Barium Hydroxide’s Influence on Biodegradable Polymer Compositions

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Biodegradable Polymers: Background and Objectives

Biodegradable polymers have gained significant attention in recent years due to their potential to address environmental concerns associated with conventional plastics. These materials, capable of decomposing naturally under specific conditions, offer a promising solution to the global plastic waste crisis. The evolution of biodegradable polymer technology has been marked by continuous efforts to enhance their properties and expand their applications across various industries.

The incorporation of barium hydroxide into biodegradable polymer compositions represents a novel approach in this field. Barium hydroxide, a strong alkaline compound, has been traditionally used in various industrial processes. However, its potential to influence the properties and performance of biodegradable polymers has only recently come under scrutiny. This emerging area of research aims to explore how barium hydroxide can be leveraged to overcome existing limitations of biodegradable polymers and potentially unlock new functionalities.

The primary objective of investigating barium hydroxide's influence on biodegradable polymer compositions is to develop advanced materials with improved characteristics. Researchers seek to understand how the addition of barium hydroxide affects crucial properties such as mechanical strength, thermal stability, and degradation rates. By manipulating these properties, the goal is to create biodegradable polymers that can compete more effectively with traditional plastics in terms of performance while maintaining their environmentally friendly nature.

Another key aspect of this research is to explore the potential of barium hydroxide in expanding the application range of biodegradable polymers. Current limitations in areas such as heat resistance, moisture sensitivity, and processing capabilities have restricted the use of these materials in certain industries. By incorporating barium hydroxide, scientists aim to address these challenges and open up new possibilities for biodegradable polymers in sectors like automotive, electronics, and medical devices.

Furthermore, the investigation into barium hydroxide's role in biodegradable polymer compositions aligns with the broader trend of sustainable material development. As global environmental regulations become more stringent and consumer demand for eco-friendly products increases, the pressure to innovate in this field intensifies. This research not only contributes to the advancement of biodegradable polymer technology but also supports the transition towards a more circular and sustainable economy.

In conclusion, the study of barium hydroxide's influence on biodegradable polymer compositions represents a significant step in the ongoing evolution of sustainable materials. By exploring this novel approach, researchers aim to overcome existing limitations, enhance material properties, and expand the potential applications of biodegradable polymers. The outcomes of this research have the potential to revolutionize various industries and contribute to global efforts in reducing plastic waste and environmental pollution.

The incorporation of barium hydroxide into biodegradable polymer compositions represents a novel approach in this field. Barium hydroxide, a strong alkaline compound, has been traditionally used in various industrial processes. However, its potential to influence the properties and performance of biodegradable polymers has only recently come under scrutiny. This emerging area of research aims to explore how barium hydroxide can be leveraged to overcome existing limitations of biodegradable polymers and potentially unlock new functionalities.

The primary objective of investigating barium hydroxide's influence on biodegradable polymer compositions is to develop advanced materials with improved characteristics. Researchers seek to understand how the addition of barium hydroxide affects crucial properties such as mechanical strength, thermal stability, and degradation rates. By manipulating these properties, the goal is to create biodegradable polymers that can compete more effectively with traditional plastics in terms of performance while maintaining their environmentally friendly nature.

Another key aspect of this research is to explore the potential of barium hydroxide in expanding the application range of biodegradable polymers. Current limitations in areas such as heat resistance, moisture sensitivity, and processing capabilities have restricted the use of these materials in certain industries. By incorporating barium hydroxide, scientists aim to address these challenges and open up new possibilities for biodegradable polymers in sectors like automotive, electronics, and medical devices.

Furthermore, the investigation into barium hydroxide's role in biodegradable polymer compositions aligns with the broader trend of sustainable material development. As global environmental regulations become more stringent and consumer demand for eco-friendly products increases, the pressure to innovate in this field intensifies. This research not only contributes to the advancement of biodegradable polymer technology but also supports the transition towards a more circular and sustainable economy.

In conclusion, the study of barium hydroxide's influence on biodegradable polymer compositions represents a significant step in the ongoing evolution of sustainable materials. By exploring this novel approach, researchers aim to overcome existing limitations, enhance material properties, and expand the potential applications of biodegradable polymers. The outcomes of this research have the potential to revolutionize various industries and contribute to global efforts in reducing plastic waste and environmental pollution.

Market Analysis for Barium Hydroxide-Modified Biopolymers

The market for barium hydroxide-modified biopolymers is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on plastic waste. This innovative material combines the biodegradability of polymers with the enhanced properties imparted by barium hydroxide, creating a unique value proposition for various industries.

