Impact of temperature fluctuations on submersible pumps.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Challenges in Submersible Pump Operations

Submersible pumps operate in challenging environments where temperature fluctuations can significantly impact their performance and longevity. These thermal challenges arise from various sources, including the surrounding fluid, motor heat generation, and environmental factors. Understanding and addressing these thermal issues is crucial for optimizing pump efficiency and reliability.

One of the primary thermal challenges in submersible pump operations is the heat generated by the motor during operation. As the pump runs, the electric motor produces heat as a byproduct of energy conversion. This heat must be effectively dissipated to prevent overheating, which can lead to premature failure of motor components, reduced efficiency, and shortened pump lifespan.

The surrounding fluid temperature also plays a critical role in the thermal management of submersible pumps. In applications such as geothermal wells or deep-sea operations, pumps may be exposed to extreme temperature variations. These fluctuations can cause thermal expansion and contraction of pump materials, potentially leading to misalignment, seal failures, or structural stress.

Thermal shock is another significant challenge, particularly in applications where pumps experience rapid temperature changes. For instance, when a cold pump is suddenly immersed in hot fluid or vice versa, the resulting thermal stress can cause component damage or failure. This is especially critical for pumps used in intermittent operations or those subject to frequent start-stop cycles.

The viscosity of the pumped fluid is also temperature-dependent, which directly affects pump performance. As temperatures fluctuate, changes in fluid viscosity can impact flow rates, power consumption, and overall pump efficiency. This relationship between temperature and viscosity must be carefully considered in pump design and operation to ensure optimal performance across a range of thermal conditions.

Thermal expansion of pump components presents another challenge. Different materials expand and contract at varying rates with temperature changes, which can lead to issues such as seal leakage, bearing misalignment, or impeller clearance problems. Engineers must account for these thermal effects in the design phase to maintain proper tolerances and prevent mechanical failures.

Addressing these thermal challenges requires a multifaceted approach. This may include the use of advanced cooling systems, selection of temperature-resistant materials, implementation of thermal sensors and monitoring systems, and the development of adaptive control strategies to optimize pump operation based on real-time temperature data. By effectively managing these thermal challenges, operators can enhance the reliability, efficiency, and lifespan of submersible pumps across a wide range of applications and operating conditions.

One of the primary thermal challenges in submersible pump operations is the heat generated by the motor during operation. As the pump runs, the electric motor produces heat as a byproduct of energy conversion. This heat must be effectively dissipated to prevent overheating, which can lead to premature failure of motor components, reduced efficiency, and shortened pump lifespan.

The surrounding fluid temperature also plays a critical role in the thermal management of submersible pumps. In applications such as geothermal wells or deep-sea operations, pumps may be exposed to extreme temperature variations. These fluctuations can cause thermal expansion and contraction of pump materials, potentially leading to misalignment, seal failures, or structural stress.

Thermal shock is another significant challenge, particularly in applications where pumps experience rapid temperature changes. For instance, when a cold pump is suddenly immersed in hot fluid or vice versa, the resulting thermal stress can cause component damage or failure. This is especially critical for pumps used in intermittent operations or those subject to frequent start-stop cycles.

The viscosity of the pumped fluid is also temperature-dependent, which directly affects pump performance. As temperatures fluctuate, changes in fluid viscosity can impact flow rates, power consumption, and overall pump efficiency. This relationship between temperature and viscosity must be carefully considered in pump design and operation to ensure optimal performance across a range of thermal conditions.

Thermal expansion of pump components presents another challenge. Different materials expand and contract at varying rates with temperature changes, which can lead to issues such as seal leakage, bearing misalignment, or impeller clearance problems. Engineers must account for these thermal effects in the design phase to maintain proper tolerances and prevent mechanical failures.

Addressing these thermal challenges requires a multifaceted approach. This may include the use of advanced cooling systems, selection of temperature-resistant materials, implementation of thermal sensors and monitoring systems, and the development of adaptive control strategies to optimize pump operation based on real-time temperature data. By effectively managing these thermal challenges, operators can enhance the reliability, efficiency, and lifespan of submersible pumps across a wide range of applications and operating conditions.

Market Demand for Temperature-Resistant Pumps

The market demand for temperature-resistant submersible pumps has been steadily increasing due to the growing awareness of the impact of temperature fluctuations on pump performance and longevity. Industries such as oil and gas, geothermal energy, and deep-sea exploration are particularly driving this demand, as they often operate in environments with extreme temperature variations.

In the oil and gas sector, submersible pumps are crucial for extracting fluids from deep wells where temperatures can range from near-freezing to over 200°C. The ability of pumps to withstand these temperature fluctuations directly affects production efficiency and operational costs. As a result, there is a strong market pull for pumps that can maintain optimal performance across a wide temperature spectrum.

