Barium Hydroxide’s Role in Developing Multi-Functional Coatings

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide Coating Evolution and Objectives

Barium hydroxide has played a significant role in the development of multi-functional coatings over the past few decades. The evolution of these coatings can be traced back to the early 1980s when researchers first began exploring the potential of barium hydroxide as a key component in protective surface treatments. Initially, the focus was primarily on its ability to enhance corrosion resistance in metal substrates.

As research progressed, scientists discovered that barium hydroxide could be incorporated into more complex coating systems, leading to the development of multi-functional coatings with a wider range of properties. By the late 1990s, these coatings were being used in various industries, including automotive, aerospace, and construction, due to their ability to provide not only corrosion protection but also improved adhesion, thermal stability, and chemical resistance.

The early 2000s saw a shift towards more environmentally friendly coating solutions, prompting researchers to investigate the use of barium hydroxide in water-based and low-VOC formulations. This led to the development of eco-friendly multi-functional coatings that maintained high performance while reducing environmental impact. Concurrently, advancements in nanotechnology opened up new possibilities for incorporating barium hydroxide into nanostructured coatings, further enhancing their properties and expanding their potential applications.

In recent years, the focus has shifted towards smart and responsive coatings, with barium hydroxide playing a crucial role in developing self-healing and stimuli-responsive systems. These advanced coatings can adapt to environmental changes or repair minor damage autonomously, significantly extending the lifespan of treated surfaces and reducing maintenance costs.

Looking ahead, the primary objectives for barium hydroxide-based multi-functional coatings include further improving their durability, expanding their range of functionalities, and enhancing their sustainability. Researchers are exploring novel synthesis methods and hybrid materials to create coatings with superior mechanical properties, increased chemical resistance, and improved thermal stability. Additionally, there is a growing interest in developing coatings with advanced functionalities such as antimicrobial properties, energy harvesting capabilities, and enhanced sensing abilities.

Another key objective is to optimize the coating processes to ensure uniform application and consistent performance across various substrate materials and geometries. This includes developing new application techniques and improving the compatibility of barium hydroxide-based coatings with different substrate materials. Furthermore, researchers are working on reducing the overall environmental footprint of these coatings by exploring bio-based alternatives and improving their recyclability and end-of-life management.

As research progressed, scientists discovered that barium hydroxide could be incorporated into more complex coating systems, leading to the development of multi-functional coatings with a wider range of properties. By the late 1990s, these coatings were being used in various industries, including automotive, aerospace, and construction, due to their ability to provide not only corrosion protection but also improved adhesion, thermal stability, and chemical resistance.

The early 2000s saw a shift towards more environmentally friendly coating solutions, prompting researchers to investigate the use of barium hydroxide in water-based and low-VOC formulations. This led to the development of eco-friendly multi-functional coatings that maintained high performance while reducing environmental impact. Concurrently, advancements in nanotechnology opened up new possibilities for incorporating barium hydroxide into nanostructured coatings, further enhancing their properties and expanding their potential applications.

In recent years, the focus has shifted towards smart and responsive coatings, with barium hydroxide playing a crucial role in developing self-healing and stimuli-responsive systems. These advanced coatings can adapt to environmental changes or repair minor damage autonomously, significantly extending the lifespan of treated surfaces and reducing maintenance costs.

Looking ahead, the primary objectives for barium hydroxide-based multi-functional coatings include further improving their durability, expanding their range of functionalities, and enhancing their sustainability. Researchers are exploring novel synthesis methods and hybrid materials to create coatings with superior mechanical properties, increased chemical resistance, and improved thermal stability. Additionally, there is a growing interest in developing coatings with advanced functionalities such as antimicrobial properties, energy harvesting capabilities, and enhanced sensing abilities.

Another key objective is to optimize the coating processes to ensure uniform application and consistent performance across various substrate materials and geometries. This includes developing new application techniques and improving the compatibility of barium hydroxide-based coatings with different substrate materials. Furthermore, researchers are working on reducing the overall environmental footprint of these coatings by exploring bio-based alternatives and improving their recyclability and end-of-life management.

Market Analysis for Multi-Functional Coatings

The multi-functional coatings market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, construction, and electronics. These coatings offer multiple benefits, including corrosion resistance, self-cleaning properties, and enhanced durability, making them highly attractive to end-users seeking to improve product performance and longevity.

The global market for multi-functional coatings is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of advanced coating technologies in emerging economies and the continuous innovation in coating formulations to meet evolving industry requirements.

