How to Expedite HEV Innovation Cycles?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Innovation Landscape

The HEV (Hybrid Electric Vehicle) innovation landscape is characterized by rapid technological advancements and evolving market demands. Over the past decade, HEV technology has seen significant improvements in battery efficiency, power management systems, and drivetrain integration. These developments have been driven by increasing environmental concerns, stricter emissions regulations, and consumer demand for more fuel-efficient vehicles.

The current HEV market is dominated by established automotive manufacturers, with Toyota, Honda, and Ford leading the way. However, new entrants from both traditional automotive and tech sectors are increasingly challenging this status quo, bringing fresh perspectives and innovative approaches to HEV development.

Key technological trends shaping the HEV innovation landscape include the development of more efficient lithium-ion batteries, advanced power electronics, and intelligent energy management systems. There is also a growing focus on lightweight materials and aerodynamic designs to further improve fuel efficiency and vehicle performance.

The HEV innovation cycle is influenced by several factors, including regulatory pressures, consumer preferences, and technological breakthroughs. Governments worldwide are implementing stricter fuel economy standards and offering incentives for low-emission vehicles, which is accelerating HEV development and adoption.

Collaboration between automotive manufacturers, technology companies, and research institutions is becoming increasingly common, fostering a more open innovation ecosystem. This collaborative approach is helping to accelerate the pace of innovation by combining diverse expertise and resources.

One of the main challenges in expediting HEV innovation cycles is the complexity of integrating multiple systems – combustion engines, electric motors, batteries, and control systems – into a cohesive and efficient package. This requires extensive testing and validation, which can be time-consuming and costly.

To address these challenges, the industry is increasingly turning to advanced simulation and modeling tools, allowing for more rapid prototyping and testing of new designs. Virtual testing environments and digital twins are being employed to reduce physical prototype iterations and accelerate the development process.

Additionally, the adoption of modular platforms and standardized components is helping to streamline HEV development. This approach allows manufacturers to more quickly adapt to changing market demands and technological advancements without completely redesigning their vehicles.

As the HEV market continues to evolve, we can expect to see further innovations in areas such as wireless charging, vehicle-to-grid integration, and advanced driver assistance systems tailored for hybrid powertrains. These developments will not only enhance the performance and efficiency of HEVs but also contribute to their integration into smart transportation ecosystems.

The current HEV market is dominated by established automotive manufacturers, with Toyota, Honda, and Ford leading the way. However, new entrants from both traditional automotive and tech sectors are increasingly challenging this status quo, bringing fresh perspectives and innovative approaches to HEV development.

Key technological trends shaping the HEV innovation landscape include the development of more efficient lithium-ion batteries, advanced power electronics, and intelligent energy management systems. There is also a growing focus on lightweight materials and aerodynamic designs to further improve fuel efficiency and vehicle performance.

The HEV innovation cycle is influenced by several factors, including regulatory pressures, consumer preferences, and technological breakthroughs. Governments worldwide are implementing stricter fuel economy standards and offering incentives for low-emission vehicles, which is accelerating HEV development and adoption.

Collaboration between automotive manufacturers, technology companies, and research institutions is becoming increasingly common, fostering a more open innovation ecosystem. This collaborative approach is helping to accelerate the pace of innovation by combining diverse expertise and resources.

One of the main challenges in expediting HEV innovation cycles is the complexity of integrating multiple systems – combustion engines, electric motors, batteries, and control systems – into a cohesive and efficient package. This requires extensive testing and validation, which can be time-consuming and costly.

To address these challenges, the industry is increasingly turning to advanced simulation and modeling tools, allowing for more rapid prototyping and testing of new designs. Virtual testing environments and digital twins are being employed to reduce physical prototype iterations and accelerate the development process.

Additionally, the adoption of modular platforms and standardized components is helping to streamline HEV development. This approach allows manufacturers to more quickly adapt to changing market demands and technological advancements without completely redesigning their vehicles.