The geothermal energy industry is another significant driver of demand for temperature-resistant pumps. As geothermal power generation expands globally, the need for pumps capable of handling high-temperature geothermal fluids has increased. These pumps must not only withstand constant exposure to hot fluids but also resist corrosion and scaling associated with mineral-rich geothermal waters.

Deep-sea exploration and subsea oil production present unique challenges for submersible pumps. In these applications, pumps may be subjected to near-freezing temperatures at great depths and must be able to start and operate reliably in these conditions. The market for pumps that can perform consistently in cold, high-pressure environments is growing as offshore operations extend into deeper waters.

The mining industry is also contributing to the demand for temperature-resistant pumps. In underground mines, where ambient temperatures can be high due to geothermal gradients, pumps are required to operate efficiently to remove groundwater and process slurries. The ability of pumps to function reliably in these warm, often abrasive environments is critical for maintaining mining operations.

Furthermore, the wastewater treatment sector is showing increased interest in temperature-resistant pumps. As climate change leads to more extreme weather events, wastewater facilities are experiencing greater temperature variations in influent streams. Pumps that can handle these fluctuations without compromising performance or requiring frequent maintenance are becoming more valuable to treatment plant operators.

The market is responding to these demands with innovations in materials science and pump design. Manufacturers are developing new alloys and composite materials that offer improved temperature resistance while maintaining the necessary mechanical properties. Advanced cooling systems and thermal management techniques are being integrated into pump designs to extend their operational temperature range.

As industries continue to push the boundaries of operational environments, the market for temperature-resistant submersible pumps is expected to grow. This growth is likely to be accompanied by a shift towards more sophisticated monitoring and control systems that can optimize pump performance in real-time based on temperature conditions. The ability to offer comprehensive solutions that address temperature fluctuations will be a key differentiator for pump manufacturers in the coming years.

In the oil and gas sector, submersible pumps are crucial for extracting fluids from deep wells where temperatures can range from near-freezing to over 200°C. The ability of pumps to withstand these temperature fluctuations directly affects production efficiency and operational costs. As a result, there is a strong market pull for pumps that can maintain optimal performance across a wide temperature spectrum.

The geothermal energy industry is another significant driver of demand for temperature-resistant pumps. As geothermal power generation expands globally, the need for pumps capable of handling high-temperature geothermal fluids has increased. These pumps must not only withstand constant exposure to hot fluids but also resist corrosion and scaling associated with mineral-rich geothermal waters.

Deep-sea exploration and subsea oil production present unique challenges for submersible pumps. In these applications, pumps may be subjected to near-freezing temperatures at great depths and must be able to start and operate reliably in these conditions. The market for pumps that can perform consistently in cold, high-pressure environments is growing as offshore operations extend into deeper waters.

The mining industry is also contributing to the demand for temperature-resistant pumps. In underground mines, where ambient temperatures can be high due to geothermal gradients, pumps are required to operate efficiently to remove groundwater and process slurries. The ability of pumps to function reliably in these warm, often abrasive environments is critical for maintaining mining operations.

Furthermore, the wastewater treatment sector is showing increased interest in temperature-resistant pumps. As climate change leads to more extreme weather events, wastewater facilities are experiencing greater temperature variations in influent streams. Pumps that can handle these fluctuations without compromising performance or requiring frequent maintenance are becoming more valuable to treatment plant operators.

The market is responding to these demands with innovations in materials science and pump design. Manufacturers are developing new alloys and composite materials that offer improved temperature resistance while maintaining the necessary mechanical properties. Advanced cooling systems and thermal management techniques are being integrated into pump designs to extend their operational temperature range.

As industries continue to push the boundaries of operational environments, the market for temperature-resistant submersible pumps is expected to grow. This growth is likely to be accompanied by a shift towards more sophisticated monitoring and control systems that can optimize pump performance in real-time based on temperature conditions. The ability to offer comprehensive solutions that address temperature fluctuations will be a key differentiator for pump manufacturers in the coming years.

Current Limitations in Thermal Management

The thermal management of submersible pumps faces several critical limitations that hinder their performance and reliability in fluctuating temperature environments. One of the primary challenges is the inadequate heat dissipation mechanisms in current pump designs. As submersible pumps operate in confined spaces, often submerged in fluids, the traditional cooling methods used in surface pumps are not applicable. This limitation leads to heat accumulation within the pump components, particularly in the motor and bearings, which can cause accelerated wear and reduced efficiency.

Another significant limitation is the lack of real-time temperature monitoring and control systems in many submersible pump models. Without accurate and continuous temperature data, it becomes difficult to implement adaptive cooling strategies or preventive maintenance protocols. This gap in thermal management capabilities often results in unexpected pump failures and increased downtime, especially in applications where temperature fluctuations are frequent and severe.

