Innovations in submersible pump dewatering applications.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution and Objectives

Submersible pumps have undergone significant evolution since their inception in the early 20th century. Initially designed for basic water removal tasks, these pumps have transformed into sophisticated dewatering solutions capable of handling diverse applications across industries. The journey of submersible pump technology reflects a continuous pursuit of efficiency, durability, and adaptability to challenging environments.

In the 1950s and 1960s, submersible pumps saw rapid advancements with the introduction of more robust materials and improved sealing technologies. This period marked a shift from rudimentary designs to more reliable and powerful units, capable of operating in deeper waters and handling higher flow rates. The 1970s and 1980s witnessed further refinements, particularly in motor efficiency and impeller design, allowing for greater pumping capacities and reduced energy consumption.

The advent of digital technologies and smart sensors in the late 20th and early 21st centuries heralded a new era for submersible pumps. Integration of these technologies enabled real-time monitoring, predictive maintenance, and automated operation, significantly enhancing pump performance and longevity. This period also saw the development of specialized pumps for specific industries, such as mining, construction, and wastewater treatment, each tailored to meet unique dewatering challenges.

Recent innovations have focused on sustainability and environmental considerations. Manufacturers are now developing pumps with reduced environmental footprints, incorporating eco-friendly materials and designs that minimize energy consumption. Additionally, there's a growing emphasis on pumps capable of handling abrasive and corrosive fluids, expanding their applicability in harsh industrial environments.

The primary objectives driving current submersible pump innovations in dewatering applications are multifaceted. Firstly, there's a push for increased energy efficiency to reduce operational costs and environmental impact. This involves optimizing hydraulic designs and incorporating high-efficiency motors. Secondly, enhancing pump durability and reliability remains a critical goal, particularly for applications in aggressive environments where downtime can be costly.

Another key objective is the development of 'smart' pumping systems. These systems aim to integrate advanced sensors, data analytics, and IoT capabilities to enable predictive maintenance, remote monitoring, and adaptive performance optimization. This not only improves operational efficiency but also reduces the need for manual intervention in challenging or hazardous environments.

Lastly, there's a growing focus on versatility and adaptability. Manufacturers are striving to create pumps that can handle a wider range of fluid types and operating conditions, reducing the need for specialized equipment and simplifying inventory management for end-users. This includes developing pumps with adjustable flow rates and the ability to operate effectively in both submerged and dry conditions.

In the 1950s and 1960s, submersible pumps saw rapid advancements with the introduction of more robust materials and improved sealing technologies. This period marked a shift from rudimentary designs to more reliable and powerful units, capable of operating in deeper waters and handling higher flow rates. The 1970s and 1980s witnessed further refinements, particularly in motor efficiency and impeller design, allowing for greater pumping capacities and reduced energy consumption.

The advent of digital technologies and smart sensors in the late 20th and early 21st centuries heralded a new era for submersible pumps. Integration of these technologies enabled real-time monitoring, predictive maintenance, and automated operation, significantly enhancing pump performance and longevity. This period also saw the development of specialized pumps for specific industries, such as mining, construction, and wastewater treatment, each tailored to meet unique dewatering challenges.

Recent innovations have focused on sustainability and environmental considerations. Manufacturers are now developing pumps with reduced environmental footprints, incorporating eco-friendly materials and designs that minimize energy consumption. Additionally, there's a growing emphasis on pumps capable of handling abrasive and corrosive fluids, expanding their applicability in harsh industrial environments.

The primary objectives driving current submersible pump innovations in dewatering applications are multifaceted. Firstly, there's a push for increased energy efficiency to reduce operational costs and environmental impact. This involves optimizing hydraulic designs and incorporating high-efficiency motors. Secondly, enhancing pump durability and reliability remains a critical goal, particularly for applications in aggressive environments where downtime can be costly.

Another key objective is the development of 'smart' pumping systems. These systems aim to integrate advanced sensors, data analytics, and IoT capabilities to enable predictive maintenance, remote monitoring, and adaptive performance optimization. This not only improves operational efficiency but also reduces the need for manual intervention in challenging or hazardous environments.

Lastly, there's a growing focus on versatility and adaptability. Manufacturers are striving to create pumps that can handle a wider range of fluid types and operating conditions, reducing the need for specialized equipment and simplifying inventory management for end-users. This includes developing pumps with adjustable flow rates and the ability to operate effectively in both submerged and dry conditions.

Dewatering Market Analysis

The dewatering market has experienced significant growth in recent years, driven by increasing urbanization, infrastructure development, and the need for effective water management solutions across various industries. The global dewatering pump market was valued at approximately $6.5 billion in 2020 and is projected to reach $8.9 billion by 2026, growing at a CAGR of 5.4% during the forecast period.

