How to Enhance Steering Wheel Grip for Precision Driving?

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Grip Evolution and Objectives

The evolution of steering wheel grip technology has been a crucial aspect of automotive engineering, focusing on enhancing driver control and precision. From the early days of automobiles, when steering wheels were simple wooden or metal rings, to today's advanced, ergonomically designed interfaces, the development has been driven by the need for improved safety, comfort, and performance.

In the 1950s and 1960s, as cars became more powerful and speeds increased, the importance of a secure grip became evident. This led to the introduction of textured surfaces and the use of materials like leather and rubber to improve traction. The 1970s and 1980s saw further advancements with the integration of thumb rests and contoured designs to accommodate different hand positions.

The 1990s marked a significant shift with the widespread adoption of airbags in steering wheels, necessitating a redesign of grip areas to ensure safety during deployment. This period also saw the introduction of multi-function steering wheels, incorporating controls for various vehicle systems, which required careful consideration of grip placement and ergonomics.

In recent years, the focus has shifted towards precision driving and enhanced feedback. Modern steering wheels often feature high-tech materials like Alcantara or specially engineered polymers that provide optimal grip in various conditions. Some manufacturers have explored variable-texture surfaces that adapt to different driving modes or weather conditions.

The current objectives in steering wheel grip technology are multifaceted. Firstly, there is a push towards creating grips that can maintain optimal performance across a wide range of temperatures and humidity levels, ensuring consistent control in diverse climates. Secondly, there is growing interest in developing "smart" grips that can detect the driver's hand position and pressure, potentially integrating with advanced driver assistance systems.

Another key objective is to enhance the tactile feedback provided through the steering wheel, allowing drivers to better sense road conditions and vehicle dynamics. This involves not only material science but also the integration of haptic technology to convey information through subtle vibrations or resistance changes in the grip.

As autonomous driving technologies advance, there is also a focus on developing steering wheel grips that can seamlessly transition between manual and automated driving modes. This includes exploring designs that can retract or transform when not in use, while still providing immediate and secure control when needed.

Lastly, with the increasing emphasis on sustainability in the automotive industry, there is a growing objective to develop eco-friendly grip materials that maintain high performance standards while reducing environmental impact. This includes research into bio-based materials and recycling processes for steering wheel components.

In the 1950s and 1960s, as cars became more powerful and speeds increased, the importance of a secure grip became evident. This led to the introduction of textured surfaces and the use of materials like leather and rubber to improve traction. The 1970s and 1980s saw further advancements with the integration of thumb rests and contoured designs to accommodate different hand positions.

The 1990s marked a significant shift with the widespread adoption of airbags in steering wheels, necessitating a redesign of grip areas to ensure safety during deployment. This period also saw the introduction of multi-function steering wheels, incorporating controls for various vehicle systems, which required careful consideration of grip placement and ergonomics.

In recent years, the focus has shifted towards precision driving and enhanced feedback. Modern steering wheels often feature high-tech materials like Alcantara or specially engineered polymers that provide optimal grip in various conditions. Some manufacturers have explored variable-texture surfaces that adapt to different driving modes or weather conditions.

The current objectives in steering wheel grip technology are multifaceted. Firstly, there is a push towards creating grips that can maintain optimal performance across a wide range of temperatures and humidity levels, ensuring consistent control in diverse climates. Secondly, there is growing interest in developing "smart" grips that can detect the driver's hand position and pressure, potentially integrating with advanced driver assistance systems.

Another key objective is to enhance the tactile feedback provided through the steering wheel, allowing drivers to better sense road conditions and vehicle dynamics. This involves not only material science but also the integration of haptic technology to convey information through subtle vibrations or resistance changes in the grip.

As autonomous driving technologies advance, there is also a focus on developing steering wheel grips that can seamlessly transition between manual and automated driving modes. This includes exploring designs that can retract or transform when not in use, while still providing immediate and secure control when needed.

