How to Use Dipropylene Glycol for Optimal Moisture Retention?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Moisture Retention Background and Objectives

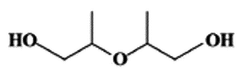

Dipropylene glycol (DPG) has emerged as a versatile compound with significant potential in moisture retention applications. This technology has evolved from its initial use as an industrial solvent to become a key ingredient in various consumer and industrial products. The development of DPG for moisture retention purposes stems from the growing demand for effective humectants in cosmetics, personal care products, and industrial processes.

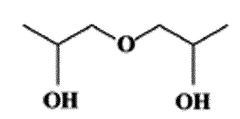

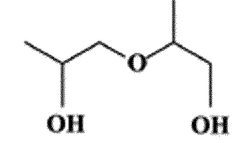

The primary objective of this technical research is to explore and optimize the use of dipropylene glycol for moisture retention. This involves understanding the molecular structure and properties of DPG that contribute to its hygroscopic nature, as well as investigating its interactions with other substances in formulations. By doing so, we aim to identify the most effective methods of incorporating DPG into products to maximize its moisture-retaining capabilities.

Another crucial aspect of this research is to examine the safety and regulatory considerations surrounding the use of DPG in various applications. As consumer awareness and regulatory scrutiny of product ingredients increase, it is essential to ensure that DPG usage aligns with current safety standards and environmental regulations. This includes assessing its potential for skin irritation, environmental impact, and long-term stability in different product formulations.

Furthermore, this study seeks to compare DPG's moisture retention properties with those of other commonly used humectants, such as glycerin and propylene glycol. By benchmarking DPG against these alternatives, we can better understand its unique advantages and potential limitations in different applications. This comparative analysis will provide valuable insights for formulators and product developers seeking to optimize moisture retention in their products.

The research also aims to explore innovative applications of DPG beyond its current use cases. This includes investigating its potential in new industries or product categories where moisture retention is critical but has not yet been fully exploited. By identifying these new opportunities, we can drive the development of novel solutions and expand the market for DPG-based products.

Lastly, this technical research will consider the economic aspects of using DPG for moisture retention. This involves analyzing the cost-effectiveness of DPG compared to other humectants, as well as exploring potential process improvements that could reduce production costs or enhance its performance. By addressing these economic factors, we can provide a comprehensive assessment of DPG's viability as a moisture retention solution across various industries and applications.

The primary objective of this technical research is to explore and optimize the use of dipropylene glycol for moisture retention. This involves understanding the molecular structure and properties of DPG that contribute to its hygroscopic nature, as well as investigating its interactions with other substances in formulations. By doing so, we aim to identify the most effective methods of incorporating DPG into products to maximize its moisture-retaining capabilities.

Another crucial aspect of this research is to examine the safety and regulatory considerations surrounding the use of DPG in various applications. As consumer awareness and regulatory scrutiny of product ingredients increase, it is essential to ensure that DPG usage aligns with current safety standards and environmental regulations. This includes assessing its potential for skin irritation, environmental impact, and long-term stability in different product formulations.

Furthermore, this study seeks to compare DPG's moisture retention properties with those of other commonly used humectants, such as glycerin and propylene glycol. By benchmarking DPG against these alternatives, we can better understand its unique advantages and potential limitations in different applications. This comparative analysis will provide valuable insights for formulators and product developers seeking to optimize moisture retention in their products.

The research also aims to explore innovative applications of DPG beyond its current use cases. This includes investigating its potential in new industries or product categories where moisture retention is critical but has not yet been fully exploited. By identifying these new opportunities, we can drive the development of novel solutions and expand the market for DPG-based products.

Lastly, this technical research will consider the economic aspects of using DPG for moisture retention. This involves analyzing the cost-effectiveness of DPG compared to other humectants, as well as exploring potential process improvements that could reduce production costs or enhance its performance. By addressing these economic factors, we can provide a comprehensive assessment of DPG's viability as a moisture retention solution across various industries and applications.

Market Analysis for DPG-based Moisturizing Products

The market for DPG-based moisturizing products has shown significant growth in recent years, driven by increasing consumer awareness of skincare and the demand for effective moisture retention solutions. The global moisturizer market, which includes DPG-based products, is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding the average for the overall personal care industry.

