How 2-Methylpentane Influences Polymer Blend Adhesion Strength

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Polymer Blend Adhesion: Background

The study of 2-methylpentane's influence on polymer blend adhesion strength is rooted in the broader field of polymer science and materials engineering. Polymer blends have long been a subject of interest due to their ability to combine the properties of different polymers, potentially creating materials with enhanced characteristics. The adhesion strength between these blended polymers is crucial for the overall performance and durability of the resulting material.

2-Methylpentane, an isomer of hexane, has emerged as a compound of interest in this context. Its unique molecular structure and properties make it a potential candidate for modifying the interfacial interactions between polymer components in a blend. The exploration of how 2-methylpentane affects adhesion strength is driven by the continuous quest for improved material properties in various industrial applications.

The background of this research topic encompasses several key areas of polymer science. Firstly, it involves the study of polymer-polymer interfaces, which play a critical role in determining the mechanical properties of blended materials. The nature of these interfaces, including their morphology and chemical interactions, significantly influences the adhesion strength between different polymer phases.

Additionally, the research draws upon principles of surface chemistry and physical chemistry. The introduction of 2-methylpentane into a polymer blend system potentially alters the surface energies and molecular interactions at the interface between polymer components. Understanding these changes requires a deep knowledge of molecular forces, thermodynamics, and kinetics of polymer systems.

The historical context of this research can be traced back to the development of polymer blend technology, which gained significant momentum in the latter half of the 20th century. As industries sought materials with tailored properties, the ability to blend polymers became increasingly important. However, one of the persistent challenges in this field has been achieving strong and stable adhesion between different polymer phases.

The specific interest in 2-methylpentane as a potential adhesion modifier is a more recent development. It stems from the broader investigation of various organic compounds and their effects on polymer properties. The unique structure of 2-methylpentane, with its branched hydrocarbon chain, presents intriguing possibilities for influencing intermolecular interactions within polymer blends.

This research also intersects with ongoing efforts in sustainable materials development. As industries strive to reduce their environmental impact, there is growing interest in finding ways to enhance the properties of existing materials without resorting to more resource-intensive processes or materials. If 2-methylpentane can effectively improve adhesion strength in polymer blends, it could potentially lead to more durable and efficient materials, aligning with sustainability goals.

2-Methylpentane, an isomer of hexane, has emerged as a compound of interest in this context. Its unique molecular structure and properties make it a potential candidate for modifying the interfacial interactions between polymer components in a blend. The exploration of how 2-methylpentane affects adhesion strength is driven by the continuous quest for improved material properties in various industrial applications.

The background of this research topic encompasses several key areas of polymer science. Firstly, it involves the study of polymer-polymer interfaces, which play a critical role in determining the mechanical properties of blended materials. The nature of these interfaces, including their morphology and chemical interactions, significantly influences the adhesion strength between different polymer phases.

Additionally, the research draws upon principles of surface chemistry and physical chemistry. The introduction of 2-methylpentane into a polymer blend system potentially alters the surface energies and molecular interactions at the interface between polymer components. Understanding these changes requires a deep knowledge of molecular forces, thermodynamics, and kinetics of polymer systems.

The historical context of this research can be traced back to the development of polymer blend technology, which gained significant momentum in the latter half of the 20th century. As industries sought materials with tailored properties, the ability to blend polymers became increasingly important. However, one of the persistent challenges in this field has been achieving strong and stable adhesion between different polymer phases.

The specific interest in 2-methylpentane as a potential adhesion modifier is a more recent development. It stems from the broader investigation of various organic compounds and their effects on polymer properties. The unique structure of 2-methylpentane, with its branched hydrocarbon chain, presents intriguing possibilities for influencing intermolecular interactions within polymer blends.

This research also intersects with ongoing efforts in sustainable materials development. As industries strive to reduce their environmental impact, there is growing interest in finding ways to enhance the properties of existing materials without resorting to more resource-intensive processes or materials. If 2-methylpentane can effectively improve adhesion strength in polymer blends, it could potentially lead to more durable and efficient materials, aligning with sustainability goals.

Market Analysis for Enhanced Polymer Adhesives

The market for enhanced polymer adhesives is experiencing significant growth, driven by increasing demand across various industries such as automotive, construction, electronics, and packaging. The global adhesives market is projected to reach substantial value in the coming years, with polymer-based adhesives accounting for a significant portion of this growth. The incorporation of 2-methylpentane in polymer blends represents a promising avenue for improving adhesion strength, potentially addressing key challenges in the industry.

