How to Improve HEV Battery Designs for E-Mobility?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Battery Evolution and Objectives

The evolution of Hybrid Electric Vehicle (HEV) battery technology has been a critical factor in the advancement of e-mobility. Over the past two decades, HEV batteries have undergone significant improvements in energy density, power output, and longevity. Initially, nickel-metal hydride (NiMH) batteries were the primary choice for HEVs due to their reliability and cost-effectiveness. However, the industry has gradually shifted towards lithium-ion (Li-ion) batteries, which offer higher energy density and improved performance.

The primary objective in HEV battery design is to achieve an optimal balance between power density, energy density, and cost. This balance is crucial for meeting the diverse needs of different HEV architectures, including mild hybrids, full hybrids, and plug-in hybrids. As the automotive industry moves towards more electrified powertrains, the demands on HEV batteries continue to increase.

One of the key goals in HEV battery evolution is to enhance energy density without compromising safety or cycle life. This involves developing new electrode materials, electrolytes, and battery management systems. Another important objective is to improve the power density of batteries, enabling faster charging and discharging rates, which is particularly crucial for regenerative braking and acceleration in HEVs.

Reducing the cost of HEV batteries remains a significant challenge and objective. As battery costs decrease, the overall cost of HEVs becomes more competitive with conventional vehicles, driving wider adoption. This cost reduction is being pursued through advancements in manufacturing processes, economies of scale, and the development of less expensive battery chemistries.

Sustainability and environmental impact are also becoming increasingly important objectives in HEV battery design. This includes developing batteries with longer lifespans, improving recyclability, and reducing the use of rare or environmentally harmful materials. The industry is exploring alternatives to cobalt-based cathodes and investigating solid-state battery technologies as potential solutions.

Another critical objective is to enhance the thermal management of HEV batteries. Efficient thermal management systems are essential for maintaining optimal battery performance, extending battery life, and ensuring safety under various operating conditions. This involves innovations in battery pack design, cooling systems, and thermal runaway prevention.

As the e-mobility landscape evolves, the objectives for HEV battery design are expanding to include faster charging capabilities, improved low-temperature performance, and enhanced integration with vehicle systems. These advancements aim to address consumer concerns about range anxiety and charging time, even in hybrid vehicles where the internal combustion engine provides a backup.

The primary objective in HEV battery design is to achieve an optimal balance between power density, energy density, and cost. This balance is crucial for meeting the diverse needs of different HEV architectures, including mild hybrids, full hybrids, and plug-in hybrids. As the automotive industry moves towards more electrified powertrains, the demands on HEV batteries continue to increase.

One of the key goals in HEV battery evolution is to enhance energy density without compromising safety or cycle life. This involves developing new electrode materials, electrolytes, and battery management systems. Another important objective is to improve the power density of batteries, enabling faster charging and discharging rates, which is particularly crucial for regenerative braking and acceleration in HEVs.

Reducing the cost of HEV batteries remains a significant challenge and objective. As battery costs decrease, the overall cost of HEVs becomes more competitive with conventional vehicles, driving wider adoption. This cost reduction is being pursued through advancements in manufacturing processes, economies of scale, and the development of less expensive battery chemistries.

Sustainability and environmental impact are also becoming increasingly important objectives in HEV battery design. This includes developing batteries with longer lifespans, improving recyclability, and reducing the use of rare or environmentally harmful materials. The industry is exploring alternatives to cobalt-based cathodes and investigating solid-state battery technologies as potential solutions.

Another critical objective is to enhance the thermal management of HEV batteries. Efficient thermal management systems are essential for maintaining optimal battery performance, extending battery life, and ensuring safety under various operating conditions. This involves innovations in battery pack design, cooling systems, and thermal runaway prevention.

As the e-mobility landscape evolves, the objectives for HEV battery design are expanding to include faster charging capabilities, improved low-temperature performance, and enhanced integration with vehicle systems. These advancements aim to address consumer concerns about range anxiety and charging time, even in hybrid vehicles where the internal combustion engine provides a backup.

E-Mobility Market Analysis

The e-mobility market has experienced significant growth in recent years, driven by increasing environmental concerns, government regulations, and advancements in battery technology. This market encompasses various electric vehicle types, including hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs). Among these, HEVs have gained substantial traction due to their ability to bridge the gap between conventional internal combustion engine vehicles and fully electric vehicles.

