How to Improve Nichrome Wire Thermal Stability?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution and Objectives

Nichrome wire, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications since its invention in the early 20th century. The evolution of nichrome wire has been driven by the continuous demand for improved thermal stability, which is crucial for enhancing the performance and longevity of heating elements in various industries.

The development of nichrome wire can be traced back to 1905 when Albert Marsh patented the alloy. Initially, the focus was on creating a material that could withstand high temperatures while maintaining its electrical properties. Over the decades, researchers and engineers have worked tirelessly to refine the composition and manufacturing processes of nichrome wire to address the challenges of thermal stability.

One of the key objectives in improving nichrome wire's thermal stability has been to minimize resistance changes at elevated temperatures. This is essential for maintaining consistent heat output in applications such as industrial furnaces, domestic appliances, and aerospace components. Another critical goal has been to enhance the wire's oxidation resistance, which directly impacts its lifespan and reliability under extreme thermal conditions.

The pursuit of these objectives has led to significant advancements in alloy composition. Modern nichrome wires often incorporate additional elements such as silicon, aluminum, or iron to fine-tune their properties. These modifications aim to create a more stable microstructure that can better withstand thermal cycling and resist grain growth at high temperatures.

Manufacturing techniques have also evolved to support the quest for improved thermal stability. Precision control of the melting and drawing processes has become crucial in producing nichrome wire with consistent properties throughout its length. Advanced heat treatment methods have been developed to optimize the wire's microstructure, further enhancing its thermal stability and mechanical properties.

Recent research has focused on developing nanostructured nichrome alloys, which promise even greater thermal stability. By controlling the grain size and distribution at the nanoscale, scientists aim to create nichrome wires that exhibit superior resistance to thermal fatigue and creep. This cutting-edge approach represents the next frontier in nichrome wire evolution, potentially opening up new applications in extreme environments.

As we look to the future, the objectives for nichrome wire development continue to center around pushing the boundaries of thermal stability. This includes exploring novel alloy compositions, investigating advanced surface treatments to enhance oxidation resistance, and developing innovative manufacturing techniques that can produce wires with even more precise and consistent properties. The ultimate goal remains to create nichrome wires that can operate reliably at higher temperatures for longer periods, meeting the ever-increasing demands of modern technology and industry.

The development of nichrome wire can be traced back to 1905 when Albert Marsh patented the alloy. Initially, the focus was on creating a material that could withstand high temperatures while maintaining its electrical properties. Over the decades, researchers and engineers have worked tirelessly to refine the composition and manufacturing processes of nichrome wire to address the challenges of thermal stability.

One of the key objectives in improving nichrome wire's thermal stability has been to minimize resistance changes at elevated temperatures. This is essential for maintaining consistent heat output in applications such as industrial furnaces, domestic appliances, and aerospace components. Another critical goal has been to enhance the wire's oxidation resistance, which directly impacts its lifespan and reliability under extreme thermal conditions.

The pursuit of these objectives has led to significant advancements in alloy composition. Modern nichrome wires often incorporate additional elements such as silicon, aluminum, or iron to fine-tune their properties. These modifications aim to create a more stable microstructure that can better withstand thermal cycling and resist grain growth at high temperatures.

Manufacturing techniques have also evolved to support the quest for improved thermal stability. Precision control of the melting and drawing processes has become crucial in producing nichrome wire with consistent properties throughout its length. Advanced heat treatment methods have been developed to optimize the wire's microstructure, further enhancing its thermal stability and mechanical properties.

Recent research has focused on developing nanostructured nichrome alloys, which promise even greater thermal stability. By controlling the grain size and distribution at the nanoscale, scientists aim to create nichrome wires that exhibit superior resistance to thermal fatigue and creep. This cutting-edge approach represents the next frontier in nichrome wire evolution, potentially opening up new applications in extreme environments.

As we look to the future, the objectives for nichrome wire development continue to center around pushing the boundaries of thermal stability. This includes exploring novel alloy compositions, investigating advanced surface treatments to enhance oxidation resistance, and developing innovative manufacturing techniques that can produce wires with even more precise and consistent properties. The ultimate goal remains to create nichrome wires that can operate reliably at higher temperatures for longer periods, meeting the ever-increasing demands of modern technology and industry.