Lastly, with the increasing emphasis on sustainability in the automotive industry, there is a growing objective to develop eco-friendly grip materials that maintain high performance standards while reducing environmental impact. This includes research into bio-based materials and recycling processes for steering wheel components.

Market Analysis for Enhanced Steering Control

The market for enhanced steering control technologies has been experiencing significant growth in recent years, driven by increasing demand for precision driving experiences and advanced safety features in vehicles. This trend is particularly evident in the premium and luxury car segments, where drivers expect superior handling and control.

The global automotive steering system market, which includes steering wheel grip enhancement technologies, was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 6.8%. This growth is attributed to the rising production of vehicles, increasing demand for electric power steering systems, and the integration of advanced driver assistance systems (ADAS) in modern vehicles.

Within this market, the segment specifically focused on steering wheel grip enhancement is gaining traction. While precise market size data for this niche is limited, industry experts estimate it to be a rapidly growing subset of the overall steering system market. The demand for enhanced steering wheel grip solutions is primarily driven by three key factors:

Firstly, the increasing emphasis on driver safety has led to a growing interest in technologies that improve vehicle control. Enhanced steering wheel grip can significantly contribute to better handling and reduced driver fatigue, especially during long journeys or in challenging driving conditions.

Secondly, the rise of performance and sports vehicles has created a market segment that values precision driving experiences. These drivers are willing to invest in technologies that offer better feedback and control, making enhanced steering wheel grip solutions particularly appealing.

Lastly, the growing adoption of autonomous and semi-autonomous vehicles has paradoxically increased the importance of steering wheel design. In vehicles where manual control may be required at short notice, a reliable and ergonomic steering wheel grip becomes crucial for safe and effective transitions between autonomous and manual driving modes.

Geographically, North America and Europe are leading the market for enhanced steering control technologies, owing to their mature automotive industries and high consumer awareness of advanced vehicle features. However, the Asia-Pacific region, particularly countries like China and India, is expected to witness the fastest growth in this market due to rapidly increasing vehicle production and rising disposable incomes.

Key players in this market include established automotive suppliers such as Bosch, Continental, and ZF Friedrichshafen, as well as specialized manufacturers focusing on steering wheel technologies. These companies are investing heavily in research and development to create innovative solutions that enhance steering wheel grip and overall driving experience.

In conclusion, the market for enhanced steering control, particularly focusing on steering wheel grip for precision driving, shows strong growth potential. As vehicle manufacturers continue to prioritize safety, performance, and driver experience, the demand for advanced steering wheel grip technologies is expected to increase, presenting significant opportunities for innovation and market expansion in the coming years.

The global automotive steering system market, which includes steering wheel grip enhancement technologies, was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 6.8%. This growth is attributed to the rising production of vehicles, increasing demand for electric power steering systems, and the integration of advanced driver assistance systems (ADAS) in modern vehicles.

Within this market, the segment specifically focused on steering wheel grip enhancement is gaining traction. While precise market size data for this niche is limited, industry experts estimate it to be a rapidly growing subset of the overall steering system market. The demand for enhanced steering wheel grip solutions is primarily driven by three key factors:

Firstly, the increasing emphasis on driver safety has led to a growing interest in technologies that improve vehicle control. Enhanced steering wheel grip can significantly contribute to better handling and reduced driver fatigue, especially during long journeys or in challenging driving conditions.

Secondly, the rise of performance and sports vehicles has created a market segment that values precision driving experiences. These drivers are willing to invest in technologies that offer better feedback and control, making enhanced steering wheel grip solutions particularly appealing.

Lastly, the growing adoption of autonomous and semi-autonomous vehicles has paradoxically increased the importance of steering wheel design. In vehicles where manual control may be required at short notice, a reliable and ergonomic steering wheel grip becomes crucial for safe and effective transitions between autonomous and manual driving modes.