As the HEV market continues to evolve, we can expect to see further innovations in areas such as wireless charging, vehicle-to-grid integration, and advanced driver assistance systems tailored for hybrid powertrains. These developments will not only enhance the performance and efficiency of HEVs but also contribute to their integration into smart transportation ecosystems.

Market Drivers for HEV

The market for Hybrid Electric Vehicles (HEVs) is experiencing significant growth, driven by a combination of environmental concerns, regulatory pressures, and consumer preferences. As governments worldwide implement stricter emissions standards and fuel economy regulations, automakers are increasingly turning to HEV technology as a viable solution to meet these requirements while maintaining performance and consumer appeal.

One of the primary market drivers for HEVs is the growing awareness of climate change and the need to reduce greenhouse gas emissions. Consumers are becoming more environmentally conscious, seeking vehicles that offer improved fuel efficiency and lower carbon footprints. HEVs provide an attractive compromise between conventional internal combustion engine vehicles and fully electric vehicles, offering reduced emissions without the range anxiety associated with pure electric vehicles.

Rising fuel prices and volatility in the global oil market have also contributed to the increasing demand for HEVs. As consumers seek ways to reduce their fuel costs, HEVs offer a compelling value proposition with their improved fuel economy. This economic benefit is particularly appealing in urban areas where stop-and-go traffic conditions allow HEVs to maximize their efficiency through regenerative braking and electric-only operation at low speeds.

Government incentives and policies play a crucial role in driving HEV adoption. Many countries offer tax credits, rebates, or other financial incentives to consumers who purchase HEVs, making them more affordable and attractive. Additionally, some cities provide benefits such as access to high-occupancy vehicle lanes or reduced parking fees for HEV owners, further incentivizing their adoption.

The automotive industry's shift towards electrification has also accelerated HEV development and market growth. As automakers invest heavily in electric vehicle technology, HEVs serve as a stepping stone, allowing manufacturers to refine their electric powertrains and battery systems while maintaining a familiar platform for consumers. This transitional role of HEVs is particularly important in markets where charging infrastructure for fully electric vehicles is still developing.

Advancements in HEV technology have led to improved performance and efficiency, expanding their appeal to a broader range of consumers. Modern HEVs offer driving experiences comparable to conventional vehicles, with the added benefits of lower emissions and better fuel economy. As battery technology continues to evolve, HEVs are becoming more powerful, efficient, and cost-effective, further driving market demand.

The commercial vehicle sector is also contributing to HEV market growth, with increasing adoption in fleet operations, public transportation, and delivery services. These applications benefit from the reduced operating costs and lower emissions of HEVs, particularly in urban environments where air quality concerns are paramount.

One of the primary market drivers for HEVs is the growing awareness of climate change and the need to reduce greenhouse gas emissions. Consumers are becoming more environmentally conscious, seeking vehicles that offer improved fuel efficiency and lower carbon footprints. HEVs provide an attractive compromise between conventional internal combustion engine vehicles and fully electric vehicles, offering reduced emissions without the range anxiety associated with pure electric vehicles.

Rising fuel prices and volatility in the global oil market have also contributed to the increasing demand for HEVs. As consumers seek ways to reduce their fuel costs, HEVs offer a compelling value proposition with their improved fuel economy. This economic benefit is particularly appealing in urban areas where stop-and-go traffic conditions allow HEVs to maximize their efficiency through regenerative braking and electric-only operation at low speeds.

Government incentives and policies play a crucial role in driving HEV adoption. Many countries offer tax credits, rebates, or other financial incentives to consumers who purchase HEVs, making them more affordable and attractive. Additionally, some cities provide benefits such as access to high-occupancy vehicle lanes or reduced parking fees for HEV owners, further incentivizing their adoption.