Market Demand Analysis for Stable Heating Elements

The market demand for stable heating elements, particularly those utilizing nichrome wire, has been steadily increasing across various industries. This growth is primarily driven by the expanding applications in sectors such as aerospace, automotive, consumer electronics, and industrial manufacturing. The global heating element market, which includes nichrome wire-based products, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

In the aerospace industry, there is a growing need for reliable heating elements in de-icing systems, cabin temperature control, and various sensor applications. The automotive sector is witnessing increased demand for stable heating elements in electric vehicles, particularly for battery thermal management systems and cabin heating. Consumer electronics, including household appliances like ovens, hair dryers, and space heaters, continue to be significant consumers of nichrome wire heating elements.

The industrial manufacturing sector presents a vast market for stable heating elements, with applications in furnaces, kilns, and heat treatment processes. The demand for precise temperature control and energy efficiency in these processes is driving the need for more thermally stable nichrome wire solutions. Additionally, the semiconductor industry requires ultra-stable heating elements for various fabrication processes, further expanding the market potential.

Emerging technologies and trends are also influencing market demand. The push for energy-efficient solutions is leading to the development of advanced nichrome wire compositions and designs that offer improved thermal stability and longevity. This trend aligns with global initiatives to reduce energy consumption and carbon emissions, creating opportunities for innovative heating element solutions.

The market is also seeing a shift towards smart and connected heating systems, which require heating elements with consistent performance and reliability. This trend is particularly evident in smart home applications and industrial Internet of Things (IoT) implementations, where remote monitoring and control of heating systems are becoming increasingly important.

Geographically, mature markets such as North America and Europe continue to show steady demand, driven by technological advancements and replacement needs. However, the Asia-Pacific region is emerging as a key growth driver, fueled by rapid industrialization, increasing consumer electronics production, and the expansion of automotive manufacturing in countries like China and India.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and the need for continuous innovation to meet evolving regulatory standards on energy efficiency and environmental impact. These factors are pushing manufacturers to invest in research and development to improve the thermal stability of nichrome wire, ensuring its relevance in future applications and maintaining its market share against alternative heating technologies.

In the aerospace industry, there is a growing need for reliable heating elements in de-icing systems, cabin temperature control, and various sensor applications. The automotive sector is witnessing increased demand for stable heating elements in electric vehicles, particularly for battery thermal management systems and cabin heating. Consumer electronics, including household appliances like ovens, hair dryers, and space heaters, continue to be significant consumers of nichrome wire heating elements.

The industrial manufacturing sector presents a vast market for stable heating elements, with applications in furnaces, kilns, and heat treatment processes. The demand for precise temperature control and energy efficiency in these processes is driving the need for more thermally stable nichrome wire solutions. Additionally, the semiconductor industry requires ultra-stable heating elements for various fabrication processes, further expanding the market potential.

Emerging technologies and trends are also influencing market demand. The push for energy-efficient solutions is leading to the development of advanced nichrome wire compositions and designs that offer improved thermal stability and longevity. This trend aligns with global initiatives to reduce energy consumption and carbon emissions, creating opportunities for innovative heating element solutions.

The market is also seeing a shift towards smart and connected heating systems, which require heating elements with consistent performance and reliability. This trend is particularly evident in smart home applications and industrial Internet of Things (IoT) implementations, where remote monitoring and control of heating systems are becoming increasingly important.

Geographically, mature markets such as North America and Europe continue to show steady demand, driven by technological advancements and replacement needs. However, the Asia-Pacific region is emerging as a key growth driver, fueled by rapid industrialization, increasing consumer electronics production, and the expansion of automotive manufacturing in countries like China and India.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and the need for continuous innovation to meet evolving regulatory standards on energy efficiency and environmental impact. These factors are pushing manufacturers to invest in research and development to improve the thermal stability of nichrome wire, ensuring its relevance in future applications and maintaining its market share against alternative heating technologies.

Current Challenges in Nichrome Wire Thermal Stability

Nichrome wire, widely used in heating elements and resistors, faces significant challenges in maintaining thermal stability under extreme conditions. The primary issue lies in its tendency to degrade and lose performance over time when subjected to high temperatures and thermal cycling.

One of the main challenges is oxidation. When exposed to high temperatures, especially in oxygen-rich environments, nichrome wire forms an oxide layer on its surface. While this layer initially provides some protection, it can grow thicker over time, leading to changes in electrical resistance and reduced heat transfer efficiency. This oxidation process accelerates at higher temperatures, limiting the wire's lifespan and reliability in high-temperature applications.