The materials used in submersible pump construction also present limitations in thermal management. While many components are designed to withstand high temperatures, the repeated thermal cycling caused by temperature fluctuations can lead to material fatigue and degradation over time. This is particularly problematic for seals, gaskets, and electrical insulation, which may lose their integrity under prolonged exposure to varying thermal stresses.

Furthermore, the current thermal management solutions for submersible pumps often fail to address the complex interplay between fluid dynamics and heat transfer. The surrounding fluid, which ideally should aid in cooling, can sometimes create thermal barriers or hotspots, especially in viscous or thermally insulating fluids. This limitation is exacerbated in applications where the pumped fluid itself undergoes significant temperature changes, creating a dynamic thermal environment that is challenging to manage with static cooling solutions.

The power electronics and control systems in submersible pumps also face thermal management limitations. As these components become more sophisticated to improve pump performance and efficiency, they generate additional heat within the confined pump housing. The current cooling solutions often struggle to adequately dissipate this heat, leading to potential electronic failures and reduced pump lifespan.

Lastly, the industry faces a limitation in standardized testing and certification procedures for thermal performance under fluctuating temperature conditions. This lack of standardization makes it difficult for manufacturers to accurately assess and compare the thermal resilience of different pump models, hindering the development and adoption of more effective thermal management solutions.

Another significant limitation is the lack of real-time temperature monitoring and control systems in many submersible pump models. Without accurate and continuous temperature data, it becomes difficult to implement adaptive cooling strategies or preventive maintenance protocols. This gap in thermal management capabilities often results in unexpected pump failures and increased downtime, especially in applications where temperature fluctuations are frequent and severe.

The materials used in submersible pump construction also present limitations in thermal management. While many components are designed to withstand high temperatures, the repeated thermal cycling caused by temperature fluctuations can lead to material fatigue and degradation over time. This is particularly problematic for seals, gaskets, and electrical insulation, which may lose their integrity under prolonged exposure to varying thermal stresses.

Furthermore, the current thermal management solutions for submersible pumps often fail to address the complex interplay between fluid dynamics and heat transfer. The surrounding fluid, which ideally should aid in cooling, can sometimes create thermal barriers or hotspots, especially in viscous or thermally insulating fluids. This limitation is exacerbated in applications where the pumped fluid itself undergoes significant temperature changes, creating a dynamic thermal environment that is challenging to manage with static cooling solutions.

The power electronics and control systems in submersible pumps also face thermal management limitations. As these components become more sophisticated to improve pump performance and efficiency, they generate additional heat within the confined pump housing. The current cooling solutions often struggle to adequately dissipate this heat, leading to potential electronic failures and reduced pump lifespan.

Lastly, the industry faces a limitation in standardized testing and certification procedures for thermal performance under fluctuating temperature conditions. This lack of standardization makes it difficult for manufacturers to accurately assess and compare the thermal resilience of different pump models, hindering the development and adoption of more effective thermal management solutions.

Existing Thermal Protection Solutions

01 Temperature compensation systems for submersible pumps

Implementing temperature compensation systems in submersible pumps to adjust operation based on temperature fluctuations. These systems may include sensors, controllers, and adaptive mechanisms to maintain optimal performance across varying thermal conditions.- Temperature compensation systems for submersible pumps: Implementing temperature compensation systems in submersible pumps to adjust operation based on temperature fluctuations. These systems may include sensors, controllers, and adaptive mechanisms to maintain optimal performance across varying thermal conditions, ensuring efficiency and longevity of the pump.