The global HEV market has shown robust growth, with major automotive manufacturers investing heavily in hybrid technology. Countries such as Japan, the United States, and several European nations have been at the forefront of HEV adoption. The market has also seen increased penetration in emerging economies, particularly in China and India, where government incentives and growing environmental awareness have spurred demand.

Consumer preferences have played a crucial role in shaping the e-mobility market. Factors such as improved fuel efficiency, reduced emissions, and lower operating costs have made HEVs an attractive option for environmentally conscious consumers. Additionally, the availability of a wider range of HEV models across different vehicle segments has contributed to their increased adoption.

The HEV battery market, a critical component of e-mobility, has witnessed substantial technological advancements. Lithium-ion batteries have emerged as the dominant technology, offering higher energy density and longer lifespan compared to traditional nickel-metal hydride batteries. This shift has led to improved performance and range of HEVs, addressing one of the key concerns of potential buyers.

Market trends indicate a growing demand for more efficient and compact battery designs in HEVs. Manufacturers are focusing on developing batteries with higher energy density, faster charging capabilities, and improved thermal management. These advancements aim to enhance the overall performance and reliability of HEVs, making them more competitive in the broader automotive market.

The e-mobility ecosystem has also expanded beyond vehicle manufacturing, encompassing charging infrastructure, battery recycling, and energy management systems. This holistic approach has created new business opportunities and partnerships across industries, further driving the growth of the HEV market.

Looking ahead, the e-mobility market, particularly the HEV segment, is poised for continued growth. Factors such as stricter emission regulations, advancements in battery technology, and increasing consumer acceptance are expected to drive this expansion. However, challenges such as high initial costs, battery performance in extreme conditions, and the need for more extensive charging infrastructure remain areas of focus for industry stakeholders.

The global HEV market has shown robust growth, with major automotive manufacturers investing heavily in hybrid technology. Countries such as Japan, the United States, and several European nations have been at the forefront of HEV adoption. The market has also seen increased penetration in emerging economies, particularly in China and India, where government incentives and growing environmental awareness have spurred demand.

Consumer preferences have played a crucial role in shaping the e-mobility market. Factors such as improved fuel efficiency, reduced emissions, and lower operating costs have made HEVs an attractive option for environmentally conscious consumers. Additionally, the availability of a wider range of HEV models across different vehicle segments has contributed to their increased adoption.

The HEV battery market, a critical component of e-mobility, has witnessed substantial technological advancements. Lithium-ion batteries have emerged as the dominant technology, offering higher energy density and longer lifespan compared to traditional nickel-metal hydride batteries. This shift has led to improved performance and range of HEVs, addressing one of the key concerns of potential buyers.

Market trends indicate a growing demand for more efficient and compact battery designs in HEVs. Manufacturers are focusing on developing batteries with higher energy density, faster charging capabilities, and improved thermal management. These advancements aim to enhance the overall performance and reliability of HEVs, making them more competitive in the broader automotive market.

The e-mobility ecosystem has also expanded beyond vehicle manufacturing, encompassing charging infrastructure, battery recycling, and energy management systems. This holistic approach has created new business opportunities and partnerships across industries, further driving the growth of the HEV market.

Looking ahead, the e-mobility market, particularly the HEV segment, is poised for continued growth. Factors such as stricter emission regulations, advancements in battery technology, and increasing consumer acceptance are expected to drive this expansion. However, challenges such as high initial costs, battery performance in extreme conditions, and the need for more extensive charging infrastructure remain areas of focus for industry stakeholders.

HEV Battery Challenges

Hybrid Electric Vehicles (HEVs) face several significant challenges in battery design that impact their performance, efficiency, and overall adoption in the e-mobility sector. One of the primary issues is the limited energy density of current battery technologies. This constraint affects the vehicle's range and overall performance, making it difficult to compete with traditional internal combustion engine vehicles in terms of driving distance and refueling convenience.

Another critical challenge is the battery's thermal management. HEV batteries generate substantial heat during charging and discharging cycles, which can lead to reduced efficiency, accelerated degradation, and potential safety hazards. Developing effective cooling systems that can maintain optimal operating temperatures without adding significant weight or complexity to the vehicle remains a persistent challenge for engineers.

The durability and lifespan of HEV batteries also present ongoing concerns. The frequent charge-discharge cycles in hybrid vehicles can lead to faster battery degradation compared to pure electric vehicles. This not only affects the vehicle's long-term performance but also raises concerns about sustainability and the environmental impact of battery replacement.

