How Steering Wheel Materials Affect Automotive Longevity?

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Material Evolution and Objectives

The evolution of steering wheel materials has been a crucial aspect of automotive development, significantly impacting vehicle longevity and overall performance. Initially, steering wheels were crafted from wood, which provided a natural and aesthetically pleasing appearance but lacked durability and safety features. As automotive technology progressed, manufacturers began experimenting with various materials to enhance both functionality and longevity.

In the mid-20th century, the introduction of plastic and rubber compounds marked a significant shift in steering wheel design. These materials offered improved grip, durability, and cost-effectiveness compared to their wooden predecessors. However, they were prone to degradation over time, particularly when exposed to extreme temperatures and UV radiation, which could lead to cracking and discoloration.

The late 20th century saw the emergence of leather-wrapped steering wheels, which combined luxury with improved grip and durability. This trend continues to be popular in many modern vehicles, especially in premium segments. Leather steering wheels, when properly maintained, can significantly contribute to a vehicle's longevity by resisting wear and maintaining their appearance over extended periods.

Recent advancements have led to the development of synthetic materials that mimic the feel of leather while offering superior durability and resistance to environmental factors. These materials, often referred to as "leatherette" or "vegan leather," are designed to withstand prolonged exposure to sunlight, temperature fluctuations, and frequent use without deteriorating.

The primary objective in steering wheel material evolution has been to strike a balance between durability, safety, and user comfort. Modern steering wheels are engineered to maintain their structural integrity and appearance throughout the vehicle's lifespan, directly contributing to the overall longevity of the automobile. This is achieved through the use of advanced polymers, high-quality leather, or synthetic alternatives that resist wear, tear, and environmental degradation.

Another crucial objective has been the integration of advanced technologies within the steering wheel structure. This includes the incorporation of airbag systems, touch-sensitive controls, and even biometric sensors. The materials used must not only accommodate these technologies but also ensure their long-term functionality and safety.

Looking forward, the automotive industry is exploring innovative materials such as carbon fiber composites and advanced plastics that offer exceptional strength-to-weight ratios. These materials promise to further enhance the durability and longevity of steering wheels while potentially reducing overall vehicle weight, thus contributing to improved fuel efficiency and performance.

In the mid-20th century, the introduction of plastic and rubber compounds marked a significant shift in steering wheel design. These materials offered improved grip, durability, and cost-effectiveness compared to their wooden predecessors. However, they were prone to degradation over time, particularly when exposed to extreme temperatures and UV radiation, which could lead to cracking and discoloration.

The late 20th century saw the emergence of leather-wrapped steering wheels, which combined luxury with improved grip and durability. This trend continues to be popular in many modern vehicles, especially in premium segments. Leather steering wheels, when properly maintained, can significantly contribute to a vehicle's longevity by resisting wear and maintaining their appearance over extended periods.

Recent advancements have led to the development of synthetic materials that mimic the feel of leather while offering superior durability and resistance to environmental factors. These materials, often referred to as "leatherette" or "vegan leather," are designed to withstand prolonged exposure to sunlight, temperature fluctuations, and frequent use without deteriorating.

The primary objective in steering wheel material evolution has been to strike a balance between durability, safety, and user comfort. Modern steering wheels are engineered to maintain their structural integrity and appearance throughout the vehicle's lifespan, directly contributing to the overall longevity of the automobile. This is achieved through the use of advanced polymers, high-quality leather, or synthetic alternatives that resist wear, tear, and environmental degradation.

Another crucial objective has been the integration of advanced technologies within the steering wheel structure. This includes the incorporation of airbag systems, touch-sensitive controls, and even biometric sensors. The materials used must not only accommodate these technologies but also ensure their long-term functionality and safety.

Looking forward, the automotive industry is exploring innovative materials such as carbon fiber composites and advanced plastics that offer exceptional strength-to-weight ratios. These materials promise to further enhance the durability and longevity of steering wheels while potentially reducing overall vehicle weight, thus contributing to improved fuel efficiency and performance.

