How Steering Wheel Innovations Reduce Production Costs?

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Cost Reduction Objectives

The primary objective of steering wheel cost reduction initiatives is to optimize the manufacturing process and design while maintaining or enhancing the quality and functionality of the final product. This goal aligns with the broader automotive industry trend of increasing efficiency and reducing overall vehicle production costs.

One key focus area is material selection and optimization. By exploring alternative materials that offer similar or superior performance at a lower cost, manufacturers can significantly reduce the overall expense of steering wheel production. This may involve the use of advanced polymers, composite materials, or innovative alloys that provide the necessary strength and durability while being more cost-effective than traditional materials.

Another crucial aspect of cost reduction is streamlining the manufacturing process. This includes implementing lean manufacturing principles, automating certain production steps, and optimizing the supply chain. By reducing waste, minimizing production time, and improving overall efficiency, manufacturers can lower the per-unit cost of steering wheels without compromising quality.

Design simplification is also a critical objective in steering wheel cost reduction. This involves reevaluating the complexity of current designs and identifying opportunities to simplify without sacrificing functionality or aesthetics. Modular design approaches, which allow for easier assembly and customization, can contribute to cost savings in both production and inventory management.

Integration of advanced technologies, such as 3D printing and computer-aided design (CAD), can lead to more efficient prototyping and testing phases. This accelerates the development process and reduces the costs associated with multiple design iterations and physical prototypes.

Sustainability considerations are increasingly becoming part of cost reduction objectives. By designing steering wheels with recyclable or eco-friendly materials, manufacturers can potentially reduce long-term costs associated with waste management and comply with evolving environmental regulations.

Lastly, the objective of reducing steering wheel production costs extends to the entire lifecycle of the product. This includes considering factors such as ease of maintenance, durability, and end-of-life recycling or disposal. By optimizing these aspects, manufacturers can offer more competitive pricing to automotive companies while potentially reducing warranty and replacement costs.

In summary, steering wheel cost reduction objectives encompass a holistic approach to design, materials, manufacturing processes, and lifecycle considerations. The ultimate aim is to create a more cost-effective product that meets or exceeds current standards of quality, safety, and performance in the automotive industry.

One key focus area is material selection and optimization. By exploring alternative materials that offer similar or superior performance at a lower cost, manufacturers can significantly reduce the overall expense of steering wheel production. This may involve the use of advanced polymers, composite materials, or innovative alloys that provide the necessary strength and durability while being more cost-effective than traditional materials.

Another crucial aspect of cost reduction is streamlining the manufacturing process. This includes implementing lean manufacturing principles, automating certain production steps, and optimizing the supply chain. By reducing waste, minimizing production time, and improving overall efficiency, manufacturers can lower the per-unit cost of steering wheels without compromising quality.

Design simplification is also a critical objective in steering wheel cost reduction. This involves reevaluating the complexity of current designs and identifying opportunities to simplify without sacrificing functionality or aesthetics. Modular design approaches, which allow for easier assembly and customization, can contribute to cost savings in both production and inventory management.

Integration of advanced technologies, such as 3D printing and computer-aided design (CAD), can lead to more efficient prototyping and testing phases. This accelerates the development process and reduces the costs associated with multiple design iterations and physical prototypes.

Sustainability considerations are increasingly becoming part of cost reduction objectives. By designing steering wheels with recyclable or eco-friendly materials, manufacturers can potentially reduce long-term costs associated with waste management and comply with evolving environmental regulations.

Lastly, the objective of reducing steering wheel production costs extends to the entire lifecycle of the product. This includes considering factors such as ease of maintenance, durability, and end-of-life recycling or disposal. By optimizing these aspects, manufacturers can offer more competitive pricing to automotive companies while potentially reducing warranty and replacement costs.

In summary, steering wheel cost reduction objectives encompass a holistic approach to design, materials, manufacturing processes, and lifecycle considerations. The ultimate aim is to create a more cost-effective product that meets or exceeds current standards of quality, safety, and performance in the automotive industry.