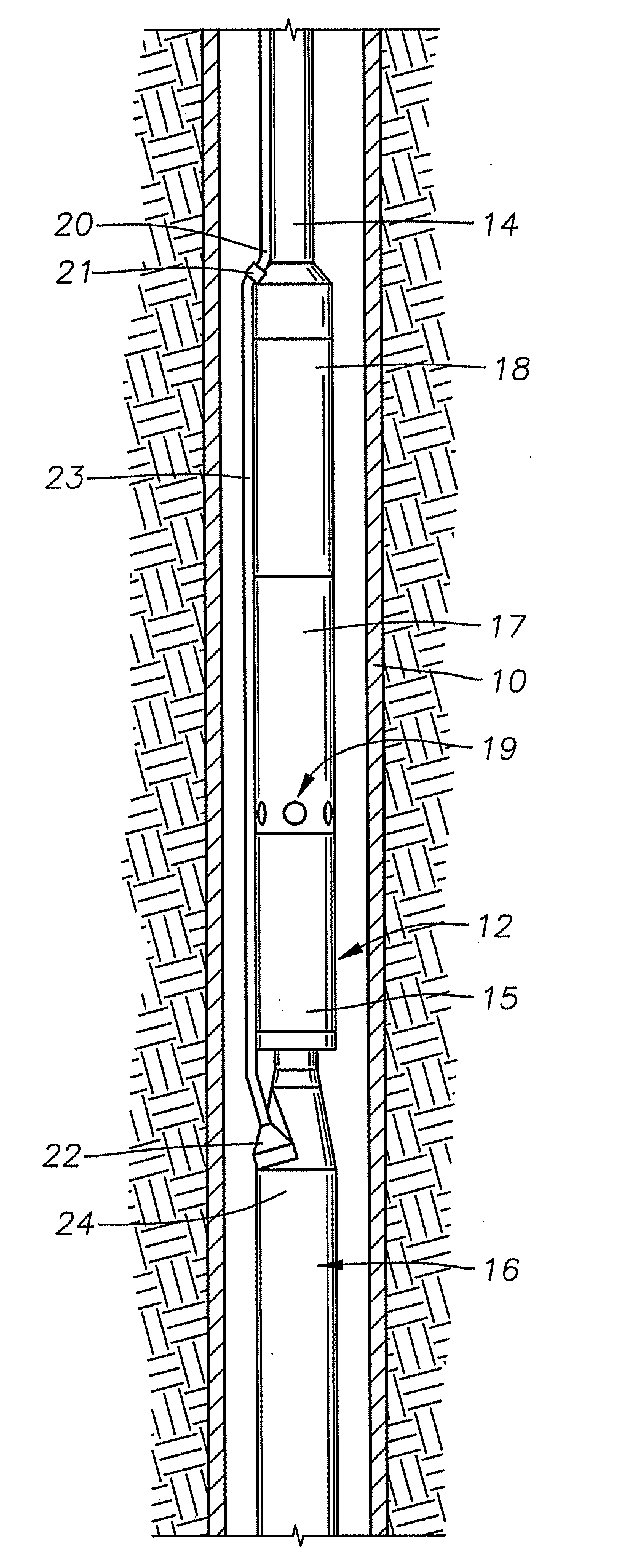

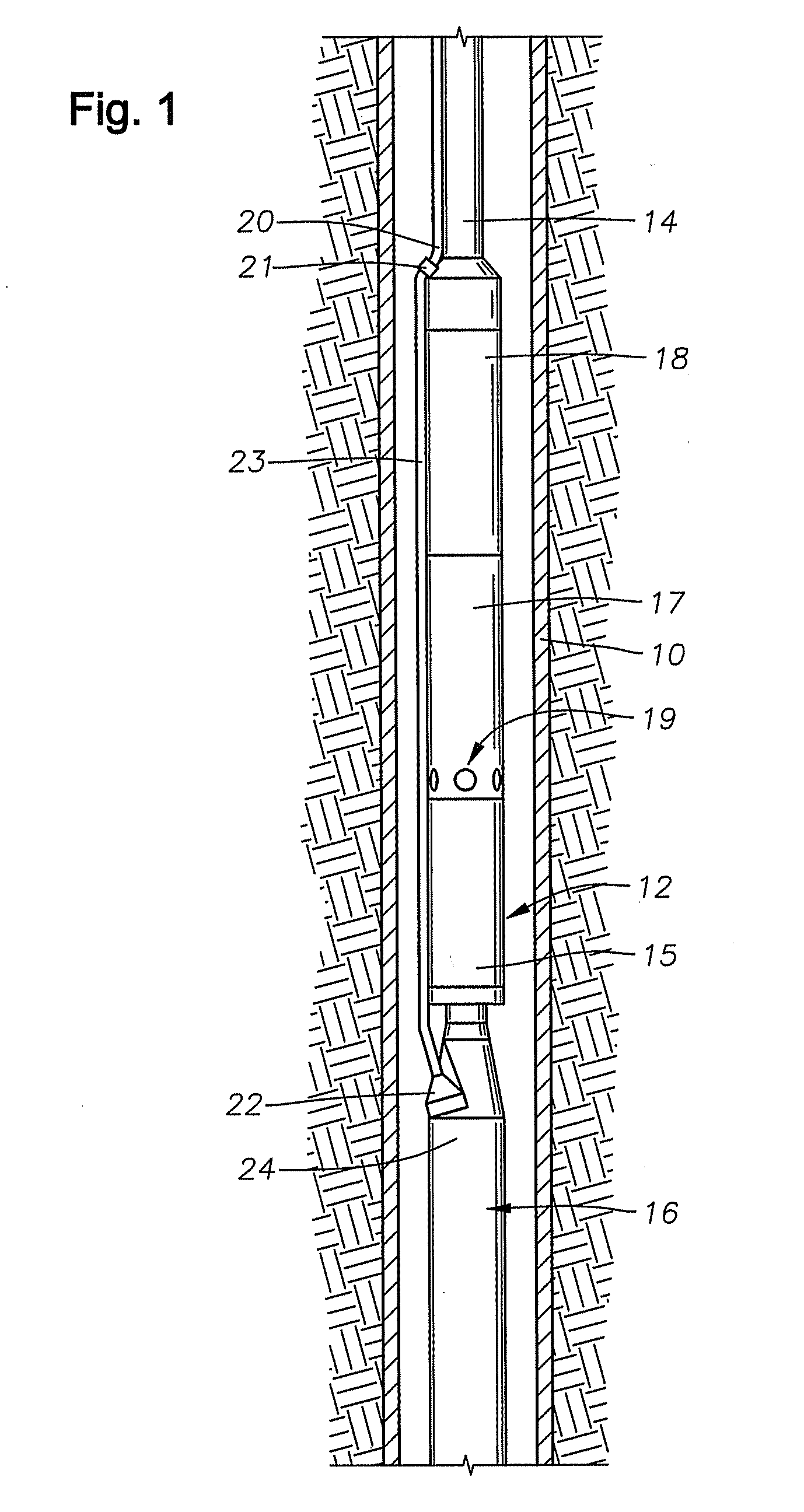

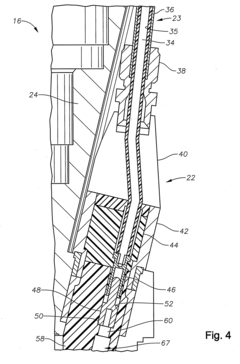

- Thermal management in downhole pumping systems: Developing specialized thermal management solutions for downhole pumping systems to address temperature fluctuations in deep well environments. This may involve the use of heat-resistant materials, cooling mechanisms, or thermal insulation techniques to protect pump components from extreme temperature variations.

- Smart control systems for temperature-adaptive pumping: Integrating smart control systems that use real-time temperature data to adjust pump operation dynamically. These systems may employ machine learning algorithms or predictive models to anticipate temperature changes and optimize pump performance accordingly, reducing wear and energy consumption.

