How to Streamline Carboxylic Acid-Based Biochemical Processes?

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid Biochemistry: Background and Objectives

Carboxylic acids play a pivotal role in biochemical processes, serving as key intermediates in various metabolic pathways and industrial applications. The evolution of carboxylic acid-based biochemistry has been marked by significant advancements in understanding their structure, reactivity, and biological functions. From simple acetic acid to complex fatty acids, these compounds have been central to life processes and industrial production for centuries.

The field of carboxylic acid biochemistry has witnessed remarkable progress, driven by the need for more efficient and sustainable processes in industries ranging from pharmaceuticals to food production. Recent years have seen a surge in research aimed at harnessing the potential of carboxylic acids in green chemistry and bioengineering. This renewed focus is largely due to the increasing demand for eco-friendly alternatives to traditional chemical processes.

One of the primary objectives in streamlining carboxylic acid-based biochemical processes is to enhance reaction efficiency while minimizing environmental impact. This involves developing novel catalysts, optimizing reaction conditions, and exploring alternative synthesis routes. Researchers are particularly interested in bio-based production methods that utilize renewable resources and generate fewer waste products.

Another crucial goal is to improve the selectivity and yield of carboxylic acid-related reactions. This is especially important in the pharmaceutical industry, where precise control over stereochemistry and purity is paramount. Advances in enzyme engineering and biocatalysis have opened new avenues for achieving these objectives, allowing for more targeted and efficient production of complex carboxylic acid derivatives.

The integration of carboxylic acid biochemistry with emerging technologies such as synthetic biology and metabolic engineering represents a promising frontier. These interdisciplinary approaches aim to create novel biosynthetic pathways and engineer microorganisms capable of producing valuable carboxylic acids from simple, renewable feedstocks. Such innovations could revolutionize the production of everything from biofuels to specialty chemicals.

As we look to the future, the streamlining of carboxylic acid-based biochemical processes is expected to play a crucial role in addressing global challenges. From developing more sustainable manufacturing practices to creating new therapies for diseases, the potential applications are vast. The ongoing research in this field is not only advancing our fundamental understanding of biochemistry but also paving the way for transformative technologies that could reshape industries and improve lives.

The field of carboxylic acid biochemistry has witnessed remarkable progress, driven by the need for more efficient and sustainable processes in industries ranging from pharmaceuticals to food production. Recent years have seen a surge in research aimed at harnessing the potential of carboxylic acids in green chemistry and bioengineering. This renewed focus is largely due to the increasing demand for eco-friendly alternatives to traditional chemical processes.

One of the primary objectives in streamlining carboxylic acid-based biochemical processes is to enhance reaction efficiency while minimizing environmental impact. This involves developing novel catalysts, optimizing reaction conditions, and exploring alternative synthesis routes. Researchers are particularly interested in bio-based production methods that utilize renewable resources and generate fewer waste products.

Another crucial goal is to improve the selectivity and yield of carboxylic acid-related reactions. This is especially important in the pharmaceutical industry, where precise control over stereochemistry and purity is paramount. Advances in enzyme engineering and biocatalysis have opened new avenues for achieving these objectives, allowing for more targeted and efficient production of complex carboxylic acid derivatives.

The integration of carboxylic acid biochemistry with emerging technologies such as synthetic biology and metabolic engineering represents a promising frontier. These interdisciplinary approaches aim to create novel biosynthetic pathways and engineer microorganisms capable of producing valuable carboxylic acids from simple, renewable feedstocks. Such innovations could revolutionize the production of everything from biofuels to specialty chemicals.

As we look to the future, the streamlining of carboxylic acid-based biochemical processes is expected to play a crucial role in addressing global challenges. From developing more sustainable manufacturing practices to creating new therapies for diseases, the potential applications are vast. The ongoing research in this field is not only advancing our fundamental understanding of biochemistry but also paving the way for transformative technologies that could reshape industries and improve lives.

Market Analysis for Streamlined Biochemical Processes

The market for streamlined carboxylic acid-based biochemical processes is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly production methods across various industries. This market segment is closely tied to the broader biochemical industry, which is projected to reach a global value of $1.2 trillion by 2028, with a compound annual growth rate (CAGR) of 7.2% from 2021 to 2028.