Thermal fatigue is another critical challenge. Repeated heating and cooling cycles cause the wire to expand and contract, leading to mechanical stress. Over time, this can result in microstructural changes, including grain growth and the formation of microcracks. These alterations compromise the wire's mechanical integrity and electrical properties, potentially leading to premature failure.

The issue of element migration presents a further complication. At elevated temperatures, the constituent elements of nichrome (primarily nickel and chromium) can diffuse within the wire. This diffusion can lead to compositional changes across the wire's cross-section, affecting its electrical resistance and thermal characteristics. In severe cases, it may result in the formation of brittle intermetallic compounds, further degrading the wire's performance and lifespan.

Contamination from the surrounding environment also poses a significant challenge. Impurities from the atmosphere or nearby materials can react with the nichrome wire at high temperatures, forming unwanted compounds on the surface or within the wire structure. These contaminants can accelerate degradation processes and introduce unpredictable changes in the wire's properties.

The challenge of maintaining dimensional stability is particularly crucial in precision applications. Thermal expansion and contraction, coupled with potential creep at high temperatures, can lead to changes in the wire's geometry. This affects not only the wire's electrical characteristics but also its mechanical fit and performance in tightly toleranced assemblies.

Addressing these challenges requires a multifaceted approach, combining materials science, engineering, and advanced manufacturing techniques. Potential solutions may involve developing new alloy compositions, applying protective coatings, or implementing novel heat treatment processes. The goal is to enhance the wire's resistance to oxidation, improve its mechanical stability under thermal cycling, and maintain consistent electrical properties over extended periods of high-temperature operation.

One of the main challenges is oxidation. When exposed to high temperatures, especially in oxygen-rich environments, nichrome wire forms an oxide layer on its surface. While this layer initially provides some protection, it can grow thicker over time, leading to changes in electrical resistance and reduced heat transfer efficiency. This oxidation process accelerates at higher temperatures, limiting the wire's lifespan and reliability in high-temperature applications.

Thermal fatigue is another critical challenge. Repeated heating and cooling cycles cause the wire to expand and contract, leading to mechanical stress. Over time, this can result in microstructural changes, including grain growth and the formation of microcracks. These alterations compromise the wire's mechanical integrity and electrical properties, potentially leading to premature failure.

The issue of element migration presents a further complication. At elevated temperatures, the constituent elements of nichrome (primarily nickel and chromium) can diffuse within the wire. This diffusion can lead to compositional changes across the wire's cross-section, affecting its electrical resistance and thermal characteristics. In severe cases, it may result in the formation of brittle intermetallic compounds, further degrading the wire's performance and lifespan.

Contamination from the surrounding environment also poses a significant challenge. Impurities from the atmosphere or nearby materials can react with the nichrome wire at high temperatures, forming unwanted compounds on the surface or within the wire structure. These contaminants can accelerate degradation processes and introduce unpredictable changes in the wire's properties.

The challenge of maintaining dimensional stability is particularly crucial in precision applications. Thermal expansion and contraction, coupled with potential creep at high temperatures, can lead to changes in the wire's geometry. This affects not only the wire's electrical characteristics but also its mechanical fit and performance in tightly toleranced assemblies.

Addressing these challenges requires a multifaceted approach, combining materials science, engineering, and advanced manufacturing techniques. Potential solutions may involve developing new alloy compositions, applying protective coatings, or implementing novel heat treatment processes. The goal is to enhance the wire's resistance to oxidation, improve its mechanical stability under thermal cycling, and maintain consistent electrical properties over extended periods of high-temperature operation.

Existing Thermal Stability Enhancement Techniques

01 Composition and structure of nichrome wire

Nichrome wire typically consists of nickel and chromium alloy, with specific compositions designed to enhance thermal stability. The structure and manufacturing process of the wire, including its diameter and surface treatment, can significantly affect its thermal performance and longevity at high temperatures.- Composition and structure of nichrome wire: Nichrome wire is typically composed of nickel and chromium alloys, with specific ratios designed to enhance thermal stability. The wire's structure, including its diameter and surface treatment, plays a crucial role in its heat resistance and durability at high temperatures.

- Heat treatment and manufacturing process: The thermal stability of nichrome wire can be improved through various heat treatment processes and manufacturing techniques. These may include annealing, quenching, and controlled cooling, which help to optimize the wire's microstructure and enhance its resistance to thermal fatigue.