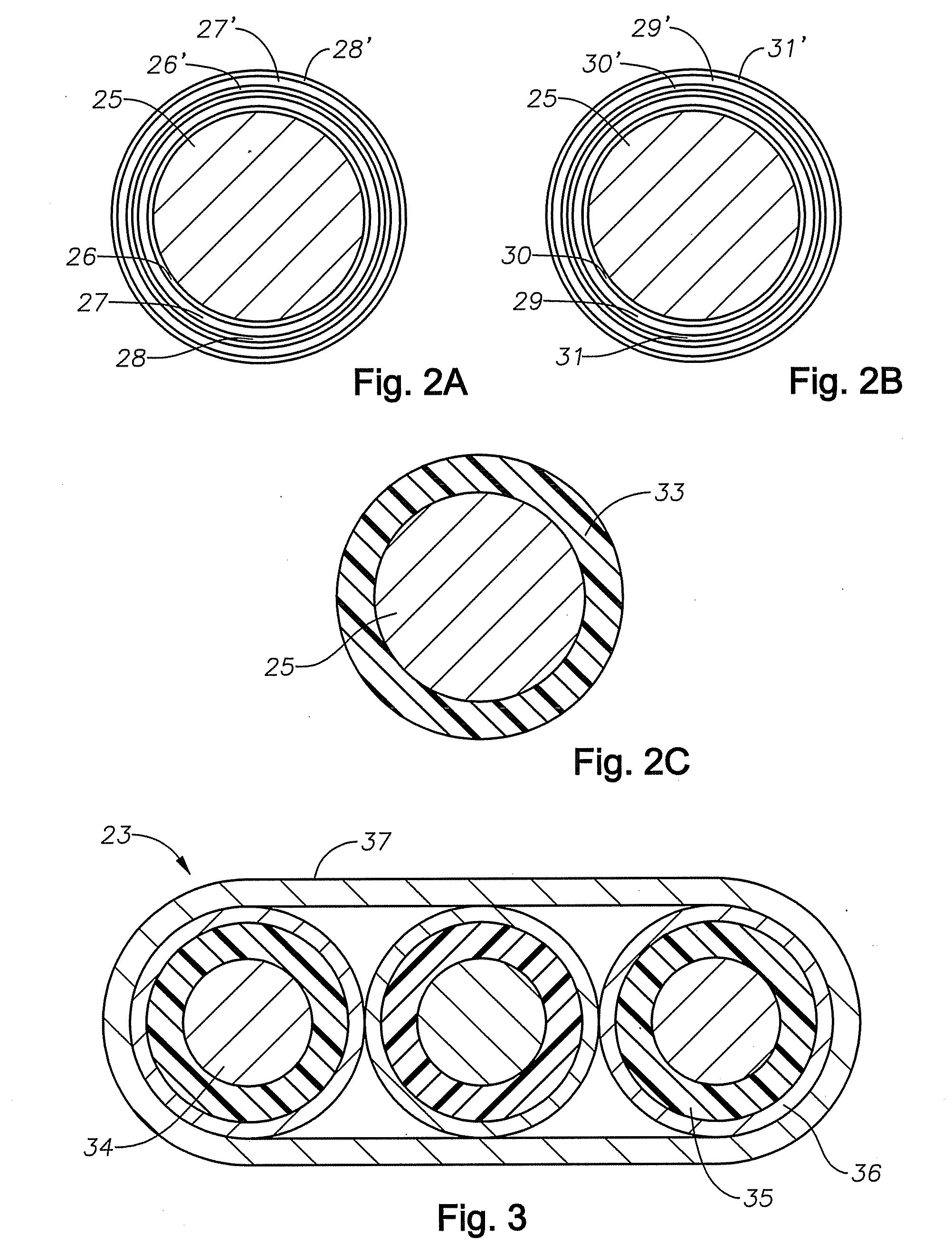

- Materials and coatings for temperature resistance: Utilizing advanced materials and coatings to enhance the temperature resistance of submersible pump components. This may include the development of novel alloys, ceramic composites, or nano-engineered surfaces that can withstand extreme temperature fluctuations without compromising pump functionality.

- Fluid circulation systems for temperature regulation: Designing fluid circulation systems within submersible pumps to regulate internal temperatures. These systems may use the pumped fluid or a separate cooling medium to dissipate heat from critical components, maintaining stable operating temperatures despite external fluctuations.

02 Thermal management in submersible pump motors

Developing effective thermal management solutions for submersible pump motors to handle temperature fluctuations. This may involve advanced cooling systems, heat-resistant materials, and innovative motor designs to ensure reliable operation in challenging thermal environments.Expand Specific Solutions03 Adaptive control systems for temperature variations

Incorporating adaptive control systems that can respond to temperature fluctuations in real-time. These systems may use advanced algorithms, machine learning, or AI to adjust pump parameters, ensuring optimal performance and efficiency across a range of temperatures.Expand Specific Solutions04 Temperature-resistant materials and coatings

Utilizing temperature-resistant materials and specialized coatings in submersible pump construction. These materials can withstand extreme temperature fluctuations, reducing wear and tear and extending the operational life of the pump in challenging environments.Expand Specific Solutions05 Innovative cooling mechanisms for submersible pumps

Developing innovative cooling mechanisms specifically designed for submersible pumps operating in environments with significant temperature fluctuations. These may include advanced fluid circulation systems, phase-change materials, or other novel approaches to maintain stable operating temperatures.Expand Specific Solutions

Key Players in Submersible Pump Industry

The impact of temperature fluctuations on submersible pumps is a critical issue in the mature oil and gas industry, with a global market size estimated at several billion dollars. The technology is well-established, yet continuous innovation is driven by the need for improved efficiency and reliability in harsh environments. Major players like Baker Hughes Co., Siemens Corp., and Flowserve Management Co. are at the forefront of developing advanced solutions. These companies, along with others such as Grundfos International As and KSB SE & Co. KGaA, are investing in research to enhance pump performance and durability under varying temperature conditions. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, each striving to differentiate through technological advancements and comprehensive service offerings.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed advanced submersible pump systems with integrated temperature monitoring and adaptive control mechanisms. Their technology utilizes real-time temperature sensors and machine learning algorithms to predict and mitigate the effects of temperature fluctuations on pump performance. The system automatically adjusts pump speed and flow rates to maintain optimal efficiency across varying temperature conditions[1]. Additionally, Baker Hughes has implemented innovative materials and coatings that enhance thermal resistance and reduce wear caused by temperature-induced stress[3].

Strengths: Advanced temperature monitoring and adaptive control; Predictive maintenance capabilities; Improved thermal resistance. Weaknesses: Potentially higher initial costs; Requires specialized maintenance and calibration.

Grundfos International As

Technical Solution: Grundfos has engineered submersible pumps with a focus on thermal management and energy efficiency. Their pumps incorporate advanced cooling systems that utilize the pumped fluid to regulate motor temperature, even in challenging environments. Grundfos' smart motor protection technology continuously monitors temperature and adjusts operation to prevent overheating[2]. The company has also developed specialized impeller designs that maintain efficiency across a wide temperature range, reducing the impact of fluctuations on pump performance[4].

Strengths: Efficient thermal management; Smart motor protection; Versatile performance across temperature ranges. Weaknesses: May have limitations in extreme temperature environments; Potential for increased complexity in pump design.