Carboxylic acids play a crucial role in numerous biochemical processes, serving as key intermediates in the production of pharmaceuticals, food additives, polymers, and specialty chemicals. The push for more efficient and environmentally friendly manufacturing processes has led to a growing interest in streamlining these biochemical pathways.

One of the primary drivers of market demand is the pharmaceutical industry, where carboxylic acids are essential in the synthesis of various active pharmaceutical ingredients (APIs). The global pharmaceutical market is expected to reach $1.5 trillion by 2023, creating a substantial opportunity for improved biochemical processes.

The food and beverage industry is another significant contributor to market growth, with carboxylic acids being used as preservatives, flavor enhancers, and acidulants. The global food additives market is projected to reach $59.15 billion by 2025, with a CAGR of 5.5% from 2020 to 2025.

In the polymer industry, carboxylic acids are utilized in the production of biodegradable plastics and other sustainable materials. The increasing focus on reducing plastic waste and promoting circular economy principles is driving demand for these innovative materials.

The specialty chemicals sector is also a key market for streamlined carboxylic acid-based processes, with applications in personal care products, lubricants, and industrial solvents. This sector is expected to grow at a CAGR of 5.2% from 2021 to 2026, reaching a value of $316.5 billion by the end of the forecast period.

Geographically, North America and Europe currently dominate the market for advanced biochemical processes, owing to their well-established pharmaceutical and chemical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in research and development, and growing environmental awareness.

The market trend towards streamlined carboxylic acid-based biochemical processes is further supported by stringent environmental regulations and sustainability goals set by governments and industries worldwide. This has led to increased investment in green chemistry initiatives and the development of more efficient, less energy-intensive production methods.

Carboxylic acids play a crucial role in numerous biochemical processes, serving as key intermediates in the production of pharmaceuticals, food additives, polymers, and specialty chemicals. The push for more efficient and environmentally friendly manufacturing processes has led to a growing interest in streamlining these biochemical pathways.

One of the primary drivers of market demand is the pharmaceutical industry, where carboxylic acids are essential in the synthesis of various active pharmaceutical ingredients (APIs). The global pharmaceutical market is expected to reach $1.5 trillion by 2023, creating a substantial opportunity for improved biochemical processes.

The food and beverage industry is another significant contributor to market growth, with carboxylic acids being used as preservatives, flavor enhancers, and acidulants. The global food additives market is projected to reach $59.15 billion by 2025, with a CAGR of 5.5% from 2020 to 2025.

In the polymer industry, carboxylic acids are utilized in the production of biodegradable plastics and other sustainable materials. The increasing focus on reducing plastic waste and promoting circular economy principles is driving demand for these innovative materials.

The specialty chemicals sector is also a key market for streamlined carboxylic acid-based processes, with applications in personal care products, lubricants, and industrial solvents. This sector is expected to grow at a CAGR of 5.2% from 2021 to 2026, reaching a value of $316.5 billion by the end of the forecast period.

Geographically, North America and Europe currently dominate the market for advanced biochemical processes, owing to their well-established pharmaceutical and chemical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in research and development, and growing environmental awareness.

The market trend towards streamlined carboxylic acid-based biochemical processes is further supported by stringent environmental regulations and sustainability goals set by governments and industries worldwide. This has led to increased investment in green chemistry initiatives and the development of more efficient, less energy-intensive production methods.

Current Challenges in Carboxylic Acid-Based Bioprocesses

Carboxylic acid-based biochemical processes face several significant challenges that hinder their widespread industrial adoption and efficiency. One of the primary obstacles is the high energy consumption associated with these processes, particularly in the separation and purification stages. The extraction of carboxylic acids from fermentation broths often requires energy-intensive operations such as distillation or liquid-liquid extraction, which can significantly impact the overall process economics.

Another major challenge is the low product yields and titers commonly observed in carboxylic acid fermentations. This is often due to product inhibition, where the accumulation of acids in the fermentation medium negatively affects microbial growth and metabolism. Overcoming this limitation requires the development of more robust microbial strains or innovative in situ product removal techniques.

The corrosive nature of carboxylic acids poses additional challenges in terms of equipment design and material selection. Specialized corrosion-resistant materials are often necessary, increasing capital costs and potentially limiting scalability. Furthermore, the handling and storage of these acids require stringent safety measures, adding complexity to process design and operation.