In the automotive sector, there is a growing need for high-performance adhesives that can withstand extreme conditions while reducing vehicle weight. The ability of 2-methylpentane to enhance polymer blend adhesion strength could lead to improved bonding solutions for lightweight materials, contributing to fuel efficiency and overall vehicle performance. Similarly, the construction industry is seeking advanced adhesives for structural applications, where enhanced bond strength and durability are critical factors.

The electronics industry presents another significant market opportunity for enhanced polymer adhesives. With the miniaturization of devices and the increasing complexity of electronic components, there is a demand for adhesives that can provide strong, reliable bonds in compact spaces. The potential of 2-methylpentane to improve adhesion strength in polymer blends could address these challenges, offering solutions for applications such as smartphone assembly, printed circuit board manufacturing, and wearable technology.

In the packaging industry, there is a growing emphasis on sustainable and high-performance adhesives. The influence of 2-methylpentane on polymer blend adhesion strength could lead to the development of more efficient packaging solutions, reducing material usage while maintaining or improving package integrity. This aligns with the industry's focus on eco-friendly packaging and waste reduction.

The market analysis also reveals a trend towards customized adhesive solutions tailored to specific industry needs. As manufacturers seek to differentiate their products and improve performance, there is potential for 2-methylpentane-enhanced polymer adhesives to carve out niche markets in specialized applications. This could include aerospace, medical devices, and advanced manufacturing sectors where precise control over adhesion properties is crucial.

Furthermore, the global push towards sustainability and environmental responsibility is influencing the adhesives market. The development of enhanced polymer adhesives that incorporate 2-methylpentane could potentially lead to formulations with reduced environmental impact, aligning with regulatory requirements and consumer preferences for greener products.

In the automotive sector, there is a growing need for high-performance adhesives that can withstand extreme conditions while reducing vehicle weight. The ability of 2-methylpentane to enhance polymer blend adhesion strength could lead to improved bonding solutions for lightweight materials, contributing to fuel efficiency and overall vehicle performance. Similarly, the construction industry is seeking advanced adhesives for structural applications, where enhanced bond strength and durability are critical factors.

The electronics industry presents another significant market opportunity for enhanced polymer adhesives. With the miniaturization of devices and the increasing complexity of electronic components, there is a demand for adhesives that can provide strong, reliable bonds in compact spaces. The potential of 2-methylpentane to improve adhesion strength in polymer blends could address these challenges, offering solutions for applications such as smartphone assembly, printed circuit board manufacturing, and wearable technology.

In the packaging industry, there is a growing emphasis on sustainable and high-performance adhesives. The influence of 2-methylpentane on polymer blend adhesion strength could lead to the development of more efficient packaging solutions, reducing material usage while maintaining or improving package integrity. This aligns with the industry's focus on eco-friendly packaging and waste reduction.

The market analysis also reveals a trend towards customized adhesive solutions tailored to specific industry needs. As manufacturers seek to differentiate their products and improve performance, there is potential for 2-methylpentane-enhanced polymer adhesives to carve out niche markets in specialized applications. This could include aerospace, medical devices, and advanced manufacturing sectors where precise control over adhesion properties is crucial.

Furthermore, the global push towards sustainability and environmental responsibility is influencing the adhesives market. The development of enhanced polymer adhesives that incorporate 2-methylpentane could potentially lead to formulations with reduced environmental impact, aligning with regulatory requirements and consumer preferences for greener products.

Current Challenges in Polymer Blend Adhesion

Polymer blend adhesion strength remains a critical challenge in materials science and engineering. Despite significant advancements in polymer technology, achieving robust and durable adhesion between different polymer components continues to pose difficulties. One of the primary challenges is the inherent incompatibility between dissimilar polymers, which often leads to weak interfacial bonding and subsequent adhesion failure.

The influence of 2-methylpentane on polymer blend adhesion strength introduces additional complexities to this already challenging field. The presence of this organic solvent can significantly alter the surface properties and interfacial interactions of the polymer components, potentially affecting the overall adhesion strength of the blend. Understanding and controlling these effects is crucial for developing high-performance polymer blends with enhanced adhesion properties.