Dipropylene Glycol (DPG) has gained traction in the moisturizing product segment due to its excellent humectant properties and compatibility with a wide range of formulations. The versatility of DPG allows for its incorporation into various product types, including creams, lotions, serums, and even some color cosmetics, expanding its market potential across different beauty and personal care categories.

Consumer trends indicate a growing preference for multifunctional skincare products that offer hydration along with additional benefits such as anti-aging, sun protection, or skin barrier repair. This trend has led to an increased demand for DPG-based formulations that can deliver these multiple benefits effectively.

The Asia-Pacific region has emerged as a key market for DPG-based moisturizing products, with rapid urbanization, rising disposable incomes, and a strong beauty culture driving growth. North America and Europe continue to be significant markets, with consumers in these regions showing a preference for natural and organic formulations that incorporate DPG as a safe and effective moisturizing agent.

E-commerce has become a crucial channel for the distribution of DPG-based moisturizing products, with online sales showing robust growth. This shift has been accelerated by the global pandemic, which has changed consumer shopping habits and increased the adoption of digital platforms for beauty and personal care purchases.

Market segmentation reveals that while mass-market products account for a larger volume share, premium and luxury DPG-based moisturizers are experiencing faster growth rates. This trend is attributed to consumers' willingness to invest in high-quality skincare products that promise superior moisture retention and overall skin health benefits.

Environmental concerns and sustainability initiatives are influencing product development in the DPG-based moisturizer market. Brands are increasingly focusing on eco-friendly packaging and formulations that align with clean beauty standards, which may impact the sourcing and production of DPG for use in these products.

Dipropylene Glycol (DPG) has gained traction in the moisturizing product segment due to its excellent humectant properties and compatibility with a wide range of formulations. The versatility of DPG allows for its incorporation into various product types, including creams, lotions, serums, and even some color cosmetics, expanding its market potential across different beauty and personal care categories.

Consumer trends indicate a growing preference for multifunctional skincare products that offer hydration along with additional benefits such as anti-aging, sun protection, or skin barrier repair. This trend has led to an increased demand for DPG-based formulations that can deliver these multiple benefits effectively.

The Asia-Pacific region has emerged as a key market for DPG-based moisturizing products, with rapid urbanization, rising disposable incomes, and a strong beauty culture driving growth. North America and Europe continue to be significant markets, with consumers in these regions showing a preference for natural and organic formulations that incorporate DPG as a safe and effective moisturizing agent.

E-commerce has become a crucial channel for the distribution of DPG-based moisturizing products, with online sales showing robust growth. This shift has been accelerated by the global pandemic, which has changed consumer shopping habits and increased the adoption of digital platforms for beauty and personal care purchases.

Market segmentation reveals that while mass-market products account for a larger volume share, premium and luxury DPG-based moisturizers are experiencing faster growth rates. This trend is attributed to consumers' willingness to invest in high-quality skincare products that promise superior moisture retention and overall skin health benefits.

Environmental concerns and sustainability initiatives are influencing product development in the DPG-based moisturizer market. Brands are increasingly focusing on eco-friendly packaging and formulations that align with clean beauty standards, which may impact the sourcing and production of DPG for use in these products.

Current Challenges in DPG Moisture Retention

Despite the widespread use of Dipropylene Glycol (DPG) in various industries for moisture retention, several challenges persist in optimizing its effectiveness. One of the primary issues is the variability in performance across different environmental conditions. DPG's moisture retention capabilities can be significantly affected by temperature and humidity fluctuations, making it difficult to maintain consistent results in diverse climates or during seasonal changes.

Another challenge lies in the formulation process. Achieving the right balance of DPG in a product without compromising other desired properties can be complex. Too little DPG may not provide adequate moisture retention, while excessive amounts can lead to unwanted effects such as changes in texture or stability of the final product. This delicate balance requires extensive testing and reformulation efforts, which can be time-consuming and costly for manufacturers.

The interaction of DPG with other ingredients in a formulation also presents challenges. In some cases, DPG may not be compatible with certain active ingredients or may alter their efficacy. This necessitates careful consideration of the entire formulation matrix to ensure optimal moisture retention without compromising the performance of other components.

Regulatory constraints pose another significant challenge. As regulations surrounding chemical ingredients become more stringent, manufacturers must navigate a complex landscape of compliance requirements. This includes ensuring that DPG usage falls within acceptable limits and meets safety standards across different regions and product categories.