In the automotive sector, multi-functional coatings are gaining traction due to their ability to provide scratch resistance, UV protection, and self-healing properties. The aerospace industry is another key market driver, where these coatings are utilized to enhance fuel efficiency by reducing drag and improving aerodynamics. The construction industry is also embracing multi-functional coatings for their weather-resistant and energy-saving characteristics.

The Asia-Pacific region is anticipated to be the fastest-growing market for multi-functional coatings, fueled by rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe continue to be significant markets, with a focus on high-performance coatings for specialized applications in the defense and healthcare sectors.

Key market trends include the development of eco-friendly and sustainable coating solutions to meet stringent environmental regulations. Water-based and powder coatings are gaining popularity as alternatives to solvent-based formulations. Additionally, there is a growing emphasis on smart coatings that can respond to external stimuli, such as temperature or pH changes, opening up new application possibilities.

The role of barium hydroxide in developing multi-functional coatings is gaining attention due to its potential to enhance certain coating properties. Its alkaline nature and unique chemical characteristics make it a promising additive for improving adhesion, corrosion resistance, and durability of coatings. As research in this area progresses, barium hydroxide-based formulations could carve out a niche in the multi-functional coatings market, particularly in applications requiring high-performance protective layers.

However, challenges such as high production costs and technical complexities in formulation remain. Manufacturers are investing in research and development to overcome these hurdles and create more cost-effective solutions. The market is also witnessing increased collaboration between coating manufacturers and raw material suppliers to develop innovative products that meet specific industry needs.

The global market for multi-functional coatings is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising adoption of advanced coating technologies in emerging economies and the continuous innovation in coating formulations to meet evolving industry requirements.

In the automotive sector, multi-functional coatings are gaining traction due to their ability to provide scratch resistance, UV protection, and self-healing properties. The aerospace industry is another key market driver, where these coatings are utilized to enhance fuel efficiency by reducing drag and improving aerodynamics. The construction industry is also embracing multi-functional coatings for their weather-resistant and energy-saving characteristics.

The Asia-Pacific region is anticipated to be the fastest-growing market for multi-functional coatings, fueled by rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe continue to be significant markets, with a focus on high-performance coatings for specialized applications in the defense and healthcare sectors.

Key market trends include the development of eco-friendly and sustainable coating solutions to meet stringent environmental regulations. Water-based and powder coatings are gaining popularity as alternatives to solvent-based formulations. Additionally, there is a growing emphasis on smart coatings that can respond to external stimuli, such as temperature or pH changes, opening up new application possibilities.

The role of barium hydroxide in developing multi-functional coatings is gaining attention due to its potential to enhance certain coating properties. Its alkaline nature and unique chemical characteristics make it a promising additive for improving adhesion, corrosion resistance, and durability of coatings. As research in this area progresses, barium hydroxide-based formulations could carve out a niche in the multi-functional coatings market, particularly in applications requiring high-performance protective layers.

However, challenges such as high production costs and technical complexities in formulation remain. Manufacturers are investing in research and development to overcome these hurdles and create more cost-effective solutions. The market is also witnessing increased collaboration between coating manufacturers and raw material suppliers to develop innovative products that meet specific industry needs.

Current Challenges in Barium Hydroxide-Based Coatings

Despite the promising potential of barium hydroxide in multi-functional coatings, several challenges currently hinder its widespread adoption and optimal performance. One of the primary issues is the limited solubility of barium hydroxide in water, which can affect the uniformity and consistency of coating formulations. This solubility constraint often leads to difficulties in achieving the desired concentration of barium ions in the coating matrix, potentially compromising the overall effectiveness of the coating.

Another significant challenge lies in the reactivity of barium hydroxide with atmospheric carbon dioxide. When exposed to air, barium hydroxide readily forms barium carbonate, which can alter the chemical properties and performance of the coating. This carbonation process not only reduces the availability of active barium ions but also affects the pH stability of the coating system, potentially diminishing its protective capabilities.

The high alkalinity of barium hydroxide-based coatings presents additional challenges in terms of compatibility with certain substrates and other coating components. The strong basic nature can lead to degradation of sensitive materials or unwanted side reactions with other additives, limiting the range of applications and formulation options.

Durability and long-term stability of barium hydroxide-based coatings remain areas of concern. The leaching of barium ions from the coating over time can result in a gradual loss of functionality and protective properties. This issue is particularly critical in applications requiring prolonged exposure to harsh environmental conditions or frequent contact with liquids.

Furthermore, the potential environmental and health impacts associated with barium compounds pose regulatory challenges. Stringent regulations regarding the use and disposal of barium-containing materials necessitate careful consideration in coating formulations and application processes. This regulatory landscape can complicate the development and commercialization of barium hydroxide-based coatings in certain markets or industries.