Market Demand for Affordable Steering Systems

The automotive industry has witnessed a growing demand for affordable steering systems, driven by the need to reduce production costs while maintaining safety and performance standards. This market trend is particularly pronounced in emerging economies where cost-sensitive consumers seek reliable yet economical vehicles. Manufacturers are under pressure to innovate and streamline their production processes to meet this demand without compromising quality.

In developed markets, there is a shift towards more advanced steering systems that offer enhanced features such as electric power assistance and autonomous driving capabilities. However, these technologies must be balanced with cost considerations to remain competitive. The challenge lies in developing steering systems that incorporate these advanced features while keeping production costs low.

The global steering system market is experiencing steady growth, with a significant portion attributed to the demand for affordable solutions. Emerging markets in Asia-Pacific and Latin America are driving this trend, as automakers seek to capture market share in these regions by offering vehicles with competitive pricing. This has led to increased investment in research and development focused on cost-effective steering technologies.

Consumer preferences are also shaping the market demand for affordable steering systems. There is a growing awareness of the importance of fuel efficiency, which is directly impacted by the weight and design of steering components. Lightweight materials and innovative designs that reduce overall vehicle weight without sacrificing durability are highly sought after.

The commercial vehicle segment presents another significant opportunity for affordable steering systems. Fleet operators and logistics companies are constantly looking for ways to reduce operational costs, and steering systems that offer longevity and low maintenance requirements are particularly attractive in this sector.

Regulatory pressures also play a role in shaping market demand. As safety standards become more stringent globally, manufacturers must find ways to meet these requirements while keeping costs in check. This has led to a focus on developing steering systems that integrate safety features without significantly increasing production costs.

The aftermarket sector for steering systems is also experiencing growth, driven by the need for cost-effective replacement parts. This has created opportunities for manufacturers to develop affordable, high-quality components that can compete with OEM parts.

Overall, the market demand for affordable steering systems is robust and multifaceted, influenced by economic factors, technological advancements, consumer preferences, and regulatory requirements. Manufacturers who can successfully innovate to reduce production costs while meeting these diverse needs are well-positioned to capture a significant share of this growing market.

In developed markets, there is a shift towards more advanced steering systems that offer enhanced features such as electric power assistance and autonomous driving capabilities. However, these technologies must be balanced with cost considerations to remain competitive. The challenge lies in developing steering systems that incorporate these advanced features while keeping production costs low.

The global steering system market is experiencing steady growth, with a significant portion attributed to the demand for affordable solutions. Emerging markets in Asia-Pacific and Latin America are driving this trend, as automakers seek to capture market share in these regions by offering vehicles with competitive pricing. This has led to increased investment in research and development focused on cost-effective steering technologies.

Consumer preferences are also shaping the market demand for affordable steering systems. There is a growing awareness of the importance of fuel efficiency, which is directly impacted by the weight and design of steering components. Lightweight materials and innovative designs that reduce overall vehicle weight without sacrificing durability are highly sought after.

The commercial vehicle segment presents another significant opportunity for affordable steering systems. Fleet operators and logistics companies are constantly looking for ways to reduce operational costs, and steering systems that offer longevity and low maintenance requirements are particularly attractive in this sector.

Regulatory pressures also play a role in shaping market demand. As safety standards become more stringent globally, manufacturers must find ways to meet these requirements while keeping costs in check. This has led to a focus on developing steering systems that integrate safety features without significantly increasing production costs.

The aftermarket sector for steering systems is also experiencing growth, driven by the need for cost-effective replacement parts. This has created opportunities for manufacturers to develop affordable, high-quality components that can compete with OEM parts.

Overall, the market demand for affordable steering systems is robust and multifaceted, influenced by economic factors, technological advancements, consumer preferences, and regulatory requirements. Manufacturers who can successfully innovate to reduce production costs while meeting these diverse needs are well-positioned to capture a significant share of this growing market.

Current Challenges in Steering Wheel Manufacturing

The steering wheel manufacturing industry faces several significant challenges in its pursuit of cost reduction and efficiency improvement. One of the primary issues is the complexity of modern steering wheel designs, which often incorporate multiple advanced features such as airbags, controls for infotainment systems, and driver assistance technologies. This complexity increases production time and material costs, making it difficult to streamline manufacturing processes.