Downstream processing of carboxylic acids presents its own set of challenges. The separation of the desired acid from other fermentation by-products and impurities can be complex and costly. Traditional separation methods may not always be suitable for all types of carboxylic acids, necessitating the development of novel, more efficient separation technologies.

Sustainability concerns also play a significant role in the challenges faced by carboxylic acid-based bioprocesses. The use of renewable feedstocks is desirable but can introduce variability in raw material quality and composition, affecting process consistency and product purity. Additionally, the environmental impact of waste streams and the overall carbon footprint of these processes require careful consideration and mitigation strategies.

Scalability remains a critical challenge for many carboxylic acid bioprocesses. While laboratory-scale production may show promise, translating these results to industrial-scale operations often encounters unforeseen difficulties. Issues such as mass transfer limitations, heat management, and maintaining consistent product quality at larger scales need to be addressed for successful commercialization.

Regulatory compliance and product certification present additional hurdles, particularly for carboxylic acids intended for food, pharmaceutical, or personal care applications. Meeting stringent quality standards and obtaining necessary approvals can be time-consuming and costly, potentially delaying market entry for new bio-based carboxylic acid products.

Another major challenge is the low product yields and titers commonly observed in carboxylic acid fermentations. This is often due to product inhibition, where the accumulation of acids in the fermentation medium negatively affects microbial growth and metabolism. Overcoming this limitation requires the development of more robust microbial strains or innovative in situ product removal techniques.

The corrosive nature of carboxylic acids poses additional challenges in terms of equipment design and material selection. Specialized corrosion-resistant materials are often necessary, increasing capital costs and potentially limiting scalability. Furthermore, the handling and storage of these acids require stringent safety measures, adding complexity to process design and operation.

Downstream processing of carboxylic acids presents its own set of challenges. The separation of the desired acid from other fermentation by-products and impurities can be complex and costly. Traditional separation methods may not always be suitable for all types of carboxylic acids, necessitating the development of novel, more efficient separation technologies.

Sustainability concerns also play a significant role in the challenges faced by carboxylic acid-based bioprocesses. The use of renewable feedstocks is desirable but can introduce variability in raw material quality and composition, affecting process consistency and product purity. Additionally, the environmental impact of waste streams and the overall carbon footprint of these processes require careful consideration and mitigation strategies.

Scalability remains a critical challenge for many carboxylic acid bioprocesses. While laboratory-scale production may show promise, translating these results to industrial-scale operations often encounters unforeseen difficulties. Issues such as mass transfer limitations, heat management, and maintaining consistent product quality at larger scales need to be addressed for successful commercialization.

Regulatory compliance and product certification present additional hurdles, particularly for carboxylic acids intended for food, pharmaceutical, or personal care applications. Meeting stringent quality standards and obtaining necessary approvals can be time-consuming and costly, potentially delaying market entry for new bio-based carboxylic acid products.

Existing Streamlining Solutions for Carboxylic Acid Processes

01 Carboxylic acid production through biochemical processes

Biochemical processes are utilized to produce carboxylic acids, streamlining the production method. These processes often involve fermentation or enzymatic reactions, which can be more environmentally friendly and cost-effective compared to traditional chemical synthesis methods.- Optimization of carboxylic acid production processes: Streamlining biochemical processes for carboxylic acid production involves optimizing fermentation conditions, improving microbial strains, and enhancing downstream processing. These improvements can lead to increased yield, reduced production costs, and improved product quality.

- Novel enzyme systems for carboxylic acid synthesis: Development of new enzyme systems or modification of existing ones can streamline carboxylic acid-based biochemical processes. These enzymes may offer improved catalytic efficiency, substrate specificity, or stability under industrial conditions, leading to more efficient production methods.

- Integration of continuous processing techniques: Implementing continuous processing techniques in carboxylic acid production can significantly streamline operations. This approach can lead to improved process control, reduced equipment size, and increased productivity compared to traditional batch processes.

- Advanced separation and purification methods: Developing and implementing advanced separation and purification methods can streamline downstream processing in carboxylic acid production. These may include novel membrane technologies, chromatographic techniques, or selective crystallization processes, resulting in higher purity products and reduced processing costs.