The construction industry remains the largest end-user segment for dewatering pumps, accounting for over 40% of the market share. This is primarily due to the rising demand for dewatering solutions in large-scale construction projects, including residential, commercial, and infrastructure developments. The mining sector is another key contributor to the dewatering pump market, with a growing need for efficient water removal in both surface and underground mining operations.

Geographically, Asia-Pacific dominates the dewatering pump market, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India are driving the demand for dewatering solutions in the region. Additionally, the increasing focus on flood control and water management in developing economies is further propelling market growth.

The market is characterized by the presence of both established players and new entrants, leading to intense competition and continuous innovation. Key market players include Grundfos, Xylem, Sulzer, and KSB, among others. These companies are investing heavily in research and development to introduce advanced submersible pump technologies that offer improved efficiency, durability, and energy savings.

One of the emerging trends in the dewatering market is the growing adoption of smart pumping solutions. These systems incorporate sensors, IoT connectivity, and advanced control algorithms to optimize pump performance, reduce energy consumption, and enable predictive maintenance. This trend is expected to gain further traction as industries increasingly prioritize operational efficiency and sustainability.

The oil and gas industry is also a significant contributor to the dewatering pump market, particularly in offshore applications. As exploration and production activities expand into deeper waters and more challenging environments, the demand for high-performance submersible pumps capable of handling extreme conditions continues to rise.

Environmental regulations and sustainability concerns are shaping the dewatering market landscape. There is a growing emphasis on developing eco-friendly pumping solutions that minimize environmental impact and comply with stringent regulatory standards. This has led to innovations in pump design, materials, and operational efficiency to reduce energy consumption and carbon footprint.

The construction industry remains the largest end-user segment for dewatering pumps, accounting for over 40% of the market share. This is primarily due to the rising demand for dewatering solutions in large-scale construction projects, including residential, commercial, and infrastructure developments. The mining sector is another key contributor to the dewatering pump market, with a growing need for efficient water removal in both surface and underground mining operations.

Geographically, Asia-Pacific dominates the dewatering pump market, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India are driving the demand for dewatering solutions in the region. Additionally, the increasing focus on flood control and water management in developing economies is further propelling market growth.

The market is characterized by the presence of both established players and new entrants, leading to intense competition and continuous innovation. Key market players include Grundfos, Xylem, Sulzer, and KSB, among others. These companies are investing heavily in research and development to introduce advanced submersible pump technologies that offer improved efficiency, durability, and energy savings.

One of the emerging trends in the dewatering market is the growing adoption of smart pumping solutions. These systems incorporate sensors, IoT connectivity, and advanced control algorithms to optimize pump performance, reduce energy consumption, and enable predictive maintenance. This trend is expected to gain further traction as industries increasingly prioritize operational efficiency and sustainability.

The oil and gas industry is also a significant contributor to the dewatering pump market, particularly in offshore applications. As exploration and production activities expand into deeper waters and more challenging environments, the demand for high-performance submersible pumps capable of handling extreme conditions continues to rise.

Environmental regulations and sustainability concerns are shaping the dewatering market landscape. There is a growing emphasis on developing eco-friendly pumping solutions that minimize environmental impact and comply with stringent regulatory standards. This has led to innovations in pump design, materials, and operational efficiency to reduce energy consumption and carbon footprint.

Submersible Pump Challenges

Submersible pumps face several significant challenges in dewatering applications, particularly in demanding environments such as construction sites, mines, and flood-prone areas. One of the primary issues is the handling of abrasive materials, including sand, silt, and other particulates, which can cause rapid wear on pump components. This wear leads to decreased efficiency and increased maintenance requirements, ultimately reducing the pump's lifespan and reliability.

Another critical challenge is the management of varying water levels and flow rates. Submersible pumps must be capable of adapting to fluctuating conditions, maintaining optimal performance whether dealing with shallow puddles or deep water bodies. This adaptability is crucial for efficient dewatering operations but presents design and control challenges for pump manufacturers.

The presence of debris and large solids in the water poses a significant obstacle for submersible pumps. Clogging can occur when these materials enter the pump, leading to reduced flow rates, increased energy consumption, and potential damage to internal components. Developing effective solids-handling capabilities without compromising pump efficiency remains a persistent challenge in the industry.

Energy efficiency is another area of concern, particularly in remote or off-grid locations where power sources may be limited. Submersible pumps must balance the need for high performance with energy conservation, a task that becomes increasingly complex as pumping requirements become more demanding.

Corrosion resistance presents an ongoing challenge, especially in environments with aggressive chemicals or saltwater. Pump materials must withstand these corrosive elements while maintaining structural integrity and performance over extended periods. This necessitates continuous research into advanced materials and protective coatings.

Heat dissipation is a critical issue for submersible pumps, as they operate in environments where natural cooling is limited. Overheating can lead to premature failure of motor windings and other components, requiring innovative cooling solutions that do not compromise the pump's submersible nature.

