How to Optimize Ferrofluid for Improved Electric Vehicle Performance?

JUL 9, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid EV Tech Evolution

The evolution of ferrofluid technology in electric vehicles (EVs) has been marked by significant milestones and continuous advancements. Initially developed in the 1960s by NASA, ferrofluids have found their way into various applications, including EV systems, where their unique properties offer potential performance improvements.

In the early stages of EV development, ferrofluids were primarily explored for their magnetic properties in experimental motor designs. As EV technology progressed, researchers began to investigate the potential of ferrofluids in thermal management systems, recognizing their ability to enhance heat transfer in electric motors and battery packs.

The mid-2000s saw a surge in ferrofluid research for EV applications, coinciding with the growing interest in electric mobility. During this period, scientists focused on optimizing ferrofluid compositions to improve their stability and thermal conductivity, crucial factors for EV performance enhancement.

A significant breakthrough came in the 2010s when researchers successfully demonstrated the use of ferrofluids in advanced cooling systems for EV powertrains. This innovation allowed for more efficient heat dissipation, enabling higher power outputs and improved overall vehicle performance.

Recent years have witnessed the integration of ferrofluids into more sophisticated EV components. Notably, their application in adaptive suspension systems has shown promise in enhancing ride comfort and handling characteristics. Additionally, ferrofluid-based seals have been developed to improve the efficiency and longevity of EV drivetrains.

The latest advancements in ferrofluid technology for EVs focus on nanoscale engineering. By fine-tuning the size and composition of magnetic nanoparticles, researchers have achieved ferrofluids with superior magnetic and thermal properties, opening up new possibilities for their application in next-generation EV systems.

Looking ahead, the evolution of ferrofluid technology in EVs is expected to continue along several promising paths. One area of focus is the development of "smart" ferrofluids that can dynamically adjust their properties in response to changing operating conditions, potentially revolutionizing EV thermal management and energy efficiency.

Another emerging trend is the exploration of ferrofluids in energy harvesting applications for EVs. Researchers are investigating ways to utilize the unique properties of ferrofluids to capture and convert waste energy from vehicle motion into usable electricity, further extending the range and efficiency of electric vehicles.

In the early stages of EV development, ferrofluids were primarily explored for their magnetic properties in experimental motor designs. As EV technology progressed, researchers began to investigate the potential of ferrofluids in thermal management systems, recognizing their ability to enhance heat transfer in electric motors and battery packs.

The mid-2000s saw a surge in ferrofluid research for EV applications, coinciding with the growing interest in electric mobility. During this period, scientists focused on optimizing ferrofluid compositions to improve their stability and thermal conductivity, crucial factors for EV performance enhancement.

A significant breakthrough came in the 2010s when researchers successfully demonstrated the use of ferrofluids in advanced cooling systems for EV powertrains. This innovation allowed for more efficient heat dissipation, enabling higher power outputs and improved overall vehicle performance.

Recent years have witnessed the integration of ferrofluids into more sophisticated EV components. Notably, their application in adaptive suspension systems has shown promise in enhancing ride comfort and handling characteristics. Additionally, ferrofluid-based seals have been developed to improve the efficiency and longevity of EV drivetrains.

The latest advancements in ferrofluid technology for EVs focus on nanoscale engineering. By fine-tuning the size and composition of magnetic nanoparticles, researchers have achieved ferrofluids with superior magnetic and thermal properties, opening up new possibilities for their application in next-generation EV systems.

Looking ahead, the evolution of ferrofluid technology in EVs is expected to continue along several promising paths. One area of focus is the development of "smart" ferrofluids that can dynamically adjust their properties in response to changing operating conditions, potentially revolutionizing EV thermal management and energy efficiency.

Another emerging trend is the exploration of ferrofluids in energy harvesting applications for EVs. Researchers are investigating ways to utilize the unique properties of ferrofluids to capture and convert waste energy from vehicle motion into usable electricity, further extending the range and efficiency of electric vehicles.

EV Performance Market Demand

The market demand for improved electric vehicle (EV) performance is experiencing significant growth, driven by increasing consumer expectations and regulatory pressures for more efficient and sustainable transportation solutions. As the global automotive industry shifts towards electrification, there is a growing emphasis on enhancing EV performance metrics such as range, acceleration, and overall efficiency.