The automotive industry's shift towards electrification has also accelerated HEV development and market growth. As automakers invest heavily in electric vehicle technology, HEVs serve as a stepping stone, allowing manufacturers to refine their electric powertrains and battery systems while maintaining a familiar platform for consumers. This transitional role of HEVs is particularly important in markets where charging infrastructure for fully electric vehicles is still developing.

Advancements in HEV technology have led to improved performance and efficiency, expanding their appeal to a broader range of consumers. Modern HEVs offer driving experiences comparable to conventional vehicles, with the added benefits of lower emissions and better fuel economy. As battery technology continues to evolve, HEVs are becoming more powerful, efficient, and cost-effective, further driving market demand.

The commercial vehicle sector is also contributing to HEV market growth, with increasing adoption in fleet operations, public transportation, and delivery services. These applications benefit from the reduced operating costs and lower emissions of HEVs, particularly in urban environments where air quality concerns are paramount.

Technical Hurdles in HEV

The development of Hybrid Electric Vehicles (HEVs) faces several significant technical hurdles that impede rapid innovation cycles. One of the primary challenges lies in the integration and optimization of multiple powertrain components. Engineers must seamlessly combine internal combustion engines, electric motors, and battery systems, ensuring they work in harmony to maximize efficiency and performance.

Battery technology remains a critical bottleneck in HEV development. Current lithium-ion batteries still struggle with energy density limitations, slow charging rates, and degradation over time. Improving battery performance while reducing costs and weight is crucial for expediting HEV innovation cycles. Additionally, thermal management of battery packs poses a significant challenge, as maintaining optimal operating temperatures is essential for battery longevity and safety.

Power electronics and control systems present another set of technical hurdles. Developing sophisticated algorithms for energy management, power distribution, and regenerative braking requires extensive research and testing. These systems must be robust enough to handle varying driving conditions while optimizing fuel efficiency and electric power usage.

The complexity of HEV powertrains also leads to challenges in durability and reliability testing. Traditional testing methods for conventional vehicles are often insufficient for hybrid systems, necessitating the development of new testing protocols and equipment. This process can be time-consuming and expensive, slowing down the overall innovation cycle.

Weight reduction is another critical area of focus in HEV development. The addition of electric components and batteries increases vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must constantly explore new materials and design strategies to offset this added weight without compromising safety or functionality.

Standardization and compatibility issues also hinder rapid innovation in the HEV sector. The lack of universal standards for components such as charging systems and battery modules can lead to fragmentation in the market and slow down the adoption of new technologies. Overcoming these compatibility challenges requires collaboration across the industry and regulatory bodies.

Manufacturing processes for HEVs present their own set of technical hurdles. The production of complex hybrid powertrains requires specialized equipment and expertise, which can be costly to develop and implement. Streamlining these processes to reduce costs and increase production efficiency is crucial for accelerating HEV innovation cycles.

Lastly, the development of more efficient and compact electric motors remains an ongoing challenge. Improving power density, reducing rare earth material usage, and enhancing motor cooling systems are all areas that require continued innovation to advance HEV technology.

Battery technology remains a critical bottleneck in HEV development. Current lithium-ion batteries still struggle with energy density limitations, slow charging rates, and degradation over time. Improving battery performance while reducing costs and weight is crucial for expediting HEV innovation cycles. Additionally, thermal management of battery packs poses a significant challenge, as maintaining optimal operating temperatures is essential for battery longevity and safety.

Power electronics and control systems present another set of technical hurdles. Developing sophisticated algorithms for energy management, power distribution, and regenerative braking requires extensive research and testing. These systems must be robust enough to handle varying driving conditions while optimizing fuel efficiency and electric power usage.

The complexity of HEV powertrains also leads to challenges in durability and reliability testing. Traditional testing methods for conventional vehicles are often insufficient for hybrid systems, necessitating the development of new testing protocols and equipment. This process can be time-consuming and expensive, slowing down the overall innovation cycle.