Market Trends in Automotive Interior Durability

The automotive industry has witnessed a significant shift in consumer preferences and market dynamics, particularly in the realm of interior durability. As vehicles become more technologically advanced and consumers demand higher quality interiors, the focus on long-lasting materials has intensified. This trend is especially evident in the steering wheel market, where durability directly impacts both safety and user experience.

Recent market research indicates a growing demand for premium materials in steering wheels, with a particular emphasis on wear-resistant and easy-to-clean surfaces. Leather-wrapped steering wheels, once considered a luxury feature, have become increasingly standard in mid-range vehicles. However, there's a notable trend towards synthetic materials that mimic the feel of leather while offering superior durability and resistance to degradation from UV exposure and frequent use.

The push for sustainable and eco-friendly options has also influenced the steering wheel market. Manufacturers are exploring bio-based materials and recycled composites that can withstand the rigors of daily use while appealing to environmentally conscious consumers. This shift is not only driven by consumer preferences but also by stringent environmental regulations in various markets.

Automotive suppliers are responding to these trends by developing innovative coatings and treatments for steering wheel materials. These advancements aim to enhance grip, reduce wear, and maintain aesthetic appeal over the vehicle's lifespan. Anti-microbial treatments have gained traction, especially in the wake of global health concerns, adding another layer of value to steering wheel materials.

The integration of technology into steering wheels has also impacted material choices. As more vehicles incorporate touch-sensitive controls and heating elements into steering wheels, there's an increased demand for materials that can accommodate these features while maintaining durability. This has led to the development of composite materials that combine traditional steering wheel coverings with conductive elements.

Market data suggests that the global automotive steering wheel market is experiencing steady growth, with a particular emphasis on premium and technologically enhanced steering wheels. Manufacturers are investing heavily in research and development to create materials that not only meet current durability standards but also anticipate future needs, such as compatibility with autonomous driving technologies.

In conclusion, the market trends in automotive interior durability, particularly concerning steering wheel materials, reflect a complex interplay of consumer expectations, technological advancements, and sustainability concerns. As vehicles evolve, the steering wheel remains a critical touchpoint for driver interaction, driving innovation in materials that balance longevity, functionality, and user comfort.

Recent market research indicates a growing demand for premium materials in steering wheels, with a particular emphasis on wear-resistant and easy-to-clean surfaces. Leather-wrapped steering wheels, once considered a luxury feature, have become increasingly standard in mid-range vehicles. However, there's a notable trend towards synthetic materials that mimic the feel of leather while offering superior durability and resistance to degradation from UV exposure and frequent use.

The push for sustainable and eco-friendly options has also influenced the steering wheel market. Manufacturers are exploring bio-based materials and recycled composites that can withstand the rigors of daily use while appealing to environmentally conscious consumers. This shift is not only driven by consumer preferences but also by stringent environmental regulations in various markets.

Automotive suppliers are responding to these trends by developing innovative coatings and treatments for steering wheel materials. These advancements aim to enhance grip, reduce wear, and maintain aesthetic appeal over the vehicle's lifespan. Anti-microbial treatments have gained traction, especially in the wake of global health concerns, adding another layer of value to steering wheel materials.

The integration of technology into steering wheels has also impacted material choices. As more vehicles incorporate touch-sensitive controls and heating elements into steering wheels, there's an increased demand for materials that can accommodate these features while maintaining durability. This has led to the development of composite materials that combine traditional steering wheel coverings with conductive elements.

Market data suggests that the global automotive steering wheel market is experiencing steady growth, with a particular emphasis on premium and technologically enhanced steering wheels. Manufacturers are investing heavily in research and development to create materials that not only meet current durability standards but also anticipate future needs, such as compatibility with autonomous driving technologies.

In conclusion, the market trends in automotive interior durability, particularly concerning steering wheel materials, reflect a complex interplay of consumer expectations, technological advancements, and sustainability concerns. As vehicles evolve, the steering wheel remains a critical touchpoint for driver interaction, driving innovation in materials that balance longevity, functionality, and user comfort.