Geographically, North America and Europe are leading the market for enhanced steering control technologies, owing to their mature automotive industries and high consumer awareness of advanced vehicle features. However, the Asia-Pacific region, particularly countries like China and India, is expected to witness the fastest growth in this market due to rapidly increasing vehicle production and rising disposable incomes.

Key players in this market include established automotive suppliers such as Bosch, Continental, and ZF Friedrichshafen, as well as specialized manufacturers focusing on steering wheel technologies. These companies are investing heavily in research and development to create innovative solutions that enhance steering wheel grip and overall driving experience.

In conclusion, the market for enhanced steering control, particularly focusing on steering wheel grip for precision driving, shows strong growth potential. As vehicle manufacturers continue to prioritize safety, performance, and driver experience, the demand for advanced steering wheel grip technologies is expected to increase, presenting significant opportunities for innovation and market expansion in the coming years.

Current Grip Technologies and Challenges

Current steering wheel grip technologies primarily focus on enhancing driver control and comfort during precision driving. Traditional materials such as leather and rubber remain popular due to their durability and tactile properties. However, advancements in material science have led to the development of synthetic compounds that offer improved grip characteristics while maintaining longevity.

One of the key challenges in steering wheel grip technology is balancing the need for a firm grip with driver comfort during extended periods of use. Manufacturers are experimenting with various textures and patterns on the wheel surface to optimize grip without causing fatigue or discomfort. Micro-texturing techniques, such as laser etching, are being employed to create subtle surface variations that enhance grip without compromising the overall feel of the wheel.

Another significant development is the integration of smart materials into steering wheel grips. These materials can adapt to different driving conditions, providing varying levels of grip based on factors such as speed, weather conditions, and driver input. For instance, some advanced systems incorporate temperature-sensitive polymers that become tackier when heated by the driver's hands, offering improved grip during intense driving situations.

Ergonomic design has also become a crucial aspect of steering wheel grip technology. Manufacturers are focusing on creating contoured grips that naturally fit the shape of the driver's hands, reducing strain and improving control. This approach often involves extensive research into hand anthropometry and biomechanics to optimize the wheel's shape and grip positions.

Despite these advancements, several challenges persist in the field of steering wheel grip technology. One major issue is the variability in driver preferences and hand sizes, making it difficult to create a universally optimal grip solution. Additionally, the need for grip enhancement must be balanced with aesthetic considerations, as the steering wheel is a prominent visual element in a vehicle's interior.

Durability remains another significant challenge, particularly for high-performance and racing applications where the grip is subjected to intense use and potentially harsh conditions. Developing materials that can maintain their grip properties over extended periods while resisting wear, UV degradation, and chemical exposure from hand oils and sweat is an ongoing area of research.

Furthermore, the increasing prevalence of autonomous driving technologies presents new challenges for steering wheel grip design. As vehicles transition between manual and autonomous modes, grip technologies must adapt to provide appropriate feedback and control to the driver when needed, while remaining unobtrusive during autonomous operation.

One of the key challenges in steering wheel grip technology is balancing the need for a firm grip with driver comfort during extended periods of use. Manufacturers are experimenting with various textures and patterns on the wheel surface to optimize grip without causing fatigue or discomfort. Micro-texturing techniques, such as laser etching, are being employed to create subtle surface variations that enhance grip without compromising the overall feel of the wheel.

Another significant development is the integration of smart materials into steering wheel grips. These materials can adapt to different driving conditions, providing varying levels of grip based on factors such as speed, weather conditions, and driver input. For instance, some advanced systems incorporate temperature-sensitive polymers that become tackier when heated by the driver's hands, offering improved grip during intense driving situations.

Ergonomic design has also become a crucial aspect of steering wheel grip technology. Manufacturers are focusing on creating contoured grips that naturally fit the shape of the driver's hands, reducing strain and improving control. This approach often involves extensive research into hand anthropometry and biomechanics to optimize the wheel's shape and grip positions.