Material selection presents another challenge. Traditional materials like leather and wood, while luxurious, are expensive and can be inconsistent in quality. Synthetic alternatives, though more cost-effective, often struggle to match the premium feel of natural materials, creating a trade-off between cost and perceived quality. This dilemma forces manufacturers to constantly seek innovative materials that balance cost, durability, and consumer appeal.

The integration of electronic components into steering wheels has become increasingly common, adding another layer of complexity to the manufacturing process. These components require specialized assembly techniques and quality control measures, which can slow down production and increase costs. Moreover, ensuring the reliability and durability of these electronic systems in the harsh automotive environment poses significant technical challenges.

Customization demands from automakers and consumers further complicate the manufacturing process. The need to produce a wide variety of steering wheel designs for different vehicle models and trim levels increases tooling costs and reduces economies of scale. This variability makes it difficult to implement standardized, high-volume production techniques that could otherwise drive down costs.

Environmental regulations and sustainability concerns also present challenges. Manufacturers must invest in developing eco-friendly materials and production processes, which can be costly in the short term. Additionally, ensuring compliance with stringent safety standards, particularly regarding airbag integration and impact resistance, requires ongoing research and development efforts.

Labor costs remain a significant factor in steering wheel production, especially for high-end models that require skilled craftsmanship. Automating these processes without compromising quality is a persistent challenge. Furthermore, the global nature of the automotive supply chain introduces logistical complexities and potential disruptions that can impact production costs and efficiency.

Lastly, the rapid pace of technological advancement in the automotive industry means that steering wheel manufacturers must continuously invest in new technologies and production methods to remain competitive. This constant need for innovation and adaptation puts pressure on research and development budgets and requires frequent retooling of production lines, adding to overall manufacturing costs.

Material selection presents another challenge. Traditional materials like leather and wood, while luxurious, are expensive and can be inconsistent in quality. Synthetic alternatives, though more cost-effective, often struggle to match the premium feel of natural materials, creating a trade-off between cost and perceived quality. This dilemma forces manufacturers to constantly seek innovative materials that balance cost, durability, and consumer appeal.

The integration of electronic components into steering wheels has become increasingly common, adding another layer of complexity to the manufacturing process. These components require specialized assembly techniques and quality control measures, which can slow down production and increase costs. Moreover, ensuring the reliability and durability of these electronic systems in the harsh automotive environment poses significant technical challenges.

Customization demands from automakers and consumers further complicate the manufacturing process. The need to produce a wide variety of steering wheel designs for different vehicle models and trim levels increases tooling costs and reduces economies of scale. This variability makes it difficult to implement standardized, high-volume production techniques that could otherwise drive down costs.

Environmental regulations and sustainability concerns also present challenges. Manufacturers must invest in developing eco-friendly materials and production processes, which can be costly in the short term. Additionally, ensuring compliance with stringent safety standards, particularly regarding airbag integration and impact resistance, requires ongoing research and development efforts.

Labor costs remain a significant factor in steering wheel production, especially for high-end models that require skilled craftsmanship. Automating these processes without compromising quality is a persistent challenge. Furthermore, the global nature of the automotive supply chain introduces logistical complexities and potential disruptions that can impact production costs and efficiency.

Lastly, the rapid pace of technological advancement in the automotive industry means that steering wheel manufacturers must continuously invest in new technologies and production methods to remain competitive. This constant need for innovation and adaptation puts pressure on research and development budgets and requires frequent retooling of production lines, adding to overall manufacturing costs.

Existing Cost-Saving Solutions for Steering Wheels

01 Cost-effective manufacturing processes

Implementing efficient manufacturing processes can significantly reduce production costs for steering wheels. This includes optimizing assembly lines, utilizing automation where possible, and streamlining the overall production workflow. By improving manufacturing efficiency, companies can minimize labor costs and material waste, leading to more cost-effective steering wheel production.- Cost-effective manufacturing processes: Implementing efficient manufacturing processes can significantly reduce production costs for steering wheels. This includes optimizing assembly lines, using automated systems, and streamlining the overall production workflow. By improving manufacturing efficiency, companies can minimize labor costs and material waste, ultimately lowering the overall production expenses.