Current Challenges in Steering Wheel Longevity

The automotive industry faces several significant challenges in ensuring the longevity of steering wheels. One of the primary concerns is material degradation over time. Steering wheels are subjected to constant use and exposure to various environmental factors, which can lead to wear and tear. UV radiation from sunlight, temperature fluctuations, and humidity can cause materials to break down, resulting in discoloration, cracking, and loss of structural integrity.

Another challenge is the impact of human interaction on steering wheel materials. Oils and sweat from hands can accelerate the deterioration of certain materials, particularly leather and synthetic coverings. This can lead to premature aging, peeling, and a decrease in the overall quality and appearance of the steering wheel.

Durability is a critical factor in steering wheel design, as these components must withstand thousands of hours of use over the vehicle's lifetime. The materials used must be resistant to abrasion, impact, and fatigue. However, balancing durability with comfort and aesthetics presents a significant challenge for manufacturers.

The increasing complexity of modern steering wheels also poses challenges for longevity. With the integration of various controls, sensors, and electronic components, there are more potential points of failure. Ensuring the long-term reliability of these integrated systems while maintaining the structural integrity of the steering wheel is a complex task.

Environmental regulations and consumer demands for sustainable materials add another layer of complexity. Manufacturers must find eco-friendly alternatives that meet performance and longevity standards while complying with stringent environmental guidelines. This often requires extensive research and development to identify suitable materials that can withstand the rigors of daily use without compromising on sustainability.

Cost considerations also play a role in steering wheel longevity challenges. While high-end materials may offer superior durability, they may not be economically viable for mass-market vehicles. Striking a balance between cost-effectiveness and longevity is an ongoing challenge for automotive manufacturers.

Lastly, the varying climatic conditions in different regions present unique challenges. Steering wheels must be designed to withstand extreme temperatures, from the freezing cold of northern climates to the intense heat of tropical regions. This requires materials that can maintain their properties and performance across a wide range of environmental conditions, further complicating the selection and development process for steering wheel materials.

Another challenge is the impact of human interaction on steering wheel materials. Oils and sweat from hands can accelerate the deterioration of certain materials, particularly leather and synthetic coverings. This can lead to premature aging, peeling, and a decrease in the overall quality and appearance of the steering wheel.

Durability is a critical factor in steering wheel design, as these components must withstand thousands of hours of use over the vehicle's lifetime. The materials used must be resistant to abrasion, impact, and fatigue. However, balancing durability with comfort and aesthetics presents a significant challenge for manufacturers.

The increasing complexity of modern steering wheels also poses challenges for longevity. With the integration of various controls, sensors, and electronic components, there are more potential points of failure. Ensuring the long-term reliability of these integrated systems while maintaining the structural integrity of the steering wheel is a complex task.

Environmental regulations and consumer demands for sustainable materials add another layer of complexity. Manufacturers must find eco-friendly alternatives that meet performance and longevity standards while complying with stringent environmental guidelines. This often requires extensive research and development to identify suitable materials that can withstand the rigors of daily use without compromising on sustainability.

Cost considerations also play a role in steering wheel longevity challenges. While high-end materials may offer superior durability, they may not be economically viable for mass-market vehicles. Striking a balance between cost-effectiveness and longevity is an ongoing challenge for automotive manufacturers.

Lastly, the varying climatic conditions in different regions present unique challenges. Steering wheels must be designed to withstand extreme temperatures, from the freezing cold of northern climates to the intense heat of tropical regions. This requires materials that can maintain their properties and performance across a wide range of environmental conditions, further complicating the selection and development process for steering wheel materials.

Existing Solutions for Enhanced Steering Wheel Durability

01 Use of advanced polymers and composites

Advanced polymers and composite materials are increasingly used in steering wheel manufacturing to enhance durability and longevity. These materials offer improved resistance to wear, UV radiation, and temperature fluctuations, resulting in steering wheels that maintain their appearance and structural integrity over extended periods of use.- Use of advanced polymers and composites: Advanced polymers and composite materials are increasingly used in steering wheel manufacturing to enhance durability and longevity. These materials offer improved resistance to wear, temperature fluctuations, and UV radiation, resulting in steering wheels that maintain their appearance and structural integrity over extended periods of use.