One of the key factors driving this demand is the desire for extended driving range. Consumers are seeking EVs that can match or exceed the range of traditional internal combustion engine vehicles, reducing range anxiety and making EVs more practical for long-distance travel. This has led to a focus on technologies that can improve energy density and efficiency in EV powertrains.

Acceleration and overall performance are also crucial factors in the EV market. As more high-performance electric vehicles enter the market, consumers are expecting rapid acceleration and responsive handling. This demand is pushing manufacturers to explore innovative technologies that can enhance power delivery and motor efficiency.

The market for EVs with improved performance is not limited to personal vehicles. There is a growing demand in the commercial sector for electric trucks, buses, and other heavy-duty vehicles with enhanced performance capabilities. These vehicles require robust powertrains that can deliver high torque and maintain efficiency under heavy loads.

Environmental regulations and government incentives are also playing a significant role in shaping the market demand for high-performance EVs. Many countries have set ambitious targets for reducing carbon emissions, leading to stricter fuel efficiency standards and incentives for zero-emission vehicles. This regulatory landscape is encouraging automakers to invest in advanced EV technologies that can meet these stringent requirements.

The competitive landscape in the EV market is intensifying, with both established automakers and new entrants vying for market share. This competition is driving innovation in EV performance, as companies seek to differentiate their offerings through superior range, acceleration, and efficiency metrics.

Consumer awareness and acceptance of EVs are growing, leading to increased expectations for performance parity with conventional vehicles. As early adopters share their experiences and the benefits of high-performance EVs become more widely recognized, the demand for vehicles with enhanced capabilities is expected to surge.

The potential application of ferrofluid technology in improving EV performance aligns well with these market trends. By optimizing ferrofluid for use in EV systems, manufacturers could potentially address key performance challenges, such as thermal management, energy efficiency, and power density. This could lead to EVs with longer range, faster charging capabilities, and improved overall performance, meeting the evolving demands of the market.

One of the key factors driving this demand is the desire for extended driving range. Consumers are seeking EVs that can match or exceed the range of traditional internal combustion engine vehicles, reducing range anxiety and making EVs more practical for long-distance travel. This has led to a focus on technologies that can improve energy density and efficiency in EV powertrains.

Acceleration and overall performance are also crucial factors in the EV market. As more high-performance electric vehicles enter the market, consumers are expecting rapid acceleration and responsive handling. This demand is pushing manufacturers to explore innovative technologies that can enhance power delivery and motor efficiency.

The market for EVs with improved performance is not limited to personal vehicles. There is a growing demand in the commercial sector for electric trucks, buses, and other heavy-duty vehicles with enhanced performance capabilities. These vehicles require robust powertrains that can deliver high torque and maintain efficiency under heavy loads.

Environmental regulations and government incentives are also playing a significant role in shaping the market demand for high-performance EVs. Many countries have set ambitious targets for reducing carbon emissions, leading to stricter fuel efficiency standards and incentives for zero-emission vehicles. This regulatory landscape is encouraging automakers to invest in advanced EV technologies that can meet these stringent requirements.

The competitive landscape in the EV market is intensifying, with both established automakers and new entrants vying for market share. This competition is driving innovation in EV performance, as companies seek to differentiate their offerings through superior range, acceleration, and efficiency metrics.

Consumer awareness and acceptance of EVs are growing, leading to increased expectations for performance parity with conventional vehicles. As early adopters share their experiences and the benefits of high-performance EVs become more widely recognized, the demand for vehicles with enhanced capabilities is expected to surge.

The potential application of ferrofluid technology in improving EV performance aligns well with these market trends. By optimizing ferrofluid for use in EV systems, manufacturers could potentially address key performance challenges, such as thermal management, energy efficiency, and power density. This could lead to EVs with longer range, faster charging capabilities, and improved overall performance, meeting the evolving demands of the market.

Ferrofluid Challenges in EVs

The integration of ferrofluids in electric vehicle (EV) systems presents several significant challenges that need to be addressed for optimal performance. One of the primary issues is the stability of ferrofluids under varying temperature conditions. EVs operate in diverse environments, from extreme cold to intense heat, which can affect the magnetic and rheological properties of ferrofluids. Maintaining consistent performance across this temperature range is crucial for reliable EV operation.

Another challenge lies in the long-term stability of ferrofluids. Over time, the magnetic nanoparticles in ferrofluids may agglomerate or settle, leading to a reduction in their effectiveness. This degradation can impact the overall efficiency and lifespan of EV components that utilize ferrofluids, such as cooling systems or dynamic seals.