- Material selection and optimization: Choosing cost-effective materials without compromising quality is crucial for reducing steering wheel production costs. This involves exploring alternative materials, such as lightweight composites or recycled materials, that offer similar performance characteristics at a lower price point. Additionally, optimizing material usage through advanced design techniques can help minimize waste and reduce overall material costs.

- Design simplification and standardization: Simplifying steering wheel designs and standardizing components across different models can lead to significant cost savings. By reducing the number of unique parts and creating modular designs, manufacturers can benefit from economies of scale and streamline their production processes. This approach also simplifies inventory management and reduces tooling costs.

- Supply chain optimization: Optimizing the supply chain for steering wheel production can lead to substantial cost reductions. This includes sourcing materials and components from cost-effective suppliers, implementing just-in-time inventory systems, and improving logistics to reduce transportation and storage costs. Establishing strong relationships with suppliers can also lead to better pricing and more efficient procurement processes.

- Integration of advanced technologies: Incorporating advanced technologies in steering wheel production can lead to long-term cost savings. This includes using computer-aided design and simulation tools to optimize designs before production, implementing quality control systems to reduce defects and rework, and utilizing data analytics to identify areas for improvement in the production process. While initial investments may be required, these technologies can significantly reduce costs over time.

02 Material selection and optimization

Choosing appropriate materials for steering wheel construction plays a crucial role in managing production costs. This involves selecting cost-effective materials that meet safety and performance requirements, as well as optimizing material usage to reduce waste. Innovative materials and composites can offer a balance between cost, durability, and functionality.Expand Specific Solutions03 Design simplification and standardization

Simplifying steering wheel designs and standardizing components across different models can lead to significant cost savings. This approach reduces the number of unique parts required, simplifies inventory management, and allows for economies of scale in production. Standardization also facilitates easier assembly and maintenance processes.Expand Specific Solutions04 Integration of advanced technologies

Incorporating advanced technologies in steering wheel production, such as 3D printing, computer-aided design (CAD), and simulation software, can help optimize designs and reduce prototyping costs. These technologies enable rapid iteration and testing of designs, potentially reducing overall development time and associated expenses.Expand Specific Solutions05 Supply chain optimization

Optimizing the supply chain for steering wheel production can lead to significant cost reductions. This includes sourcing materials and components from cost-effective suppliers, improving logistics and inventory management, and establishing strategic partnerships with suppliers. Efficient supply chain management can help reduce overall production costs and improve lead times.Expand Specific Solutions

Key Players in Automotive Steering Industry

The steering wheel innovation market is in a growth phase, driven by increasing demand for cost-effective and advanced automotive safety solutions. The market size is expanding as automakers seek to reduce production costs while enhancing vehicle safety features. Technologically, the field is moderately mature, with established players like Autoliv Development AB, ZF Automotive Safety Germany GmbH, and Honda Motor Co., Ltd. leading innovation. These companies are focusing on integrating advanced materials and smart technologies into steering wheels to optimize production processes and reduce costs. Emerging players such as Joyson Safety Systems Germany GmbH and JTEKT Corp. are also contributing to the competitive landscape, pushing for more efficient and cost-effective steering wheel solutions.

Autoliv Development AB

Technical Solution: Autoliv has developed innovative steering wheel technologies to reduce production costs while maintaining safety standards. Their approach includes the use of advanced materials such as high-strength polymers and lightweight metals, which decrease overall weight and material costs[1]. They have also implemented modular design principles, allowing for easier assembly and customization[2]. Autoliv's steering wheels incorporate integrated airbag systems that simplify production processes, reducing the number of components and assembly steps[3]. Additionally, they have invested in automated manufacturing techniques, including robotic assembly and 3D printing for prototyping, which significantly cut down on labor costs and production time[4].