- Integration of self-healing materials: Self-healing materials are being incorporated into steering wheel designs to address minor scratches and wear. These innovative materials can repair small surface damages autonomously, extending the aesthetic lifespan of the steering wheel and maintaining its tactile properties over time.

- Coating technologies for enhanced protection: Advanced coating technologies are applied to steering wheel materials to provide additional protection against environmental factors and daily use. These coatings can include UV-resistant layers, anti-microbial treatments, and scratch-resistant finishes, all contributing to the longevity of the steering wheel's appearance and functionality.

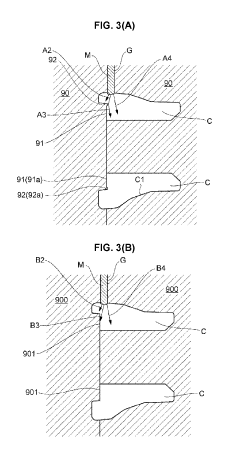

- Ergonomic design for reduced wear: Ergonomic design principles are applied to steering wheel construction to optimize grip positions and reduce localized wear. By distributing user contact more evenly across the wheel's surface, these designs help to minimize wear patterns and extend the overall lifespan of the steering wheel materials.

- Smart materials for adaptive durability: Incorporation of smart materials in steering wheel design allows for adaptive responses to various environmental conditions. These materials can adjust their properties based on temperature, humidity, or user interaction, potentially extending the functional lifespan of the steering wheel by mitigating factors that typically lead to material degradation.

02 Incorporation of self-healing materials

Self-healing materials are being integrated into steering wheel designs to address minor scratches and damages automatically. These innovative materials can repair themselves when exposed to certain stimuli, such as heat or pressure, thereby extending the lifespan of the steering wheel and maintaining its aesthetic appeal.Expand Specific Solutions03 Application of protective coatings

Specialized protective coatings are applied to steering wheel materials to enhance their resistance to environmental factors, chemicals, and physical wear. These coatings can include UV-resistant layers, anti-microbial treatments, and scratch-resistant finishes, all contributing to increased longevity of the steering wheel.Expand Specific Solutions04 Integration of smart materials for adaptability

Smart materials that can adapt to various environmental conditions are being incorporated into steering wheel designs. These materials can change their properties in response to temperature, humidity, or user interaction, ensuring optimal performance and longevity across diverse operating conditions.Expand Specific Solutions05 Ergonomic design for reduced wear

Ergonomic principles are applied in steering wheel design to minimize stress points and distribute wear more evenly. This approach includes optimizing grip areas, contouring surfaces, and strategically placing reinforcements to reduce material fatigue and extend the overall lifespan of the steering wheel.Expand Specific Solutions

Key Automotive and Material Suppliers Analysis

The automotive steering wheel materials market is in a mature stage, with a steady growth trajectory driven by increasing vehicle production and consumer demand for enhanced comfort and safety. The global market size is substantial, estimated to be in the billions of dollars, with potential for further expansion in emerging markets. Technologically, the field is advancing, with companies like ZF Automotive Safety Germany GmbH, TOKAI RIKA CO., LTD., and Autoliv Development AB leading innovations in materials and design. These firms, along with major automakers such as Hyundai Motor Co., Ltd. and Honda Motor Co., Ltd., are focusing on developing lightweight, durable, and eco-friendly materials to improve vehicle performance and sustainability. The competitive landscape is characterized by a mix of specialized component manufacturers and integrated automotive companies, all striving to balance cost-effectiveness with advanced functionality and aesthetics.

Hyundai Motor Co., Ltd.

