft rotation speed, reducing gear shift times by 30% and improving acceleration and fuel economy[7]. Hyundai has also developed a Continuously Variable Valve Duration (CVVD) engine technology that optimizes valve timing for different driving conditions, improving fuel efficiency by 5% and emissions performance by 12%[8]. Their latest HEV powertrains incorporate a compact 6-speed hybrid transmission that integrates the electric motor, allowing for a more streamlined powertrain package and improved packaging efficiency[9].

Strengths: Innovative transmission control technology, improved shift quality, and compact powertrain design. Weaknesses: Relatively newer to the HEV market compared to some competitors, potentially leading to less real-world data on long-term reliability.

Core Innovations

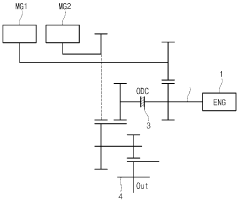

Powertrain of hybrid electric vehicle

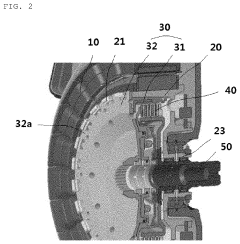

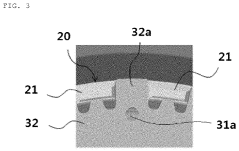

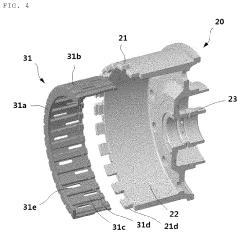

PatentInactiveUS20200025257A1

Innovation

- A powertrain design featuring a sleeve drum with equidistantly spaced protrusions and corresponding insertion grooves, integrated with a retainer cover, manufactured through flow-forming forging, to ensure close contact and prevent rattling noise by attenuating vibrations through inertia.

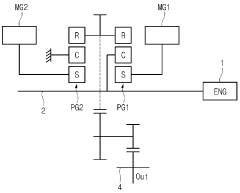

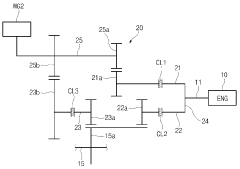

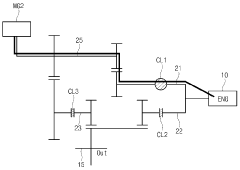

Hybrid powertrain

PatentActiveKR1020160063037A

Innovation

- A driving device for a hybrid vehicle with a transmission mechanism incorporating multiple clutches and power transmission units, allowing for high-efficiency EV, parallel HEV, serial, and direct connection modes by selectively engaging and releasing clutches to optimize power distribution between the engine and motor.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and integration of Hybrid Electric Vehicle (HEV) powertrains. As governments worldwide strive to reduce greenhouse gas emissions and improve air quality, automotive manufacturers face increasingly stringent standards for vehicle emissions. These regulations have become a primary driver for enhancing HEV powertrain integration, pushing the industry towards more efficient and cleaner technologies.

The evolution of emissions standards has been marked by progressively tighter limits on pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. In the European Union, the introduction of Euro 6d standards has set new benchmarks for vehicle emissions, with real-world driving emissions (RDE) tests ensuring compliance under various driving conditions. Similarly, the United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have implemented rigorous standards, including the Corporate Average Fuel Economy (CAFE) regulations.

These regulatory frameworks have spurred innovation in HEV powertrain integration, encouraging manufacturers to optimize the interplay between internal combustion engines and electric propulsion systems. Advanced engine management systems, regenerative braking technologies, and sophisticated power electronics have become essential components in meeting emissions targets. The integration of these systems requires a holistic approach to vehicle design, considering factors such as weight reduction, aerodynamics, and overall energy efficiency.

The impact of emissions regulations extends beyond tailpipe emissions to encompass the entire lifecycle of HEVs. Manufacturers are now compelled to consider the environmental footprint of vehicle production, battery manufacturing, and end-of-life recycling. This comprehensive approach to emissions reduction has led to advancements in materials science, battery technology, and manufacturing processes, all of which contribute to enhanced powertrain integration.

Looking ahead, the regulatory landscape is set to become even more demanding. Many countries have announced plans to phase out internal combustion engines entirely, with target dates ranging from 2030 to 2050. This shift towards zero-emission vehicles is accelerating the development of plug-in hybrid electric vehicles (PHEVs) and full electric vehicles (EVs), pushing the boundaries of powertrain integration even further.

As a result, HEV powertrain integration is evolving to incorporate more advanced electric motors, higher capacity batteries, and intelligent energy management systems. The goal is to maximize electric-only driving range while minimizing emissions during hybrid operation. This requires sophisticated control algorithms that can seamlessly transition between power sources, optimize energy recuperation, and adapt to various driving conditions and user preferences.

In conclusion, emissions regulations serve as a powerful catalyst for enhancing HEV powertrain integration. They drive technological innovation, shape market trends, and ultimately contribute to the development of more sustainable transportation solutions. As regulations continue to tighten, the automotive industry must remain agile, investing in research and development to stay ahead of compliance requirements and meet the growing demand for cleaner, more efficient vehicles.

The evolution of emissions standards has been marked by progressively tighter limits on pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. In the European Union, the introduction of Euro 6d standards has set new benchmarks for vehicle emissions, with real-world driving emissions (RDE) tests ensuring compliance under various driving conditions. Similarly, the United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have implemented rigorous standards, including the Corporate Average Fuel Economy (CAFE) regulations.

These regulatory frameworks have spurred innovation in HEV powertrain integration, encouraging manufacturers to optimize the interplay between internal combustion engines and electric propulsion systems. Advanced engine management systems, regenerative braking technologies, and sophisticated power electronics have become essential components in meeting emissions targets. The integration of these systems requires a holistic approach to vehicle design, considering factors such as weight reduction, aerodynamics, and overall energy efficiency.