Strengths: Advanced materials reduce weight and costs; modular design enhances customization; integrated systems simplify production. Weaknesses: Initial investment in new technologies may be high; potential challenges in scaling up production for diverse vehicle models.|

ZF Automotive Safety Germany GmbH

Technical Solution: ZF has introduced cost-effective steering wheel innovations focusing on integrating multiple functions into a single unit. Their smart steering wheel concept incorporates touch-sensitive controls, haptic feedback, and gesture recognition, eliminating the need for separate buttons and switches[1]. This consolidation of components reduces material and assembly costs. ZF has also developed a steer-by-wire system that replaces mechanical linkages with electronic controls, simplifying the steering column structure and reducing production complexity[2]. Their use of advanced plastics and composite materials in steering wheel construction has led to a 20% weight reduction compared to traditional designs, lowering material costs[3]. Furthermore, ZF's implementation of Industry 4.0 principles in their production lines has optimized manufacturing processes, resulting in a 15% decrease in production time[4].

Strengths: Integration of multiple functions reduces component count; steer-by-wire technology simplifies production; lightweight materials lower costs. Weaknesses: High initial R&D costs; potential reliability concerns with complex electronic systems.|

Innovative Materials and Production Techniques

Custom steering wheels

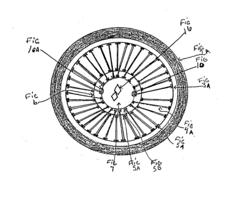

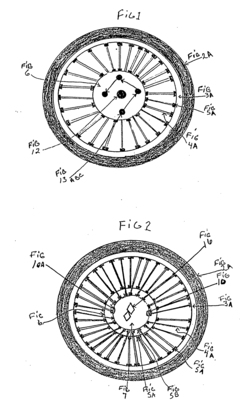

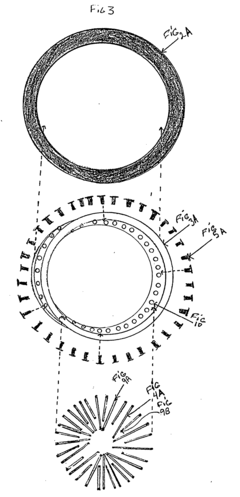

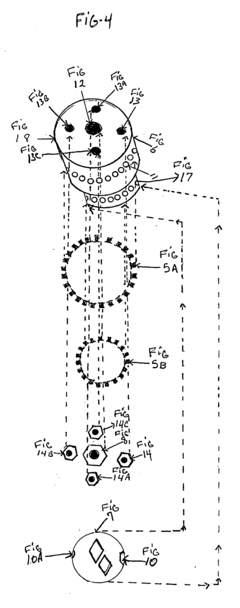

PatentInactiveUS20070227292A1

Innovation

- A custom steering wheel design featuring a hub, rim, and 72-100 spokes made from a metal alloy, where the hub core and base body are molded together with the spokes, eliminating the need for a separate skeleton, and allowing for integration of a reinforcing insert for gas bag module support, using a pressureless injection method with an aluminum alloy material.

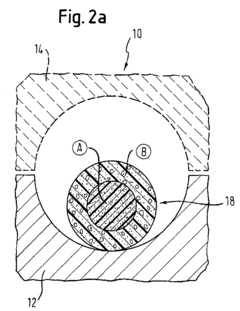

Process of fabrication of a steering wheel

PatentInactiveEP1302384A3

Innovation

- A method using a two-part foam mold to inject two different foam components - a central support component and a soft component - into an open mold, which is then closed and heated to shape the steering wheel, eliminating the need for post-processing and providing a comfortable grip.

Supply Chain Optimization Strategies

Supply chain optimization strategies play a crucial role in reducing production costs for steering wheel innovations. By streamlining the entire supply chain process, manufacturers can achieve significant cost savings while maintaining or even improving product quality.

One key strategy is to implement just-in-time (JIT) inventory management. This approach minimizes inventory holding costs by ensuring that raw materials and components arrive at the production facility precisely when needed. For steering wheel production, this could involve coordinating closely with suppliers of leather, plastics, and electronic components to deliver materials in smaller, more frequent batches.