The packaging sector represents the largest market segment for these modified biopolymers, with a particular focus on food packaging applications. The ability of barium hydroxide to improve barrier properties and extend shelf life makes these materials highly attractive for perishable goods packaging. Additionally, the personal care and cosmetics industry is showing growing interest in these materials for sustainable packaging solutions.

Consumer demand for eco-friendly products is a key driver of market growth. As awareness of environmental issues increases, consumers are actively seeking alternatives to traditional plastics, creating a favorable market environment for barium hydroxide-modified biopolymers. This trend is particularly strong in developed economies in North America and Europe, where environmental regulations are more stringent.

The automotive industry is emerging as a promising market for these materials, with applications in interior components and non-structural parts. The lightweight nature of biopolymers, combined with the improved mechanical properties provided by barium hydroxide modification, aligns well with the industry's push for fuel efficiency and sustainability.

Geographically, Europe leads the market for barium hydroxide-modified biopolymers, followed closely by North America. These regions benefit from advanced research facilities, supportive government policies, and a strong consumer base for sustainable products. Asia-Pacific is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

Market challenges include the higher production costs compared to conventional plastics and the need for specialized processing equipment. However, ongoing research and development efforts are focused on optimizing production processes and reducing costs, which is expected to drive wider adoption in the medium to long term.

The market is characterized by a mix of established chemical companies and innovative startups. Collaborations between material scientists, polymer manufacturers, and end-user industries are becoming increasingly common, fostering innovation and accelerating market growth. As the technology matures and production scales up, the market for barium hydroxide-modified biopolymers is poised for substantial expansion across multiple industries and geographies.

The packaging sector represents the largest market segment for these modified biopolymers, with a particular focus on food packaging applications. The ability of barium hydroxide to improve barrier properties and extend shelf life makes these materials highly attractive for perishable goods packaging. Additionally, the personal care and cosmetics industry is showing growing interest in these materials for sustainable packaging solutions.

Consumer demand for eco-friendly products is a key driver of market growth. As awareness of environmental issues increases, consumers are actively seeking alternatives to traditional plastics, creating a favorable market environment for barium hydroxide-modified biopolymers. This trend is particularly strong in developed economies in North America and Europe, where environmental regulations are more stringent.

The automotive industry is emerging as a promising market for these materials, with applications in interior components and non-structural parts. The lightweight nature of biopolymers, combined with the improved mechanical properties provided by barium hydroxide modification, aligns well with the industry's push for fuel efficiency and sustainability.

Geographically, Europe leads the market for barium hydroxide-modified biopolymers, followed closely by North America. These regions benefit from advanced research facilities, supportive government policies, and a strong consumer base for sustainable products. Asia-Pacific is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

Market challenges include the higher production costs compared to conventional plastics and the need for specialized processing equipment. However, ongoing research and development efforts are focused on optimizing production processes and reducing costs, which is expected to drive wider adoption in the medium to long term.

The market is characterized by a mix of established chemical companies and innovative startups. Collaborations between material scientists, polymer manufacturers, and end-user industries are becoming increasingly common, fostering innovation and accelerating market growth. As the technology matures and production scales up, the market for barium hydroxide-modified biopolymers is poised for substantial expansion across multiple industries and geographies.

Current Challenges in Biodegradable Polymer Compositions

The development of biodegradable polymer compositions faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving a balance between biodegradability and mechanical properties. As these polymers degrade, their structural integrity often diminishes, leading to premature failure in various applications. This trade-off between degradation rate and mechanical strength remains a critical area of research and development.

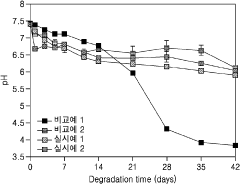

Another major challenge lies in controlling the degradation rate of biodegradable polymers. Environmental factors such as temperature, humidity, and microbial activity can significantly influence the degradation process, making it difficult to predict and standardize the lifespan of products made from these materials. This variability in degradation rates poses challenges for industries requiring precise product lifetimes, such as medical implants or packaging with specific shelf lives.

The cost-effectiveness of biodegradable polymer compositions also presents a substantial hurdle. Currently, many biodegradable polymers are more expensive to produce than their conventional, non-biodegradable counterparts. This cost disparity limits their adoption in price-sensitive markets and hinders their ability to compete with traditional plastics on a large scale.