Cost remains a significant barrier to widespread HEV adoption. The high cost of advanced battery technologies contributes substantially to the overall vehicle price, making HEVs less accessible to a broader consumer base. Reducing battery costs while maintaining or improving performance is crucial for market expansion.

Weight and space optimization pose additional challenges. HEVs must accommodate both an internal combustion engine and an electric powertrain, including batteries. This dual system requirement puts a premium on compact, lightweight battery designs that do not compromise vehicle dynamics or interior space.

The integration of battery systems with other vehicle components presents complex engineering challenges. Optimizing the interaction between the battery, electric motor, and internal combustion engine to achieve seamless power delivery and efficient energy management requires sophisticated control systems and software.

Charging infrastructure compatibility is another area of concern. As charging technologies evolve, ensuring that HEV batteries can adapt to various charging standards and speeds is essential for user convenience and market acceptance. This includes developing batteries that can handle fast charging without significant degradation or safety risks.

Addressing these challenges requires innovative approaches in materials science, thermal engineering, and system integration. Advances in solid-state batteries, improved battery management systems, and novel cooling technologies are among the promising avenues being explored to overcome these hurdles and enhance HEV battery performance for e-mobility applications.

Another critical challenge is the battery's thermal management. HEV batteries generate substantial heat during charging and discharging cycles, which can lead to reduced efficiency, accelerated degradation, and potential safety hazards. Developing effective cooling systems that can maintain optimal operating temperatures without adding significant weight or complexity to the vehicle remains a persistent challenge for engineers.

The durability and lifespan of HEV batteries also present ongoing concerns. The frequent charge-discharge cycles in hybrid vehicles can lead to faster battery degradation compared to pure electric vehicles. This not only affects the vehicle's long-term performance but also raises concerns about sustainability and the environmental impact of battery replacement.

Cost remains a significant barrier to widespread HEV adoption. The high cost of advanced battery technologies contributes substantially to the overall vehicle price, making HEVs less accessible to a broader consumer base. Reducing battery costs while maintaining or improving performance is crucial for market expansion.

Weight and space optimization pose additional challenges. HEVs must accommodate both an internal combustion engine and an electric powertrain, including batteries. This dual system requirement puts a premium on compact, lightweight battery designs that do not compromise vehicle dynamics or interior space.

The integration of battery systems with other vehicle components presents complex engineering challenges. Optimizing the interaction between the battery, electric motor, and internal combustion engine to achieve seamless power delivery and efficient energy management requires sophisticated control systems and software.

Charging infrastructure compatibility is another area of concern. As charging technologies evolve, ensuring that HEV batteries can adapt to various charging standards and speeds is essential for user convenience and market acceptance. This includes developing batteries that can handle fast charging without significant degradation or safety risks.

Addressing these challenges requires innovative approaches in materials science, thermal engineering, and system integration. Advances in solid-state batteries, improved battery management systems, and novel cooling technologies are among the promising avenues being explored to overcome these hurdles and enhance HEV battery performance for e-mobility applications.

Current HEV Battery Solutions

01 Battery cell design and configuration

HEV battery design focuses on optimizing cell configuration and arrangement to improve energy density, power output, and thermal management. This includes innovations in electrode structure, separator materials, and cell stacking techniques to enhance overall battery performance and longevity.- Battery cell design and configuration: HEV battery design focuses on optimizing cell configuration and arrangement to enhance overall performance. This includes developing efficient cell stacking methods, improving interconnections between cells, and designing compact battery modules. The goal is to maximize energy density, power output, and thermal management within the limited space of hybrid electric vehicles.

- Thermal management systems: Effective thermal management is crucial for HEV battery performance and longevity. This involves designing cooling systems, heat dissipation mechanisms, and temperature control strategies. Advanced thermal management solutions may include liquid cooling, phase change materials, or innovative air cooling designs to maintain optimal operating temperatures and prevent overheating.

- Battery management system (BMS) integration: Integrating sophisticated battery management systems is essential for HEV battery design. This includes developing algorithms for state-of-charge estimation, cell balancing, and fault detection. The BMS also manages power distribution, monitors battery health, and ensures safe operation under various driving conditions.

- Materials selection and electrode design: Advancements in HEV battery design involve selecting and optimizing materials for electrodes, electrolytes, and separators. This includes developing high-capacity cathode materials, improving anode structures, and exploring novel electrolyte compositions. The focus is on enhancing energy density, cycle life, and fast-charging capabilities while maintaining safety and cost-effectiveness.