From a manufacturing perspective, the handling and processing of barium hydroxide present technical challenges. Its hygroscopic nature and sensitivity to atmospheric conditions require specialized storage and processing equipment, potentially increasing production costs and complexity.

Lastly, achieving optimal dispersion and integration of barium hydroxide within various coating matrices remains a technical hurdle. The tendency of barium compounds to agglomerate can lead to inconsistencies in coating performance and appearance, necessitating advanced formulation techniques and dispersion technologies to ensure uniform distribution and functionality throughout the coating.

Another significant challenge lies in the reactivity of barium hydroxide with atmospheric carbon dioxide. When exposed to air, barium hydroxide readily forms barium carbonate, which can alter the chemical properties and performance of the coating. This carbonation process not only reduces the availability of active barium ions but also affects the pH stability of the coating system, potentially diminishing its protective capabilities.

The high alkalinity of barium hydroxide-based coatings presents additional challenges in terms of compatibility with certain substrates and other coating components. The strong basic nature can lead to degradation of sensitive materials or unwanted side reactions with other additives, limiting the range of applications and formulation options.

Durability and long-term stability of barium hydroxide-based coatings remain areas of concern. The leaching of barium ions from the coating over time can result in a gradual loss of functionality and protective properties. This issue is particularly critical in applications requiring prolonged exposure to harsh environmental conditions or frequent contact with liquids.

Furthermore, the potential environmental and health impacts associated with barium compounds pose regulatory challenges. Stringent regulations regarding the use and disposal of barium-containing materials necessitate careful consideration in coating formulations and application processes. This regulatory landscape can complicate the development and commercialization of barium hydroxide-based coatings in certain markets or industries.

From a manufacturing perspective, the handling and processing of barium hydroxide present technical challenges. Its hygroscopic nature and sensitivity to atmospheric conditions require specialized storage and processing equipment, potentially increasing production costs and complexity.

Lastly, achieving optimal dispersion and integration of barium hydroxide within various coating matrices remains a technical hurdle. The tendency of barium compounds to agglomerate can lead to inconsistencies in coating performance and appearance, necessitating advanced formulation techniques and dispersion technologies to ensure uniform distribution and functionality throughout the coating.

Existing Barium Hydroxide Coating Solutions

01 Use in chemical processes and reactions

Barium hydroxide is utilized in various chemical processes and reactions, including as a reagent, catalyst, or intermediate. It plays a role in organic synthesis, inorganic reactions, and industrial applications due to its alkaline properties and reactivity.- Use in water treatment and purification: Barium hydroxide is utilized in water treatment processes for removing impurities and contaminants. It can be used to precipitate sulfates and other dissolved solids, improving water quality. The compound's alkaline nature also helps in pH adjustment and softening of water.

- Application in chemical synthesis and reactions: Barium hydroxide serves as a versatile reagent in various chemical syntheses and reactions. It can be used as a base in organic reactions, a catalyst in certain processes, and a precursor for other barium compounds. Its strong alkaline properties make it suitable for neutralization reactions and pH control in industrial processes.

- Role in materials production and processing: Barium hydroxide plays a significant role in the production and processing of various materials. It is used in the manufacture of lubricants, ceramics, and specialty glasses. The compound can also be employed in the treatment of wood and other materials to improve their properties or durability.

- Environmental applications and waste treatment: Barium hydroxide finds applications in environmental remediation and waste treatment processes. It can be used for the removal of sulfur dioxide from flue gases, treatment of contaminated soils, and stabilization of hazardous wastes. The compound's ability to form insoluble precipitates with certain pollutants makes it valuable in environmental protection efforts.

- Use in energy storage and battery technologies: Barium hydroxide has potential applications in energy storage and battery technologies. It can be used in the production of certain types of batteries, such as nickel-barium batteries, and in the development of energy storage materials. The compound's properties make it suitable for use in electrochemical systems and thermal energy storage applications.