Innovations in Temperature-Resistant Materials

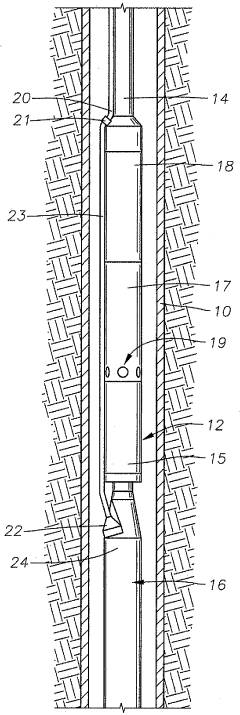

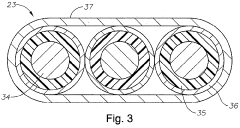

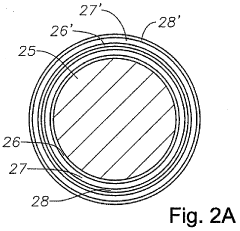

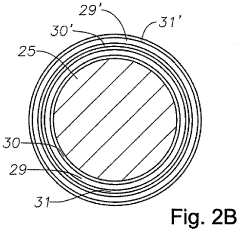

Electrical submersible pump system having improved magnet wire leads

PatentWO2012036871A2

Innovation

- The electric submersible pumping system employs high-temperature electrical insulation, including E-base polyimide film and perfluoropolymer materials, to protect magnet wires and conductors, along with a PAO dielectric lubricant to mitigate chemical reactions and extend motor life.

Electrical Submersible Pump System Having High Temperature Insulation Materials and Buffered Lubricant

PatentActiveUS20120063932A1

Innovation

- The use of high-temperature electrical insulation materials such as E-base polyimide film, fluoropolymer adhesives, and perfluoropolymers in the motor and power cable components, along with a PAO dielectric lubricant with additives to mitigate acid generation and enhance insulation stability, allows the ESP system to operate effectively at temperatures above 180°C.

Environmental Impact of Pump Cooling Systems

The environmental impact of pump cooling systems in submersible pumps is a critical consideration in the context of temperature fluctuations. These systems play a vital role in maintaining optimal operating conditions for submersible pumps, but their design and operation can have significant environmental implications.

Cooling systems in submersible pumps typically utilize either water or oil as the cooling medium. Water-based cooling systems are more environmentally friendly but may be less effective in certain high-temperature applications. Oil-based systems, while more efficient in heat transfer, pose a greater risk of environmental contamination if leaks occur.

The energy consumption of cooling systems is a major factor in their environmental impact. As temperature fluctuations become more extreme, cooling systems must work harder to maintain stable operating temperatures, leading to increased energy usage. This not only raises operational costs but also contributes to higher carbon emissions if the energy source is not renewable.

Water usage is another environmental concern, particularly in water-cooled systems. In areas experiencing water scarcity, the use of large volumes of water for cooling purposes can strain local water resources. Additionally, the discharge of heated water back into natural water bodies can disrupt aquatic ecosystems, affecting local flora and fauna.

Chemical treatments used in cooling systems to prevent corrosion and microbial growth can have detrimental effects on the environment if not properly managed. These chemicals, when released into water bodies, can alter water chemistry and harm aquatic life. Proper treatment and disposal of these chemicals are essential to minimize environmental impact.

The materials used in cooling system components also contribute to the overall environmental footprint. The production and disposal of these materials, particularly in systems that require frequent replacement due to harsh operating conditions, can lead to increased resource consumption and waste generation.

Noise pollution is an often-overlooked environmental impact of pump cooling systems. In industrial settings, the operation of large cooling systems can contribute significantly to ambient noise levels, potentially affecting local wildlife and human populations.

To mitigate these environmental impacts, manufacturers and operators are increasingly focusing on developing more sustainable cooling solutions. This includes the use of more efficient heat exchangers, implementation of closed-loop systems to reduce water consumption, and exploration of alternative cooling technologies such as thermoelectric cooling or phase-change materials.

Cooling systems in submersible pumps typically utilize either water or oil as the cooling medium. Water-based cooling systems are more environmentally friendly but may be less effective in certain high-temperature applications. Oil-based systems, while more efficient in heat transfer, pose a greater risk of environmental contamination if leaks occur.

The energy consumption of cooling systems is a major factor in their environmental impact. As temperature fluctuations become more extreme, cooling systems must work harder to maintain stable operating temperatures, leading to increased energy usage. This not only raises operational costs but also contributes to higher carbon emissions if the energy source is not renewable.

Water usage is another environmental concern, particularly in water-cooled systems. In areas experiencing water scarcity, the use of large volumes of water for cooling purposes can strain local water resources. Additionally, the discharge of heated water back into natural water bodies can disrupt aquatic ecosystems, affecting local flora and fauna.

Chemical treatments used in cooling systems to prevent corrosion and microbial growth can have detrimental effects on the environment if not properly managed. These chemicals, when released into water bodies, can alter water chemistry and harm aquatic life. Proper treatment and disposal of these chemicals are essential to minimize environmental impact.

The materials used in cooling system components also contribute to the overall environmental footprint. The production and disposal of these materials, particularly in systems that require frequent replacement due to harsh operating conditions, can lead to increased resource consumption and waste generation.

Noise pollution is an often-overlooked environmental impact of pump cooling systems. In industrial settings, the operation of large cooling systems can contribute significantly to ambient noise levels, potentially affecting local wildlife and human populations.