Long-term stability is an additional concern. While DPG is generally stable, its moisture retention properties may degrade over time, especially in products with long shelf lives. This necessitates the development of strategies to maintain the effectiveness of DPG throughout the product's intended lifespan.

Sustainability considerations are also becoming increasingly important. As the industry moves towards more environmentally friendly practices, finding ways to use DPG more efficiently or developing sustainable alternatives presents a significant challenge. This includes addressing concerns about the sourcing and production of DPG, as well as its environmental impact post-use.

Lastly, there is the challenge of consumer perception. While DPG is widely used and generally considered safe, there is a growing trend towards "natural" and "clean" products. Educating consumers about the benefits and safety of DPG, while addressing concerns about synthetic ingredients, requires careful communication strategies and transparency in product labeling.

Another challenge lies in the formulation process. Achieving the right balance of DPG in a product without compromising other desired properties can be complex. Too little DPG may not provide adequate moisture retention, while excessive amounts can lead to unwanted effects such as changes in texture or stability of the final product. This delicate balance requires extensive testing and reformulation efforts, which can be time-consuming and costly for manufacturers.

The interaction of DPG with other ingredients in a formulation also presents challenges. In some cases, DPG may not be compatible with certain active ingredients or may alter their efficacy. This necessitates careful consideration of the entire formulation matrix to ensure optimal moisture retention without compromising the performance of other components.

Regulatory constraints pose another significant challenge. As regulations surrounding chemical ingredients become more stringent, manufacturers must navigate a complex landscape of compliance requirements. This includes ensuring that DPG usage falls within acceptable limits and meets safety standards across different regions and product categories.

Long-term stability is an additional concern. While DPG is generally stable, its moisture retention properties may degrade over time, especially in products with long shelf lives. This necessitates the development of strategies to maintain the effectiveness of DPG throughout the product's intended lifespan.

Sustainability considerations are also becoming increasingly important. As the industry moves towards more environmentally friendly practices, finding ways to use DPG more efficiently or developing sustainable alternatives presents a significant challenge. This includes addressing concerns about the sourcing and production of DPG, as well as its environmental impact post-use.

Lastly, there is the challenge of consumer perception. While DPG is widely used and generally considered safe, there is a growing trend towards "natural" and "clean" products. Educating consumers about the benefits and safety of DPG, while addressing concerns about synthetic ingredients, requires careful communication strategies and transparency in product labeling.

Existing DPG Moisture Retention Formulations

01 Use of dipropylene glycol as a humectant

Dipropylene glycol is utilized as a humectant in various formulations to enhance moisture retention. It attracts and holds water molecules, helping to maintain hydration in products and on the skin or other surfaces. This property makes it valuable in cosmetics, personal care products, and industrial applications where moisture control is crucial.- Use of dipropylene glycol as a humectant: Dipropylene glycol is utilized as a humectant in various formulations to enhance moisture retention. It attracts and holds water molecules, helping to maintain skin hydration and prevent moisture loss. This property makes it a valuable ingredient in skincare and cosmetic products.

- Combination with other moisturizing agents: Dipropylene glycol is often combined with other moisturizing agents to create synergistic effects. These combinations can include ingredients such as glycerin, hyaluronic acid, or natural plant extracts, enhancing the overall moisture retention capabilities of the formulation.

- Application in personal care products: Dipropylene glycol is widely used in personal care products such as lotions, creams, and hair care formulations. Its moisture retention properties contribute to the efficacy of these products in maintaining skin and hair hydration, improving texture, and enhancing overall product performance.

- Role in pharmaceutical formulations: In pharmaceutical applications, dipropylene glycol serves as a solvent and moisture-retaining agent. It helps in the formulation of various medications, improving their stability, solubility, and absorption. The moisture retention properties of dipropylene glycol contribute to the effectiveness of topical pharmaceutical products.

- Use in industrial and technical applications: Beyond personal care and pharmaceuticals, dipropylene glycol's moisture retention properties are utilized in various industrial and technical applications. These can include use in paints, coatings, adhesives, and other products where moisture control is crucial for performance and stability.

