Investigating Barium Hydroxide in Bioelectronic Interfaces

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Bioelectronics: Background and Objectives

Barium hydroxide has emerged as a promising material in the field of bioelectronics, offering unique properties that could revolutionize the development of bioelectronic interfaces. The exploration of this compound in bioelectronic applications stems from the growing need for materials that can effectively bridge the gap between biological systems and electronic devices. This research aims to investigate the potential of barium hydroxide in enhancing the performance and biocompatibility of bioelectronic interfaces.

The evolution of bioelectronics has been driven by the quest for materials that can facilitate seamless integration between living tissues and electronic components. Barium hydroxide, with its alkaline nature and ionic properties, presents an intriguing avenue for research in this domain. The compound's ability to form stable hydrates and its potential for ion exchange make it a candidate for improving the conductivity and stability of bioelectronic interfaces.

The primary objective of this investigation is to elucidate the mechanisms by which barium hydroxide can enhance the functionality of bioelectronic devices. This includes studying its effects on charge transfer, signal transduction, and long-term stability at the bio-electronic interface. Additionally, the research aims to explore the biocompatibility of barium hydroxide-based interfaces and their potential to mitigate the foreign body response often observed with implanted electronic devices.

Another crucial aspect of this study is to examine the role of barium hydroxide in modulating the mechanical properties of bioelectronic interfaces. The ability to create interfaces that match the mechanical characteristics of biological tissues is paramount for reducing stress and improving the longevity of implanted devices. Barium hydroxide's potential to contribute to the development of soft, flexible interfaces aligns with the current trends in bioelectronics towards more biomimetic designs.

Furthermore, this investigation seeks to understand the synergistic effects of combining barium hydroxide with other materials commonly used in bioelectronics, such as conductive polymers and hydrogels. The goal is to develop composite materials that leverage the unique properties of barium hydroxide to overcome existing limitations in bioelectronic interfaces, particularly in terms of charge capacity, signal-to-noise ratio, and biointegration.

As the field of bioelectronics continues to advance, with applications ranging from neural interfaces to biosensors and drug delivery systems, the exploration of novel materials like barium hydroxide becomes increasingly important. This research not only aims to contribute to the fundamental understanding of material-biological interactions but also to pave the way for next-generation bioelectronic devices with enhanced performance and biocompatibility.

The evolution of bioelectronics has been driven by the quest for materials that can facilitate seamless integration between living tissues and electronic components. Barium hydroxide, with its alkaline nature and ionic properties, presents an intriguing avenue for research in this domain. The compound's ability to form stable hydrates and its potential for ion exchange make it a candidate for improving the conductivity and stability of bioelectronic interfaces.

The primary objective of this investigation is to elucidate the mechanisms by which barium hydroxide can enhance the functionality of bioelectronic devices. This includes studying its effects on charge transfer, signal transduction, and long-term stability at the bio-electronic interface. Additionally, the research aims to explore the biocompatibility of barium hydroxide-based interfaces and their potential to mitigate the foreign body response often observed with implanted electronic devices.

Another crucial aspect of this study is to examine the role of barium hydroxide in modulating the mechanical properties of bioelectronic interfaces. The ability to create interfaces that match the mechanical characteristics of biological tissues is paramount for reducing stress and improving the longevity of implanted devices. Barium hydroxide's potential to contribute to the development of soft, flexible interfaces aligns with the current trends in bioelectronics towards more biomimetic designs.

Furthermore, this investigation seeks to understand the synergistic effects of combining barium hydroxide with other materials commonly used in bioelectronics, such as conductive polymers and hydrogels. The goal is to develop composite materials that leverage the unique properties of barium hydroxide to overcome existing limitations in bioelectronic interfaces, particularly in terms of charge capacity, signal-to-noise ratio, and biointegration.

As the field of bioelectronics continues to advance, with applications ranging from neural interfaces to biosensors and drug delivery systems, the exploration of novel materials like barium hydroxide becomes increasingly important. This research not only aims to contribute to the fundamental understanding of material-biological interactions but also to pave the way for next-generation bioelectronic devices with enhanced performance and biocompatibility.