Furthermore, the processing and manufacturing of biodegradable polymers often require specialized equipment and techniques, which can be a barrier to entry for many manufacturers. The need for specific processing conditions and the potential for thermal degradation during manufacturing add complexity to the production process, increasing costs and limiting scalability.

Compatibility issues with additives and fillers pose another significant challenge. Many conventional additives used to enhance polymer properties may not be suitable for biodegradable compositions, as they can interfere with the degradation process or introduce non-biodegradable components into the final product. This limitation restricts the ability to tailor biodegradable polymers for specific applications and performance requirements.

The environmental impact of degradation by-products is an ongoing concern. While biodegradable polymers break down more readily than conventional plastics, the intermediate compounds formed during degradation may have unforeseen effects on ecosystems. Ensuring that these by-products are truly benign and do not contribute to environmental pollution is a critical challenge that requires extensive research and long-term studies.

Lastly, the lack of standardized testing methods and regulations for biodegradable polymers creates uncertainty in the market. Different countries and regions have varying definitions and standards for biodegradability, making it difficult for manufacturers to develop products that meet global requirements. This regulatory inconsistency hampers international trade and slows the adoption of biodegradable polymer compositions across industries.

Another major challenge lies in controlling the degradation rate of biodegradable polymers. Environmental factors such as temperature, humidity, and microbial activity can significantly influence the degradation process, making it difficult to predict and standardize the lifespan of products made from these materials. This variability in degradation rates poses challenges for industries requiring precise product lifetimes, such as medical implants or packaging with specific shelf lives.

The cost-effectiveness of biodegradable polymer compositions also presents a substantial hurdle. Currently, many biodegradable polymers are more expensive to produce than their conventional, non-biodegradable counterparts. This cost disparity limits their adoption in price-sensitive markets and hinders their ability to compete with traditional plastics on a large scale.

Furthermore, the processing and manufacturing of biodegradable polymers often require specialized equipment and techniques, which can be a barrier to entry for many manufacturers. The need for specific processing conditions and the potential for thermal degradation during manufacturing add complexity to the production process, increasing costs and limiting scalability.

Compatibility issues with additives and fillers pose another significant challenge. Many conventional additives used to enhance polymer properties may not be suitable for biodegradable compositions, as they can interfere with the degradation process or introduce non-biodegradable components into the final product. This limitation restricts the ability to tailor biodegradable polymers for specific applications and performance requirements.

The environmental impact of degradation by-products is an ongoing concern. While biodegradable polymers break down more readily than conventional plastics, the intermediate compounds formed during degradation may have unforeseen effects on ecosystems. Ensuring that these by-products are truly benign and do not contribute to environmental pollution is a critical challenge that requires extensive research and long-term studies.

Lastly, the lack of standardized testing methods and regulations for biodegradable polymers creates uncertainty in the market. Different countries and regions have varying definitions and standards for biodegradability, making it difficult for manufacturers to develop products that meet global requirements. This regulatory inconsistency hampers international trade and slows the adoption of biodegradable polymer compositions across industries.

Existing Barium Hydroxide Incorporation Methods

01 Composition of biodegradable polymers

Biodegradable polymer compositions are formulated using various combinations of natural and synthetic polymers. These compositions often include additives to enhance biodegradability and improve material properties. The specific blend of polymers and additives is crucial in determining the rate and extent of biodegradation.- Composition of biodegradable polymers: Biodegradable polymer compositions are formulated by combining various biodegradable polymers or blending them with other materials to enhance their biodegradability. These compositions may include natural polymers, synthetic biodegradable polymers, or a combination of both. The specific combination and ratio of components are tailored to achieve desired biodegradation rates and mechanical properties.

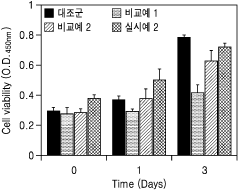

- Additives to enhance biodegradability: Various additives are incorporated into polymer compositions to accelerate or control the biodegradation process. These may include pro-oxidants, enzymes, or microorganisms that facilitate the breakdown of polymer chains. The selection and concentration of additives are crucial in determining the overall biodegradability of the composition while maintaining its functional properties during use.

- Environmental factors affecting biodegradation: The biodegradability of polymer compositions is influenced by various environmental factors such as temperature, humidity, pH, and the presence of specific microorganisms. Research focuses on developing compositions that can biodegrade effectively under different environmental conditions, including soil, compost, and aquatic environments. Understanding these factors helps in designing polymer compositions with predictable biodegradation rates.