Lastly, the need for remote monitoring and control capabilities has become increasingly important in modern dewatering applications. Integrating smart technologies that allow for real-time performance tracking, predictive maintenance, and automated operation presents both opportunities and challenges for pump designers and manufacturers.

Another critical challenge is the management of varying water levels and flow rates. Submersible pumps must be capable of adapting to fluctuating conditions, maintaining optimal performance whether dealing with shallow puddles or deep water bodies. This adaptability is crucial for efficient dewatering operations but presents design and control challenges for pump manufacturers.

The presence of debris and large solids in the water poses a significant obstacle for submersible pumps. Clogging can occur when these materials enter the pump, leading to reduced flow rates, increased energy consumption, and potential damage to internal components. Developing effective solids-handling capabilities without compromising pump efficiency remains a persistent challenge in the industry.

Energy efficiency is another area of concern, particularly in remote or off-grid locations where power sources may be limited. Submersible pumps must balance the need for high performance with energy conservation, a task that becomes increasingly complex as pumping requirements become more demanding.

Corrosion resistance presents an ongoing challenge, especially in environments with aggressive chemicals or saltwater. Pump materials must withstand these corrosive elements while maintaining structural integrity and performance over extended periods. This necessitates continuous research into advanced materials and protective coatings.

Heat dissipation is a critical issue for submersible pumps, as they operate in environments where natural cooling is limited. Overheating can lead to premature failure of motor windings and other components, requiring innovative cooling solutions that do not compromise the pump's submersible nature.

Lastly, the need for remote monitoring and control capabilities has become increasingly important in modern dewatering applications. Integrating smart technologies that allow for real-time performance tracking, predictive maintenance, and automated operation presents both opportunities and challenges for pump designers and manufacturers.

Current Dewatering Solutions

01 Design and construction of submersible pumps

Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor closely coupled to the pump body. The design focuses on efficient operation underwater, including features for heat dissipation, pressure equalization, and protection against liquid ingress.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor closely coupled to the pump body. The design focuses on efficient operation underwater, with features to prevent liquid ingress into the motor and electrical components. These pumps are used in various applications, including well pumping, wastewater management, and industrial processes.

- Motor and impeller configurations: The motor and impeller configurations in submersible pumps are crucial for their performance. Innovations in this area include improved motor designs for better efficiency, advanced impeller geometries for increased flow rates, and the use of materials resistant to corrosion and wear. Some designs incorporate multiple stages or variable speed capabilities to adapt to different pumping requirements.

- Control systems and monitoring: Modern submersible pumps often incorporate advanced control systems and monitoring capabilities. These may include sensors for temperature, pressure, and flow rate, as well as remote monitoring and control features. Such systems help optimize pump performance, prevent failures, and enable predictive maintenance, thereby increasing the overall efficiency and lifespan of the pump.

- Energy efficiency and environmental considerations: Recent developments in submersible pump technology focus on improving energy efficiency and reducing environmental impact. This includes the use of high-efficiency motors, optimized hydraulic designs, and the integration of renewable energy sources such as solar power. Some pumps are designed to operate with variable frequency drives to further enhance energy savings and adapt to changing demand.

- Application-specific designs: Submersible pumps are often tailored for specific applications. This includes designs for deep well pumping, handling abrasive or corrosive fluids, and pumps for use in extreme environments such as offshore oil and gas operations. These specialized designs may incorporate features like self-priming capabilities, ability to handle solids, or resistance to specific chemical or environmental conditions.

02 Control systems for submersible pumps

Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can adjust pump operation based on real-time data, improving efficiency and preventing damage.Expand Specific Solutions03 Energy efficiency improvements in submersible pumps

Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance.Expand Specific Solutions04 Materials and coatings for submersible pumps

The selection of materials and coatings plays a crucial role in the durability and performance of submersible pumps. Corrosion-resistant alloys, advanced polymers, and specialized coatings are used to protect pump components from harsh underwater environments and extend their operational life.Expand Specific Solutions05 Application-specific submersible pump designs

Submersible pumps are tailored for specific applications such as wastewater treatment, oil and gas extraction, and deep-sea exploration. These specialized designs incorporate features to handle particular fluid types, operating depths, and environmental conditions unique to each application.Expand Specific Solutions

Key Submersible Pump Manufacturers

The submersible pump dewatering applications market is in a mature growth stage, with a global market size estimated to exceed $5 billion by 2025. The industry is characterized by intense competition among established players like Baker Hughes Co., Schlumberger Technologies, Inc., and Weir Group companies. These firms are focusing on technological innovations to enhance pump efficiency and durability. The market is driven by increasing demand in mining, construction, and oil & gas sectors. Emerging players such as Xylem Europe GmbH and Franklin Electric Co., Inc. are also making significant strides in product development. The technology's maturity is evident in the advanced features offered by major companies, including remote monitoring capabilities and energy-efficient designs.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed innovative submersible pump dewatering solutions, focusing on improving efficiency and reliability in challenging environments. Their ESP (Electric Submersible Pump) systems incorporate advanced materials and designs to handle high solid content and abrasive fluids. The company's Centrilift XP enhanced-run-life ESP system features a patented abrasion-resistant bearing material and optimized impeller designs, significantly extending pump life in harsh conditions[1]. Baker Hughes has also introduced smart monitoring and control systems, such as their ProductionLink platform, which uses real-time data analytics to optimize pump performance and predict maintenance needs[2]. This approach has resulted in up to 30% increase in run life and 20% reduction in energy consumption for dewatering applications[3].