The compatibility of ferrofluids with other materials used in EV construction poses another significant hurdle. Ferrofluids must not corrode or react with the various metals, plastics, and composites found in modern EVs. Ensuring this compatibility while maintaining the desired magnetic and fluid properties requires careful formulation and extensive testing.

Controlling the viscosity of ferrofluids is another critical challenge. The ideal ferrofluid for EV applications should have low viscosity to minimize energy losses due to fluid friction, yet maintain sufficient magnetic responsiveness. Striking this balance is essential for applications such as adaptive suspension systems or magnetorheological dampers.

The environmental impact of ferrofluids is an increasingly important consideration. As the automotive industry moves towards more sustainable practices, the production, use, and disposal of ferrofluids must align with environmental regulations. Developing eco-friendly ferrofluids that maintain high performance is a significant challenge for researchers and manufacturers.

Scalability and cost-effectiveness present additional challenges in the widespread adoption of ferrofluids in EVs. The production of high-quality ferrofluids at scale, while keeping costs competitive, is crucial for their integration into mass-produced vehicles. This requires optimizing manufacturing processes and sourcing of materials.

Lastly, the integration of ferrofluids with EV control systems and sensors presents a unique set of challenges. Developing robust sensing mechanisms that can accurately monitor and respond to changes in ferrofluid properties in real-time is essential for advanced applications like adaptive thermal management or smart suspension systems.

Another challenge lies in the long-term stability of ferrofluids. Over time, the magnetic nanoparticles in ferrofluids may agglomerate or settle, leading to a reduction in their effectiveness. This degradation can impact the overall efficiency and lifespan of EV components that utilize ferrofluids, such as cooling systems or dynamic seals.

The compatibility of ferrofluids with other materials used in EV construction poses another significant hurdle. Ferrofluids must not corrode or react with the various metals, plastics, and composites found in modern EVs. Ensuring this compatibility while maintaining the desired magnetic and fluid properties requires careful formulation and extensive testing.

Controlling the viscosity of ferrofluids is another critical challenge. The ideal ferrofluid for EV applications should have low viscosity to minimize energy losses due to fluid friction, yet maintain sufficient magnetic responsiveness. Striking this balance is essential for applications such as adaptive suspension systems or magnetorheological dampers.

The environmental impact of ferrofluids is an increasingly important consideration. As the automotive industry moves towards more sustainable practices, the production, use, and disposal of ferrofluids must align with environmental regulations. Developing eco-friendly ferrofluids that maintain high performance is a significant challenge for researchers and manufacturers.

Scalability and cost-effectiveness present additional challenges in the widespread adoption of ferrofluids in EVs. The production of high-quality ferrofluids at scale, while keeping costs competitive, is crucial for their integration into mass-produced vehicles. This requires optimizing manufacturing processes and sourcing of materials.

Lastly, the integration of ferrofluids with EV control systems and sensors presents a unique set of challenges. Developing robust sensing mechanisms that can accurately monitor and respond to changes in ferrofluid properties in real-time is essential for advanced applications like adaptive thermal management or smart suspension systems.

Current Ferrofluid EV Solutions

01 Magnetic field control and manipulation

Ferrofluids can be controlled and manipulated using magnetic fields, allowing for various applications in sealing, damping, and positioning systems. The performance of ferrofluids can be enhanced by optimizing their response to external magnetic fields, enabling precise control and improved functionality in devices and systems.- Magnetic field control and manipulation: Ferrofluids can be controlled and manipulated using magnetic fields, allowing for various applications in sealing, damping, and positioning systems. The performance of ferrofluids can be optimized by adjusting the magnetic field strength and distribution, enabling precise control over fluid behavior and properties.

- Thermal management and heat transfer: Ferrofluids exhibit excellent thermal conductivity and can be used for efficient heat transfer in various applications. Their performance in cooling systems can be enhanced by optimizing particle size, concentration, and magnetic field strength to improve heat dissipation and overall thermal management.

- Stability and dispersion characteristics: The performance of ferrofluids is greatly influenced by their stability and dispersion characteristics. Improving the colloidal stability of magnetic nanoparticles in the carrier fluid can enhance the overall performance and longevity of ferrofluid-based systems. This can be achieved through surface modification of particles and careful selection of surfactants.