Weight reduction is another critical area of focus in HEV development. The addition of electric components and batteries increases vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must constantly explore new materials and design strategies to offset this added weight without compromising safety or functionality.

Standardization and compatibility issues also hinder rapid innovation in the HEV sector. The lack of universal standards for components such as charging systems and battery modules can lead to fragmentation in the market and slow down the adoption of new technologies. Overcoming these compatibility challenges requires collaboration across the industry and regulatory bodies.

Manufacturing processes for HEVs present their own set of technical hurdles. The production of complex hybrid powertrains requires specialized equipment and expertise, which can be costly to develop and implement. Streamlining these processes to reduce costs and increase production efficiency is crucial for accelerating HEV innovation cycles.

Lastly, the development of more efficient and compact electric motors remains an ongoing challenge. Improving power density, reducing rare earth material usage, and enhancing motor cooling systems are all areas that require continued innovation to advance HEV technology.

Current HEV Solutions

01 Thermal management systems for HEVs

Innovative thermal management systems are crucial for HEVs to maintain optimal operating temperatures for various components. These systems often include advanced cooling circuits, heat exchangers, and temperature control mechanisms to enhance efficiency and performance of the vehicle's powertrain and battery systems.- Thermal management systems for HEVs: Innovative thermal management systems are crucial for HEVs to maintain optimal operating temperatures for various components. These systems often involve advanced cooling circuits, heat exchangers, and temperature control strategies to improve efficiency and performance of the vehicle's powertrain and battery systems.

- Battery technology advancements: Continuous improvements in battery technology are driving HEV innovation cycles. This includes developments in battery chemistry, cell design, and battery management systems to enhance energy density, charging speed, and overall lifespan of HEV batteries.

- Power electronics and control systems: Advancements in power electronics and control systems are essential for optimizing HEV performance. This includes innovations in inverters, converters, and sophisticated control algorithms that manage power flow between the internal combustion engine and electric motor(s) for improved efficiency and driving dynamics.

- Regenerative braking and energy recovery: Innovations in regenerative braking systems and energy recovery mechanisms are key to improving HEV efficiency. These technologies focus on capturing and storing energy during deceleration and braking, which can then be used to recharge the battery or power auxiliary systems.

- Lightweight materials and aerodynamics: The use of lightweight materials and improved aerodynamics is an important aspect of HEV innovation cycles. This includes the integration of advanced composites, high-strength alloys, and aerodynamic design features to reduce vehicle weight and improve overall energy efficiency.

02 Battery technology advancements

Continuous improvements in battery technology are driving HEV innovation cycles. This includes developments in energy density, charging efficiency, and battery life. Advanced battery management systems and novel cell designs are being implemented to enhance overall vehicle performance and range.Expand Specific Solutions03 Powertrain integration and control

HEV innovation focuses on seamless integration of electric and combustion powertrains. This involves sophisticated control systems that optimize power distribution, improve fuel efficiency, and enhance driving performance. Advanced algorithms and sensors are used to manage the interplay between different power sources.Expand Specific Solutions04 Regenerative braking and energy recovery

Innovations in regenerative braking systems are key to improving HEV efficiency. These systems capture and convert kinetic energy during deceleration into electrical energy, which is then stored in the battery. Advancements in this area focus on maximizing energy recovery and improving overall vehicle efficiency.Expand Specific Solutions05 Lightweight materials and aerodynamics

HEV innovation cycles include the development and application of lightweight materials to reduce vehicle weight and improve fuel efficiency. Additionally, advancements in aerodynamic design help minimize drag and enhance overall vehicle performance. These innovations contribute to extended electric range and improved energy efficiency.Expand Specific Solutions

Key HEV Manufacturers

The competition landscape for expediting HEV innovation cycles is characterized by a mature industry in a growth phase, with a rapidly expanding market driven by increasing environmental concerns and government regulations. The global HEV market size is projected to reach significant volumes in the coming years, attracting major players across the automotive sector. Technologically, the field is advancing rapidly, with companies like Ford, GM, Toyota, and BYD leading the way in research and development. These firms are investing heavily in improving battery technology, powertrain efficiency, and overall vehicle performance. Emerging players from China, such as Chery and Great Wall Motor, are also making significant strides, intensifying the competition and driving innovation forward.