- Safety features and protective mechanisms: Designing robust safety features is paramount in HEV battery development. This involves implementing protective mechanisms against overcharging, over-discharging, short circuits, and thermal runaway. Advanced safety designs may include smart fuses, pressure relief valves, and isolation systems to prevent catastrophic failures and ensure passenger safety.

02 Thermal management systems

Effective thermal management is crucial for HEV battery design. This involves developing cooling systems, heat dissipation methods, and temperature control mechanisms to maintain optimal operating conditions, prevent overheating, and extend battery life.Expand Specific Solutions03 Battery management and control systems

Advanced battery management systems are essential for HEV battery design. These systems monitor and control various parameters such as state of charge, voltage balancing, and current distribution to optimize battery performance, safety, and lifespan.Expand Specific Solutions04 Materials and chemistry innovations

Research in HEV battery design focuses on developing new electrode materials, electrolytes, and additives to improve energy density, power output, and cycle life. This includes exploring novel cathode and anode materials, as well as advanced electrolyte formulations.Expand Specific Solutions05 Safety and protection mechanisms

Enhancing safety features is a critical aspect of HEV battery design. This involves developing protective measures against overcharging, short circuits, and thermal runaway, as well as implementing fail-safe mechanisms and robust battery enclosures.Expand Specific Solutions

Key HEV Battery Manufacturers

The competition landscape for improving HEV battery designs in e-mobility is characterized by a mature market with significant growth potential. Major players like Ford, BYD, GM, and Samsung SDI are investing heavily in research and development to enhance battery performance and efficiency. The market is experiencing rapid expansion due to increasing demand for electric vehicles and government initiatives promoting clean energy. Technological advancements are focused on improving energy density, charging speed, and overall battery life. Companies such as Rimac Technology and SK On are pushing boundaries with innovative battery solutions, while established automakers like Nissan and Hyundai are integrating advanced battery technologies into their vehicle lineups. The competitive landscape is dynamic, with collaborations between automotive manufacturers and battery specialists driving progress in this critical area of e-mobility.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Battery Management System (BMS) for HEVs that utilizes predictive analytics and machine learning algorithms to optimize battery performance and longevity. The system continuously monitors battery health, temperature, and charge state, adjusting charging and discharging patterns in real-time. Ford's BMS incorporates a novel thermal management solution that uses phase-change materials to maintain optimal battery temperature, significantly extending battery life and improving overall efficiency[1][3]. Additionally, Ford has implemented a modular battery design that allows for easier maintenance and replacement of individual cells, reducing long-term costs and environmental impact[5].

Strengths: Advanced predictive analytics, efficient thermal management, and modular design for easy maintenance. Weaknesses: Potentially higher initial costs and complexity in implementation.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology, which is particularly suitable for HEVs due to its high energy density, safety, and longevity. The Blade Battery uses lithium iron phosphate (LFP) chemistry in a unique cell-to-pack design that increases energy density by 50% compared to traditional LFP batteries[2]. For HEV applications, BYD has adapted this technology to create a hybrid-specific version that balances power output and energy storage. The company has also developed an intelligent energy management system that optimizes the interplay between the electric motor and internal combustion engine, maximizing fuel efficiency and reducing emissions[4]. BYD's battery design incorporates advanced cooling technology using a liquid cooling system integrated directly into the battery pack structure, ensuring optimal temperature control even under high-stress conditions[6].

Strengths: High energy density, enhanced safety features, and innovative cell-to-pack design. Weaknesses: Limited track record in HEV-specific applications compared to traditional HEV battery suppliers.

Innovative HEV Battery Patents

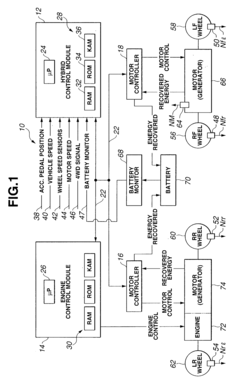

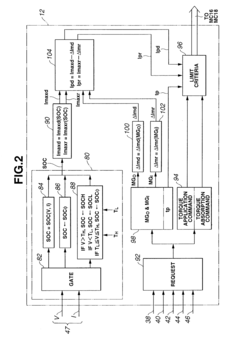

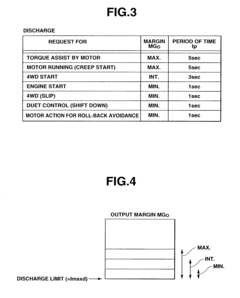

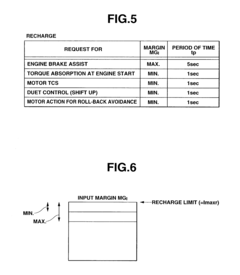

Hybrid electric vehicle with enhanced battery control

PatentInactiveUS7173396B2

Innovation

- A system that determines discharge and recharge allowances and time limits based on different operating conditions of the hybrid electric vehicle, using a hybrid control module and engine control module to regulate the battery's operation through microprocessors and sensors, allowing for dynamic adjustment of discharge and recharge currents.

