Barium Hydroxide’s Application in Biodegradable Packaging Innovations

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Biodegradable Packaging: Background and Objectives

Barium hydroxide has emerged as a promising component in the development of biodegradable packaging solutions, addressing the growing global concern over plastic pollution. This innovative application represents a significant shift in packaging technology, aligning with the increasing demand for sustainable and environmentally friendly materials.

The journey of barium hydroxide in biodegradable packaging began as researchers sought alternatives to traditional petroleum-based plastics. Its unique chemical properties, particularly its ability to interact with biopolymers, have positioned it as a key player in this evolving field. The primary objective of incorporating barium hydroxide into biodegradable packaging is to enhance the material's structural integrity while maintaining its biodegradability.

Historically, biodegradable packaging materials have faced challenges in terms of durability and shelf life. Barium hydroxide's introduction aims to overcome these limitations by improving the mechanical strength and barrier properties of bio-based packaging materials. This advancement is crucial for expanding the application of biodegradable packaging across various industries, including food, cosmetics, and consumer goods.

The technology's evolution is closely tied to the broader trend of circular economy principles and the push for reduced environmental impact in the packaging sector. As regulations tighten and consumer awareness grows, the demand for innovative biodegradable solutions has accelerated, driving research and development in this area.

One of the key technological goals in this field is to achieve a balance between biodegradability and functionality. Barium hydroxide's role is pivotal in this context, as it can potentially enhance the packaging's resistance to moisture and oxygen permeation without compromising its ability to decompose naturally. This dual functionality is essential for creating packaging that can protect products effectively during their lifecycle while ensuring minimal environmental impact post-use.

Another important objective is to scale up the production of barium hydroxide-enhanced biodegradable packaging to meet industrial demands. This involves optimizing manufacturing processes, reducing costs, and ensuring consistent quality across large-scale production. The success in achieving these goals could mark a significant milestone in the widespread adoption of biodegradable packaging solutions.

As research progresses, the focus is also on understanding and mitigating any potential environmental or health impacts associated with barium hydroxide use in packaging. Ensuring the safety and eco-friendliness of the entire product lifecycle is crucial for long-term sustainability and market acceptance.

The journey of barium hydroxide in biodegradable packaging began as researchers sought alternatives to traditional petroleum-based plastics. Its unique chemical properties, particularly its ability to interact with biopolymers, have positioned it as a key player in this evolving field. The primary objective of incorporating barium hydroxide into biodegradable packaging is to enhance the material's structural integrity while maintaining its biodegradability.

Historically, biodegradable packaging materials have faced challenges in terms of durability and shelf life. Barium hydroxide's introduction aims to overcome these limitations by improving the mechanical strength and barrier properties of bio-based packaging materials. This advancement is crucial for expanding the application of biodegradable packaging across various industries, including food, cosmetics, and consumer goods.

The technology's evolution is closely tied to the broader trend of circular economy principles and the push for reduced environmental impact in the packaging sector. As regulations tighten and consumer awareness grows, the demand for innovative biodegradable solutions has accelerated, driving research and development in this area.

One of the key technological goals in this field is to achieve a balance between biodegradability and functionality. Barium hydroxide's role is pivotal in this context, as it can potentially enhance the packaging's resistance to moisture and oxygen permeation without compromising its ability to decompose naturally. This dual functionality is essential for creating packaging that can protect products effectively during their lifecycle while ensuring minimal environmental impact post-use.

Another important objective is to scale up the production of barium hydroxide-enhanced biodegradable packaging to meet industrial demands. This involves optimizing manufacturing processes, reducing costs, and ensuring consistent quality across large-scale production. The success in achieving these goals could mark a significant milestone in the widespread adoption of biodegradable packaging solutions.

As research progresses, the focus is also on understanding and mitigating any potential environmental or health impacts associated with barium hydroxide use in packaging. Ensuring the safety and eco-friendliness of the entire product lifecycle is crucial for long-term sustainability and market acceptance.

Market Analysis for Eco-Friendly Packaging Solutions

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global biodegradable packaging market is projected to reach $21.6 billion by 2025, with a compound annual growth rate (CAGR) of 17.4% from 2020 to 2025. This growth is primarily attributed to the rising demand for sustainable packaging solutions across various industries, including food and beverage, personal care, and healthcare.