GM Global Technology Operations LLC

Technical Solution: GM's approach to expediting HEV innovation cycles focuses on advanced software-defined vehicle architectures and virtual development tools. They utilize a digital twin methodology, creating virtual representations of their HEV systems for rapid testing and iteration[4]. GM's "Ultium" platform serves as a flexible foundation for various electrified vehicles, including HEVs, allowing for faster integration of new technologies[5]. The company has invested heavily in AI-driven design optimization tools to quickly evaluate and refine hybrid powertrain configurations. GM also employs agile development methodologies in their engineering processes, enabling faster prototyping and testing cycles. Their strategic partnerships with battery manufacturers and tech companies facilitate accelerated innovation in key HEV components[6].

Strengths: Strong software and electrical engineering capabilities, flexible vehicle platforms. Weaknesses: Historically less focus on HEVs compared to full EVs, which may require catch-up in some areas.

BYD Co., Ltd.

Technical Solution: BYD's strategy for expediting HEV innovation cycles leverages their vertically integrated business model. As both a battery manufacturer and automaker, BYD can rapidly iterate on battery and powertrain designs in-house[7]. They employ advanced computer-aided engineering (CAE) tools for quick simulation and optimization of hybrid systems. BYD's modular e-platform 3.0 allows for flexible integration of hybrid technologies across multiple vehicle types[8]. The company utilizes rapid prototyping techniques, including 3D printing, to accelerate component development. BYD also focuses on continuous improvement in manufacturing processes, implementing Industry 4.0 concepts to reduce production lead times for new HEV models. Their collaborative approach with Chinese universities and research institutions helps to fast-track emerging technologies into their development pipeline[9].

Strengths: Vertical integration allows for rapid iteration, strong battery technology expertise. Weaknesses: Less experience in global markets may limit access to some international innovation resources.

Breakthrough HEV Tech

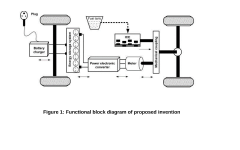

Hybrid electric vehicle with electric motor providing strategic power assist to load balance internal combustion engine

PatentPendingIN202441000035A

Innovation

- A Hybrid Electric Vehicle (HEV) system with an electric motor providing strategic power assist to the internal combustion engine, optimizing power distribution and energy management through advanced control algorithms.

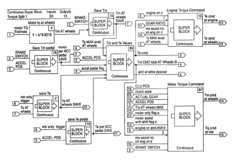

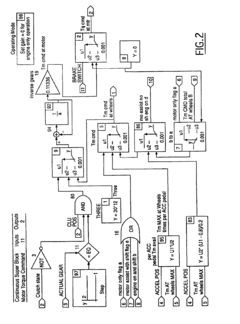

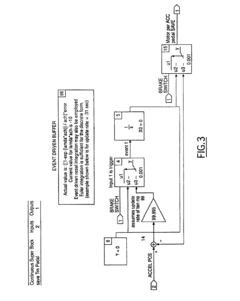

Hybrid electric vehicle torque distribution

PatentInactiveUS6827167B2

Innovation

- A control algorithm for a hybrid electric vehicle that transitions between electric motor and IC engine power based on predefined operational parameters, scaling the accelerator pedal travel to maintain a consistent torque demand, ensuring that the vehicle behaves similarly to a conventional IC engine vehicle by distributing torque in a manner invisible to the driver, using a post-transmission parallel hybrid powertrain configuration.