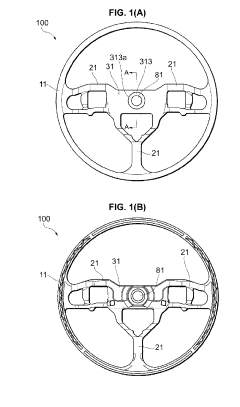

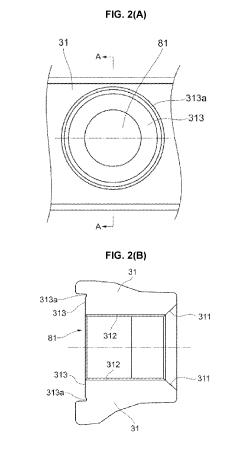

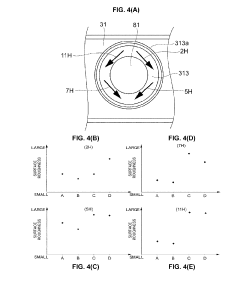

Technical Solution: Hyundai has introduced a novel approach to steering wheel materials with their "Smart Wheel" concept. The core structure utilizes a lightweight, high-strength aluminum alloy that provides excellent rigidity while reducing overall weight by up to 30% compared to traditional designs[13]. The outer layer incorporates a self-regulating polymer that can adjust its properties based on environmental conditions. In high temperatures, the material becomes more porous to improve grip and comfort, while in colder conditions, it contracts to maintain its shape and feel[14]. Hyundai has also integrated a thin layer of piezoelectric material within the wheel structure, which harvests energy from steering inputs to power embedded sensors that monitor the wheel's condition over time[15]. This allows for predictive maintenance, potentially extending the wheel's functional lifespan.

Strengths: Adaptive material properties, energy harvesting capabilities, and predictive maintenance features. Weaknesses: Complex technology integration may lead to higher costs and potential reliability concerns in the long term.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a bio-based steering wheel material that aims to improve both sustainability and longevity. The core is made from a composite of recycled aluminum and plant-derived resins, reducing weight while maintaining structural integrity[10]. The outer layer utilizes a bio-polyurethane derived from castor oil, which has shown improved resistance to UV degradation and hydrolysis compared to petroleum-based alternatives[11]. Honda's research indicates that this material can maintain its properties for up to 15 years under normal use conditions, a 25% improvement over their previous steering wheel materials[12]. Additionally, the company has implemented a special texturing process that enhances grip while reducing wear from frequent use.

Strengths: Environmentally friendly materials, improved longevity, and enhanced grip. Weaknesses: Potential limitations in extreme temperature conditions and higher initial production costs.

Innovative Materials and Coatings for Steering Wheels

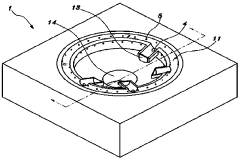

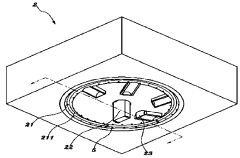

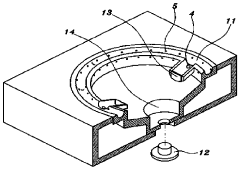

Monolithic expanded polypropylene steering wheel, manufacturing apparatus and method thereof

PatentWO2010074476A1

Innovation

- A manufacturing apparatus and method that forms a monolithic expanded polypropylene steering wheel by coupling upper and lower molds, injecting polypropylene material, and using a heat source to expand it uniformly around the steering wheel, with movable parts to ensure even coverage and reduce the number of components and processes.

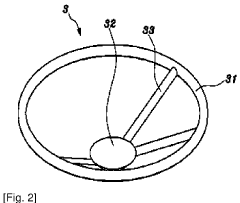

Steering-wheel core

PatentActiveUS20190224746A1

Innovation

- A steering-wheel core design featuring a boss core portion with an annular recess on the nut seat surface, which alters the flow direction of molten magnesium alloy during casting to reduce direct contact with the die surface, thereby minimizing surface roughness and eliminating the need for post-casting finishing.

Environmental Impact of Steering Wheel Materials

The environmental impact of steering wheel materials is a crucial consideration in the automotive industry, as it directly affects the sustainability and longevity of vehicles. Traditional steering wheel materials, such as leather and plastic, have long been associated with negative environmental consequences due to their production processes and end-of-life disposal.