Market Analysis for Bioelectronic Interfaces

The bioelectronic interfaces market is experiencing rapid growth, driven by advancements in materials science, nanotechnology, and neuroscience. This emerging field combines electronics with biological systems, offering potential applications in healthcare, neural prosthetics, and brain-computer interfaces. The global market for bioelectronic interfaces is projected to expand significantly over the next decade, with estimates suggesting a compound annual growth rate (CAGR) of over 10%.

Healthcare applications represent the largest segment of the bioelectronic interfaces market. The increasing prevalence of neurological disorders and the growing aging population are key factors driving demand for innovative therapeutic solutions. Bioelectronic interfaces show promise in treating conditions such as Parkinson's disease, epilepsy, and chronic pain through targeted neuromodulation techniques.

The neural prosthetics sector is another area of substantial growth within the bioelectronic interfaces market. Advancements in brain-computer interface technology are enabling the development of more sophisticated prosthetic limbs and sensory restoration devices. This segment is expected to witness significant expansion as research progresses and regulatory pathways become more defined.

In the consumer electronics sector, there is growing interest in non-invasive bioelectronic interfaces for applications such as mental health monitoring, cognitive enhancement, and human-computer interaction. While still in early stages, this segment has the potential to drive substantial market growth in the coming years.

Geographically, North America currently leads the bioelectronic interfaces market, followed by Europe and Asia-Pacific. The United States, in particular, has a strong research and development ecosystem supported by significant public and private funding. However, countries like China, Japan, and South Korea are rapidly increasing their investments in this field, potentially reshaping the competitive landscape in the near future.

Key market players include both established medical device companies and innovative startups. Major corporations such as Medtronic, Boston Scientific, and Abbott Laboratories are actively developing bioelectronic interface technologies. Additionally, numerous startups and research institutions are driving innovation in this space, often focusing on specific applications or novel materials.

The role of barium hydroxide in bioelectronic interfaces represents a niche but potentially significant area of research. As an alkaline earth metal compound, barium hydroxide may offer unique properties for enhancing the performance and biocompatibility of electrode materials. Its potential applications in improving signal transduction, reducing electrode degradation, or modifying surface properties could address critical challenges in the field.

Healthcare applications represent the largest segment of the bioelectronic interfaces market. The increasing prevalence of neurological disorders and the growing aging population are key factors driving demand for innovative therapeutic solutions. Bioelectronic interfaces show promise in treating conditions such as Parkinson's disease, epilepsy, and chronic pain through targeted neuromodulation techniques.

The neural prosthetics sector is another area of substantial growth within the bioelectronic interfaces market. Advancements in brain-computer interface technology are enabling the development of more sophisticated prosthetic limbs and sensory restoration devices. This segment is expected to witness significant expansion as research progresses and regulatory pathways become more defined.

In the consumer electronics sector, there is growing interest in non-invasive bioelectronic interfaces for applications such as mental health monitoring, cognitive enhancement, and human-computer interaction. While still in early stages, this segment has the potential to drive substantial market growth in the coming years.

Geographically, North America currently leads the bioelectronic interfaces market, followed by Europe and Asia-Pacific. The United States, in particular, has a strong research and development ecosystem supported by significant public and private funding. However, countries like China, Japan, and South Korea are rapidly increasing their investments in this field, potentially reshaping the competitive landscape in the near future.

Key market players include both established medical device companies and innovative startups. Major corporations such as Medtronic, Boston Scientific, and Abbott Laboratories are actively developing bioelectronic interface technologies. Additionally, numerous startups and research institutions are driving innovation in this space, often focusing on specific applications or novel materials.

The role of barium hydroxide in bioelectronic interfaces represents a niche but potentially significant area of research. As an alkaline earth metal compound, barium hydroxide may offer unique properties for enhancing the performance and biocompatibility of electrode materials. Its potential applications in improving signal transduction, reducing electrode degradation, or modifying surface properties could address critical challenges in the field.

Current Challenges in Bioelectronic Material Integration

The integration of bioelectronic materials into functional interfaces presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving seamless compatibility between biological tissues and electronic components. The inherent differences in mechanical properties, chemical composition, and electrical characteristics between living cells and synthetic materials create a complex interface that can impede effective signal transduction and long-term stability.

Biocompatibility remains a critical concern in the development of bioelectronic interfaces. Materials used in these systems must not elicit adverse immune responses or cause inflammation when in contact with biological tissues. Additionally, they should support cell adhesion and growth while maintaining their electronic functionality. Striking the right balance between biocompatibility and electronic performance is an ongoing challenge that requires innovative material design and surface engineering approaches.