Strengths: Advanced materials and designs for harsh environments, smart monitoring systems for optimized performance. Weaknesses: Higher initial costs, may require specialized training for operation and maintenance.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has made significant advancements in submersible pump dewatering technology through their REDA Pump portfolio. Their latest innovation, the REDA Continuum extended-life ESP system, incorporates a unique stage design that improves solid handling capabilities and reduces erosion[4]. The system features a patented mixed-flow impeller geometry that can handle up to 40% higher solid content compared to conventional designs[5]. Schlumberger has also developed the Lift IQ production life cycle management service, which uses artificial intelligence to optimize pump performance and predict failures, resulting in a 20% increase in run life for dewatering applications[6]. Additionally, their PowerSave low-energy ESP system has demonstrated up to 30% reduction in power consumption while maintaining high efficiency in dewatering operations[7].

Strengths: Advanced stage design for improved solid handling, AI-driven optimization services. Weaknesses: Complex systems may require specialized expertise for installation and maintenance.

Innovative Pump Designs

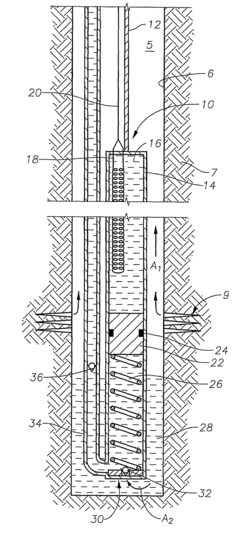

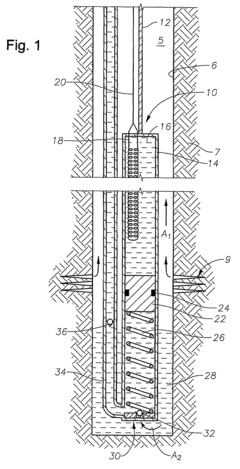

Positive displacement pump

PatentInactiveUS7610964B2

Innovation

- A downhole submersible pumping system utilizing an expandable fluid within a housing, where a piston is coaxially slidable, driven by thermal expansion and contraction of the fluid, allowing for efficient pumping of wellbore fluids through selective heating and cooling, and incorporating a one-way valve and resilient member for fluid management.