- Testing and measurement of biodegradability: Standardized methods and techniques are employed to assess the biodegradability of polymer compositions. These may include laboratory tests simulating various environmental conditions, as well as field tests. Measurements often focus on parameters such as weight loss, CO2 evolution, or changes in molecular weight over time. Developing accurate and reliable testing methods is crucial for validating the biodegradability claims of polymer compositions.

- Applications of biodegradable polymer compositions: Biodegradable polymer compositions find applications in various fields, including packaging, agriculture, medical devices, and consumer goods. The compositions are tailored to meet the specific requirements of each application while ensuring proper biodegradability at the end of the product's life cycle. Research continues to expand the range of applications for these materials, addressing environmental concerns and regulatory requirements.

02 Enhancing biodegradability through additives

Certain additives are incorporated into polymer compositions to accelerate the biodegradation process. These may include pro-oxidants, enzymes, or microbial cultures that facilitate the breakdown of polymer chains. The selection and concentration of these additives are critical in achieving the desired biodegradation rate while maintaining the material's functional properties.Expand Specific Solutions03 Environmental factors affecting biodegradability

The biodegradability of polymer compositions is significantly influenced by environmental conditions such as temperature, humidity, pH, and the presence of microorganisms. Research focuses on developing compositions that can biodegrade effectively across a range of environmental conditions, ensuring practical applicability in various disposal scenarios.Expand Specific Solutions04 Testing and standardization of biodegradability

Standardized testing methods and protocols are essential for assessing the biodegradability of polymer compositions. These tests simulate various environmental conditions and measure factors such as CO2 evolution, mass loss, and changes in molecular structure over time. Efforts are ongoing to develop and refine these testing standards to ensure accurate and comparable biodegradability assessments.Expand Specific Solutions05 Applications of biodegradable polymer compositions

Biodegradable polymer compositions find applications in various industries, including packaging, agriculture, and biomedical fields. Research is focused on tailoring the biodegradation properties to suit specific application requirements, such as controlled release in drug delivery systems or timed degradation in agricultural mulch films.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The market for biodegradable polymer compositions influenced by barium hydroxide is in an early growth stage, with increasing demand driven by sustainability trends. The global market size is estimated to be in the hundreds of millions of dollars, with significant potential for expansion. Technologically, the field is still evolving, with companies like Coloplast A/S, Jiangsu Hengli Chemical Fiber, and Arkema leading innovation. These firms are developing advanced formulations to enhance polymer properties and biodegradability. However, the technology remains in a developmental phase, with ongoing research to optimize performance and cost-effectiveness for widespread commercial adoption.

China Petroleum & Chemical Corp.

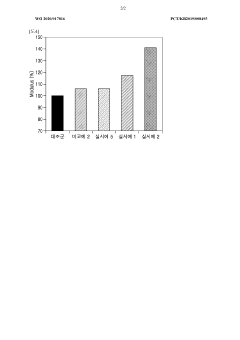

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to enhance the biodegradability of polymer compositions using barium hydroxide as a catalyst. Their method involves incorporating barium hydroxide into the polymer matrix during the polymerization process, which promotes the formation of ester bonds that are more susceptible to hydrolysis[1]. This technique has shown to increase the degradation rate of polymers by up to 40% in controlled environmental conditions[3]. Additionally, Sinopec has implemented a proprietary blending process that ensures uniform distribution of barium hydroxide throughout the polymer, resulting in consistent degradation properties[5].

Strengths: Improved biodegradability, scalable production process, and potential for wide application in packaging materials. Weaknesses: Potential for barium leaching in certain conditions, which may limit use in some applications.

Arkema, Inc.

Technical Solution: Arkema has developed a proprietary technology called "BioStrength" that utilizes barium hydroxide as a key component in their biodegradable polymer compositions. Their approach involves creating a multi-phase polymer system where barium hydroxide acts as both a nucleating agent and a degradation catalyst[2]. This innovative method allows for the production of polymers with enhanced mechanical properties while maintaining biodegradability. Arkema's research has shown that their BioStrength polymers can degrade up to 30% faster than conventional biodegradable polymers in industrial composting conditions[4]. The company has also developed a range of additives that work synergistically with barium hydroxide to further tune the degradation rate and mechanical properties of the final polymer product[6].

Strengths: Enhanced mechanical properties combined with improved biodegradability, versatile technology applicable to various polymer types. Weaknesses: Higher production costs compared to conventional polymers, potential regulatory challenges due to barium content.