Despite these advancements, several challenges persist in the field of steering wheel grip technology. One major issue is the variability in driver preferences and hand sizes, making it difficult to create a universally optimal grip solution. Additionally, the need for grip enhancement must be balanced with aesthetic considerations, as the steering wheel is a prominent visual element in a vehicle's interior.

Durability remains another significant challenge, particularly for high-performance and racing applications where the grip is subjected to intense use and potentially harsh conditions. Developing materials that can maintain their grip properties over extended periods while resisting wear, UV degradation, and chemical exposure from hand oils and sweat is an ongoing area of research.

Furthermore, the increasing prevalence of autonomous driving technologies presents new challenges for steering wheel grip design. As vehicles transition between manual and autonomous modes, grip technologies must adapt to provide appropriate feedback and control to the driver when needed, while remaining unobtrusive during autonomous operation.

Existing Grip Enhancement Techniques

01 Ergonomic steering wheel grip design

Ergonomically designed steering wheel grips improve driver comfort and control. These designs consider factors such as hand positioning, grip circumference, and material texture to reduce fatigue and enhance steering precision during long drives.- Ergonomic steering wheel grip designs: Various ergonomic designs for steering wheel grips aim to improve comfort and control for drivers. These designs may include contoured shapes, textured surfaces, or adjustable features to accommodate different hand sizes and driving styles. Such ergonomic grips can reduce fatigue during long drives and enhance overall driving experience.

- Heated steering wheel grips: Heated steering wheel grips provide comfort in cold weather conditions. These systems typically incorporate heating elements within the grip material or beneath the surface. Temperature control mechanisms may be included to allow drivers to adjust the heat level according to their preferences.

- Smart steering wheel grip technologies: Advanced steering wheel grips incorporate smart technologies for enhanced functionality and safety. These may include sensors to detect driver grip pressure, hand position, or even biometric data. Such technologies can be integrated with vehicle systems to provide alerts, adjust steering sensitivity, or monitor driver alertness.

- Customizable and interchangeable steering wheel grips: Customizable steering wheel grip systems allow drivers to personalize their driving experience. These may include interchangeable grip covers, modular designs, or adjustable components. Such systems cater to individual preferences for grip material, texture, and thickness.

- Steering wheel grip materials and manufacturing techniques: Innovations in materials and manufacturing processes for steering wheel grips focus on improving durability, grip performance, and aesthetic appeal. Advanced polymers, composite materials, and specialized coatings may be used to enhance grip properties while maintaining long-term wear resistance. Novel manufacturing techniques, such as overmolding or 3D printing, can be employed to create complex grip designs.

02 Heated steering wheel grips

Heated steering wheel grips provide comfort in cold weather conditions. These systems incorporate heating elements within the grip material, allowing drivers to maintain better control and comfort when driving in low temperatures.Expand Specific Solutions03 Adjustable steering wheel grip systems

Adjustable steering wheel grip systems allow drivers to customize the wheel's position and grip to their preferences. These systems may include telescoping, tilting, or rotating mechanisms to accommodate different driving styles and body types.Expand Specific Solutions04 Smart steering wheel grips with integrated controls

Smart steering wheel grips incorporate various controls and sensors directly into the grip surface. These may include touch-sensitive areas, buttons, or gesture recognition technology for controlling vehicle functions without removing hands from the wheel.Expand Specific Solutions05 Anti-slip and vibration-dampening steering wheel grips

Specialized materials and textures are used in steering wheel grips to enhance grip and reduce vibrations. These designs improve driver control in various weather conditions and driving scenarios while also minimizing fatigue from road vibrations.Expand Specific Solutions