Vertical integration is another effective strategy for cost reduction. By bringing certain aspects of the supply chain in-house, steering wheel manufacturers can reduce dependency on external suppliers and potentially lower costs. For instance, a company might invest in its own plastic injection molding capabilities or leather processing facilities, giving it greater control over quality and costs.

Leveraging advanced analytics and artificial intelligence can significantly optimize supply chain operations. These technologies can help predict demand more accurately, allowing for better production planning and reduced waste. They can also identify potential bottlenecks or inefficiencies in the supply chain, enabling proactive problem-solving.

Collaborative relationships with suppliers are essential for cost reduction. By fostering long-term partnerships, steering wheel manufacturers can negotiate better prices, ensure consistent quality, and work together on cost-saving innovations. This might involve joint research and development efforts or shared investments in new technologies.

Adopting lean manufacturing principles throughout the supply chain can lead to substantial cost savings. This involves eliminating waste, reducing unnecessary steps in the production process, and continuously improving efficiency. For steering wheel production, this could mean redesigning the assembly line layout or implementing more efficient packaging methods.

Geographical optimization of the supply chain is another important consideration. Locating production facilities closer to key suppliers or end markets can reduce transportation costs and lead times. This strategy may involve establishing regional manufacturing hubs or working with local suppliers in different markets.

Embracing automation and robotics in the supply chain can significantly reduce labor costs and improve consistency. For steering wheel production, this might include automated stitching machines for leather covers or robotic systems for assembly and quality control.

By implementing these supply chain optimization strategies, steering wheel manufacturers can achieve substantial reductions in production costs, ultimately leading to more competitive pricing and improved profitability.

One key strategy is to implement just-in-time (JIT) inventory management. This approach minimizes inventory holding costs by ensuring that raw materials and components arrive at the production facility precisely when needed. For steering wheel production, this could involve coordinating closely with suppliers of leather, plastics, and electronic components to deliver materials in smaller, more frequent batches.

Vertical integration is another effective strategy for cost reduction. By bringing certain aspects of the supply chain in-house, steering wheel manufacturers can reduce dependency on external suppliers and potentially lower costs. For instance, a company might invest in its own plastic injection molding capabilities or leather processing facilities, giving it greater control over quality and costs.

Leveraging advanced analytics and artificial intelligence can significantly optimize supply chain operations. These technologies can help predict demand more accurately, allowing for better production planning and reduced waste. They can also identify potential bottlenecks or inefficiencies in the supply chain, enabling proactive problem-solving.

Collaborative relationships with suppliers are essential for cost reduction. By fostering long-term partnerships, steering wheel manufacturers can negotiate better prices, ensure consistent quality, and work together on cost-saving innovations. This might involve joint research and development efforts or shared investments in new technologies.

Adopting lean manufacturing principles throughout the supply chain can lead to substantial cost savings. This involves eliminating waste, reducing unnecessary steps in the production process, and continuously improving efficiency. For steering wheel production, this could mean redesigning the assembly line layout or implementing more efficient packaging methods.

Geographical optimization of the supply chain is another important consideration. Locating production facilities closer to key suppliers or end markets can reduce transportation costs and lead times. This strategy may involve establishing regional manufacturing hubs or working with local suppliers in different markets.

Embracing automation and robotics in the supply chain can significantly reduce labor costs and improve consistency. For steering wheel production, this might include automated stitching machines for leather covers or robotic systems for assembly and quality control.

By implementing these supply chain optimization strategies, steering wheel manufacturers can achieve substantial reductions in production costs, ultimately leading to more competitive pricing and improved profitability.

Environmental Impact of Cost-Reduction Measures

The environmental impact of cost-reduction measures in steering wheel production is a critical consideration as manufacturers strive to balance economic efficiency with ecological responsibility. Innovations aimed at reducing production costs often have far-reaching environmental implications, both positive and negative.

One of the primary environmental benefits of cost-reduction measures is the potential decrease in material usage. By optimizing steering wheel designs and manufacturing processes, companies can significantly reduce the amount of raw materials required. This not only lowers production costs but also minimizes resource extraction and associated environmental degradation. For instance, the adoption of lightweight materials and advanced molding techniques can result in steering wheels that use less plastic and metal while maintaining structural integrity.