Leather steering wheels, while luxurious, contribute to deforestation and greenhouse gas emissions through cattle farming. The tanning process also involves harmful chemicals that can pollute water sources. Plastic steering wheels, on the other hand, are derived from non-renewable petroleum resources and can take hundreds of years to decompose in landfills.

In recent years, there has been a shift towards more sustainable materials for steering wheels. Synthetic leather alternatives, made from recycled plastics or plant-based materials, offer a more eco-friendly option without compromising on aesthetics or durability. These materials reduce the carbon footprint associated with production and are often more easily recyclable at the end of the vehicle's life.

Wood-based steering wheels, particularly those made from sustainably sourced timber or reclaimed wood, present another environmentally conscious option. These materials are renewable and biodegradable, although care must be taken to ensure responsible forestry practices are employed in their sourcing.

The use of advanced composites in steering wheel construction is also gaining traction. These materials, often incorporating natural fibers like flax or hemp, offer excellent strength-to-weight ratios and can be engineered for improved recyclability. Their lightweight nature contributes to overall vehicle efficiency, indirectly reducing fuel consumption and emissions over the car's lifespan.

The environmental impact of steering wheel materials extends beyond their production and disposal. The durability and resistance to wear of these materials play a significant role in determining how often steering wheels need to be replaced. More durable materials can extend the life of the steering wheel, reducing the need for replacements and the associated environmental costs of manufacturing and disposing of additional components.

Furthermore, the choice of steering wheel material can influence the overall weight of the vehicle. Lighter materials contribute to improved fuel efficiency, which in turn reduces the vehicle's carbon emissions throughout its operational life. This long-term environmental benefit underscores the importance of considering material selection in the context of the entire vehicle lifecycle.

As automotive manufacturers increasingly prioritize sustainability, the development of new, eco-friendly steering wheel materials continues to evolve. Innovations in biomaterials and circular economy principles are driving the creation of steering wheels that are not only environmentally responsible in their production but also in their ability to be recycled or biodegraded at the end of their useful life.

Leather steering wheels, while luxurious, contribute to deforestation and greenhouse gas emissions through cattle farming. The tanning process also involves harmful chemicals that can pollute water sources. Plastic steering wheels, on the other hand, are derived from non-renewable petroleum resources and can take hundreds of years to decompose in landfills.

In recent years, there has been a shift towards more sustainable materials for steering wheels. Synthetic leather alternatives, made from recycled plastics or plant-based materials, offer a more eco-friendly option without compromising on aesthetics or durability. These materials reduce the carbon footprint associated with production and are often more easily recyclable at the end of the vehicle's life.

Wood-based steering wheels, particularly those made from sustainably sourced timber or reclaimed wood, present another environmentally conscious option. These materials are renewable and biodegradable, although care must be taken to ensure responsible forestry practices are employed in their sourcing.

The use of advanced composites in steering wheel construction is also gaining traction. These materials, often incorporating natural fibers like flax or hemp, offer excellent strength-to-weight ratios and can be engineered for improved recyclability. Their lightweight nature contributes to overall vehicle efficiency, indirectly reducing fuel consumption and emissions over the car's lifespan.

The environmental impact of steering wheel materials extends beyond their production and disposal. The durability and resistance to wear of these materials play a significant role in determining how often steering wheels need to be replaced. More durable materials can extend the life of the steering wheel, reducing the need for replacements and the associated environmental costs of manufacturing and disposing of additional components.

Furthermore, the choice of steering wheel material can influence the overall weight of the vehicle. Lighter materials contribute to improved fuel efficiency, which in turn reduces the vehicle's carbon emissions throughout its operational life. This long-term environmental benefit underscores the importance of considering material selection in the context of the entire vehicle lifecycle.

As automotive manufacturers increasingly prioritize sustainability, the development of new, eco-friendly steering wheel materials continues to evolve. Innovations in biomaterials and circular economy principles are driving the creation of steering wheels that are not only environmentally responsible in their production but also in their ability to be recycled or biodegraded at the end of their useful life.