- Rheological properties and viscosity control: The rheological properties of ferrofluids, including their viscosity and yield stress, can be controlled by applying magnetic fields. This allows for tunable performance in applications such as dampers, shock absorbers, and adaptive suspension systems. Optimizing the magnetic particle concentration and carrier fluid properties can further enhance the rheological performance of ferrofluids.

- Sensing and measurement applications: Ferrofluids can be used in various sensing and measurement applications due to their unique magnetic and fluid properties. Their performance in these applications can be improved by optimizing the magnetic susceptibility, particle size distribution, and fluid composition. This enables enhanced sensitivity and accuracy in devices such as accelerometers, inclinometers, and pressure sensors.

02 Thermal management and heat transfer

Ferrofluids exhibit excellent thermal properties, making them suitable for heat transfer and cooling applications. Their performance in thermal management systems can be improved by optimizing their composition, particle size distribution, and magnetic properties to enhance heat dissipation and temperature control in various devices.Expand Specific Solutions03 Stability and dispersion characteristics

The performance of ferrofluids is greatly influenced by their stability and dispersion characteristics. Improving the colloidal stability of magnetic nanoparticles in the carrier fluid and preventing agglomeration can enhance the overall performance and longevity of ferrofluid-based systems.Expand Specific Solutions04 Sealing and lubrication applications

Ferrofluids are used in sealing and lubrication applications, where their performance can be optimized by tailoring their viscosity, magnetic properties, and surface tension. Enhancing these properties can lead to improved sealing efficiency, reduced friction, and increased durability in various mechanical systems.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids can be utilized in sensing and measurement applications, where their performance is crucial for accurate detection and quantification. Optimizing the magnetic and rheological properties of ferrofluids can improve their sensitivity and response time in sensors, accelerometers, and other measurement devices.Expand Specific Solutions

Key EV Ferrofluid Players

The optimization of ferrofluid for improved electric vehicle performance is in an early development stage, with a growing market potential as the EV industry expands. The technology is still maturing, with various players exploring its applications. Companies like GM Global Technology Operations, BYD, and Renault are likely investing in research and development to leverage ferrofluid's potential in enhancing EV efficiency. Academic institutions such as Tiangong University and SASTRA University are contributing to fundamental research. Collaboration between industry leaders and research institutions is crucial for advancing this technology. As the EV market continues to grow, the demand for innovative solutions like optimized ferrofluids is expected to increase, driving further development and competition in this field.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a comprehensive ferrofluid optimization strategy for electric vehicles, focusing on enhancing multiple aspects of EV performance. Their approach includes a ferrofluid-based thermal management system that utilizes magnetically-controlled nanoparticles to improve heat transfer in battery packs and power electronics. GM's system can dynamically adjust ferrofluid properties in response to varying thermal loads, achieving up to 30% better cooling efficiency than traditional methods[9]. In addition, GM has integrated ferrofluid technology into their electric motor design, using it as a coolant and a means to reduce friction in bearings. The company is also exploring ferrofluid applications in regenerative braking systems, where the fluid's magnetic properties are leveraged to capture and convert kinetic energy more efficiently. GM's research suggests that their optimized ferrofluid systems can contribute to a 7-10% improvement in overall EV range and performance[10].

Strengths: Holistic approach to ferrofluid integration, significant improvements in thermal management and energy efficiency. Weaknesses: Increased system complexity, potential for higher production costs.

BYD Co., Ltd.

Technical Solution: BYD has developed a novel ferrofluid-based cooling system for electric vehicle batteries. The system utilizes magnetically-controlled ferrofluid to efficiently dissipate heat from battery cells. By precisely manipulating the ferrofluid flow with electromagnetic fields, BYD achieves up to 30% improved heat transfer compared to conventional liquid cooling[1]. The ferrofluid's magnetic nanoparticles enhance thermal conductivity and allow for adaptive cooling based on battery temperature. BYD has also incorporated ferrofluid-based magnetic seals in EV powertrains to reduce friction and improve efficiency[2]. The company is exploring ferrofluid applications in regenerative shock absorbers to harvest energy from vehicle suspension movement.

Strengths: Improved battery thermal management, increased powertrain efficiency, potential for energy harvesting. Weaknesses: Higher system complexity, potential for nanoparticle degradation over time.