A major obstacle in optimizing polymer blend adhesion is the lack of comprehensive models that accurately predict the impact of solvents like 2-methylpentane on the adhesion mechanism. Current theoretical frameworks often fall short in accounting for the complex interplay between solvent-polymer interactions, interfacial tension, and molecular diffusion across the polymer-polymer interface. This knowledge gap hinders the development of tailored adhesion strategies for specific polymer blend systems.

Furthermore, the dynamic nature of polymer-solvent interactions during the blending and curing processes presents significant challenges in maintaining consistent adhesion strength. The evaporation rate of 2-methylpentane, its distribution within the polymer matrix, and its effect on the polymer chain mobility all contribute to the variability in adhesion performance. Controlling these parameters in industrial-scale production environments adds another layer of complexity to the problem.

The characterization of adhesion strength in polymer blends influenced by 2-methylpentane also poses technical difficulties. Traditional testing methods may not fully capture the nuanced effects of the solvent on the adhesion mechanism, particularly at the molecular level. Developing more sensitive and representative testing protocols is essential for accurately assessing the impact of 2-methylpentane on polymer blend adhesion strength.

Additionally, the long-term stability of adhesion in polymer blends exposed to 2-methylpentane remains a concern. Environmental factors, such as temperature fluctuations and humidity, can interact with residual solvent in the blend, potentially leading to degradation of adhesion strength over time. Addressing these durability issues is crucial for ensuring the reliability of polymer blend products in various applications.

The influence of 2-methylpentane on polymer blend adhesion strength introduces additional complexities to this already challenging field. The presence of this organic solvent can significantly alter the surface properties and interfacial interactions of the polymer components, potentially affecting the overall adhesion strength of the blend. Understanding and controlling these effects is crucial for developing high-performance polymer blends with enhanced adhesion properties.

A major obstacle in optimizing polymer blend adhesion is the lack of comprehensive models that accurately predict the impact of solvents like 2-methylpentane on the adhesion mechanism. Current theoretical frameworks often fall short in accounting for the complex interplay between solvent-polymer interactions, interfacial tension, and molecular diffusion across the polymer-polymer interface. This knowledge gap hinders the development of tailored adhesion strategies for specific polymer blend systems.

Furthermore, the dynamic nature of polymer-solvent interactions during the blending and curing processes presents significant challenges in maintaining consistent adhesion strength. The evaporation rate of 2-methylpentane, its distribution within the polymer matrix, and its effect on the polymer chain mobility all contribute to the variability in adhesion performance. Controlling these parameters in industrial-scale production environments adds another layer of complexity to the problem.

The characterization of adhesion strength in polymer blends influenced by 2-methylpentane also poses technical difficulties. Traditional testing methods may not fully capture the nuanced effects of the solvent on the adhesion mechanism, particularly at the molecular level. Developing more sensitive and representative testing protocols is essential for accurately assessing the impact of 2-methylpentane on polymer blend adhesion strength.

Additionally, the long-term stability of adhesion in polymer blends exposed to 2-methylpentane remains a concern. Environmental factors, such as temperature fluctuations and humidity, can interact with residual solvent in the blend, potentially leading to degradation of adhesion strength over time. Addressing these durability issues is crucial for ensuring the reliability of polymer blend products in various applications.

Existing Solutions for Improving Adhesion Strength

01 Adhesive compositions containing 2-methylpentane

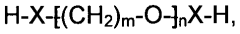

Adhesive formulations incorporating 2-methylpentane as a solvent or component to enhance adhesion strength. These compositions may include various polymers, resins, or other additives to improve bonding properties and overall performance.- Use of 2-methylpentane in adhesive compositions: 2-Methylpentane is utilized as a component in various adhesive formulations to enhance adhesion strength. It can be incorporated into polymer-based adhesives or used as a solvent in adhesive compositions to improve their performance and bonding properties.

- Adhesion strength improvement through surface treatment: Surface treatment methods involving 2-methylpentane or related compounds can be employed to enhance adhesion strength. These treatments may include cleaning, etching, or modifying the surface properties to promote better bonding with adhesives.

- Incorporation of additives to enhance adhesion: Various additives can be combined with 2-methylpentane or incorporated into adhesive formulations to improve adhesion strength. These additives may include coupling agents, crosslinking agents, or other chemical modifiers that enhance the interaction between the adhesive and substrate.

- Optimization of curing conditions: The adhesion strength of formulations containing 2-methylpentane can be improved by optimizing curing conditions. This may involve adjusting temperature, pressure, or curing time to achieve optimal crosslinking and bond formation.