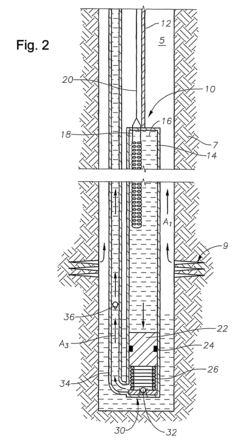

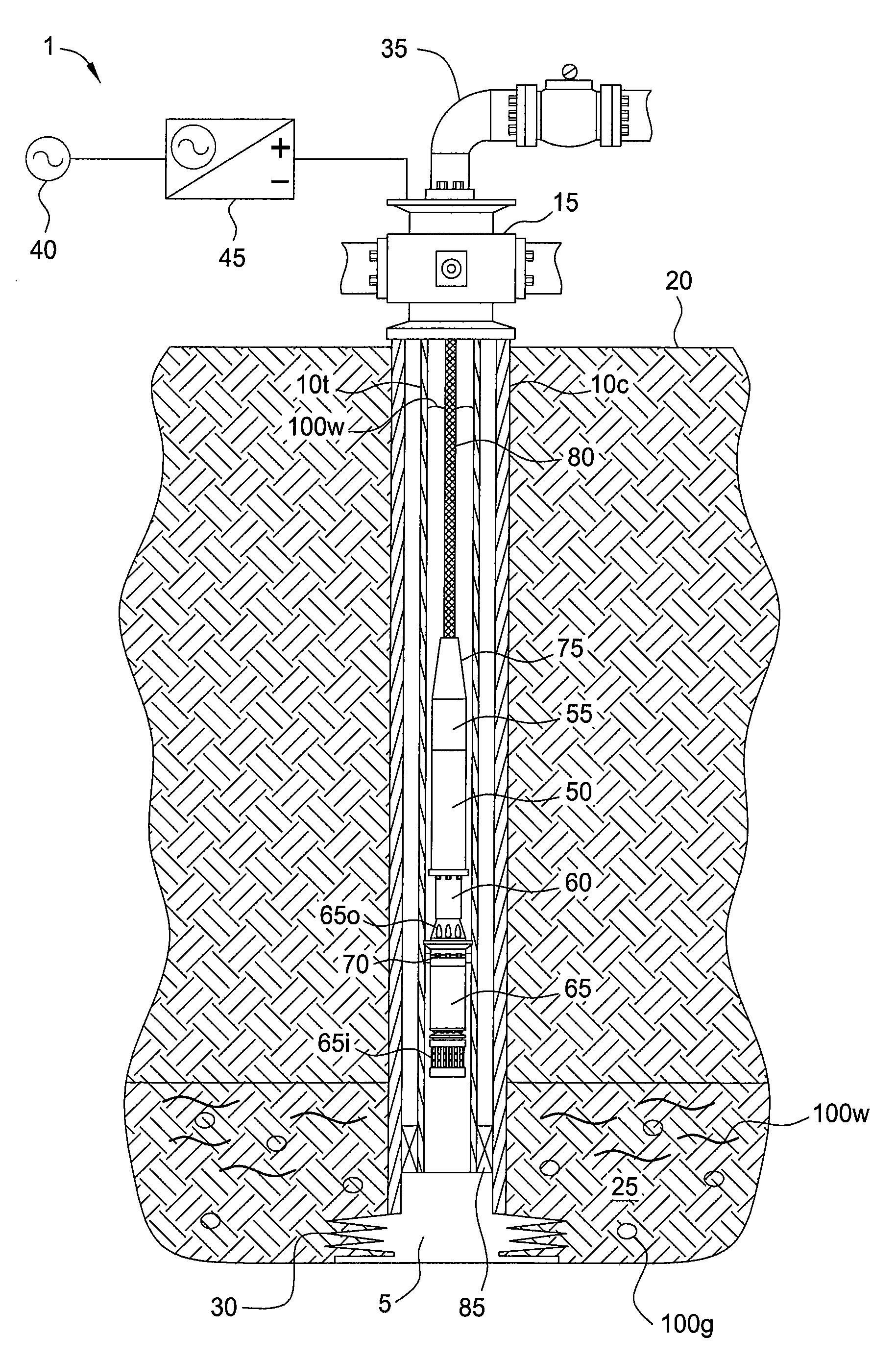

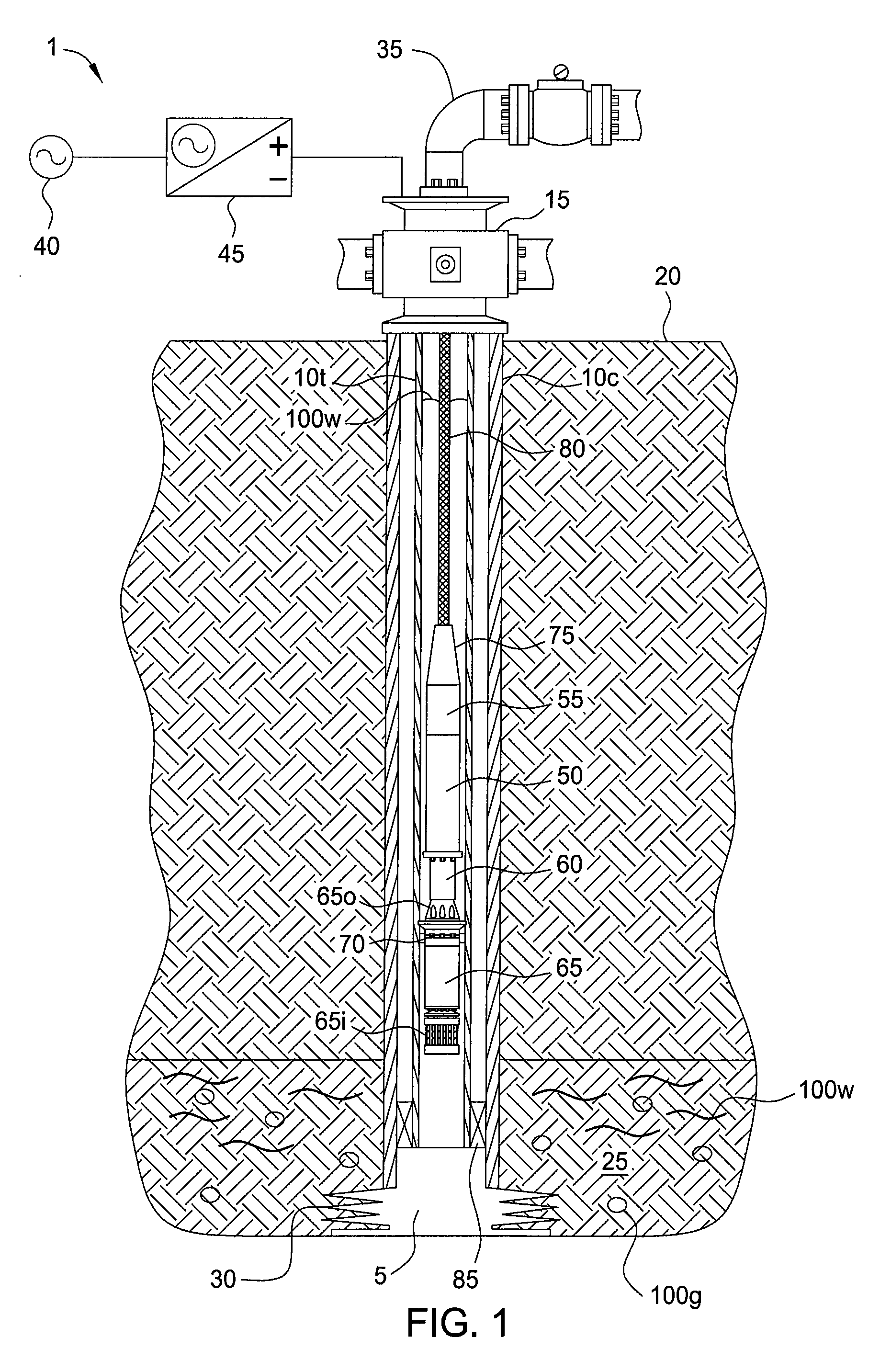

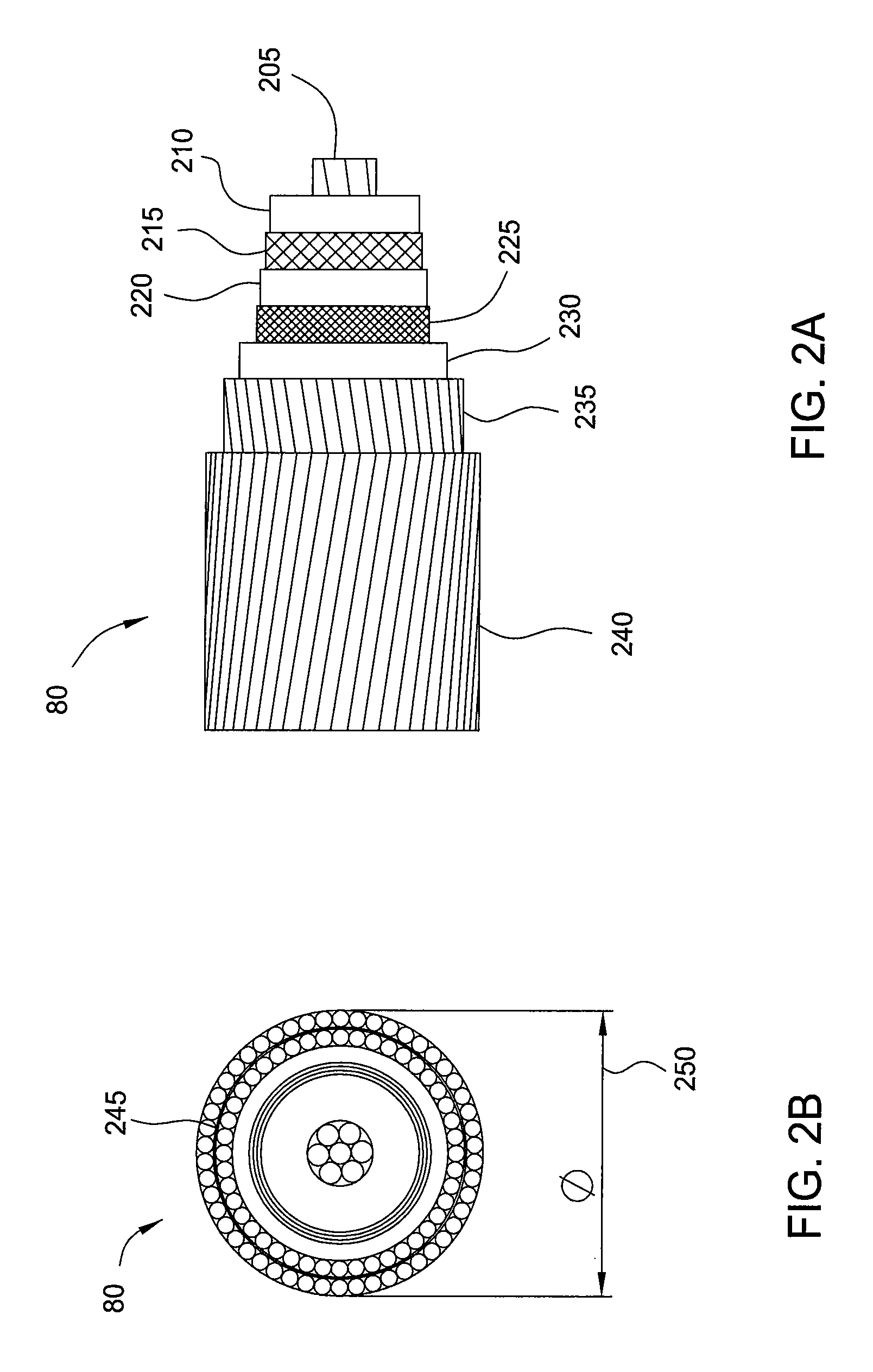

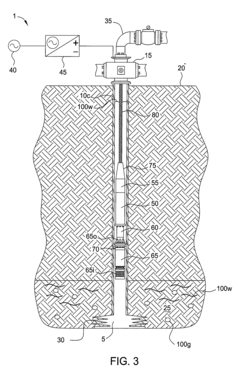

Electric submersible pumping system for dewatering gas wells

PatentInactiveUS20100288501A1

Innovation

- An electric submersible pumping system is deployed into the wellbore with a motor, isolation device, and pump, using a compact cable to operate the pump, isolate the inlet from the outlet, and rotationally fix the system to the tubular string, allowing for efficient dewatering without removing the production tubing string.

Environmental Impact Assessment

Submersible pump dewatering applications have significant environmental implications that require careful assessment and mitigation strategies. The primary environmental concerns associated with these systems include water quality impacts, habitat disruption, and energy consumption.

Water quality is a critical consideration in dewatering operations. The discharge of pumped water can introduce sediments, contaminants, and altered temperature regimes into receiving water bodies. This may lead to increased turbidity, changes in pH levels, and potential introduction of pollutants. To address these issues, innovative filtration systems and water treatment technologies are being developed and integrated into submersible pump designs. These advancements aim to minimize the release of suspended solids and harmful substances, ensuring compliance with environmental regulations and protecting aquatic ecosystems.