Regulatory Standards for Automotive Interior Materials

Regulatory standards for automotive interior materials play a crucial role in ensuring the safety, durability, and environmental impact of vehicles. These standards are established by various regulatory bodies worldwide, including the National Highway Traffic Safety Administration (NHTSA) in the United States, the European Union's European Committee for Standardization (CEN), and the United Nations Economic Commission for Europe (UNECE).

One of the primary concerns addressed by these regulations is the flammability of interior materials. Standards such as FMVSS 302 in the US and ECE R118 in Europe set specific requirements for the burn rate of materials used in vehicle interiors, including steering wheels. These standards aim to minimize the risk of fire spreading within the vehicle in the event of an accident.

Chemical emissions from interior materials are another critical aspect regulated by automotive standards. Volatile Organic Compounds (VOCs) emitted by plastics, adhesives, and other materials used in steering wheels can affect air quality inside the vehicle and potentially impact occupant health. Regulations like GB/T 27630-2011 in China and VDA 278 in Europe set limits on VOC emissions from automotive interiors.

Durability and wear resistance of steering wheel materials are also subject to regulatory scrutiny. Standards such as SAE J2236 provide guidelines for testing the wear resistance of automotive interior trim materials, including those used in steering wheels. These standards ensure that the materials can withstand prolonged use and maintain their integrity over the vehicle's lifespan.

Environmental considerations are increasingly being incorporated into regulatory standards for automotive materials. The European Union's End-of-Life Vehicles (ELV) Directive, for instance, sets requirements for the recyclability and recoverability of vehicle components, including interior materials. This directive encourages the use of sustainable and recyclable materials in steering wheel construction.

Regulatory bodies also address the potential health impacts of materials used in automotive interiors. For example, the REACH regulation in Europe restricts the use of certain hazardous substances in vehicle components, including steering wheels. This regulation aims to protect both manufacturing workers and vehicle occupants from exposure to harmful chemicals.

As vehicle technology advances, new standards are being developed to address emerging materials and technologies. For instance, the increasing use of touch-sensitive controls and displays integrated into steering wheels has led to the development of standards for electromagnetic compatibility and durability of these electronic components.

One of the primary concerns addressed by these regulations is the flammability of interior materials. Standards such as FMVSS 302 in the US and ECE R118 in Europe set specific requirements for the burn rate of materials used in vehicle interiors, including steering wheels. These standards aim to minimize the risk of fire spreading within the vehicle in the event of an accident.

Chemical emissions from interior materials are another critical aspect regulated by automotive standards. Volatile Organic Compounds (VOCs) emitted by plastics, adhesives, and other materials used in steering wheels can affect air quality inside the vehicle and potentially impact occupant health. Regulations like GB/T 27630-2011 in China and VDA 278 in Europe set limits on VOC emissions from automotive interiors.

Durability and wear resistance of steering wheel materials are also subject to regulatory scrutiny. Standards such as SAE J2236 provide guidelines for testing the wear resistance of automotive interior trim materials, including those used in steering wheels. These standards ensure that the materials can withstand prolonged use and maintain their integrity over the vehicle's lifespan.

Environmental considerations are increasingly being incorporated into regulatory standards for automotive materials. The European Union's End-of-Life Vehicles (ELV) Directive, for instance, sets requirements for the recyclability and recoverability of vehicle components, including interior materials. This directive encourages the use of sustainable and recyclable materials in steering wheel construction.

Regulatory bodies also address the potential health impacts of materials used in automotive interiors. For example, the REACH regulation in Europe restricts the use of certain hazardous substances in vehicle components, including steering wheels. This regulation aims to protect both manufacturing workers and vehicle occupants from exposure to harmful chemicals.

As vehicle technology advances, new standards are being developed to address emerging materials and technologies. For instance, the increasing use of touch-sensitive controls and displays integrated into steering wheels has led to the development of standards for electromagnetic compatibility and durability of these electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!