Key Players in Automotive Grip Solutions

The steering wheel grip enhancement technology for precision driving is in a mature development stage, with a substantial market size driven by the automotive industry's focus on safety and performance. The competitive landscape is dominated by established automotive manufacturers and specialized component suppliers. Companies like Honda, Toyota, BMW, and Renault are investing heavily in this technology, leveraging their extensive R&D capabilities. Tier 1 suppliers such as ZF Lenksysteme and ThyssenKrupp Presta are also key players, offering innovative solutions to OEMs. The market is characterized by a blend of in-house development by major automakers and collaborations with specialized suppliers, indicating a high level of technological maturity and ongoing refinement to meet evolving driver expectations and safety standards.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced steering wheel grip enhancement system that combines tactile feedback and adaptive surface technology. The system utilizes micro-textured surfaces with variable friction coefficients that can dynamically adjust based on driving conditions and user preferences[1]. Embedded sensors detect the driver's grip strength and hand position, allowing the system to optimize grip in real-time. Additionally, Honda has integrated haptic feedback mechanisms that provide subtle vibrations to alert the driver of potential hazards or changes in road conditions, enhancing overall driving precision[3]. The steering wheel also incorporates thermoelectric elements to maintain an optimal temperature range, preventing sweaty palms that could compromise grip[5].

Strengths: Highly responsive and adaptable to various driving conditions; Integrates multiple sensory feedback mechanisms for enhanced precision. Weaknesses: May be complex and costly to implement; Potential for system malfunction could impact safety.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a steering wheel grip enhancement technology called "Dynamic Grip Control" (DGC). This system utilizes a combination of advanced materials and electronic control units to optimize steering wheel grip. The DGC incorporates a layer of electroactive polymers beneath the steering wheel surface that can alter their texture and firmness in milliseconds[2]. This allows the system to provide varying levels of grip based on vehicle speed, steering angle, and road conditions. GM has also integrated biometric sensors that can detect driver fatigue or distraction through grip patterns and adjust the wheel's responsiveness accordingly[4]. Furthermore, the system includes a novel "micro-suction" technology that creates temporary vacuum pockets on the wheel surface, significantly increasing grip during high-precision maneuvers without requiring excessive force from the driver[6].

Strengths: Highly adaptive and responsive to both driving conditions and driver state; Innovative micro-suction technology for enhanced grip. Weaknesses: May require regular maintenance of the electroactive polymer layer; Potential for over-reliance on the system by drivers.

Innovative Materials for Optimal Grip

Automotive steering wheel

PatentInactiveEP1621441A3

Innovation

- A steering wheel design featuring flexible, shape-retaining gripping devices made of materials like kneaded plastic or silicone, integrated into the gripping areas and extending over partial circumferences of the steering wheel rim, allowing drivers to customize the shape for improved grip and comfort.

Steering wheel

PatentActiveJP2020049967A

Innovation

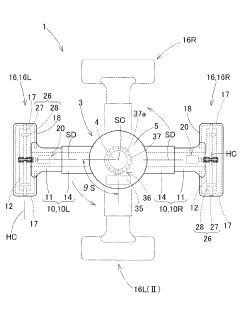

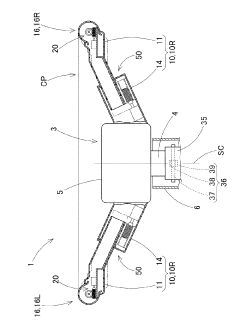

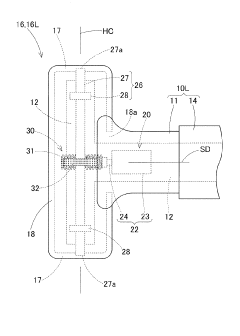

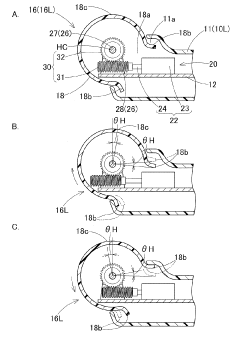

- A steering wheel design with rotatable grip portions that adjust their position and distance from the boss portion based on the steering angle, using a rotary drive device and expansion mechanism to minimize wrist twisting.

Safety Regulations for Steering Wheel Design

Safety regulations for steering wheel design are crucial in ensuring the safety and effectiveness of vehicle control systems. These regulations are established by various national and international bodies, such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the United Nations Economic Commission for Europe (UNECE) globally. The primary focus of these regulations is to maintain a balance between driver comfort, control precision, and safety in the event of a collision.