- Process intensification and integration: Streamlining carboxylic acid-based biochemical processes through process intensification and integration involves combining multiple unit operations, reducing equipment footprint, and optimizing energy usage. This approach can lead to more efficient production systems with reduced capital and operating costs.

02 Optimization of carboxylic acid extraction and purification

Improved techniques for extracting and purifying carboxylic acids from biochemical processes have been developed. These methods may include advanced separation technologies, membrane filtration, or chromatography, leading to higher yields and purer end products.Expand Specific Solutions03 Genetic engineering for enhanced carboxylic acid production

Genetic modification of microorganisms to improve their carboxylic acid production capabilities has been explored. This approach can lead to increased yields, improved product specificity, and enhanced tolerance to process conditions.Expand Specific Solutions04 Continuous flow processes for carboxylic acid synthesis

Implementation of continuous flow processes in carboxylic acid production has been investigated. This approach can lead to improved efficiency, reduced reaction times, and better control over reaction conditions compared to batch processes.Expand Specific Solutions05 Integration of carboxylic acid production with other bioprocesses

Efforts have been made to integrate carboxylic acid production with other bioprocesses, such as biofuel production or waste treatment. This integration can lead to more efficient use of resources, reduced waste, and improved overall process economics.Expand Specific Solutions

Key Players in Biochemical Process Optimization

The competitive landscape for streamlining carboxylic acid-based biochemical processes is characterized by a mature market with significant potential for innovation. Major players like BASF, Eastman Chemical, and Evonik are investing heavily in research and development to optimize these processes. The market is driven by increasing demand for sustainable and cost-effective chemical production methods. Companies such as Daicel Corp. and China Petrochemical Development Corp. are focusing on developing advanced catalysts and process technologies to improve efficiency and reduce environmental impact. The involvement of research institutions like Nanjing Tech University and the Agency for Science, Technology & Research indicates a strong emphasis on collaborative efforts to push technological boundaries in this field.

Daicel Corp.

Technical Solution: Daicel Corporation has made significant strides in streamlining carboxylic acid-based biochemical processes through their expertise in chiral technologies and green chemistry. They have developed asymmetric synthesis methods for producing optically pure carboxylic acids, which are crucial in pharmaceutical and fine chemical industries[12]. Daicel's approach includes the use of proprietary chiral catalysts and biocatalytic processes that offer high enantioselectivity and yield. In addition, they have implemented continuous flow technologies for the synthesis of carboxylic acids, allowing for improved process control and scalability[13]. Daicel has also focused on developing environmentally friendly oxidation processes for carboxylic acid production, utilizing molecular oxygen as a green oxidant in combination with novel metal catalysts[14]. Their research extends to the application of carboxylic acids in biodegradable polymers, contributing to the circular economy initiatives.

Strengths: Expertise in chiral chemistry, focus on green processes, and application in high-value sectors. Weaknesses: Potentially higher costs associated with specialized catalysts and limited applicability to bulk chemical production.

Evonik Operations GmbH

Technical Solution: Evonik has developed a range of technologies to streamline carboxylic acid-based processes. Their approach includes the use of advanced membrane separation techniques for efficient product isolation and purification[4]. They have also implemented process intensification strategies, such as reactive distillation, which combines reaction and separation steps to improve overall process efficiency[5]. Evonik's research has focused on developing green chemistry routes for carboxylic acid synthesis, including the use of bio-based feedstocks and catalytic oxidation processes that minimize waste generation[6]. Furthermore, they have explored the application of flow chemistry principles to carboxylic acid production, allowing for better control of reaction parameters and improved safety profiles[7].

Strengths: Improved process efficiency, reduced environmental impact, and potential for continuous manufacturing. Weaknesses: Higher initial investment costs and potential challenges in scaling up novel technologies.

Innovative Approaches in Carboxylic Acid Biochemistry

Carboxylation of terminal alkynes

PatentInactiveUS20120323038A1

Innovation

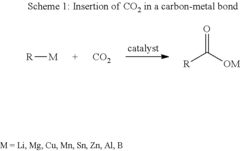

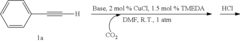

- A copper(I)-catalyzed process involving a base and a complexing agent, such as a carbonate salt and a poly-N-heterocyclic carbene, is used to convert terminal alkynes into alkynoic acids under mild conditions, avoiding the need for organometallic reagents and allowing for C—H bond activation and carboxylation.