Consumer preferences have shifted towards environmentally responsible products, with 73% of consumers willing to pay more for sustainable packaging. This trend has prompted major retailers and brands to commit to using recyclable, reusable, or compostable packaging materials. The food and beverage industry, in particular, has shown a strong inclination towards biodegradable packaging, accounting for over 40% of the market share.

Regionally, Europe leads the eco-friendly packaging market, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market for biodegradable packaging materials is diverse, with bioplastics, paper-based materials, and innovative composites gaining traction. Polylactic acid (PLA), starch-based plastics, and cellulose-based materials are among the most popular biodegradable options. The integration of nanotechnology and advanced material science is opening new avenues for enhancing the performance and versatility of eco-friendly packaging solutions.

However, challenges persist in the widespread adoption of biodegradable packaging. Cost remains a significant barrier, with biodegradable materials often being more expensive than traditional plastics. Additionally, concerns about the performance and shelf life of biodegradable packaging in certain applications need to be addressed. The lack of standardized disposal and composting infrastructure in many regions also poses challenges to the effective end-of-life management of these materials.

Despite these challenges, the market outlook for eco-friendly packaging solutions remains highly positive. Ongoing research and development efforts, including the exploration of novel materials like barium hydroxide-based composites, are expected to drive innovation and improve the cost-effectiveness of biodegradable packaging. As governments worldwide continue to implement stricter environmental regulations and consumers become increasingly eco-conscious, the demand for sustainable packaging solutions is poised for sustained growth in the foreseeable future.

Consumer preferences have shifted towards environmentally responsible products, with 73% of consumers willing to pay more for sustainable packaging. This trend has prompted major retailers and brands to commit to using recyclable, reusable, or compostable packaging materials. The food and beverage industry, in particular, has shown a strong inclination towards biodegradable packaging, accounting for over 40% of the market share.

Regionally, Europe leads the eco-friendly packaging market, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market for biodegradable packaging materials is diverse, with bioplastics, paper-based materials, and innovative composites gaining traction. Polylactic acid (PLA), starch-based plastics, and cellulose-based materials are among the most popular biodegradable options. The integration of nanotechnology and advanced material science is opening new avenues for enhancing the performance and versatility of eco-friendly packaging solutions.

However, challenges persist in the widespread adoption of biodegradable packaging. Cost remains a significant barrier, with biodegradable materials often being more expensive than traditional plastics. Additionally, concerns about the performance and shelf life of biodegradable packaging in certain applications need to be addressed. The lack of standardized disposal and composting infrastructure in many regions also poses challenges to the effective end-of-life management of these materials.

Despite these challenges, the market outlook for eco-friendly packaging solutions remains highly positive. Ongoing research and development efforts, including the exploration of novel materials like barium hydroxide-based composites, are expected to drive innovation and improve the cost-effectiveness of biodegradable packaging. As governments worldwide continue to implement stricter environmental regulations and consumers become increasingly eco-conscious, the demand for sustainable packaging solutions is poised for sustained growth in the foreseeable future.

Current Challenges in Biodegradable Packaging Technology

The biodegradable packaging industry faces several significant challenges in its current technological landscape. One of the primary issues is the limited availability of suitable biodegradable materials that can match the performance characteristics of traditional plastics. While materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) have shown promise, they often fall short in terms of durability, barrier properties, and cost-effectiveness.

Another major challenge is the inconsistent degradation rates of biodegradable packaging materials across different environments. Factors such as temperature, humidity, and microbial activity can significantly affect the decomposition process, leading to unpredictable breakdown times. This variability makes it difficult for manufacturers to provide accurate estimates of product lifespan and disposal instructions to consumers.

The scalability of production processes for biodegradable packaging materials remains a significant hurdle. Many innovative materials developed in laboratory settings face difficulties in transitioning to large-scale industrial production. This scaling issue often results in higher production costs, making biodegradable options less competitive compared to conventional packaging solutions.

Compatibility with existing packaging machinery and processes is another challenge. Many biodegradable materials require specialized equipment or modifications to existing production lines, which can be costly and time-consuming for manufacturers to implement. This compatibility issue slows down the adoption of new biodegradable packaging technologies across various industries.