One of the key aspects of steering wheel safety regulations is the requirement for energy-absorbing designs. This mandates that steering wheels must be constructed in a way that minimizes the risk of injury to the driver during a crash. Manufacturers are required to use materials and designs that can deform or collapse in a controlled manner upon impact, reducing the force transmitted to the driver's body.

Regulations also specify the minimum diameter of steering wheels, typically ranging from 13 to 15 inches for passenger vehicles. This ensures that drivers have sufficient leverage for steering control while also providing an adequate surface area for airbag deployment. The shape and contour of the steering wheel rim are also subject to regulations, with requirements for smooth surfaces and rounded edges to prevent injuries in case of sudden contact.

Another critical aspect of steering wheel safety regulations is the integration of airbag systems. Regulations dictate the positioning, deployment characteristics, and overall safety performance of steering wheel-mounted airbags. These requirements ensure that airbags deploy effectively in various crash scenarios while minimizing the risk of injury from the airbag itself.

Grip enhancement features, while not explicitly regulated, must comply with overall safety standards. Any texturing or materials used to improve grip must not compromise the structural integrity of the steering wheel or interfere with airbag deployment. Additionally, these features should not create sharp edges or protrusions that could cause injury during normal use or in the event of a crash.

Regulations also address the steering wheel's connection to the steering column. This includes specifications for the strength and durability of the connection, as well as requirements for collapsible steering columns that can absorb energy in frontal collisions. These measures are designed to prevent the steering wheel from being pushed towards the driver in a severe crash.

In recent years, with the advent of advanced driver assistance systems (ADAS) and semi-autonomous driving features, regulations have begun to address the integration of controls and indicators on steering wheels. These regulations ensure that any additional functionality does not compromise the primary purpose of the steering wheel or distract the driver from the task of driving.

One of the key aspects of steering wheel safety regulations is the requirement for energy-absorbing designs. This mandates that steering wheels must be constructed in a way that minimizes the risk of injury to the driver during a crash. Manufacturers are required to use materials and designs that can deform or collapse in a controlled manner upon impact, reducing the force transmitted to the driver's body.

Regulations also specify the minimum diameter of steering wheels, typically ranging from 13 to 15 inches for passenger vehicles. This ensures that drivers have sufficient leverage for steering control while also providing an adequate surface area for airbag deployment. The shape and contour of the steering wheel rim are also subject to regulations, with requirements for smooth surfaces and rounded edges to prevent injuries in case of sudden contact.

Another critical aspect of steering wheel safety regulations is the integration of airbag systems. Regulations dictate the positioning, deployment characteristics, and overall safety performance of steering wheel-mounted airbags. These requirements ensure that airbags deploy effectively in various crash scenarios while minimizing the risk of injury from the airbag itself.

Grip enhancement features, while not explicitly regulated, must comply with overall safety standards. Any texturing or materials used to improve grip must not compromise the structural integrity of the steering wheel or interfere with airbag deployment. Additionally, these features should not create sharp edges or protrusions that could cause injury during normal use or in the event of a crash.

Regulations also address the steering wheel's connection to the steering column. This includes specifications for the strength and durability of the connection, as well as requirements for collapsible steering columns that can absorb energy in frontal collisions. These measures are designed to prevent the steering wheel from being pushed towards the driver in a severe crash.

In recent years, with the advent of advanced driver assistance systems (ADAS) and semi-autonomous driving features, regulations have begun to address the integration of controls and indicators on steering wheels. These regulations ensure that any additional functionality does not compromise the primary purpose of the steering wheel or distract the driver from the task of driving.

Ergonomic Considerations in Grip Design

Ergonomic considerations play a crucial role in the design of steering wheel grips for precision driving. The primary goal is to optimize the interface between the driver's hands and the steering wheel, ensuring maximum control, comfort, and safety during various driving conditions.