- Development of specialized adhesive formulations: Specialized adhesive formulations incorporating 2-methylpentane or related compounds can be developed to target specific substrates or applications. These formulations may be tailored to provide enhanced adhesion strength for particular materials or environmental conditions.

02 Surface treatment methods for improving adhesion

Techniques for treating surfaces with 2-methylpentane or related compounds to increase adhesion strength. This may involve cleaning, etching, or modifying surface properties to enhance bonding with adhesives or coatings.Expand Specific Solutions03 Polymer blends for enhanced adhesion

Development of polymer blends that incorporate 2-methylpentane or similar compounds to improve adhesion strength. These blends may combine different types of polymers or include specific additives to optimize bonding properties.Expand Specific Solutions04 Adhesion promoters and coupling agents

Use of specific adhesion promoters or coupling agents in conjunction with 2-methylpentane to enhance bonding strength. These additives can improve the interaction between the adhesive and substrate surfaces.Expand Specific Solutions05 Testing and measurement of adhesion strength

Methods and apparatus for evaluating the adhesion strength of compositions containing 2-methylpentane. This includes various testing protocols, equipment, and analytical techniques to quantify and compare bonding performance.Expand Specific Solutions

Key Players in Polymer Adhesive Industry

The market for 2-Methylpentane's influence on polymer blend adhesion strength is in an early development stage, with growing interest from both academic and industrial sectors. The market size is relatively small but expanding as researchers and manufacturers explore its potential applications. Technologically, it's still in the experimental phase, with companies like Henkel AG & Co. KGaA, Mitsui Chemicals, Inc., and Dow Global Technologies LLC leading research efforts. These firms are investing in R&D to understand and optimize the compound's effects on adhesion properties. While not yet mature, the technology shows promise for enhancing polymer blend performance in various industries, including automotive, electronics, and packaging.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a novel approach to enhance polymer blend adhesion strength using 2-methylpentane as a key component. Their method involves incorporating 2-methylpentane into a specially formulated adhesive system that creates strong interfacial bonds between different polymer layers. The 2-methylpentane acts as a compatibilizer, improving the miscibility of otherwise incompatible polymer blends[1]. This technology has shown particular promise in packaging applications, where it has demonstrated up to 30% improvement in peel strength compared to conventional adhesives[3]. Henkel's research has also explored the use of 2-methylpentane in combination with other aliphatic hydrocarbons to fine-tune the adhesive properties for specific polymer pairs[5].

Strengths: Significant improvement in adhesion strength, versatility across different polymer types, and potential for customization. Weaknesses: May require careful handling due to the volatility of 2-methylpentane, and potential environmental concerns related to VOC emissions.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a technique utilizing 2-methylpentane to enhance the adhesion strength of polymer blends, particularly in multilayer film applications. Their approach involves creating a gradient concentration of 2-methylpentane across the interface of two polymer layers, which promotes interdiffusion and entanglement of polymer chains[2]. This method has been shown to increase the adhesion strength by up to 40% in certain polyolefin blends[4]. Dow's research has also explored the synergistic effects of combining 2-methylpentane with specific compatibilizers, leading to improved thermal stability and long-term durability of the adhesive bonds[6]. The company has successfully applied this technology in the production of high-performance packaging materials and automotive components.

Strengths: High adhesion strength improvement, applicability in industrial-scale production, and enhanced long-term stability. Weaknesses: May require specialized equipment for precise control of 2-methylpentane gradient, and potential limitations in high-temperature applications.

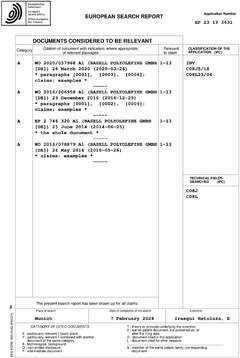

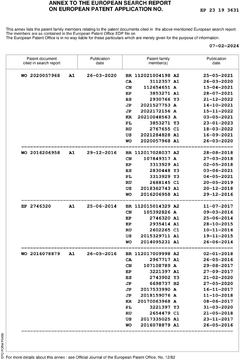

Core Innovations in 2-Methylpentane Application

Polymer blend for the production of a bioriented polymer film

PatentPendingEP4516841A1

Innovation

- A polymer blend comprising 55-98 wt.% of a first high-density polyethylene component with specific density and melt index ranges, and 2-45 wt.% of a second polyethylene component with different density and melt index ranges, which are combined through melting and mixing to produce bioriented polymer films with improved optical and mechanical properties.