HEV Supply Chain Optim

Optimizing the supply chain for Hybrid Electric Vehicles (HEVs) is crucial for expediting innovation cycles and improving overall efficiency in the automotive industry. A well-structured supply chain can significantly reduce lead times, minimize costs, and enhance the quality of HEV components, ultimately accelerating the pace of innovation.

One key aspect of HEV supply chain optimization is the implementation of just-in-time (JIT) manufacturing principles. By adopting JIT practices, manufacturers can reduce inventory costs and improve production flexibility. This approach allows for quicker adaptation to market demands and technological advancements, enabling faster integration of new innovations into the production process.

Vertical integration is another strategy that can streamline the HEV supply chain. By bringing key component production in-house, automakers can have greater control over the quality and availability of critical parts. This approach can reduce dependencies on external suppliers and minimize potential disruptions in the supply chain, leading to more consistent production schedules and faster innovation cycles.

Collaboration and partnerships within the supply chain ecosystem are essential for accelerating HEV innovation. Establishing strong relationships with suppliers and fostering open communication channels can lead to joint research and development efforts. This collaborative approach can result in faster problem-solving, shared expertise, and more rapid implementation of new technologies across the supply chain.

Leveraging advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) can significantly enhance supply chain visibility and efficiency. AI-powered predictive analytics can help forecast demand more accurately, optimize inventory levels, and identify potential bottlenecks in the supply chain. IoT sensors can provide real-time tracking of components and materials, enabling proactive management of supply chain issues.

Standardization of components and processes across the HEV supply chain can also contribute to faster innovation cycles. By establishing common standards and interfaces, manufacturers can reduce complexity, improve interoperability, and accelerate the integration of new technologies. This approach can lead to more modular designs, allowing for easier upgrades and modifications as new innovations emerge.

Lastly, investing in sustainable and localized supply chains can provide long-term benefits for HEV innovation. By reducing reliance on long-distance transportation and focusing on regional sourcing, manufacturers can decrease lead times and minimize the environmental impact of their operations. This approach can also enhance resilience against global supply chain disruptions, ensuring a more stable foundation for continuous innovation in HEV technology.

One key aspect of HEV supply chain optimization is the implementation of just-in-time (JIT) manufacturing principles. By adopting JIT practices, manufacturers can reduce inventory costs and improve production flexibility. This approach allows for quicker adaptation to market demands and technological advancements, enabling faster integration of new innovations into the production process.

Vertical integration is another strategy that can streamline the HEV supply chain. By bringing key component production in-house, automakers can have greater control over the quality and availability of critical parts. This approach can reduce dependencies on external suppliers and minimize potential disruptions in the supply chain, leading to more consistent production schedules and faster innovation cycles.

Collaboration and partnerships within the supply chain ecosystem are essential for accelerating HEV innovation. Establishing strong relationships with suppliers and fostering open communication channels can lead to joint research and development efforts. This collaborative approach can result in faster problem-solving, shared expertise, and more rapid implementation of new technologies across the supply chain.

Leveraging advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) can significantly enhance supply chain visibility and efficiency. AI-powered predictive analytics can help forecast demand more accurately, optimize inventory levels, and identify potential bottlenecks in the supply chain. IoT sensors can provide real-time tracking of components and materials, enabling proactive management of supply chain issues.

Standardization of components and processes across the HEV supply chain can also contribute to faster innovation cycles. By establishing common standards and interfaces, manufacturers can reduce complexity, improve interoperability, and accelerate the integration of new technologies. This approach can lead to more modular designs, allowing for easier upgrades and modifications as new innovations emerge.

Lastly, investing in sustainable and localized supply chains can provide long-term benefits for HEV innovation. By reducing reliance on long-distance transportation and focusing on regional sourcing, manufacturers can decrease lead times and minimize the environmental impact of their operations. This approach can also enhance resilience against global supply chain disruptions, ensuring a more stable foundation for continuous innovation in HEV technology.