One of the key aspects of ergonomic grip design is the shape and contour of the steering wheel. A slightly oval or D-shaped wheel can provide better hand positioning and leverage compared to a perfectly circular design. The cross-section of the wheel rim should be carefully engineered to fit comfortably in the driver's hands, typically featuring a slightly flattened profile with rounded edges to reduce pressure points.

Material selection is another critical factor in ergonomic grip design. High-quality, non-slip materials such as perforated leather, Alcantara, or textured rubber compounds can enhance grip stability and reduce hand fatigue during extended driving sessions. These materials should also be able to wick away moisture, maintaining a secure grip even in high-stress or warm conditions.

The thickness of the steering wheel rim is an important consideration, as it affects the driver's ability to maintain a firm grip. Generally, a rim thickness between 2.5 to 3.5 inches (6.35 to 8.89 cm) is considered optimal for most drivers, allowing for a comfortable and secure grip without causing undue strain on the hands and forearms.

Ergonomic grip design also takes into account the placement and design of control buttons on the steering wheel. These controls should be easily accessible without requiring the driver to significantly alter their grip or compromise steering control. Tactile feedback and clear differentiation between buttons are essential for operating controls without taking eyes off the road.

The angle of the steering wheel in relation to the driver's seating position is another crucial ergonomic factor. An adjustable steering column allows drivers to set the wheel at an optimal angle, typically between 10 to 15 degrees from vertical, to reduce shoulder and arm fatigue during long drives or precision maneuvers.

Incorporating hand-specific contours into the grip design can further enhance control and comfort. This may include subtle indentations or raised areas that naturally guide the hands into the optimal position for both relaxed cruising and precise steering inputs.

Finally, the overall diameter of the steering wheel must be considered in ergonomic design. A smaller diameter wheel (typically 14-15 inches or 35.5-38 cm) can provide quicker steering response and is often preferred in performance driving scenarios, while a slightly larger diameter may be more comfortable for everyday driving and longer trips.

One of the key aspects of ergonomic grip design is the shape and contour of the steering wheel. A slightly oval or D-shaped wheel can provide better hand positioning and leverage compared to a perfectly circular design. The cross-section of the wheel rim should be carefully engineered to fit comfortably in the driver's hands, typically featuring a slightly flattened profile with rounded edges to reduce pressure points.

Material selection is another critical factor in ergonomic grip design. High-quality, non-slip materials such as perforated leather, Alcantara, or textured rubber compounds can enhance grip stability and reduce hand fatigue during extended driving sessions. These materials should also be able to wick away moisture, maintaining a secure grip even in high-stress or warm conditions.

The thickness of the steering wheel rim is an important consideration, as it affects the driver's ability to maintain a firm grip. Generally, a rim thickness between 2.5 to 3.5 inches (6.35 to 8.89 cm) is considered optimal for most drivers, allowing for a comfortable and secure grip without causing undue strain on the hands and forearms.

Ergonomic grip design also takes into account the placement and design of control buttons on the steering wheel. These controls should be easily accessible without requiring the driver to significantly alter their grip or compromise steering control. Tactile feedback and clear differentiation between buttons are essential for operating controls without taking eyes off the road.

The angle of the steering wheel in relation to the driver's seating position is another crucial ergonomic factor. An adjustable steering column allows drivers to set the wheel at an optimal angle, typically between 10 to 15 degrees from vertical, to reduce shoulder and arm fatigue during long drives or precision maneuvers.

Incorporating hand-specific contours into the grip design can further enhance control and comfort. This may include subtle indentations or raised areas that naturally guide the hands into the optimal position for both relaxed cruising and precise steering inputs.

Finally, the overall diameter of the steering wheel must be considered in ergonomic design. A smaller diameter wheel (typically 14-15 inches or 35.5-38 cm) can provide quicker steering response and is often preferred in performance driving scenarios, while a slightly larger diameter may be more comfortable for everyday driving and longer trips.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!