Habitat disruption is another key environmental concern. Dewatering activities can alter local hydrology, potentially affecting groundwater levels and surface water flows. This may impact aquatic and riparian habitats, as well as the species that depend on them. To mitigate these effects, recent innovations focus on developing more precise pumping controls and adaptive management systems. These technologies allow for real-time monitoring of water levels and flow rates, enabling operators to adjust pumping activities to minimize ecological disturbances.

Energy consumption is a significant factor in the environmental footprint of submersible pump dewatering applications. Traditional pumps often operate at fixed speeds, consuming excessive energy during periods of low demand. Recent innovations in this area include the development of variable frequency drives (VFDs) and smart pump controllers. These technologies optimize pump performance based on actual dewatering requirements, significantly reducing energy consumption and associated greenhouse gas emissions.

Noise pollution is an often-overlooked environmental impact of dewatering operations. Innovations in pump design and materials are addressing this issue by incorporating sound-dampening technologies and improved hydraulic efficiency. These advancements not only reduce noise levels but also contribute to overall energy efficiency improvements.

The disposal of dewatered sediments and materials presents another environmental challenge. Innovative approaches are being developed to repurpose these materials for beneficial uses, such as land reclamation or construction applications. This not only reduces waste but also promotes circular economy principles in dewatering operations.

As environmental regulations become more stringent, the importance of comprehensive monitoring and reporting systems grows. Recent innovations in this area include the integration of IoT sensors and cloud-based data management platforms. These technologies enable real-time environmental monitoring, facilitating rapid response to potential issues and providing valuable data for long-term environmental impact assessments.

Water quality is a critical consideration in dewatering operations. The discharge of pumped water can introduce sediments, contaminants, and altered temperature regimes into receiving water bodies. This may lead to increased turbidity, changes in pH levels, and potential introduction of pollutants. To address these issues, innovative filtration systems and water treatment technologies are being developed and integrated into submersible pump designs. These advancements aim to minimize the release of suspended solids and harmful substances, ensuring compliance with environmental regulations and protecting aquatic ecosystems.

Habitat disruption is another key environmental concern. Dewatering activities can alter local hydrology, potentially affecting groundwater levels and surface water flows. This may impact aquatic and riparian habitats, as well as the species that depend on them. To mitigate these effects, recent innovations focus on developing more precise pumping controls and adaptive management systems. These technologies allow for real-time monitoring of water levels and flow rates, enabling operators to adjust pumping activities to minimize ecological disturbances.

Energy consumption is a significant factor in the environmental footprint of submersible pump dewatering applications. Traditional pumps often operate at fixed speeds, consuming excessive energy during periods of low demand. Recent innovations in this area include the development of variable frequency drives (VFDs) and smart pump controllers. These technologies optimize pump performance based on actual dewatering requirements, significantly reducing energy consumption and associated greenhouse gas emissions.