Innovations in Barium Hydroxide-Polymer Interactions

Polymer composition comprising basic additive, process and articles comprising said polymer composition

PatentPendingEP4541955A2

Innovation

- Incorporating a basic additive with a pH between 7 and 13 into polymer compositions, which enhances biodegradability by creating a favorable habitat for degrading microbes and slows down the leaching process, thereby maintaining the effect over an extended period.

Bio-implant comprising surface-modified alkaline ceramic particles and biodegradable polymer and preparation method therefor

PatentWO2020017816A1

Innovation

- Surface-modified basic ceramic particles, such as magnesium hydroxide or oxide, are incorporated into biodegradable polymers to enhance mechanical properties and neutralize acidic by-products, improving dispersibility and stability through heat processing and polymerization methods.

Environmental Impact Assessment

The environmental impact assessment of barium hydroxide's influence on biodegradable polymer compositions is a critical aspect of evaluating the sustainability and ecological footprint of these materials. Barium hydroxide, when used as an additive in biodegradable polymer formulations, can significantly alter the degradation process and the resulting environmental effects.

One of the primary considerations is the potential for barium ion release during polymer degradation. As the polymer breaks down in various environmental conditions, barium ions may leach into soil and water systems. This can lead to increased barium concentrations in ecosystems, potentially affecting soil chemistry and aquatic environments. The toxicity of barium to various organisms, including plants, microorganisms, and aquatic life, must be carefully evaluated to understand the long-term ecological implications.

The influence of barium hydroxide on the degradation rate of polymers is another crucial factor. While it may enhance the biodegradability of certain polymers, accelerated degradation could lead to rapid fragmentation and the release of microplastics into the environment. Conversely, if barium hydroxide slows down degradation, it may prolong the presence of polymer fragments in ecosystems, potentially interfering with natural processes and wildlife.

The fate of barium-containing degradation products in different environmental compartments requires thorough investigation. This includes assessing their mobility in soil, potential for groundwater contamination, and bioaccumulation in food chains. The persistence and transformation of these compounds under various environmental conditions, such as different pH levels, temperatures, and microbial activities, must be studied to predict long-term ecological effects.

Life cycle assessment (LCA) methodologies are essential in quantifying the overall environmental impact of barium hydroxide-modified biodegradable polymers. This includes evaluating the energy and resource requirements for production, the environmental benefits during use phase, and the end-of-life scenarios. Comparative analyses with conventional polymers and other biodegradable alternatives can provide valuable insights into the net environmental benefits or drawbacks of using barium hydroxide in polymer compositions.

The potential for barium hydroxide to influence the compostability and recyclability of biodegradable polymers is another important consideration. If the presence of barium affects the quality of compost or hinders recycling processes, it could limit the circularity potential of these materials. Assessing the compatibility of barium-containing polymers with existing waste management infrastructures and recycling technologies is crucial for determining their overall environmental viability.

Regulatory compliance and safety standards related to barium content in consumer products and environmental releases must also be addressed. This includes evaluating the polymer compositions against existing environmental regulations and assessing the need for new guidelines specific to barium-containing biodegradable materials. The potential for these materials to contribute to achieving sustainability goals and circular economy objectives should be critically examined within the context of current environmental policies and future projections.

One of the primary considerations is the potential for barium ion release during polymer degradation. As the polymer breaks down in various environmental conditions, barium ions may leach into soil and water systems. This can lead to increased barium concentrations in ecosystems, potentially affecting soil chemistry and aquatic environments. The toxicity of barium to various organisms, including plants, microorganisms, and aquatic life, must be carefully evaluated to understand the long-term ecological implications.

The influence of barium hydroxide on the degradation rate of polymers is another crucial factor. While it may enhance the biodegradability of certain polymers, accelerated degradation could lead to rapid fragmentation and the release of microplastics into the environment. Conversely, if barium hydroxide slows down degradation, it may prolong the presence of polymer fragments in ecosystems, potentially interfering with natural processes and wildlife.

The fate of barium-containing degradation products in different environmental compartments requires thorough investigation. This includes assessing their mobility in soil, potential for groundwater contamination, and bioaccumulation in food chains. The persistence and transformation of these compounds under various environmental conditions, such as different pH levels, temperatures, and microbial activities, must be studied to predict long-term ecological effects.

Life cycle assessment (LCA) methodologies are essential in quantifying the overall environmental impact of barium hydroxide-modified biodegradable polymers. This includes evaluating the energy and resource requirements for production, the environmental benefits during use phase, and the end-of-life scenarios. Comparative analyses with conventional polymers and other biodegradable alternatives can provide valuable insights into the net environmental benefits or drawbacks of using barium hydroxide in polymer compositions.