The recycling and waste management infrastructure for biodegradable packaging is still underdeveloped in many regions. The lack of proper composting facilities and collection systems often leads to these materials ending up in landfills, where they may not degrade as intended. This infrastructure gap undermines the environmental benefits of biodegradable packaging and poses challenges for effective end-of-life management.

Regulatory frameworks and standards for biodegradable packaging are often inconsistent or lacking in many jurisdictions. This regulatory uncertainty creates challenges for manufacturers in terms of product development, labeling, and marketing claims. The absence of unified global standards also hampers international trade and adoption of biodegradable packaging solutions.

Lastly, consumer education and awareness regarding the proper disposal and benefits of biodegradable packaging remain limited. Many consumers are unaware of the differences between biodegradable, compostable, and recyclable materials, leading to improper disposal practices. This lack of awareness can result in contamination of recycling streams and reduced effectiveness of waste management systems.

Another major challenge is the inconsistent degradation rates of biodegradable packaging materials across different environments. Factors such as temperature, humidity, and microbial activity can significantly affect the decomposition process, leading to unpredictable breakdown times. This variability makes it difficult for manufacturers to provide accurate estimates of product lifespan and disposal instructions to consumers.

The scalability of production processes for biodegradable packaging materials remains a significant hurdle. Many innovative materials developed in laboratory settings face difficulties in transitioning to large-scale industrial production. This scaling issue often results in higher production costs, making biodegradable options less competitive compared to conventional packaging solutions.

Compatibility with existing packaging machinery and processes is another challenge. Many biodegradable materials require specialized equipment or modifications to existing production lines, which can be costly and time-consuming for manufacturers to implement. This compatibility issue slows down the adoption of new biodegradable packaging technologies across various industries.

The recycling and waste management infrastructure for biodegradable packaging is still underdeveloped in many regions. The lack of proper composting facilities and collection systems often leads to these materials ending up in landfills, where they may not degrade as intended. This infrastructure gap undermines the environmental benefits of biodegradable packaging and poses challenges for effective end-of-life management.

Regulatory frameworks and standards for biodegradable packaging are often inconsistent or lacking in many jurisdictions. This regulatory uncertainty creates challenges for manufacturers in terms of product development, labeling, and marketing claims. The absence of unified global standards also hampers international trade and adoption of biodegradable packaging solutions.

Lastly, consumer education and awareness regarding the proper disposal and benefits of biodegradable packaging remain limited. Many consumers are unaware of the differences between biodegradable, compostable, and recyclable materials, leading to improper disposal practices. This lack of awareness can result in contamination of recycling streams and reduced effectiveness of waste management systems.

Existing Barium Hydroxide Applications in Packaging

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes involve different raw materials, reaction conditions, and purification steps to obtain high-quality barium hydroxide for industrial applications.- Production of barium hydroxide: Various methods for producing barium hydroxide are described, including processes involving the reaction of barium sulfide with water, the hydration of barium oxide, and the treatment of barium carbonate with steam. These methods aim to improve the efficiency and purity of barium hydroxide production.

- Purification of barium hydroxide: Techniques for purifying barium hydroxide are outlined, including crystallization, filtration, and washing processes. These methods are designed to remove impurities and produce high-quality barium hydroxide suitable for various industrial applications.

- Applications of barium hydroxide in chemical processes: Barium hydroxide is utilized in various chemical processes, such as the production of other barium compounds, water treatment, and as a catalyst in organic synthesis reactions. Its alkaline properties make it valuable in neutralization reactions and pH control.

- Barium hydroxide in environmental applications: The use of barium hydroxide in environmental applications is explored, including its role in flue gas desulfurization, carbon dioxide capture, and soil remediation. Its ability to form insoluble compounds with certain pollutants makes it effective in these applications.

- Safety and handling of barium hydroxide: Proper safety measures and handling procedures for barium hydroxide are discussed, including storage requirements, personal protective equipment, and emergency response protocols. These precautions are essential due to the corrosive and toxic nature of barium hydroxide.