Battery system

PatentWO2018128703A2

Innovation

- A rechargeable and removable battery pack system that can be transferred between vehicles, power tools, equipment, and residential/commercial buildings, featuring a vehicle power station with ports for coupling and control modules for charging/discharging, enabling multiple configurations and energy arbitrage.

Environmental Impact of HEV Batteries

The environmental impact of HEV batteries is a critical consideration in the development and adoption of hybrid electric vehicles. These batteries, while essential for reducing overall vehicle emissions, have their own ecological footprint that must be carefully managed throughout their lifecycle.

During the production phase, the manufacturing of HEV batteries involves energy-intensive processes and the extraction of raw materials, which can lead to significant carbon emissions and environmental degradation. The mining of lithium, cobalt, and other rare earth elements used in battery production often results in habitat destruction and water pollution in mining regions.

However, the operational phase of HEV batteries presents a more positive environmental picture. By enabling vehicles to operate on electric power for portions of their journeys, these batteries contribute to reduced tailpipe emissions and lower overall fuel consumption. This translates to decreased air pollution and greenhouse gas emissions in urban areas, where the impact of vehicle emissions is most pronounced.

The end-of-life stage of HEV batteries poses both challenges and opportunities. Improper disposal can lead to soil and water contamination due to the toxic materials contained within the batteries. However, advancements in recycling technologies are making it increasingly feasible to recover valuable materials from spent batteries, reducing the need for new raw material extraction and minimizing waste.

Efforts to improve the environmental profile of HEV batteries are ongoing. Researchers are exploring more sustainable battery chemistries that rely less on rare or toxic materials. Additionally, the development of more efficient manufacturing processes and the use of renewable energy in production facilities are helping to reduce the carbon footprint associated with battery manufacturing.

The longevity and performance of HEV batteries also play a crucial role in their environmental impact. Batteries with longer lifespans and higher energy densities can reduce the frequency of replacement and improve overall vehicle efficiency, leading to a lower environmental burden over the vehicle's lifetime.

As the automotive industry continues to shift towards electrification, the environmental impact of HEV batteries remains a key focus area. Balancing the benefits of reduced vehicle emissions against the ecological costs of battery production and disposal is essential for ensuring that hybrid electric vehicles truly contribute to a more sustainable transportation future.

During the production phase, the manufacturing of HEV batteries involves energy-intensive processes and the extraction of raw materials, which can lead to significant carbon emissions and environmental degradation. The mining of lithium, cobalt, and other rare earth elements used in battery production often results in habitat destruction and water pollution in mining regions.

However, the operational phase of HEV batteries presents a more positive environmental picture. By enabling vehicles to operate on electric power for portions of their journeys, these batteries contribute to reduced tailpipe emissions and lower overall fuel consumption. This translates to decreased air pollution and greenhouse gas emissions in urban areas, where the impact of vehicle emissions is most pronounced.

The end-of-life stage of HEV batteries poses both challenges and opportunities. Improper disposal can lead to soil and water contamination due to the toxic materials contained within the batteries. However, advancements in recycling technologies are making it increasingly feasible to recover valuable materials from spent batteries, reducing the need for new raw material extraction and minimizing waste.

Efforts to improve the environmental profile of HEV batteries are ongoing. Researchers are exploring more sustainable battery chemistries that rely less on rare or toxic materials. Additionally, the development of more efficient manufacturing processes and the use of renewable energy in production facilities are helping to reduce the carbon footprint associated with battery manufacturing.

The longevity and performance of HEV batteries also play a crucial role in their environmental impact. Batteries with longer lifespans and higher energy densities can reduce the frequency of replacement and improve overall vehicle efficiency, leading to a lower environmental burden over the vehicle's lifetime.