- Protective coatings and surface modifications: Applying protective coatings or surface modifications to nichrome wire can significantly improve its thermal stability. These treatments may include oxidation-resistant layers, ceramic coatings, or other high-temperature resistant materials that protect the wire from degradation in extreme heat conditions.

- Application-specific design considerations: The thermal stability of nichrome wire can be optimized for specific applications by adjusting its design parameters. This may involve varying the wire's thickness, shape, or configuration to better distribute heat and minimize thermal stress in high-temperature environments.

- Integration with supporting materials and structures: The thermal stability of nichrome wire can be enhanced by integrating it with supporting materials or structures that provide additional heat resistance or dissipation. This may include embedding the wire in ceramic substrates, using heat-resistant insulation, or incorporating it into composite materials designed for high-temperature applications.

02 Application in heating elements

Nichrome wire is widely used in heating elements due to its excellent thermal stability. It can maintain consistent performance under repeated heating and cooling cycles, making it suitable for various applications such as electric heaters, ovens, and industrial furnaces. The wire's resistance to oxidation at high temperatures contributes to its durability in these applications.Expand Specific Solutions03 Thermal stability enhancement techniques

Various techniques are employed to enhance the thermal stability of nichrome wire. These may include adding specific alloying elements, applying protective coatings, or using specialized heat treatment processes. Such enhancements can improve the wire's resistance to deformation, oxidation, and other forms of degradation at high temperatures.Expand Specific Solutions04 Performance in extreme temperature conditions

Nichrome wire exhibits remarkable thermal stability in extreme temperature conditions. It can maintain its electrical and mechanical properties over a wide range of temperatures, from cryogenic to very high temperatures. This stability makes it suitable for use in aerospace, automotive, and other industries where components are exposed to severe thermal stress.Expand Specific Solutions05 Long-term reliability and aging characteristics

The long-term reliability and aging characteristics of nichrome wire are crucial for its thermal stability. Studies and tests are conducted to evaluate how the wire's properties change over time under various thermal conditions. This information is used to predict the wire's lifespan and ensure its consistent performance in long-term applications.Expand Specific Solutions

Key Manufacturers and Competitors in Nichrome Industry

The competition landscape for improving nichrome wire thermal stability is characterized by a mature market with established players and ongoing research efforts. The global market for high-temperature alloys, including nichrome wire, is substantial and growing, driven by increasing demand in aerospace, electronics, and industrial applications. Major players like POSCO Holdings, Kobe Steel, and Hitachi are investing in R&D to enhance material properties. Specialized companies such as Yancheng Xinyang Electric Heating Material and Furuya Metal are focusing on niche applications. Academic institutions like Northeastern University and Slovak Technical University are contributing to fundamental research. The technology is relatively mature, but there's continuous innovation in alloy composition and manufacturing processes to improve thermal stability and performance.

Heraeus Precious Metals GmbH & Co. KG (New)

Technical Solution: Heraeus has developed advanced nichrome alloys with improved thermal stability through precise composition control and innovative manufacturing processes. They utilize a proprietary blend of nickel, chromium, and trace elements to enhance high-temperature performance. The company employs advanced powder metallurgy techniques to create uniform microstructures that resist grain growth at elevated temperatures[1]. Additionally, Heraeus has implemented surface treatment methods, such as controlled oxidation, to form protective oxide layers that further improve thermal stability and extend the wire's lifespan[2].

Strengths: Expertise in precious metals and alloys, advanced manufacturing capabilities, and a strong focus on research and development. Weaknesses: Higher production costs due to premium materials and processes, which may limit market penetration in cost-sensitive applications.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed a novel approach to improving nichrome wire thermal stability through microstructure engineering. Their method involves a combination of controlled cold working and precise heat treatment processes to create a fine-grained structure with enhanced dislocation density[3]. This microstructure modification results in improved creep resistance and reduced grain boundary sliding at high temperatures. Furthermore, Kobe Steel has incorporated small amounts of rare earth elements into their nichrome alloy composition, which form stable oxide dispersions that pin grain boundaries and inhibit grain growth during prolonged exposure to high temperatures[4].

Strengths: Strong metallurgical expertise, extensive research facilities, and a diverse product portfolio. Weaknesses: Potential challenges in scaling up production of specialized alloys and higher costs associated with rare earth element additions.