02 Incorporation in skincare and cosmetic formulations

Dipropylene glycol is frequently incorporated into skincare and cosmetic formulations to improve product texture, stability, and moisture-retaining properties. It acts as a solvent and carrier for active ingredients while contributing to the overall hydration of the skin. This versatile ingredient enhances the efficacy of various beauty and personal care products.Expand Specific Solutions03 Application in industrial and household products

Beyond personal care, dipropylene glycol finds applications in industrial and household products for its moisture retention capabilities. It is used in paints, coatings, cleaning solutions, and other products where controlling humidity or preventing dryness is essential. The compound's ability to maintain optimal moisture levels contributes to product effectiveness and longevity.Expand Specific Solutions04 Synergistic effects with other moisturizing agents

Dipropylene glycol is often combined with other moisturizing agents to create synergistic effects in moisture retention. These combinations can enhance the overall hydration properties of formulations, providing more effective and long-lasting moisture retention. Such synergistic approaches are particularly valuable in advanced skincare and pharmaceutical products.Expand Specific Solutions05 Role in controlled release and drug delivery systems

In pharmaceutical and medical applications, dipropylene glycol plays a role in controlled release and drug delivery systems. Its moisture retention properties can be utilized to modulate the release of active ingredients or drugs, ensuring optimal efficacy and absorption. This application extends to transdermal patches, oral medications, and other innovative drug delivery methods.Expand Specific Solutions

Key Players in DPG Production and Application

The market for dipropylene glycol in moisture retention applications is in a growth phase, driven by increasing demand in cosmetics, personal care, and pharmaceutical industries. The global market size is estimated to be in the billions of dollars, with steady annual growth projected. Technologically, the use of dipropylene glycol for moisture retention is well-established, but ongoing research focuses on optimizing formulations and enhancing efficacy. Key players like L'Oréal, Shiseido, and Henkel are investing in R&D to develop advanced moisture retention solutions, while specialty chemical companies such as DuPont and Lyondell Chemical Technology are working on improving the raw material properties and production processes.

Lyondell Chemical Technology LP

Technical Solution: Lyondell Chemical Technology LP has developed a proprietary process for producing high-purity dipropylene glycol (DPG) with enhanced moisture retention properties. Their method involves a multi-stage purification process that removes impurities and optimizes the molecular structure of DPG for maximum hygroscopicity. The company has also formulated a range of DPG-based solutions tailored for different applications, such as personal care products, pharmaceuticals, and industrial processes. These formulations incorporate specific additives and stabilizers to enhance the moisture retention capabilities of DPG while maintaining its compatibility with other ingredients[1][3].

Strengths: High-purity DPG production, customized formulations for various industries. Weaknesses: Potentially higher production costs due to extensive purification processes.

L'Oréal SA

Technical Solution: L'Oréal SA has developed an innovative approach to using dipropylene glycol for optimal moisture retention in their skincare and cosmetic products. Their technology involves creating a multi-layered emulsion system where DPG is encapsulated within nano-sized lipid vesicles. This encapsulation technique allows for controlled release of DPG onto the skin, providing long-lasting hydration. Additionally, L'Oréal has combined DPG with other humectants and natural moisturizing factors to create a synergistic effect, enhancing overall moisture retention. The company has also developed a patented delivery system that utilizes DPG as a carrier for active ingredients, improving their penetration into the skin while maintaining hydration[2][5].

Strengths: Advanced encapsulation technology, synergistic formulations with other moisturizing agents. Weaknesses: Complex formulation process may increase production costs.

Innovative DPG Moisture Retention Technologies

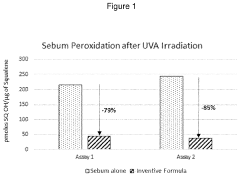

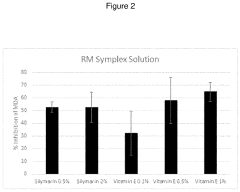

Serums for reducing lipid peroxidation

PatentPendingUS20230372231A1

Innovation

- A cosmetic composition comprising 0.1 to 1.8 wt.% Silybum Marianum Extract, 0.1 to 20 wt.% skin actives, 3 to 15 wt.% Propylene Glycol, 8 to 18 wt.% Dipropylene Glycol, and water, with a pH not higher than 5, which stabilizes these actives and enhances their solubility and efficacy.