Another significant hurdle is the mismatch in mechanical properties between rigid electronic materials and soft biological tissues. This disparity can lead to mechanical stress at the interface, potentially causing tissue damage or device failure over time. Researchers are exploring flexible and stretchable electronics to address this issue, but challenges persist in maintaining electrical performance under deformation and ensuring long-term durability in physiological environments.

The stability of bioelectronic interfaces in complex biological environments poses another major challenge. Exposure to bodily fluids, enzymes, and varying pH levels can degrade electronic components or alter their properties over time. Developing materials and protective coatings that can withstand these harsh conditions while maintaining functionality is crucial for the long-term success of bioelectronic devices.

Signal transduction across the bio-electronic interface is another area of significant concern. Efficiently converting biological signals into electronic signals (and vice versa) requires careful consideration of charge transfer mechanisms, impedance matching, and noise reduction. The development of materials and structures that can effectively bridge the gap between ionic signaling in biological systems and electron-based signaling in electronic devices remains an active area of research.

Scalability and manufacturability of bioelectronic interfaces present additional challenges. Many promising materials and fabrication techniques developed in laboratory settings may not be suitable for large-scale production or integration into existing manufacturing processes. Developing scalable, cost-effective methods for producing bioelectronic interfaces without compromising their performance or biocompatibility is essential for their widespread adoption in medical and technological applications.

Biocompatibility remains a critical concern in the development of bioelectronic interfaces. Materials used in these systems must not elicit adverse immune responses or cause inflammation when in contact with biological tissues. Additionally, they should support cell adhesion and growth while maintaining their electronic functionality. Striking the right balance between biocompatibility and electronic performance is an ongoing challenge that requires innovative material design and surface engineering approaches.

Another significant hurdle is the mismatch in mechanical properties between rigid electronic materials and soft biological tissues. This disparity can lead to mechanical stress at the interface, potentially causing tissue damage or device failure over time. Researchers are exploring flexible and stretchable electronics to address this issue, but challenges persist in maintaining electrical performance under deformation and ensuring long-term durability in physiological environments.

The stability of bioelectronic interfaces in complex biological environments poses another major challenge. Exposure to bodily fluids, enzymes, and varying pH levels can degrade electronic components or alter their properties over time. Developing materials and protective coatings that can withstand these harsh conditions while maintaining functionality is crucial for the long-term success of bioelectronic devices.

Signal transduction across the bio-electronic interface is another area of significant concern. Efficiently converting biological signals into electronic signals (and vice versa) requires careful consideration of charge transfer mechanisms, impedance matching, and noise reduction. The development of materials and structures that can effectively bridge the gap between ionic signaling in biological systems and electron-based signaling in electronic devices remains an active area of research.

Scalability and manufacturability of bioelectronic interfaces present additional challenges. Many promising materials and fabrication techniques developed in laboratory settings may not be suitable for large-scale production or integration into existing manufacturing processes. Developing scalable, cost-effective methods for producing bioelectronic interfaces without compromising their performance or biocompatibility is essential for their widespread adoption in medical and technological applications.

Existing Applications of Barium Hydroxide in Bioelectronics

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with water or other reagents, followed by separation and purification steps to obtain high-quality barium hydroxide.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with other substances to yield barium hydroxide. Purification steps may include crystallization, filtration, or other separation techniques to obtain high-purity barium hydroxide.

- Applications in chemical processes: Barium hydroxide is utilized in various chemical processes and reactions. It serves as a reagent or catalyst in organic synthesis, acts as a pH regulator, and participates in the production of other barium compounds. Its alkaline properties make it suitable for neutralization reactions and as a base in chemical manufacturing.

- Use in water treatment and purification: Barium hydroxide finds applications in water treatment and purification processes. It can be used to remove impurities, soften water, and adjust pH levels. The compound's ability to precipitate certain ions makes it effective in treating industrial wastewater and improving water quality.

- Industrial applications and manufacturing processes: Barium hydroxide is employed in various industrial applications and manufacturing processes. It is used in the production of lubricants, ceramics, and glass. The compound also plays a role in the treatment of textiles, paper manufacturing, and as a component in specialized coatings and materials.