Energy consumption is another key area where cost-reduction innovations can yield environmental benefits. Streamlined production processes, such as automated assembly lines and energy-efficient machinery, can substantially reduce the energy required to manufacture steering wheels. This translates to lower greenhouse gas emissions and a smaller carbon footprint for the automotive industry. Additionally, the implementation of smart factory systems and IoT technologies enables real-time monitoring and optimization of energy usage, further enhancing environmental performance.

However, it is crucial to consider potential negative environmental impacts that may arise from cost-reduction measures. For example, the use of cheaper, less durable materials to cut costs could lead to shorter product lifecycles and increased waste generation. This highlights the importance of adopting a holistic approach to cost reduction that considers the entire lifecycle of the steering wheel, from production to disposal.

Waste reduction and recycling initiatives play a vital role in mitigating the environmental impact of steering wheel production. Innovations in recycling technologies and the use of recyclable materials can significantly reduce the amount of waste sent to landfills. Moreover, the implementation of closed-loop manufacturing systems, where waste materials are reintegrated into the production process, can further minimize environmental impact while reducing raw material costs.

The shift towards more sustainable production methods often requires initial investments in new technologies and processes. While these upfront costs may seem to contradict cost-reduction goals, they often lead to long-term savings and improved environmental performance. For instance, investing in advanced 3D printing technologies for steering wheel components can reduce material waste, energy consumption, and transportation costs associated with traditional manufacturing methods.

In conclusion, the environmental impact of cost-reduction measures in steering wheel production is multifaceted. While many innovations offer significant environmental benefits through reduced material usage, energy consumption, and waste generation, it is essential to carefully evaluate and mitigate potential negative impacts. By adopting a comprehensive approach that balances economic and environmental considerations, manufacturers can achieve sustainable cost reductions while minimizing their ecological footprint.

One of the primary environmental benefits of cost-reduction measures is the potential decrease in material usage. By optimizing steering wheel designs and manufacturing processes, companies can significantly reduce the amount of raw materials required. This not only lowers production costs but also minimizes resource extraction and associated environmental degradation. For instance, the adoption of lightweight materials and advanced molding techniques can result in steering wheels that use less plastic and metal while maintaining structural integrity.

Energy consumption is another key area where cost-reduction innovations can yield environmental benefits. Streamlined production processes, such as automated assembly lines and energy-efficient machinery, can substantially reduce the energy required to manufacture steering wheels. This translates to lower greenhouse gas emissions and a smaller carbon footprint for the automotive industry. Additionally, the implementation of smart factory systems and IoT technologies enables real-time monitoring and optimization of energy usage, further enhancing environmental performance.

However, it is crucial to consider potential negative environmental impacts that may arise from cost-reduction measures. For example, the use of cheaper, less durable materials to cut costs could lead to shorter product lifecycles and increased waste generation. This highlights the importance of adopting a holistic approach to cost reduction that considers the entire lifecycle of the steering wheel, from production to disposal.

Waste reduction and recycling initiatives play a vital role in mitigating the environmental impact of steering wheel production. Innovations in recycling technologies and the use of recyclable materials can significantly reduce the amount of waste sent to landfills. Moreover, the implementation of closed-loop manufacturing systems, where waste materials are reintegrated into the production process, can further minimize environmental impact while reducing raw material costs.

The shift towards more sustainable production methods often requires initial investments in new technologies and processes. While these upfront costs may seem to contradict cost-reduction goals, they often lead to long-term savings and improved environmental performance. For instance, investing in advanced 3D printing technologies for steering wheel components can reduce material waste, energy consumption, and transportation costs associated with traditional manufacturing methods.

In conclusion, the environmental impact of cost-reduction measures in steering wheel production is multifaceted. While many innovations offer significant environmental benefits through reduced material usage, energy consumption, and waste generation, it is essential to carefully evaluate and mitigate potential negative impacts. By adopting a comprehensive approach that balances economic and environmental considerations, manufacturers can achieve sustainable cost reductions while minimizing their ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!