The impact of emissions regulations extends beyond tailpipe emissions to encompass the entire lifecycle of HEVs. Manufacturers are now compelled to consider the environmental footprint of vehicle production, battery manufacturing, and end-of-life recycling. This comprehensive approach to emissions reduction has led to advancements in materials science, battery technology, and manufacturing processes, all of which contribute to enhanced powertrain integration.

Looking ahead, the regulatory landscape is set to become even more demanding. Many countries have announced plans to phase out internal combustion engines entirely, with target dates ranging from 2030 to 2050. This shift towards zero-emission vehicles is accelerating the development of plug-in hybrid electric vehicles (PHEVs) and full electric vehicles (EVs), pushing the boundaries of powertrain integration even further.

As a result, HEV powertrain integration is evolving to incorporate more advanced electric motors, higher capacity batteries, and intelligent energy management systems. The goal is to maximize electric-only driving range while minimizing emissions during hybrid operation. This requires sophisticated control algorithms that can seamlessly transition between power sources, optimize energy recuperation, and adapt to various driving conditions and user preferences.

In conclusion, emissions regulations serve as a powerful catalyst for enhancing HEV powertrain integration. They drive technological innovation, shape market trends, and ultimately contribute to the development of more sustainable transportation solutions. As regulations continue to tighten, the automotive industry must remain agile, investing in research and development to stay ahead of compliance requirements and meet the growing demand for cleaner, more efficient vehicles.

Cost-Benefit Analysis

Enhancing HEV powertrain integration requires a comprehensive cost-benefit analysis to evaluate the economic viability and potential advantages of various integration strategies. This analysis is crucial for determining the most efficient and cost-effective approaches to powertrain integration in hybrid electric vehicles.

The primary costs associated with HEV powertrain integration include research and development expenses, manufacturing costs, and potential redesign of existing vehicle architectures. These costs can be substantial, particularly when implementing advanced integration techniques or introducing new technologies. However, they must be weighed against the long-term benefits and potential cost savings.

One of the key benefits of enhanced powertrain integration is improved fuel efficiency. By optimizing the interaction between the internal combustion engine and electric motor, HEVs can achieve significant reductions in fuel consumption. This translates to lower operating costs for consumers and reduced environmental impact, which can be quantified in terms of fuel savings and reduced emissions over the vehicle's lifetime.

Another important benefit is the potential for increased power density and performance. Improved integration can lead to more compact and lightweight powertrains, resulting in better vehicle dynamics and handling. This can enhance the overall driving experience and potentially increase the market appeal of HEVs, leading to higher sales volumes and improved brand reputation.

Maintenance costs should also be considered in the cost-benefit analysis. While initial integration costs may be higher, a well-integrated powertrain can lead to reduced wear and tear on components, potentially lowering long-term maintenance expenses. This factor is particularly important for fleet operators and consumers concerned about total cost of ownership.

The analysis should also account for potential regulatory benefits. As emissions standards become increasingly stringent, enhanced powertrain integration can help manufacturers meet these requirements more effectively. This can result in avoided penalties and potential incentives, which should be factored into the overall cost-benefit calculation.

Production scalability is another critical aspect to consider. While initial integration efforts may be costly, the potential for economies of scale in manufacturing can significantly reduce per-unit costs over time. This is especially relevant for automakers planning to implement integrated powertrain solutions across multiple vehicle models or platforms.

Lastly, the cost-benefit analysis should consider the competitive advantage gained through enhanced powertrain integration. Automakers that successfully implement advanced integration strategies may gain a technological edge in the market, potentially leading to increased market share and brand value. This long-term strategic benefit, while more difficult to quantify, is an essential factor in the overall analysis.

The primary costs associated with HEV powertrain integration include research and development expenses, manufacturing costs, and potential redesign of existing vehicle architectures. These costs can be substantial, particularly when implementing advanced integration techniques or introducing new technologies. However, they must be weighed against the long-term benefits and potential cost savings.

One of the key benefits of enhanced powertrain integration is improved fuel efficiency. By optimizing the interaction between the internal combustion engine and electric motor, HEVs can achieve significant reductions in fuel consumption. This translates to lower operating costs for consumers and reduced environmental impact, which can be quantified in terms of fuel savings and reduced emissions over the vehicle's lifetime.

Another important benefit is the potential for increased power density and performance. Improved integration can lead to more compact and lightweight powertrains, resulting in better vehicle dynamics and handling. This can enhance the overall driving experience and potentially increase the market appeal of HEVs, leading to higher sales volumes and improved brand reputation.

Maintenance costs should also be considered in the cost-benefit analysis. While initial integration costs may be higher, a well-integrated powertrain can lead to reduced wear and tear on components, potentially lowering long-term maintenance expenses. This factor is particularly important for fleet operators and consumers concerned about total cost of ownership.

The analysis should also account for potential regulatory benefits. As emissions standards become increasingly stringent, enhanced powertrain integration can help manufacturers meet these requirements more effectively. This can result in avoided penalties and potential incentives, which should be factored into the overall cost-benefit calculation.

Production scalability is another critical aspect to consider. While initial integration efforts may be costly, the potential for economies of scale in manufacturing can significantly reduce per-unit costs over time. This is especially relevant for automakers planning to implement integrated powertrain solutions across multiple vehicle models or platforms.

Lastly, the cost-benefit analysis should consider the competitive advantage gained through enhanced powertrain integration. Automakers that successfully implement advanced integration strategies may gain a technological edge in the market, potentially leading to increased market share and brand value. This long-term strategic benefit, while more difficult to quantify, is an essential factor in the overall analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!