Noise pollution is an often-overlooked environmental impact of dewatering operations. Innovations in pump design and materials are addressing this issue by incorporating sound-dampening technologies and improved hydraulic efficiency. These advancements not only reduce noise levels but also contribute to overall energy efficiency improvements.

The disposal of dewatered sediments and materials presents another environmental challenge. Innovative approaches are being developed to repurpose these materials for beneficial uses, such as land reclamation or construction applications. This not only reduces waste but also promotes circular economy principles in dewatering operations.

As environmental regulations become more stringent, the importance of comprehensive monitoring and reporting systems grows. Recent innovations in this area include the integration of IoT sensors and cloud-based data management platforms. These technologies enable real-time environmental monitoring, facilitating rapid response to potential issues and providing valuable data for long-term environmental impact assessments.

Energy Efficiency Advancements

Energy efficiency advancements in submersible pump dewatering applications have become a critical focus for manufacturers and end-users alike. The drive towards more sustainable and cost-effective solutions has led to significant innovations in pump design and operation.

One of the key areas of improvement has been in motor efficiency. The introduction of premium efficiency motors, such as those meeting IE4 and IE5 standards, has substantially reduced energy consumption. These motors utilize advanced materials and improved designs to minimize losses, resulting in higher overall efficiency and reduced operating costs.

Variable frequency drives (VFDs) have also played a crucial role in enhancing energy efficiency. By allowing pumps to operate at varying speeds based on demand, VFDs optimize power consumption and reduce unnecessary energy usage. This technology has proven particularly effective in dewatering applications where flow requirements can fluctuate significantly.

Hydraulic design improvements have further contributed to energy savings. Advanced computational fluid dynamics (CFD) modeling has enabled manufacturers to optimize impeller and volute designs, reducing turbulence and improving overall pump efficiency. These refinements have led to pumps that can move more water with less energy input.

The integration of smart sensors and monitoring systems has revolutionized pump operation and maintenance. Real-time data collection and analysis allow for predictive maintenance and performance optimization. By identifying inefficiencies early and adjusting operation parameters accordingly, these systems help maintain peak energy efficiency throughout the pump's lifecycle.

Material innovations have also played a role in improving energy efficiency. The use of lightweight, corrosion-resistant materials in pump construction has reduced the overall weight of submersible pumps, requiring less energy to operate. Additionally, advanced coatings and surface treatments have minimized friction and wear, further enhancing efficiency and extending pump life.

Energy recovery systems have emerged as a promising technology in dewatering applications. These systems capture and utilize the kinetic energy of water discharge, converting it back into electrical energy. While still in the early stages of adoption, energy recovery systems have shown potential for significant energy savings in high-flow dewatering operations.

The development of hybrid pump systems, combining electric and hydraulic power, has opened new avenues for energy efficiency in challenging dewatering environments. These systems can optimize power usage based on specific site conditions, offering flexibility and improved overall efficiency compared to traditional single-power-source pumps.

One of the key areas of improvement has been in motor efficiency. The introduction of premium efficiency motors, such as those meeting IE4 and IE5 standards, has substantially reduced energy consumption. These motors utilize advanced materials and improved designs to minimize losses, resulting in higher overall efficiency and reduced operating costs.

Variable frequency drives (VFDs) have also played a crucial role in enhancing energy efficiency. By allowing pumps to operate at varying speeds based on demand, VFDs optimize power consumption and reduce unnecessary energy usage. This technology has proven particularly effective in dewatering applications where flow requirements can fluctuate significantly.

Hydraulic design improvements have further contributed to energy savings. Advanced computational fluid dynamics (CFD) modeling has enabled manufacturers to optimize impeller and volute designs, reducing turbulence and improving overall pump efficiency. These refinements have led to pumps that can move more water with less energy input.

The integration of smart sensors and monitoring systems has revolutionized pump operation and maintenance. Real-time data collection and analysis allow for predictive maintenance and performance optimization. By identifying inefficiencies early and adjusting operation parameters accordingly, these systems help maintain peak energy efficiency throughout the pump's lifecycle.

Material innovations have also played a role in improving energy efficiency. The use of lightweight, corrosion-resistant materials in pump construction has reduced the overall weight of submersible pumps, requiring less energy to operate. Additionally, advanced coatings and surface treatments have minimized friction and wear, further enhancing efficiency and extending pump life.

Energy recovery systems have emerged as a promising technology in dewatering applications. These systems capture and utilize the kinetic energy of water discharge, converting it back into electrical energy. While still in the early stages of adoption, energy recovery systems have shown potential for significant energy savings in high-flow dewatering operations.

The development of hybrid pump systems, combining electric and hydraulic power, has opened new avenues for energy efficiency in challenging dewatering environments. These systems can optimize power usage based on specific site conditions, offering flexibility and improved overall efficiency compared to traditional single-power-source pumps.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!