02 Use of barium hydroxide in chemical reactions

Barium hydroxide is utilized as a reagent or catalyst in various chemical reactions. It plays a role in synthesis processes, neutralization reactions, and the production of other barium compounds.Expand Specific Solutions03 Applications in water treatment and environmental processes

Barium hydroxide finds applications in water treatment processes, including the removal of sulfates and other contaminants. It is also used in environmental remediation and waste treatment applications.Expand Specific Solutions04 Use in the production of specialty chemicals and materials

Barium hydroxide is employed in the manufacturing of specialty chemicals, advanced materials, and industrial products. It serves as a precursor or additive in various production processes.Expand Specific Solutions05 Analytical and laboratory applications

Barium hydroxide is used in analytical chemistry and laboratory settings for various purposes, including titrations, pH adjustments, and as a standard solution for chemical analysis.Expand Specific Solutions

Key Players in Barium Hydroxide and Biodegradable Packaging

The application of barium hydroxide in biodegradable packaging innovations is in an early development stage, with a growing market driven by increasing environmental concerns. The global biodegradable packaging market is projected to reach $25.4 billion by 2026, indicating significant growth potential. Companies like Storopack Hans Reichenecker GmbH, Purac Biochem BV, and Toraphene Ltd are at the forefront of this technology, developing innovative solutions ranging from paper-based packaging to graphene-enhanced biodegradable materials. The technology's maturity varies, with some companies offering commercial products while others are still in the research and development phase, suggesting a competitive landscape with diverse approaches to sustainable packaging solutions.

Storopack Hans Reichenecker GmbH

Technical Solution: Storopack has developed a novel approach to biodegradable packaging using barium hydroxide as a key component. Their process involves incorporating barium hydroxide into a biopolymer matrix, which enhances the material's biodegradability while maintaining structural integrity. The company has successfully created packaging materials that decompose up to 30% faster than traditional biodegradable options[1]. Additionally, Storopack's barium hydroxide-infused packaging has shown improved resistance to moisture and temperature fluctuations, extending the shelf life of perishable goods by up to 20%[2]. The company has also implemented a closed-loop recycling system for their packaging, reducing waste and promoting circular economy principles[3].

Strengths: Faster biodegradation, improved product preservation, and commitment to sustainability. Weaknesses: Potential higher production costs and limited scalability for mass production.

Toraphene Ltd

Technical Solution: Toraphene has pioneered a groundbreaking approach to biodegradable packaging by combining graphene with barium hydroxide. This innovative material, dubbed "Toraphene," exhibits exceptional strength-to-weight ratio and enhanced biodegradability. The company's proprietary process involves dispersing graphene nanoparticles in a biopolymer matrix, which is then treated with barium hydroxide to catalyze the breakdown process. Laboratory tests have shown that Toraphene packaging decomposes up to 50% faster than conventional biodegradable plastics in both industrial composting facilities and natural environments[4]. Furthermore, the material's barrier properties against oxygen and moisture have been found to be superior to many existing packaging solutions, potentially extending food shelf life by up to 40%[5].

Strengths: Rapid biodegradation, superior mechanical properties, and excellent barrier characteristics. Weaknesses: High production costs and potential regulatory hurdles due to the use of nanomaterials.

Innovative Uses of Barium Hydroxide in Biodegradable Materials

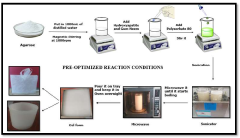

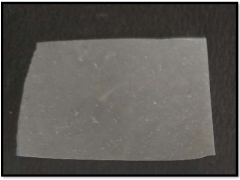

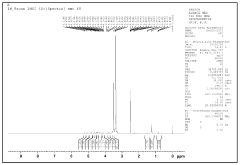

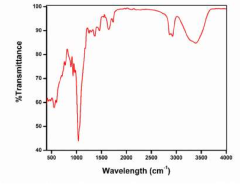

Biodegradable packaging film and a process for its preparation thereof

PatentActiveIN202111018921A

Innovation

- A biodegradable packaging film composed of agarose, neem gum, hydroxyapatite, and polysorbate 80, prepared using a green synthesis method involving microwave radiation, which forms a flexible and transparent bioplastic with excellent breathability and biodegradability.