Innovative Approaches to Nichrome Wire Stabilization

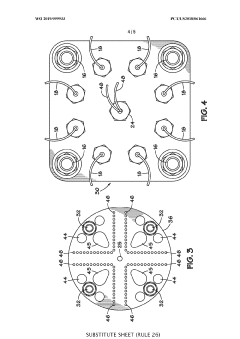

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

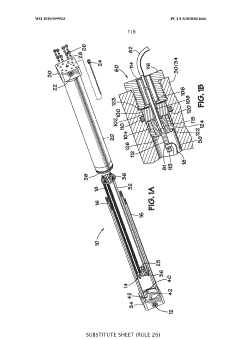

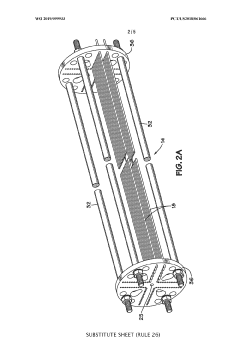

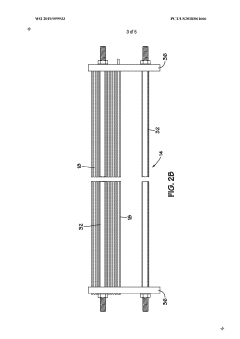

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

Environmental Impact of Nichrome Wire Production

The production of nichrome wire, while essential for various industrial applications, carries significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of raw materials, primarily nickel and chromium, which can lead to substantial environmental degradation. Mining operations for these metals often result in habitat destruction, soil erosion, and water pollution. The refining and alloying processes require substantial energy inputs, contributing to greenhouse gas emissions and exacerbating climate change concerns.

Furthermore, the production of nichrome wire generates hazardous waste materials, including heavy metal residues and chemical byproducts. These substances can contaminate soil and water sources if not properly managed, posing risks to local ecosystems and human health. The disposal of manufacturing waste and end-of-life nichrome wire products also presents challenges, as improper handling can lead to the release of toxic substances into the environment.

Air pollution is another significant concern associated with nichrome wire production. The smelting and alloying processes emit particulate matter, sulfur dioxide, and other air pollutants, which can contribute to respiratory issues and acid rain in surrounding areas. Additionally, the transportation of raw materials and finished products adds to the carbon footprint of nichrome wire manufacturing.

Water usage in the production process is substantial, with potential impacts on local water resources. The cooling and cleaning processes in wire manufacturing facilities can strain water supplies, particularly in water-scarce regions. Wastewater from these operations may contain dissolved metals and other contaminants, requiring careful treatment before release to prevent ecosystem damage.

The environmental impact of nichrome wire production extends to the energy consumption during its use phase. While the wire's thermal stability contributes to its longevity, the high temperatures at which it operates in various applications result in significant energy consumption over its lifetime. This indirect environmental cost must be considered alongside the direct impacts of production.

To mitigate these environmental concerns, the nichrome wire industry is exploring more sustainable production methods. These include implementing closed-loop recycling systems to recover and reuse metals, adopting cleaner energy sources for manufacturing processes, and developing more efficient production techniques that reduce waste and emissions. Additionally, research into alternative materials that could offer similar thermal stability with reduced environmental impact is ongoing, potentially leading to more sustainable solutions in the future.

Furthermore, the production of nichrome wire generates hazardous waste materials, including heavy metal residues and chemical byproducts. These substances can contaminate soil and water sources if not properly managed, posing risks to local ecosystems and human health. The disposal of manufacturing waste and end-of-life nichrome wire products also presents challenges, as improper handling can lead to the release of toxic substances into the environment.

Air pollution is another significant concern associated with nichrome wire production. The smelting and alloying processes emit particulate matter, sulfur dioxide, and other air pollutants, which can contribute to respiratory issues and acid rain in surrounding areas. Additionally, the transportation of raw materials and finished products adds to the carbon footprint of nichrome wire manufacturing.

Water usage in the production process is substantial, with potential impacts on local water resources. The cooling and cleaning processes in wire manufacturing facilities can strain water supplies, particularly in water-scarce regions. Wastewater from these operations may contain dissolved metals and other contaminants, requiring careful treatment before release to prevent ecosystem damage.

The environmental impact of nichrome wire production extends to the energy consumption during its use phase. While the wire's thermal stability contributes to its longevity, the high temperatures at which it operates in various applications result in significant energy consumption over its lifetime. This indirect environmental cost must be considered alongside the direct impacts of production.