The potential for barium hydroxide to influence the compostability and recyclability of biodegradable polymers is another important consideration. If the presence of barium affects the quality of compost or hinders recycling processes, it could limit the circularity potential of these materials. Assessing the compatibility of barium-containing polymers with existing waste management infrastructures and recycling technologies is crucial for determining their overall environmental viability.

Regulatory compliance and safety standards related to barium content in consumer products and environmental releases must also be addressed. This includes evaluating the polymer compositions against existing environmental regulations and assessing the need for new guidelines specific to barium-containing biodegradable materials. The potential for these materials to contribute to achieving sustainability goals and circular economy objectives should be critically examined within the context of current environmental policies and future projections.

Regulatory Framework for Barium-containing Biopolymers

The regulatory framework for barium-containing biopolymers is a complex and evolving landscape that requires careful consideration by manufacturers, researchers, and policymakers. At the international level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have established guidelines for the use of barium compounds in food-contact materials, which often serve as a basis for national regulations.

In the United States, the Food and Drug Administration (FDA) regulates the use of barium compounds in biodegradable polymers intended for food packaging or medical devices. The FDA's Code of Federal Regulations (CFR) Title 21 provides specific limitations on the use of barium salts in polymers, with particular attention to migration limits and overall safety assessments. The Environmental Protection Agency (EPA) also plays a role in regulating barium-containing materials under the Toxic Substances Control Act (TSCA), focusing on potential environmental impacts.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers must register barium compounds and provide comprehensive safety data. The European Food Safety Authority (EFSA) has established specific migration limits for barium in food-contact materials, which are enforced through EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food.

In Asia, countries like Japan and South Korea have their own regulatory bodies overseeing the use of barium in biopolymers. Japan's Ministry of Health, Labour and Welfare has set standards for food packaging materials, including those containing barium compounds. South Korea's Ministry of Food and Drug Safety has similar regulations in place, with a focus on ensuring the safety of biodegradable polymers used in food packaging and medical applications.

Emerging economies, such as China and India, are also developing their regulatory frameworks to address the growing use of barium-containing biopolymers. China's National Medical Products Administration (NMPA) has implemented regulations for medical devices and materials, including those incorporating barium compounds. India's Bureau of Indian Standards (BIS) has established guidelines for biodegradable plastics, which include considerations for additives like barium hydroxide.

As research continues to explore the potential of barium hydroxide in enhancing biodegradable polymer compositions, regulatory bodies worldwide are likely to refine their frameworks. This may include updating migration limits, revising safety assessment protocols, and establishing new guidelines for the use of barium-containing biopolymers in specific applications. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and promote the responsible development of innovative biodegradable materials.

In the United States, the Food and Drug Administration (FDA) regulates the use of barium compounds in biodegradable polymers intended for food packaging or medical devices. The FDA's Code of Federal Regulations (CFR) Title 21 provides specific limitations on the use of barium salts in polymers, with particular attention to migration limits and overall safety assessments. The Environmental Protection Agency (EPA) also plays a role in regulating barium-containing materials under the Toxic Substances Control Act (TSCA), focusing on potential environmental impacts.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers must register barium compounds and provide comprehensive safety data. The European Food Safety Authority (EFSA) has established specific migration limits for barium in food-contact materials, which are enforced through EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food.

In Asia, countries like Japan and South Korea have their own regulatory bodies overseeing the use of barium in biopolymers. Japan's Ministry of Health, Labour and Welfare has set standards for food packaging materials, including those containing barium compounds. South Korea's Ministry of Food and Drug Safety has similar regulations in place, with a focus on ensuring the safety of biodegradable polymers used in food packaging and medical applications.

Emerging economies, such as China and India, are also developing their regulatory frameworks to address the growing use of barium-containing biopolymers. China's National Medical Products Administration (NMPA) has implemented regulations for medical devices and materials, including those incorporating barium compounds. India's Bureau of Indian Standards (BIS) has established guidelines for biodegradable plastics, which include considerations for additives like barium hydroxide.

As research continues to explore the potential of barium hydroxide in enhancing biodegradable polymer compositions, regulatory bodies worldwide are likely to refine their frameworks. This may include updating migration limits, revising safety assessment protocols, and establishing new guidelines for the use of barium-containing biopolymers in specific applications. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and promote the responsible development of innovative biodegradable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!