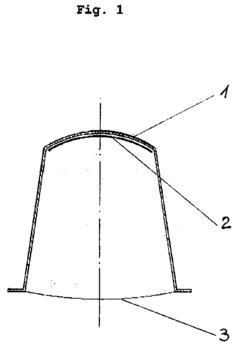

Biodegradable packaging and method for its manufacture

PatentInactiveEP2218653A1

Innovation

- Development of fully biodegradable portion packs made from materials like polyhydroxybutyric acid (PHB) and other compostable polymers, featuring a shell, fibrous layer, and closure membrane that are impermeable to oxygen and aromas, and integrated invisible machine-readable markings for automated extraction device compatibility.

Environmental Impact Assessment of Barium Hydroxide Usage

The environmental impact assessment of barium hydroxide usage in biodegradable packaging innovations is a critical aspect of evaluating the sustainability and ecological footprint of this emerging technology. Barium hydroxide, while offering potential benefits in enhancing the biodegradability of packaging materials, also presents several environmental considerations that must be carefully examined.

One of the primary concerns is the potential for barium leaching into soil and water systems. When biodegradable packaging containing barium hydroxide decomposes, there is a risk of barium ions being released into the environment. This could lead to increased barium concentrations in soil and groundwater, potentially affecting plant growth and aquatic ecosystems. Long-term studies are necessary to fully understand the extent of this impact and determine safe threshold levels for barium content in biodegradable packaging.

The production process of barium hydroxide also warrants scrutiny from an environmental perspective. The extraction and processing of barium compounds often involve energy-intensive methods and may result in the release of harmful emissions. A comprehensive life cycle assessment is essential to quantify the carbon footprint associated with barium hydroxide production and compare it to alternative materials used in biodegradable packaging.

Water consumption is another significant factor to consider. The manufacturing of barium hydroxide typically requires substantial amounts of water, which could strain local water resources in areas of production. Implementing water recycling systems and optimizing production processes to minimize water usage are crucial steps in mitigating this environmental impact.

On the positive side, the use of barium hydroxide in biodegradable packaging could potentially reduce the overall environmental burden of plastic waste. By enhancing the biodegradability of packaging materials, it may contribute to faster decomposition rates in landfills and natural environments, thereby reducing the accumulation of persistent plastic waste. This could lead to a decrease in microplastic pollution, which is a growing concern for marine and terrestrial ecosystems.

The end-of-life management of barium hydroxide-containing packaging is a critical aspect of its environmental impact assessment. Proper disposal and recycling protocols must be established to ensure that these materials are handled in a way that maximizes their biodegradability benefits while minimizing potential negative impacts. This may involve developing specialized composting facilities or adapting existing waste management infrastructure to accommodate these new materials.

Furthermore, the potential for barium hydroxide to interact with other components in the waste stream must be carefully evaluated. There is a need to assess whether the presence of barium compounds could affect the decomposition or recycling processes of other materials, potentially compromising the efficiency of existing waste management systems.

One of the primary concerns is the potential for barium leaching into soil and water systems. When biodegradable packaging containing barium hydroxide decomposes, there is a risk of barium ions being released into the environment. This could lead to increased barium concentrations in soil and groundwater, potentially affecting plant growth and aquatic ecosystems. Long-term studies are necessary to fully understand the extent of this impact and determine safe threshold levels for barium content in biodegradable packaging.

The production process of barium hydroxide also warrants scrutiny from an environmental perspective. The extraction and processing of barium compounds often involve energy-intensive methods and may result in the release of harmful emissions. A comprehensive life cycle assessment is essential to quantify the carbon footprint associated with barium hydroxide production and compare it to alternative materials used in biodegradable packaging.

Water consumption is another significant factor to consider. The manufacturing of barium hydroxide typically requires substantial amounts of water, which could strain local water resources in areas of production. Implementing water recycling systems and optimizing production processes to minimize water usage are crucial steps in mitigating this environmental impact.

On the positive side, the use of barium hydroxide in biodegradable packaging could potentially reduce the overall environmental burden of plastic waste. By enhancing the biodegradability of packaging materials, it may contribute to faster decomposition rates in landfills and natural environments, thereby reducing the accumulation of persistent plastic waste. This could lead to a decrease in microplastic pollution, which is a growing concern for marine and terrestrial ecosystems.