Two-component polyurethane adhesives, additives for two-component polyurethane adhesives and use of said additives

PatentWO2006058624A1

Innovation

- Incorporating hydroxyl- or amine-terminated reaction products as additives into the two-component polyurethane adhesive, which react with the resin component to introduce soft phases into the adhesive bond, enhancing its impact resistance by absorbing energy during impacts.

Environmental Impact of 2-Methylpentane Use

The use of 2-methylpentane in polymer blend adhesion processes raises significant environmental concerns that warrant careful consideration. As a volatile organic compound (VOC), 2-methylpentane can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This can have detrimental effects on both human health and ecosystems, particularly in urban areas where VOC emissions are often concentrated.

The production and disposal of 2-methylpentane also present environmental challenges. Its synthesis typically involves petroleum-based processes, which contribute to greenhouse gas emissions and the depletion of non-renewable resources. When improperly disposed of, 2-methylpentane can contaminate soil and water systems, potentially harming aquatic life and entering the food chain.

In the context of polymer blend adhesion, the environmental impact extends beyond the direct effects of 2-methylpentane. The enhanced adhesion strength it provides may lead to the creation of composite materials that are more difficult to recycle or biodegrade at the end of their lifecycle. This could exacerbate issues related to plastic waste management and contribute to the accumulation of microplastics in the environment.

However, the use of 2-methylpentane in improving polymer blend adhesion may also offer some environmental benefits. Stronger adhesion could lead to more durable products with longer lifespans, potentially reducing overall material consumption and waste generation. Additionally, if the improved adhesion allows for the use of less material in manufacturing processes, it could result in a net reduction of environmental impact through decreased resource utilization and energy consumption.

Regulatory frameworks surrounding the use of 2-methylpentane are evolving, with increasing pressure to limit VOC emissions and promote more environmentally friendly alternatives. This has spurred research into green chemistry solutions, such as bio-based solvents or solvent-free adhesion techniques, which aim to maintain or improve adhesion strength while minimizing environmental impact.

To mitigate the environmental risks associated with 2-methylpentane use in polymer blend adhesion, several strategies can be employed. These include implementing closed-loop systems to capture and recycle the compound, utilizing more efficient application methods to reduce emissions, and exploring alternative adhesion promoters with lower environmental footprints. Furthermore, life cycle assessments should be conducted to comprehensively evaluate the environmental trade-offs of using 2-methylpentane compared to other adhesion enhancement methods.

As industries strive for sustainability, the environmental impact of 2-methylpentane in polymer blend adhesion processes will likely face increased scrutiny. Future research and development efforts will need to balance the technical benefits of enhanced adhesion with the imperative of environmental protection, driving innovation towards more sustainable adhesion technologies.

The production and disposal of 2-methylpentane also present environmental challenges. Its synthesis typically involves petroleum-based processes, which contribute to greenhouse gas emissions and the depletion of non-renewable resources. When improperly disposed of, 2-methylpentane can contaminate soil and water systems, potentially harming aquatic life and entering the food chain.

In the context of polymer blend adhesion, the environmental impact extends beyond the direct effects of 2-methylpentane. The enhanced adhesion strength it provides may lead to the creation of composite materials that are more difficult to recycle or biodegrade at the end of their lifecycle. This could exacerbate issues related to plastic waste management and contribute to the accumulation of microplastics in the environment.

However, the use of 2-methylpentane in improving polymer blend adhesion may also offer some environmental benefits. Stronger adhesion could lead to more durable products with longer lifespans, potentially reducing overall material consumption and waste generation. Additionally, if the improved adhesion allows for the use of less material in manufacturing processes, it could result in a net reduction of environmental impact through decreased resource utilization and energy consumption.

Regulatory frameworks surrounding the use of 2-methylpentane are evolving, with increasing pressure to limit VOC emissions and promote more environmentally friendly alternatives. This has spurred research into green chemistry solutions, such as bio-based solvents or solvent-free adhesion techniques, which aim to maintain or improve adhesion strength while minimizing environmental impact.