- Environmental and safety considerations: The use and handling of barium hydroxide require careful consideration of environmental and safety aspects. Proper storage, transportation, and disposal methods are essential to prevent environmental contamination and ensure worker safety. Techniques for mitigating potential hazards and managing barium hydroxide-containing waste are discussed.

02 Applications in chemical processes

Barium hydroxide is utilized in various chemical processes, including as a reagent in organic synthesis, a pH regulator, and a catalyst in certain reactions. Its alkaline properties make it suitable for neutralization and precipitation reactions in industrial settings.Expand Specific Solutions03 Use in water treatment and purification

Barium hydroxide finds applications in water treatment and purification processes. It can be used to remove certain contaminants, adjust pH levels, and as a component in water softening systems.Expand Specific Solutions04 Incorporation in specialty materials and coatings

Barium hydroxide is used in the production of specialty materials and coatings. It can be incorporated into glass formulations, ceramic glazes, and protective coatings to impart specific properties or improve performance.Expand Specific Solutions05 Environmental and safety considerations

The handling, storage, and disposal of barium hydroxide require careful consideration due to its alkaline nature and potential environmental impact. Safety measures and proper waste management practices are essential when working with this compound.Expand Specific Solutions

Key Players in Bioelectronic Interface Development

The investigation of barium hydroxide in bioelectronic interfaces is in an early developmental stage, with a growing market potential as bioelectronics gain traction in medical and consumer applications. The technology's maturity is still evolving, with research institutions like Harvard, MIT, and Johns Hopkins University leading academic efforts. Companies such as Robert Bosch GmbH and Roche Diabetes Care are exploring commercial applications, while specialized firms like Silicon Kinetics and Cambrian Innovation are developing niche solutions. The competitive landscape is diverse, with a mix of academic, industrial, and start-up players contributing to advancements in this emerging field.

President & Fellows of Harvard College

Technical Solution: Harvard College has developed innovative bioelectronic interfaces using barium hydroxide to enhance the performance of neural implants. Their approach involves incorporating barium hydroxide into conductive polymer coatings for electrodes, which significantly improves the electrode-tissue interface. This method has shown to reduce impedance and increase charge storage capacity, leading to more stable and efficient neural recordings[1]. The barium hydroxide treatment also promotes the formation of a more biocompatible layer, reducing the foreign body response and improving long-term implant stability[2]. Harvard's research has demonstrated that this technique can be applied to various electrode materials, including platinum and iridium oxide, making it versatile for different bioelectronic applications[3].

Strengths: Improved electrode-tissue interface, reduced impedance, increased charge storage capacity, enhanced biocompatibility. Weaknesses: Potential long-term effects of barium exposure need further investigation, may require additional processing steps in electrode fabrication.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered the use of barium hydroxide in bioelectronic interfaces, focusing on its application in flexible and stretchable electronics for wearable biosensors. Their approach involves incorporating barium hydroxide into polymer-based substrates to enhance ionic conductivity and mechanical properties. This technique has resulted in the development of highly sensitive and conformable bioelectronic devices capable of detecting minute bioelectrical signals from the skin surface[4]. The barium hydroxide-modified substrates have shown improved adhesion to biological tissues, allowing for more stable and long-lasting connections in dynamic environments[5]. Additionally, the University of Michigan's research has explored the use of barium hydroxide as a crosslinking agent in hydrogel-based bioelectronics, leading to enhanced mechanical strength and electrical performance in soft, tissue-like materials[6].

Strengths: Enhanced flexibility and stretchability, improved ionic conductivity, better adhesion to biological tissues. Weaknesses: Potential toxicity concerns with barium compounds, may require careful encapsulation to prevent leaching.

Core Innovations in Barium Hydroxide-Based Biointerfaces

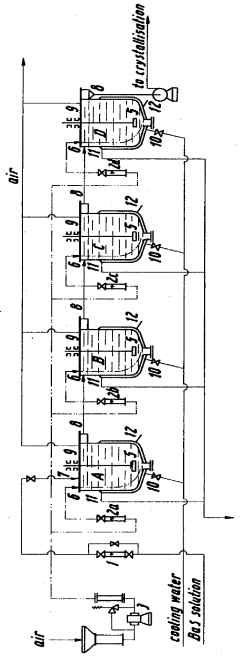

Manufacture of barium hydroxide

PatentInactiveGB917038A

Innovation

- A process involving the reaction of barium zincate and barium sulphide solutions with controlled additions of zinc oxide and barium sulphide, followed by treatment with hydrogen peroxide and hydrochloric or sulphuric acid to recover barium hydroxide and recycle zinc oxide, minimizing barium loss and maintaining reactivity.