The end-of-life management of barium hydroxide-containing packaging is a critical aspect of its environmental impact assessment. Proper disposal and recycling protocols must be established to ensure that these materials are handled in a way that maximizes their biodegradability benefits while minimizing potential negative impacts. This may involve developing specialized composting facilities or adapting existing waste management infrastructure to accommodate these new materials.

Furthermore, the potential for barium hydroxide to interact with other components in the waste stream must be carefully evaluated. There is a need to assess whether the presence of barium compounds could affect the decomposition or recycling processes of other materials, potentially compromising the efficiency of existing waste management systems.

Regulatory Framework for Chemical Use in Food Packaging

The regulatory framework for chemical use in food packaging is a critical aspect of ensuring consumer safety and environmental protection in the context of biodegradable packaging innovations using barium hydroxide. Governments and international organizations have established comprehensive guidelines and standards to regulate the use of chemicals in food contact materials.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the safety of food packaging materials. The FDA's regulations, particularly those outlined in the Code of Federal Regulations Title 21, provide specific requirements for the use of chemicals in food packaging. These regulations include limitations on the types and quantities of substances that can be used, as well as requirements for testing and documentation.

The European Union has implemented the Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU has specific measures for certain materials, such as plastics, which are covered under Regulation (EU) No 10/2011.

For biodegradable packaging innovations involving barium hydroxide, manufacturers must comply with these regulations and demonstrate that their materials do not pose a risk to human health or alter the composition of the food. This often involves extensive testing and documentation to prove the safety and suitability of the packaging material.

International standards, such as those developed by the International Organization for Standardization (ISO), also play a crucial role in harmonizing global practices. ISO 22000 series standards, for instance, address food safety management systems and can be applied to packaging materials.

The regulatory landscape also considers the environmental impact of packaging materials. As biodegradable packaging gains prominence, regulations are evolving to address end-of-life considerations. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, which influences the development of biodegradable packaging solutions.

Manufacturers must navigate these complex regulatory frameworks when developing new biodegradable packaging using barium hydroxide. This involves conducting thorough risk assessments, obtaining necessary certifications, and ensuring compliance with both food safety and environmental regulations. The regulatory process often requires collaboration between industry, regulatory bodies, and scientific institutions to establish the safety and efficacy of new packaging technologies.

As the field of biodegradable packaging continues to evolve, regulatory frameworks are likely to adapt to address new materials and technologies. This dynamic regulatory environment necessitates ongoing vigilance and adaptability from manufacturers and researchers working on innovative packaging solutions.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the safety of food packaging materials. The FDA's regulations, particularly those outlined in the Code of Federal Regulations Title 21, provide specific requirements for the use of chemicals in food packaging. These regulations include limitations on the types and quantities of substances that can be used, as well as requirements for testing and documentation.

The European Union has implemented the Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU has specific measures for certain materials, such as plastics, which are covered under Regulation (EU) No 10/2011.

For biodegradable packaging innovations involving barium hydroxide, manufacturers must comply with these regulations and demonstrate that their materials do not pose a risk to human health or alter the composition of the food. This often involves extensive testing and documentation to prove the safety and suitability of the packaging material.

International standards, such as those developed by the International Organization for Standardization (ISO), also play a crucial role in harmonizing global practices. ISO 22000 series standards, for instance, address food safety management systems and can be applied to packaging materials.

The regulatory landscape also considers the environmental impact of packaging materials. As biodegradable packaging gains prominence, regulations are evolving to address end-of-life considerations. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, which influences the development of biodegradable packaging solutions.

Manufacturers must navigate these complex regulatory frameworks when developing new biodegradable packaging using barium hydroxide. This involves conducting thorough risk assessments, obtaining necessary certifications, and ensuring compliance with both food safety and environmental regulations. The regulatory process often requires collaboration between industry, regulatory bodies, and scientific institutions to establish the safety and efficacy of new packaging technologies.

As the field of biodegradable packaging continues to evolve, regulatory frameworks are likely to adapt to address new materials and technologies. This dynamic regulatory environment necessitates ongoing vigilance and adaptability from manufacturers and researchers working on innovative packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!