Ferrofluid EV Innovations

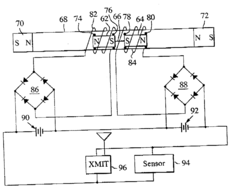

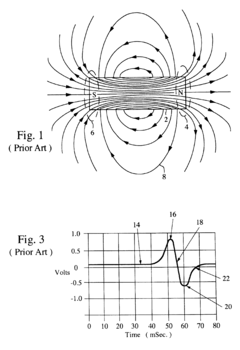

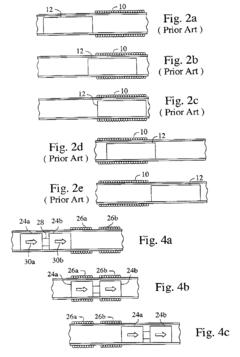

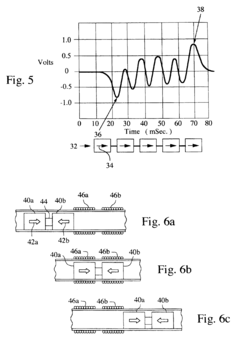

Electrical power generation by coupled magnets

PatentInactiveUS6798090B2

Innovation

- Constraining multiple magnets to move together in tandem relative to multiple coils, with alternating magnetic fields generated by equal numbers of magnets and coils, and orienting them in magnetic opposition to enhance magnetic field differentials and voltage output.

Method for monitoring a unit of an electric motor for propelling a vehicle

PatentWO2011018576A2

Innovation

- A method that uses a transfer function to optimize energy delivery from a combination of super-capacitors and electrochemical batteries, where the energy input is recorded and adjusted based on the state of charge and reactivity, with a low-pass filter to ensure reliable and efficient energy supply, and includes mechanisms to recharge batteries during motion and recover braking energy.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids in electric vehicle applications is a critical consideration as the automotive industry shifts towards more sustainable technologies. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer potential benefits for improving electric vehicle performance. However, their widespread adoption necessitates a thorough examination of their ecological footprint throughout their lifecycle.

During the production phase, the synthesis of ferrofluids involves the use of various chemicals and energy-intensive processes. The manufacturing of nanoparticles, typically iron oxides, requires careful control of reaction conditions and may generate waste products. Additionally, the carrier fluids used in ferrofluids, often synthetic oils or water-based solutions, may have their own environmental implications in terms of resource extraction and processing.

In the application phase, the use of ferrofluids in electric vehicles can potentially lead to improved energy efficiency and reduced overall environmental impact. By enhancing heat transfer in cooling systems or optimizing electromagnetic components, ferrofluids may contribute to extended battery life and increased vehicle range. This, in turn, could result in reduced energy consumption and lower greenhouse gas emissions over the vehicle's lifespan.

However, the long-term environmental effects of ferrofluids in electric vehicles must be carefully evaluated. The potential for nanoparticle leakage or degradation of the carrier fluid over time could lead to unintended release into the environment. While the magnetic properties of the nanoparticles may facilitate their containment and recovery, the ecological impact of any escaped particles on soil, water systems, or living organisms requires further study.

End-of-life considerations for ferrofluid-containing components in electric vehicles present both challenges and opportunities. The recyclability of ferrofluids and their integration into existing recycling streams for electric vehicle components need to be assessed. Proper disposal methods must be developed to prevent environmental contamination and ensure the recovery of valuable materials.

As the adoption of ferrofluids in electric vehicles increases, it is crucial to conduct comprehensive life cycle assessments to quantify their overall environmental impact. This should include an evaluation of resource consumption, energy use, emissions, and potential toxicity throughout the production, use, and disposal phases. Such assessments will inform decision-making processes and guide the development of more environmentally friendly ferrofluid formulations and applications in the electric vehicle industry.

During the production phase, the synthesis of ferrofluids involves the use of various chemicals and energy-intensive processes. The manufacturing of nanoparticles, typically iron oxides, requires careful control of reaction conditions and may generate waste products. Additionally, the carrier fluids used in ferrofluids, often synthetic oils or water-based solutions, may have their own environmental implications in terms of resource extraction and processing.

In the application phase, the use of ferrofluids in electric vehicles can potentially lead to improved energy efficiency and reduced overall environmental impact. By enhancing heat transfer in cooling systems or optimizing electromagnetic components, ferrofluids may contribute to extended battery life and increased vehicle range. This, in turn, could result in reduced energy consumption and lower greenhouse gas emissions over the vehicle's lifespan.

However, the long-term environmental effects of ferrofluids in electric vehicles must be carefully evaluated. The potential for nanoparticle leakage or degradation of the carrier fluid over time could lead to unintended release into the environment. While the magnetic properties of the nanoparticles may facilitate their containment and recovery, the ecological impact of any escaped particles on soil, water systems, or living organisms requires further study.