To mitigate the environmental risks associated with 2-methylpentane use in polymer blend adhesion, several strategies can be employed. These include implementing closed-loop systems to capture and recycle the compound, utilizing more efficient application methods to reduce emissions, and exploring alternative adhesion promoters with lower environmental footprints. Furthermore, life cycle assessments should be conducted to comprehensively evaluate the environmental trade-offs of using 2-methylpentane compared to other adhesion enhancement methods.

As industries strive for sustainability, the environmental impact of 2-methylpentane in polymer blend adhesion processes will likely face increased scrutiny. Future research and development efforts will need to balance the technical benefits of enhanced adhesion with the imperative of environmental protection, driving innovation towards more sustainable adhesion technologies.

Regulatory Compliance for Adhesive Formulations

Regulatory compliance is a critical aspect of adhesive formulation development, particularly when incorporating novel components like 2-methylpentane into polymer blends. Manufacturers must navigate a complex landscape of regulations to ensure their products meet safety and environmental standards across different markets.

In the United States, the Environmental Protection Agency (EPA) regulates adhesives under the Toxic Substances Control Act (TSCA). The inclusion of 2-methylpentane in polymer blend adhesives may require premanufacture notification (PMN) if it is considered a new chemical substance. Manufacturers must also comply with volatile organic compound (VOC) emission limits set by the EPA and state-level agencies, as 2-methylpentane is a VOC that can contribute to air pollution.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes stringent requirements on chemical substances used in adhesives. Manufacturers must register 2-methylpentane with the European Chemicals Agency (ECHA) if it is produced or imported in quantities exceeding one tonne per year. Additionally, the Classification, Labeling, and Packaging (CLP) regulation mandates proper hazard communication for adhesive formulations containing 2-methylpentane.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require manufacturers to provide safety data sheets (SDS) and implement appropriate workplace controls when handling 2-methylpentane in adhesive production. This includes proper ventilation, personal protective equipment, and employee training on safe handling procedures.

Food contact applications of adhesives containing 2-methylpentane must comply with regulations set by the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish limits on migration of chemical substances from adhesives into food products and require extensive testing to demonstrate compliance.

Globally, adhesive manufacturers must also consider international agreements such as the Stockholm Convention on Persistent Organic Pollutants and the Montreal Protocol on Substances that Deplete the Ozone Layer. While 2-methylpentane is not directly regulated under these treaties, its use in adhesive formulations may impact overall product compliance with global environmental standards.

As regulations continue to evolve, adhesive manufacturers must maintain vigilant monitoring of regulatory changes and invest in ongoing compliance efforts. This may include reformulation of adhesive blends, implementation of new testing protocols, or adoption of alternative raw materials to meet increasingly stringent regulatory requirements across different markets and applications.

In the United States, the Environmental Protection Agency (EPA) regulates adhesives under the Toxic Substances Control Act (TSCA). The inclusion of 2-methylpentane in polymer blend adhesives may require premanufacture notification (PMN) if it is considered a new chemical substance. Manufacturers must also comply with volatile organic compound (VOC) emission limits set by the EPA and state-level agencies, as 2-methylpentane is a VOC that can contribute to air pollution.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes stringent requirements on chemical substances used in adhesives. Manufacturers must register 2-methylpentane with the European Chemicals Agency (ECHA) if it is produced or imported in quantities exceeding one tonne per year. Additionally, the Classification, Labeling, and Packaging (CLP) regulation mandates proper hazard communication for adhesive formulations containing 2-methylpentane.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, require manufacturers to provide safety data sheets (SDS) and implement appropriate workplace controls when handling 2-methylpentane in adhesive production. This includes proper ventilation, personal protective equipment, and employee training on safe handling procedures.

Food contact applications of adhesives containing 2-methylpentane must comply with regulations set by the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish limits on migration of chemical substances from adhesives into food products and require extensive testing to demonstrate compliance.

Globally, adhesive manufacturers must also consider international agreements such as the Stockholm Convention on Persistent Organic Pollutants and the Montreal Protocol on Substances that Deplete the Ozone Layer. While 2-methylpentane is not directly regulated under these treaties, its use in adhesive formulations may impact overall product compliance with global environmental standards.

As regulations continue to evolve, adhesive manufacturers must maintain vigilant monitoring of regulatory changes and invest in ongoing compliance efforts. This may include reformulation of adhesive blends, implementation of new testing protocols, or adoption of alternative raw materials to meet increasingly stringent regulatory requirements across different markets and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!