HEV Regulatory Trends

The regulatory landscape for Hybrid Electric Vehicles (HEVs) is rapidly evolving, driven by global efforts to reduce carbon emissions and improve air quality. Governments worldwide are implementing increasingly stringent regulations to accelerate the adoption of HEVs and other low-emission vehicles. These regulatory trends are significantly impacting HEV innovation cycles, pushing manufacturers to expedite their research and development processes.

In the United States, the Corporate Average Fuel Economy (CAFE) standards continue to be a major driver for HEV innovation. The Biden administration has proposed new standards that would require automakers to achieve an average fuel economy of 49 miles per gallon for new vehicles by 2026. This ambitious target is forcing manufacturers to accelerate their HEV development timelines and invest heavily in more efficient powertrain technologies.

The European Union has set even more aggressive targets through its CO2 emission standards for new passenger cars and vans. The EU aims to reduce CO2 emissions from new cars by 37.5% by 2030, compared to 2021 levels. This regulation is pushing European automakers to rapidly expand their HEV offerings and improve existing models to meet these stringent requirements.

China, the world's largest automotive market, has implemented a dual-credit policy that combines fuel consumption regulations with new energy vehicle (NEV) credits. This policy incentivizes automakers to produce more HEVs and electric vehicles, effectively shortening innovation cycles as companies race to meet credit requirements and avoid penalties.

Regulatory trends are also focusing on the entire lifecycle of HEVs, including battery production and end-of-life recycling. The EU's proposed Battery Regulation aims to ensure sustainable and ethical sourcing of raw materials, improve battery performance, and mandate recycling. These regulations are driving innovation in battery technology and manufacturing processes, further accelerating HEV development cycles.

Local and regional regulations are also playing a crucial role in shaping HEV innovation. Many cities are implementing low-emission zones and providing incentives for HEV adoption, creating localized demand that spurs manufacturers to develop market-specific HEV solutions more rapidly.

The global nature of these regulatory trends is forcing automakers to adopt a more agile and collaborative approach to HEV innovation. Cross-border partnerships and technology sharing agreements are becoming more common as companies seek to pool resources and expertise to meet diverse regulatory requirements across different markets.

In the United States, the Corporate Average Fuel Economy (CAFE) standards continue to be a major driver for HEV innovation. The Biden administration has proposed new standards that would require automakers to achieve an average fuel economy of 49 miles per gallon for new vehicles by 2026. This ambitious target is forcing manufacturers to accelerate their HEV development timelines and invest heavily in more efficient powertrain technologies.

The European Union has set even more aggressive targets through its CO2 emission standards for new passenger cars and vans. The EU aims to reduce CO2 emissions from new cars by 37.5% by 2030, compared to 2021 levels. This regulation is pushing European automakers to rapidly expand their HEV offerings and improve existing models to meet these stringent requirements.

China, the world's largest automotive market, has implemented a dual-credit policy that combines fuel consumption regulations with new energy vehicle (NEV) credits. This policy incentivizes automakers to produce more HEVs and electric vehicles, effectively shortening innovation cycles as companies race to meet credit requirements and avoid penalties.

Regulatory trends are also focusing on the entire lifecycle of HEVs, including battery production and end-of-life recycling. The EU's proposed Battery Regulation aims to ensure sustainable and ethical sourcing of raw materials, improve battery performance, and mandate recycling. These regulations are driving innovation in battery technology and manufacturing processes, further accelerating HEV development cycles.

Local and regional regulations are also playing a crucial role in shaping HEV innovation. Many cities are implementing low-emission zones and providing incentives for HEV adoption, creating localized demand that spurs manufacturers to develop market-specific HEV solutions more rapidly.

The global nature of these regulatory trends is forcing automakers to adopt a more agile and collaborative approach to HEV innovation. Cross-border partnerships and technology sharing agreements are becoming more common as companies seek to pool resources and expertise to meet diverse regulatory requirements across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!