Process for preparation of 4-n-substituted amino-2-aza-1-oxabicyclo[3.3.0] oct-2-ene-6-carboxylic acid esters and process for preparation of their intermediates

PatentInactiveUS7038059B2

Innovation

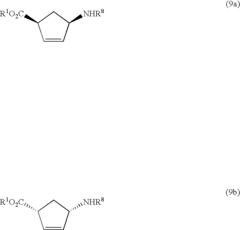

- A process involving the methanolysis of 2-azabicyclo[2.2.1]hept-5-en-3-one with a Brønsted acid, followed by desalting and reaction with a hypohalogenite and aldoxime, allows for the efficient production of cis-4-amino-2-cyclopentene-1-carboxylic acid esters, which can be optically resolved and protected to produce the desired ester.

Environmental Impact of Carboxylic Acid Bioprocesses

Carboxylic acid-based biochemical processes have significant environmental implications that warrant careful consideration. These processes, while essential for various industries, can potentially impact ecosystems and human health if not managed properly. One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during production and handling of carboxylic acids. These emissions can contribute to air pollution and the formation of ground-level ozone, which can harm vegetation and cause respiratory issues in humans.

Water pollution is another critical environmental aspect of carboxylic acid bioprocesses. Effluents from these processes often contain high levels of organic matter and may have low pH values. If not adequately treated before discharge, these effluents can disrupt aquatic ecosystems, leading to oxygen depletion and potential harm to aquatic life. Additionally, the accumulation of carboxylic acids in soil can alter soil chemistry and affect plant growth, potentially impacting agricultural productivity.

Energy consumption is a significant factor in the environmental footprint of carboxylic acid bioprocesses. The production and purification of these compounds often require substantial energy inputs, contributing to greenhouse gas emissions if fossil fuels are the primary energy source. Implementing energy-efficient technologies and exploring renewable energy options can help mitigate this impact.

Waste management is crucial in minimizing the environmental impact of these processes. Proper disposal or recycling of byproducts and spent materials is essential to prevent soil and water contamination. Some carboxylic acid production methods generate significant amounts of solid waste, which must be managed responsibly to avoid landfill overuse and potential leaching of harmful substances into the environment.

On a positive note, many carboxylic acid-based biochemical processes offer environmental benefits when compared to their petrochemical counterparts. Bioprocesses often use renewable feedstocks, reducing reliance on fossil resources. They typically operate under milder conditions, potentially lowering energy requirements and reducing the risk of hazardous chemical releases. Furthermore, some carboxylic acids produced through bioprocesses are biodegradable, minimizing long-term environmental persistence.

Advancements in green chemistry and bioengineering are continually improving the environmental profile of carboxylic acid bioprocesses. Techniques such as in situ product recovery, process intensification, and the use of engineered microorganisms can enhance efficiency and reduce waste generation. These innovations not only mitigate environmental impacts but also often lead to more economically viable processes.

Water pollution is another critical environmental aspect of carboxylic acid bioprocesses. Effluents from these processes often contain high levels of organic matter and may have low pH values. If not adequately treated before discharge, these effluents can disrupt aquatic ecosystems, leading to oxygen depletion and potential harm to aquatic life. Additionally, the accumulation of carboxylic acids in soil can alter soil chemistry and affect plant growth, potentially impacting agricultural productivity.

Energy consumption is a significant factor in the environmental footprint of carboxylic acid bioprocesses. The production and purification of these compounds often require substantial energy inputs, contributing to greenhouse gas emissions if fossil fuels are the primary energy source. Implementing energy-efficient technologies and exploring renewable energy options can help mitigate this impact.

Waste management is crucial in minimizing the environmental impact of these processes. Proper disposal or recycling of byproducts and spent materials is essential to prevent soil and water contamination. Some carboxylic acid production methods generate significant amounts of solid waste, which must be managed responsibly to avoid landfill overuse and potential leaching of harmful substances into the environment.