To mitigate these environmental concerns, the nichrome wire industry is exploring more sustainable production methods. These include implementing closed-loop recycling systems to recover and reuse metals, adopting cleaner energy sources for manufacturing processes, and developing more efficient production techniques that reduce waste and emissions. Additionally, research into alternative materials that could offer similar thermal stability with reduced environmental impact is ongoing, potentially leading to more sustainable solutions in the future.

Safety Standards for High-Temperature Resistive Materials

Safety standards for high-temperature resistive materials play a crucial role in ensuring the reliability and longevity of nichrome wire applications. These standards encompass a wide range of requirements, including thermal stability, electrical performance, and mechanical properties. For nichrome wire, which is commonly used in heating elements and resistors, thermal stability is of paramount importance.

The primary safety standards for high-temperature resistive materials focus on several key aspects. Firstly, they address the maximum operating temperature of the material. Nichrome wire typically has a maximum continuous operating temperature of around 1100°C to 1200°C, depending on the specific alloy composition. Safety standards require that the wire maintains its structural integrity and electrical properties within this temperature range without significant degradation or failure.

Oxidation resistance is another critical factor covered by these standards. Nichrome wire forms a protective chromium oxide layer when exposed to high temperatures, which helps prevent further oxidation. Safety standards specify the acceptable rate of oxidation and the minimum thickness of the protective layer to ensure long-term stability and performance.

Electrical resistivity and its stability over time and temperature are also addressed in the safety standards. The resistance of nichrome wire should remain consistent within specified tolerances throughout its operational life. Standards may define acceptable ranges for resistance drift and methods for measuring and verifying resistivity under various conditions.

Mechanical properties, such as tensile strength and ductility, are included in the safety standards to ensure that the wire can withstand thermal cycling and mechanical stresses without failure. These properties are particularly important in applications where the wire is subjected to repeated heating and cooling cycles or vibrations.

Safety standards also cover the purity and composition of the nichrome alloy. The precise ratio of nickel to chromium, along with any additional alloying elements, must be carefully controlled to achieve the desired thermal and electrical properties. Standards may specify acceptable ranges for each element and methods for verifying the composition.

Environmental considerations are increasingly being incorporated into safety standards for high-temperature resistive materials. This includes regulations on the use of hazardous substances and requirements for recyclability or disposal of the materials at the end of their lifecycle.

Compliance with these safety standards is typically verified through rigorous testing procedures. These may include accelerated aging tests, thermal cycling tests, and long-term performance evaluations under various environmental conditions. Manufacturers must demonstrate that their nichrome wire products meet or exceed these standards to ensure safety and reliability in high-temperature applications.

The primary safety standards for high-temperature resistive materials focus on several key aspects. Firstly, they address the maximum operating temperature of the material. Nichrome wire typically has a maximum continuous operating temperature of around 1100°C to 1200°C, depending on the specific alloy composition. Safety standards require that the wire maintains its structural integrity and electrical properties within this temperature range without significant degradation or failure.

Oxidation resistance is another critical factor covered by these standards. Nichrome wire forms a protective chromium oxide layer when exposed to high temperatures, which helps prevent further oxidation. Safety standards specify the acceptable rate of oxidation and the minimum thickness of the protective layer to ensure long-term stability and performance.

Electrical resistivity and its stability over time and temperature are also addressed in the safety standards. The resistance of nichrome wire should remain consistent within specified tolerances throughout its operational life. Standards may define acceptable ranges for resistance drift and methods for measuring and verifying resistivity under various conditions.

Mechanical properties, such as tensile strength and ductility, are included in the safety standards to ensure that the wire can withstand thermal cycling and mechanical stresses without failure. These properties are particularly important in applications where the wire is subjected to repeated heating and cooling cycles or vibrations.

Safety standards also cover the purity and composition of the nichrome alloy. The precise ratio of nickel to chromium, along with any additional alloying elements, must be carefully controlled to achieve the desired thermal and electrical properties. Standards may specify acceptable ranges for each element and methods for verifying the composition.

Environmental considerations are increasingly being incorporated into safety standards for high-temperature resistive materials. This includes regulations on the use of hazardous substances and requirements for recyclability or disposal of the materials at the end of their lifecycle.

Compliance with these safety standards is typically verified through rigorous testing procedures. These may include accelerated aging tests, thermal cycling tests, and long-term performance evaluations under various environmental conditions. Manufacturers must demonstrate that their nichrome wire products meet or exceed these standards to ensure safety and reliability in high-temperature applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!