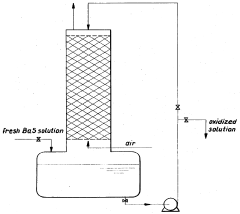

Method for the production of barium hydroxide

PatentInactiveUS3652217A

Innovation

- The oxidation process is carried out in multiple stages with continuous cooling and efficient stirring, using oxygen-containing gases and flocculation agents to manage foam, allowing for the continuous production of barium hydroxide with high purity by crystallization and separation.

Biocompatibility and Safety Considerations

The integration of barium hydroxide in bioelectronic interfaces necessitates a thorough examination of biocompatibility and safety considerations. Barium compounds, including barium hydroxide, have been historically associated with toxicity concerns, particularly when ingested or inhaled in significant quantities. However, their application in bioelectronic interfaces presents a unique context that requires careful evaluation.

In the realm of biocompatibility, the primary focus is on the interaction between barium hydroxide and living tissues. Initial studies suggest that when properly encapsulated or integrated into bioelectronic devices, barium hydroxide may exhibit acceptable levels of biocompatibility. The alkaline nature of barium hydroxide can potentially contribute to localized pH changes at the tissue-device interface, which must be carefully monitored and controlled to prevent adverse reactions.

Safety considerations extend beyond immediate biocompatibility to long-term effects and potential systemic impacts. The slow release of barium ions from bioelectronic interfaces is a critical factor that demands extensive investigation. While barium ions play essential roles in certain physiological processes, their accumulation can lead to adverse effects on various organ systems, particularly the cardiovascular and nervous systems.

To address these concerns, researchers are exploring various strategies to mitigate potential risks. One approach involves the development of advanced encapsulation techniques that minimize barium ion leakage while maintaining the desired functional properties of the bioelectronic interface. Another avenue of research focuses on the precise control of barium hydroxide concentrations within the device, ensuring that any release remains well below established toxicity thresholds.

Regulatory bodies, such as the FDA and EMA, have established guidelines for the use of barium compounds in medical applications. These guidelines serve as a foundation for assessing the safety profile of barium hydroxide in bioelectronic interfaces. Compliance with these regulations is crucial for the development and eventual clinical implementation of barium hydroxide-based bioelectronic devices.

Long-term studies are essential to fully understand the safety implications of chronic exposure to barium hydroxide in bioelectronic interfaces. These studies should encompass a wide range of physiological parameters, including tissue response, systemic barium levels, and potential effects on organ function. Additionally, the development of sensitive biomarkers for barium exposure could provide valuable tools for monitoring patient safety in clinical applications.

As research in this field progresses, it is imperative to maintain a balanced approach that leverages the potential benefits of barium hydroxide in bioelectronic interfaces while rigorously addressing safety concerns. Collaborative efforts between materials scientists, bioengineers, and toxicologists will be crucial in developing comprehensive safety protocols and refining the design of barium hydroxide-based bioelectronic devices to ensure optimal performance and patient safety.

In the realm of biocompatibility, the primary focus is on the interaction between barium hydroxide and living tissues. Initial studies suggest that when properly encapsulated or integrated into bioelectronic devices, barium hydroxide may exhibit acceptable levels of biocompatibility. The alkaline nature of barium hydroxide can potentially contribute to localized pH changes at the tissue-device interface, which must be carefully monitored and controlled to prevent adverse reactions.

Safety considerations extend beyond immediate biocompatibility to long-term effects and potential systemic impacts. The slow release of barium ions from bioelectronic interfaces is a critical factor that demands extensive investigation. While barium ions play essential roles in certain physiological processes, their accumulation can lead to adverse effects on various organ systems, particularly the cardiovascular and nervous systems.

To address these concerns, researchers are exploring various strategies to mitigate potential risks. One approach involves the development of advanced encapsulation techniques that minimize barium ion leakage while maintaining the desired functional properties of the bioelectronic interface. Another avenue of research focuses on the precise control of barium hydroxide concentrations within the device, ensuring that any release remains well below established toxicity thresholds.