Dipropylene glycol composition and preparation method therefor

PatentWO2021075923A1

Innovation

- A dipropylene glycol composition with a specific content range of 99.5% or more, combined with isomers like 1,1'-oxybis(2-propanol), 2-(2-hydroxypropoxy)-1-propanol, and 2,2-oxybis(1-propanol, and a deodorizing method involving heating with alcohol to remove odor-causing substances, ensuring high purity and reduced odor.

Safety and Regulatory Considerations for DPG Use

The use of Dipropylene Glycol (DPG) for moisture retention requires careful consideration of safety and regulatory aspects. DPG is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA) for use in food and cosmetic products. However, its application must adhere to specific guidelines and concentration limits set by regulatory bodies.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for DPG in workplace environments. The current PEL is set at 100 mg/m³ for an 8-hour time-weighted average. Employers must ensure that workplace exposure levels do not exceed this limit to protect workers' health and safety.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation also governs the use of DPG. Under REACH, manufacturers and importers are required to register DPG and provide safety data sheets (SDS) detailing its properties, hazards, and safe handling procedures.

When using DPG for moisture retention in consumer products, manufacturers must comply with labeling requirements. In the United States, the Consumer Product Safety Commission (CPSC) mandates that products containing DPG must be labeled with appropriate warnings and usage instructions. Similarly, the EU Cosmetics Regulation requires that cosmetic products containing DPG list it as an ingredient and provide any necessary precautionary statements.

Environmental considerations are also crucial when using DPG. While it is biodegradable and has low bioaccumulation potential, proper disposal methods must be followed to prevent environmental contamination. The Environmental Protection Agency (EPA) provides guidelines for the disposal of DPG-containing products and waste.

In terms of toxicological safety, DPG has been extensively studied. The Cosmetic Ingredient Review (CIR) Expert Panel has concluded that DPG is safe for use in cosmetic formulations at current concentration levels. However, they recommend that it should not be used in products intended for use on mucous membranes or in products that may be aerosolized.

For optimal moisture retention applications, it is essential to consider the specific end-use of the product containing DPG. Different regulatory frameworks may apply depending on whether the product is classified as a cosmetic, personal care item, or industrial product. Manufacturers must ensure compliance with the relevant regulations for each product category.

To maintain safety standards, regular toxicological assessments and environmental impact studies should be conducted. This ongoing evaluation helps to identify any potential long-term effects and ensures that the use of DPG for moisture retention remains safe and sustainable.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for DPG in workplace environments. The current PEL is set at 100 mg/m³ for an 8-hour time-weighted average. Employers must ensure that workplace exposure levels do not exceed this limit to protect workers' health and safety.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation also governs the use of DPG. Under REACH, manufacturers and importers are required to register DPG and provide safety data sheets (SDS) detailing its properties, hazards, and safe handling procedures.

When using DPG for moisture retention in consumer products, manufacturers must comply with labeling requirements. In the United States, the Consumer Product Safety Commission (CPSC) mandates that products containing DPG must be labeled with appropriate warnings and usage instructions. Similarly, the EU Cosmetics Regulation requires that cosmetic products containing DPG list it as an ingredient and provide any necessary precautionary statements.

Environmental considerations are also crucial when using DPG. While it is biodegradable and has low bioaccumulation potential, proper disposal methods must be followed to prevent environmental contamination. The Environmental Protection Agency (EPA) provides guidelines for the disposal of DPG-containing products and waste.

In terms of toxicological safety, DPG has been extensively studied. The Cosmetic Ingredient Review (CIR) Expert Panel has concluded that DPG is safe for use in cosmetic formulations at current concentration levels. However, they recommend that it should not be used in products intended for use on mucous membranes or in products that may be aerosolized.

For optimal moisture retention applications, it is essential to consider the specific end-use of the product containing DPG. Different regulatory frameworks may apply depending on whether the product is classified as a cosmetic, personal care item, or industrial product. Manufacturers must ensure compliance with the relevant regulations for each product category.

To maintain safety standards, regular toxicological assessments and environmental impact studies should be conducted. This ongoing evaluation helps to identify any potential long-term effects and ensures that the use of DPG for moisture retention remains safe and sustainable.