As the automotive industry continues to shift towards electrification, the environmental impact of HEV batteries remains a key focus area. Balancing the benefits of reduced vehicle emissions against the ecological costs of battery production and disposal is essential for ensuring that hybrid electric vehicles truly contribute to a more sustainable transportation future.

HEV Battery Safety Standards

Safety standards for HEV batteries are crucial in ensuring the reliability and security of electric mobility solutions. These standards encompass a wide range of requirements, from design and manufacturing to testing and disposal. The primary focus is on preventing thermal runaway, electrical hazards, and mechanical damage that could lead to catastrophic failures.

One of the key standards in this field is ISO 6469-1, which specifies safety requirements for rechargeable energy storage systems (RESS) in road vehicles. This standard covers aspects such as vibration resistance, thermal shock, and fire resistance. It also outlines procedures for testing the electrical safety of battery systems, including insulation resistance and voltage withstand capability.

Another important standard is UN 38.3, which defines requirements for the safe transport of lithium-ion batteries. This standard includes a series of tests to evaluate the battery's ability to withstand conditions typically encountered during shipping, such as altitude simulation, thermal cycling, and external short circuit.

The SAE J2464 standard provides a comprehensive set of guidelines for electric and hybrid vehicle rechargeable energy storage systems. It addresses safety and abuse testing of batteries, covering areas such as mechanical shock, crush resistance, and immersion in water. This standard is particularly relevant for improving HEV battery designs as it helps identify potential failure modes and safety risks.

In the United States, the NHTSA (National Highway Traffic Safety Administration) has established FMVSS No. 305, which sets performance requirements for electric vehicles in the event of a crash. This standard includes specifications for battery retention systems and protection against electrical shock.

The IEC 62660 series of standards focuses on secondary lithium-ion cells for the propulsion of electric road vehicles. These standards cover performance testing, reliability and abuse testing, and safety requirements. They provide valuable guidance for battery manufacturers and vehicle designers in improving the overall safety and performance of HEV battery systems.

As the e-mobility sector continues to evolve, safety standards are also adapting to address new challenges. For instance, there is growing emphasis on developing standards for battery management systems (BMS) to ensure accurate monitoring and control of battery performance and safety. Additionally, standards are being developed to address the unique safety considerations of solid-state batteries, which are seen as a promising future technology for HEVs.

Compliance with these safety standards is not only essential for regulatory approval but also plays a crucial role in building consumer confidence in e-mobility solutions. As such, understanding and implementing these standards is a key aspect of improving HEV battery designs for enhanced safety and reliability in electric mobility applications.

One of the key standards in this field is ISO 6469-1, which specifies safety requirements for rechargeable energy storage systems (RESS) in road vehicles. This standard covers aspects such as vibration resistance, thermal shock, and fire resistance. It also outlines procedures for testing the electrical safety of battery systems, including insulation resistance and voltage withstand capability.

Another important standard is UN 38.3, which defines requirements for the safe transport of lithium-ion batteries. This standard includes a series of tests to evaluate the battery's ability to withstand conditions typically encountered during shipping, such as altitude simulation, thermal cycling, and external short circuit.

The SAE J2464 standard provides a comprehensive set of guidelines for electric and hybrid vehicle rechargeable energy storage systems. It addresses safety and abuse testing of batteries, covering areas such as mechanical shock, crush resistance, and immersion in water. This standard is particularly relevant for improving HEV battery designs as it helps identify potential failure modes and safety risks.

In the United States, the NHTSA (National Highway Traffic Safety Administration) has established FMVSS No. 305, which sets performance requirements for electric vehicles in the event of a crash. This standard includes specifications for battery retention systems and protection against electrical shock.

The IEC 62660 series of standards focuses on secondary lithium-ion cells for the propulsion of electric road vehicles. These standards cover performance testing, reliability and abuse testing, and safety requirements. They provide valuable guidance for battery manufacturers and vehicle designers in improving the overall safety and performance of HEV battery systems.

As the e-mobility sector continues to evolve, safety standards are also adapting to address new challenges. For instance, there is growing emphasis on developing standards for battery management systems (BMS) to ensure accurate monitoring and control of battery performance and safety. Additionally, standards are being developed to address the unique safety considerations of solid-state batteries, which are seen as a promising future technology for HEVs.

Compliance with these safety standards is not only essential for regulatory approval but also plays a crucial role in building consumer confidence in e-mobility solutions. As such, understanding and implementing these standards is a key aspect of improving HEV battery designs for enhanced safety and reliability in electric mobility applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!