To mitigate these environmental impacts, manufacturers and operators are increasingly focusing on developing more sustainable cooling solutions. This includes the use of more efficient heat exchangers, implementation of closed-loop systems to reduce water consumption, and exploration of alternative cooling technologies such as thermoelectric cooling or phase-change materials.

Energy Efficiency in Temperature-Controlled Pumps

Energy efficiency in temperature-controlled pumps has become a critical focus in the submersible pump industry, particularly in light of the significant impact temperature fluctuations can have on pump performance and longevity. As energy costs continue to rise and environmental concerns grow, manufacturers and end-users alike are seeking innovative solutions to optimize pump efficiency across varying temperature conditions.

Temperature fluctuations can significantly affect the viscosity of the pumped fluid, which in turn influences the pump's power consumption and overall efficiency. In colder temperatures, fluid viscosity increases, requiring more energy to maintain the same flow rate. Conversely, higher temperatures can lead to decreased viscosity, potentially causing cavitation and reduced pump efficiency. To address these challenges, advanced temperature control systems have been developed to maintain optimal fluid temperatures, ensuring consistent pump performance and energy efficiency.

One key approach to enhancing energy efficiency in temperature-controlled pumps is the implementation of variable frequency drives (VFDs). These devices allow for precise control of pump speed based on temperature and flow requirements, reducing energy consumption during periods of lower demand or more favorable temperature conditions. By adjusting the pump's operation to match the specific needs of the system, VFDs can significantly reduce overall energy consumption and extend the life of the pump.

Another innovative solution is the integration of smart sensors and IoT technology into submersible pump systems. These sensors continuously monitor temperature, pressure, and flow rates, providing real-time data to control systems. This enables predictive maintenance and dynamic adjustments to pump operation, optimizing energy efficiency based on current conditions. Machine learning algorithms can analyze this data to further refine pump operation, anticipating temperature fluctuations and adjusting accordingly.

Materials science has also played a crucial role in improving the energy efficiency of temperature-controlled pumps. Advanced composite materials and coatings have been developed to reduce friction and wear, even under extreme temperature conditions. These materials not only improve pump efficiency but also extend the operational life of the pump, reducing the need for frequent replacements and associated energy costs.

Furthermore, heat recovery systems have been integrated into some submersible pump designs, capturing waste heat generated during operation and using it to pre-heat incoming fluids or for other processes. This not only improves overall system efficiency but also helps maintain more stable fluid temperatures, reducing the impact of external temperature fluctuations on pump performance.

As research in this field continues, we can expect to see further advancements in energy-efficient, temperature-controlled pump technologies. These may include the development of self-adapting pump systems that can automatically optimize their operation based on changing temperature conditions, as well as the integration of renewable energy sources to power pump systems in remote or off-grid applications.

Temperature fluctuations can significantly affect the viscosity of the pumped fluid, which in turn influences the pump's power consumption and overall efficiency. In colder temperatures, fluid viscosity increases, requiring more energy to maintain the same flow rate. Conversely, higher temperatures can lead to decreased viscosity, potentially causing cavitation and reduced pump efficiency. To address these challenges, advanced temperature control systems have been developed to maintain optimal fluid temperatures, ensuring consistent pump performance and energy efficiency.

One key approach to enhancing energy efficiency in temperature-controlled pumps is the implementation of variable frequency drives (VFDs). These devices allow for precise control of pump speed based on temperature and flow requirements, reducing energy consumption during periods of lower demand or more favorable temperature conditions. By adjusting the pump's operation to match the specific needs of the system, VFDs can significantly reduce overall energy consumption and extend the life of the pump.

Another innovative solution is the integration of smart sensors and IoT technology into submersible pump systems. These sensors continuously monitor temperature, pressure, and flow rates, providing real-time data to control systems. This enables predictive maintenance and dynamic adjustments to pump operation, optimizing energy efficiency based on current conditions. Machine learning algorithms can analyze this data to further refine pump operation, anticipating temperature fluctuations and adjusting accordingly.

Materials science has also played a crucial role in improving the energy efficiency of temperature-controlled pumps. Advanced composite materials and coatings have been developed to reduce friction and wear, even under extreme temperature conditions. These materials not only improve pump efficiency but also extend the operational life of the pump, reducing the need for frequent replacements and associated energy costs.

Furthermore, heat recovery systems have been integrated into some submersible pump designs, capturing waste heat generated during operation and using it to pre-heat incoming fluids or for other processes. This not only improves overall system efficiency but also helps maintain more stable fluid temperatures, reducing the impact of external temperature fluctuations on pump performance.

As research in this field continues, we can expect to see further advancements in energy-efficient, temperature-controlled pump technologies. These may include the development of self-adapting pump systems that can automatically optimize their operation based on changing temperature conditions, as well as the integration of renewable energy sources to power pump systems in remote or off-grid applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!