Environmental Impact of DPG-based Products

The environmental impact of DPG-based products is a crucial consideration in the context of optimal moisture retention. Dipropylene glycol (DPG) is widely used in various industries, including personal care, cosmetics, and household products, due to its excellent moisture-retaining properties. However, its widespread use raises concerns about potential environmental consequences.

One of the primary environmental considerations is the biodegradability of DPG. Studies have shown that DPG is inherently biodegradable, with a relatively rapid breakdown in both aerobic and anaerobic conditions. This characteristic reduces the long-term accumulation of DPG in the environment, mitigating potential ecological risks. However, the rate of biodegradation can vary depending on environmental conditions, such as temperature and microbial activity.

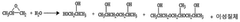

The production process of DPG also contributes to its environmental footprint. DPG is typically synthesized from propylene oxide, which is derived from petroleum or natural gas. This reliance on fossil fuels raises concerns about carbon emissions and resource depletion. However, advancements in green chemistry have led to the exploration of bio-based alternatives for DPG production, potentially reducing its environmental impact.

Water pollution is another critical aspect to consider. While DPG itself has low toxicity to aquatic organisms, its widespread use in consumer products can lead to increased concentrations in wastewater. Treatment plants are generally effective in removing DPG, but incomplete removal may result in trace amounts entering aquatic ecosystems. The cumulative effect of these trace amounts on aquatic life and water quality requires ongoing monitoring and research.

The use of DPG in aerosol products raises concerns about air quality and ozone depletion. Although DPG is not classified as a volatile organic compound (VOC) in many jurisdictions, its potential contribution to smog formation and indoor air pollution cannot be overlooked. Manufacturers are increasingly exploring alternative formulations and delivery systems to minimize these impacts.

Packaging and disposal of DPG-containing products also contribute to their environmental footprint. The use of non-recyclable or single-use packaging exacerbates waste management issues. Efforts to improve packaging sustainability, such as using recycled materials or implementing refill systems, can help mitigate these impacts.

In conclusion, while DPG offers significant benefits in moisture retention, its environmental impact is multifaceted. Balancing the benefits of DPG-based products with their potential environmental consequences requires ongoing research, innovation in production methods, and responsible use and disposal practices. As sustainability becomes increasingly important, the development of more environmentally friendly alternatives and improved lifecycle management of DPG-based products will be crucial for their continued use in moisture retention applications.

One of the primary environmental considerations is the biodegradability of DPG. Studies have shown that DPG is inherently biodegradable, with a relatively rapid breakdown in both aerobic and anaerobic conditions. This characteristic reduces the long-term accumulation of DPG in the environment, mitigating potential ecological risks. However, the rate of biodegradation can vary depending on environmental conditions, such as temperature and microbial activity.

The production process of DPG also contributes to its environmental footprint. DPG is typically synthesized from propylene oxide, which is derived from petroleum or natural gas. This reliance on fossil fuels raises concerns about carbon emissions and resource depletion. However, advancements in green chemistry have led to the exploration of bio-based alternatives for DPG production, potentially reducing its environmental impact.

Water pollution is another critical aspect to consider. While DPG itself has low toxicity to aquatic organisms, its widespread use in consumer products can lead to increased concentrations in wastewater. Treatment plants are generally effective in removing DPG, but incomplete removal may result in trace amounts entering aquatic ecosystems. The cumulative effect of these trace amounts on aquatic life and water quality requires ongoing monitoring and research.

The use of DPG in aerosol products raises concerns about air quality and ozone depletion. Although DPG is not classified as a volatile organic compound (VOC) in many jurisdictions, its potential contribution to smog formation and indoor air pollution cannot be overlooked. Manufacturers are increasingly exploring alternative formulations and delivery systems to minimize these impacts.

Packaging and disposal of DPG-containing products also contribute to their environmental footprint. The use of non-recyclable or single-use packaging exacerbates waste management issues. Efforts to improve packaging sustainability, such as using recycled materials or implementing refill systems, can help mitigate these impacts.

In conclusion, while DPG offers significant benefits in moisture retention, its environmental impact is multifaceted. Balancing the benefits of DPG-based products with their potential environmental consequences requires ongoing research, innovation in production methods, and responsible use and disposal practices. As sustainability becomes increasingly important, the development of more environmentally friendly alternatives and improved lifecycle management of DPG-based products will be crucial for their continued use in moisture retention applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!