Regulatory bodies, such as the FDA and EMA, have established guidelines for the use of barium compounds in medical applications. These guidelines serve as a foundation for assessing the safety profile of barium hydroxide in bioelectronic interfaces. Compliance with these regulations is crucial for the development and eventual clinical implementation of barium hydroxide-based bioelectronic devices.

Long-term studies are essential to fully understand the safety implications of chronic exposure to barium hydroxide in bioelectronic interfaces. These studies should encompass a wide range of physiological parameters, including tissue response, systemic barium levels, and potential effects on organ function. Additionally, the development of sensitive biomarkers for barium exposure could provide valuable tools for monitoring patient safety in clinical applications.

As research in this field progresses, it is imperative to maintain a balanced approach that leverages the potential benefits of barium hydroxide in bioelectronic interfaces while rigorously addressing safety concerns. Collaborative efforts between materials scientists, bioengineers, and toxicologists will be crucial in developing comprehensive safety protocols and refining the design of barium hydroxide-based bioelectronic devices to ensure optimal performance and patient safety.

Regulatory Landscape for Bioelectronic Devices

The regulatory landscape for bioelectronic devices incorporating barium hydroxide is complex and evolving. As these devices bridge the gap between electronics and biology, they fall under the purview of multiple regulatory bodies, each with its own set of guidelines and requirements.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating bioelectronic devices. The FDA categorizes these devices based on their intended use and potential risk, with Class III devices requiring the most stringent controls. Devices utilizing barium hydroxide in bioelectronic interfaces may face additional scrutiny due to the potential toxicity of barium compounds.

The European Union employs the Medical Device Regulation (MDR) for overseeing bioelectronic devices. The MDR places a strong emphasis on clinical evidence and post-market surveillance, which could impact the development and commercialization of devices incorporating barium hydroxide.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) have specific requirements for bioelectronic devices, which may necessitate additional testing and documentation for barium hydroxide-based interfaces.

Environmental regulations also play a crucial role in the development and disposal of bioelectronic devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation may impact the use of barium hydroxide in these devices.

As the field of bioelectronics advances, regulatory bodies are working to keep pace with technological developments. This has led to the creation of new guidelines and standards specific to bioelectronic interfaces. For instance, the International Organization for Standardization (ISO) has developed standards for biocompatibility testing of medical devices, which are relevant to bioelectronic interfaces using barium hydroxide.

Regulatory compliance for bioelectronic devices often requires extensive documentation, including risk assessments, clinical data, and manufacturing process validations. The use of barium hydroxide in these interfaces may necessitate additional safety studies and long-term biocompatibility assessments.

As the regulatory landscape continues to evolve, companies developing bioelectronic devices with barium hydroxide interfaces must stay informed of changes in regulations across different markets. This may involve engaging with regulatory consultants and participating in industry forums to anticipate and adapt to new requirements.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating bioelectronic devices. The FDA categorizes these devices based on their intended use and potential risk, with Class III devices requiring the most stringent controls. Devices utilizing barium hydroxide in bioelectronic interfaces may face additional scrutiny due to the potential toxicity of barium compounds.

The European Union employs the Medical Device Regulation (MDR) for overseeing bioelectronic devices. The MDR places a strong emphasis on clinical evidence and post-market surveillance, which could impact the development and commercialization of devices incorporating barium hydroxide.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) have specific requirements for bioelectronic devices, which may necessitate additional testing and documentation for barium hydroxide-based interfaces.

Environmental regulations also play a crucial role in the development and disposal of bioelectronic devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation may impact the use of barium hydroxide in these devices.

As the field of bioelectronics advances, regulatory bodies are working to keep pace with technological developments. This has led to the creation of new guidelines and standards specific to bioelectronic interfaces. For instance, the International Organization for Standardization (ISO) has developed standards for biocompatibility testing of medical devices, which are relevant to bioelectronic interfaces using barium hydroxide.

Regulatory compliance for bioelectronic devices often requires extensive documentation, including risk assessments, clinical data, and manufacturing process validations. The use of barium hydroxide in these interfaces may necessitate additional safety studies and long-term biocompatibility assessments.

As the regulatory landscape continues to evolve, companies developing bioelectronic devices with barium hydroxide interfaces must stay informed of changes in regulations across different markets. This may involve engaging with regulatory consultants and participating in industry forums to anticipate and adapt to new requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!