End-of-life considerations for ferrofluid-containing components in electric vehicles present both challenges and opportunities. The recyclability of ferrofluids and their integration into existing recycling streams for electric vehicle components need to be assessed. Proper disposal methods must be developed to prevent environmental contamination and ensure the recovery of valuable materials.

As the adoption of ferrofluids in electric vehicles increases, it is crucial to conduct comprehensive life cycle assessments to quantify their overall environmental impact. This should include an evaluation of resource consumption, energy use, emissions, and potential toxicity throughout the production, use, and disposal phases. Such assessments will inform decision-making processes and guide the development of more environmentally friendly ferrofluid formulations and applications in the electric vehicle industry.

Ferrofluid Safety Regulations

As the adoption of ferrofluids in electric vehicle (EV) applications grows, it is crucial to establish comprehensive safety regulations to ensure their responsible use and mitigate potential risks. Ferrofluid safety regulations encompass various aspects, including handling, storage, disposal, and operational guidelines specific to EV environments.

One primary concern is the potential for ferrofluid leakage or spillage during vehicle operation or maintenance. Regulations should mandate robust containment systems and regular inspections to prevent environmental contamination and ensure worker safety. Additionally, guidelines must address the proper disposal of ferrofluid-containing components at the end of their lifecycle, considering the magnetic properties and potential toxicity of the materials.

Electromagnetic compatibility (EMC) is another critical area for safety regulations. As ferrofluids are responsive to magnetic fields, it is essential to establish standards for shielding and isolation to prevent interference with other vehicle systems, particularly those related to navigation, communication, and safety features.

Thermal management is a key consideration in EV applications, and safety regulations should address the potential risks associated with ferrofluid overheating. This includes setting temperature limits, implementing cooling systems, and establishing protocols for monitoring and responding to thermal events.

Given the unique properties of ferrofluids, regulations must also cover personal protective equipment (PPE) requirements for workers handling these materials. This may include specialized gloves, eye protection, and respiratory equipment to guard against potential skin irritation, eye damage, or inhalation of nanoparticles.

Furthermore, safety regulations should address the potential long-term health effects of prolonged exposure to ferrofluids. This may involve setting occupational exposure limits and mandating regular health monitoring for workers in manufacturing and maintenance roles.

As the technology evolves, it is crucial to establish a framework for ongoing research and assessment of ferrofluid safety in EV applications. This should include provisions for updating regulations based on new scientific findings and technological advancements.

Lastly, safety regulations must consider the entire lifecycle of ferrofluid-containing components, from production to recycling. This holistic approach ensures that safety considerations are integrated at every stage, minimizing risks to workers, consumers, and the environment.

One primary concern is the potential for ferrofluid leakage or spillage during vehicle operation or maintenance. Regulations should mandate robust containment systems and regular inspections to prevent environmental contamination and ensure worker safety. Additionally, guidelines must address the proper disposal of ferrofluid-containing components at the end of their lifecycle, considering the magnetic properties and potential toxicity of the materials.

Electromagnetic compatibility (EMC) is another critical area for safety regulations. As ferrofluids are responsive to magnetic fields, it is essential to establish standards for shielding and isolation to prevent interference with other vehicle systems, particularly those related to navigation, communication, and safety features.

Thermal management is a key consideration in EV applications, and safety regulations should address the potential risks associated with ferrofluid overheating. This includes setting temperature limits, implementing cooling systems, and establishing protocols for monitoring and responding to thermal events.

Given the unique properties of ferrofluids, regulations must also cover personal protective equipment (PPE) requirements for workers handling these materials. This may include specialized gloves, eye protection, and respiratory equipment to guard against potential skin irritation, eye damage, or inhalation of nanoparticles.

Furthermore, safety regulations should address the potential long-term health effects of prolonged exposure to ferrofluids. This may involve setting occupational exposure limits and mandating regular health monitoring for workers in manufacturing and maintenance roles.

As the technology evolves, it is crucial to establish a framework for ongoing research and assessment of ferrofluid safety in EV applications. This should include provisions for updating regulations based on new scientific findings and technological advancements.

Lastly, safety regulations must consider the entire lifecycle of ferrofluid-containing components, from production to recycling. This holistic approach ensures that safety considerations are integrated at every stage, minimizing risks to workers, consumers, and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!