On a positive note, many carboxylic acid-based biochemical processes offer environmental benefits when compared to their petrochemical counterparts. Bioprocesses often use renewable feedstocks, reducing reliance on fossil resources. They typically operate under milder conditions, potentially lowering energy requirements and reducing the risk of hazardous chemical releases. Furthermore, some carboxylic acids produced through bioprocesses are biodegradable, minimizing long-term environmental persistence.

Advancements in green chemistry and bioengineering are continually improving the environmental profile of carboxylic acid bioprocesses. Techniques such as in situ product recovery, process intensification, and the use of engineered microorganisms can enhance efficiency and reduce waste generation. These innovations not only mitigate environmental impacts but also often lead to more economically viable processes.

Economic Feasibility of Streamlined Biochemical Methods

The economic feasibility of streamlined biochemical methods for carboxylic acid-based processes is a critical consideration in the development and implementation of these technologies. The potential for cost reduction and increased efficiency in production processes makes this an attractive area for research and investment.

One of the primary economic advantages of streamlined biochemical methods is the potential for reduced energy consumption. Traditional chemical processes often require high temperatures and pressures, resulting in significant energy costs. In contrast, biochemical methods can often operate under milder conditions, potentially leading to substantial energy savings. This reduction in energy requirements not only decreases operational costs but also aligns with growing environmental concerns and regulations.

Raw material costs can also be significantly impacted by streamlined biochemical methods. Many of these processes utilize renewable feedstocks, such as biomass or agricultural waste, which are often less expensive than traditional petrochemical feedstocks. This shift towards more sustainable and cost-effective raw materials can provide a competitive advantage in the market.

The potential for increased product yield and selectivity is another economic driver for streamlined biochemical methods. Enzymes and microorganisms used in these processes often exhibit high specificity, potentially reducing the formation of unwanted by-products. This can lead to improved product quality and reduced purification costs, both of which contribute to overall economic efficiency.

Capital expenditure considerations are also favorable for many streamlined biochemical methods. These processes often require less complex equipment and can be implemented using existing infrastructure with minimal modifications. This can result in lower initial investment costs and faster time-to-market for new products or processes.

However, it is important to note that the economic feasibility of these methods can vary depending on the specific application and scale of production. Factors such as enzyme stability, product recovery efficiency, and process scalability can significantly impact the overall economics. Additionally, the cost of developing and optimizing new biochemical processes must be considered in the overall economic assessment.

Market dynamics also play a crucial role in determining the economic feasibility of streamlined biochemical methods. The growing demand for sustainable and bio-based products creates opportunities for processes that can produce carboxylic acids and their derivatives more efficiently and with a lower environmental impact. This market pull can justify investment in research and development of these technologies.

One of the primary economic advantages of streamlined biochemical methods is the potential for reduced energy consumption. Traditional chemical processes often require high temperatures and pressures, resulting in significant energy costs. In contrast, biochemical methods can often operate under milder conditions, potentially leading to substantial energy savings. This reduction in energy requirements not only decreases operational costs but also aligns with growing environmental concerns and regulations.

Raw material costs can also be significantly impacted by streamlined biochemical methods. Many of these processes utilize renewable feedstocks, such as biomass or agricultural waste, which are often less expensive than traditional petrochemical feedstocks. This shift towards more sustainable and cost-effective raw materials can provide a competitive advantage in the market.

The potential for increased product yield and selectivity is another economic driver for streamlined biochemical methods. Enzymes and microorganisms used in these processes often exhibit high specificity, potentially reducing the formation of unwanted by-products. This can lead to improved product quality and reduced purification costs, both of which contribute to overall economic efficiency.

Capital expenditure considerations are also favorable for many streamlined biochemical methods. These processes often require less complex equipment and can be implemented using existing infrastructure with minimal modifications. This can result in lower initial investment costs and faster time-to-market for new products or processes.

However, it is important to note that the economic feasibility of these methods can vary depending on the specific application and scale of production. Factors such as enzyme stability, product recovery efficiency, and process scalability can significantly impact the overall economics. Additionally, the cost of developing and optimizing new biochemical processes must be considered in the overall economic assessment.

Market dynamics also play a crucial role in determining the economic feasibility of streamlined biochemical methods. The growing demand for sustainable and bio-based products creates opportunities for processes that can produce carboxylic acids and their derivatives more efficiently and with a lower environmental impact. This market pull can justify investment in research and development of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!