02 Water treatment and purification

Barium hydroxide is employed in water treatment and purification processes. It can be used for softening water, removing impurities, and adjusting pH levels in industrial and municipal water systems.Expand Specific Solutions03 Production of barium compounds

Barium hydroxide serves as a precursor in the production of various barium compounds, such as barium carbonate, barium oxide, and other barium salts. These compounds have applications in industries like ceramics, glass, and electronics.Expand Specific Solutions04 Environmental applications

Barium hydroxide finds use in environmental applications, including flue gas desulfurization, carbon dioxide capture, and soil remediation. Its ability to react with acidic compounds makes it valuable in neutralizing pollutants and improving air and soil quality.Expand Specific Solutions05 Material processing and manufacturing

In material processing and manufacturing, barium hydroxide is utilized for surface treatment, as a flux in metallurgy, and in the production of specialty materials. It contributes to improving material properties and enhancing manufacturing processes in various industries.Expand Specific Solutions

Key Industry Players and Competitors

The development of multi-functional coatings using barium hydroxide is in an emerging phase, with growing market potential due to increasing demand for advanced coating solutions across various industries. The global market for specialty coatings is expanding, driven by technological advancements and applications in automotive, construction, and electronics sectors. While the technology is still evolving, several key players are making significant strides in research and development. Companies like BASF Coatings GmbH, PPG Industries Ohio, Inc., and Shiseido Co., Ltd. are at the forefront, leveraging their expertise in chemical engineering and materials science to innovate in this field. Academic institutions such as Zhengzhou University and Harbin Institute of Technology are also contributing to the advancement of this technology through collaborative research efforts.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed a multi-functional coating system incorporating barium hydroxide for enhanced corrosion protection and adhesion properties. Their approach involves a multi-layer coating structure where barium hydroxide is integrated into the primer layer. This primer formulation utilizes the alkaline nature of barium hydroxide to create a passivating effect on metal substrates, effectively inhibiting corrosion initiation [1]. Additionally, the barium hydroxide particles act as nucleation sites for the formation of a dense, cross-linked polymer network, improving the overall adhesion and durability of the coating system [3]. The company has also explored the synergistic effects of combining barium hydroxide with other functional additives to achieve specific performance characteristics, such as self-healing properties or enhanced UV resistance [5].

Strengths: Superior corrosion protection, improved adhesion, and potential for multi-functional properties. Weaknesses: Possible environmental concerns due to barium content, and potential for increased cost compared to traditional coating systems.

J. M. Huber Corp.

Technical Solution: J. M. Huber Corp. has developed a novel approach to multi-functional coatings utilizing barium hydroxide as a key ingredient. Their technology focuses on creating a hybrid organic-inorganic coating system where barium hydroxide is chemically integrated into a silica-based network. This approach involves a sol-gel process where barium hydroxide is reacted with alkoxysilanes to form a barium silicate precursor [1]. The resulting coating exhibits excellent barrier properties due to the dense inorganic network, while the barium component provides alkaline corrosion protection [3]. Additionally, the company has incorporated functional organic moieties into the silica network, allowing for the tailoring of surface properties such as hydrophobicity or oleophobicity [5]. This versatile platform enables the development of coatings with a wide range of applications, from industrial protective coatings to functional coatings for consumer products.

Strengths: Excellent barrier properties, customizable surface characteristics, and potential for high durability. Weaknesses: Complex synthesis process may lead to higher production costs, and potential limitations in flexibility compared to purely organic systems.

Innovative Approaches in Barium Hydroxide Application

Preparation method of anti-corrosion and anti-erosion multifunctional coating

PatentActiveCN116213227A

Innovation

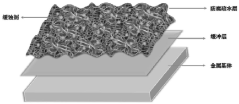

- A modified two-dimensional porous material is used to prepare a double-layer hydroxide intercalation as a corrosion inhibitor nanocontainer. The two-dimensional material is modified by biological buffer salt and dopamine, combined with the buffer layer and hot pressing method to form a super-hydrophobic and anti-scouring nanocontainer. , Anti-corrosion triple function coating.

Environmental Impact and Sustainability Considerations

The use of barium hydroxide in developing multi-functional coatings presents both environmental challenges and opportunities for sustainability. As a key component in these advanced coatings, barium hydroxide's environmental impact must be carefully considered throughout the product lifecycle.

During the production phase, the extraction and processing of barium compounds can lead to potential environmental issues. Mining activities may result in habitat disruption and soil contamination if not properly managed. Additionally, the energy-intensive nature of barium hydroxide production contributes to greenhouse gas emissions. However, advancements in cleaner production technologies and stricter regulations are helping to mitigate these impacts.

In the application of multi-functional coatings, barium hydroxide's role in enhancing durability and resistance properties can indirectly contribute to sustainability. Coatings with improved longevity reduce the frequency of reapplication, thereby decreasing overall material consumption and waste generation. This extended lifespan of coated surfaces aligns with principles of resource efficiency and circular economy.

The potential leaching of barium compounds from coatings into the environment is a concern that requires ongoing research and monitoring. While barium hydroxide itself has low solubility, the long-term behavior of barium-containing coatings under various environmental conditions needs thorough investigation to ensure minimal ecological impact.

End-of-life considerations for multi-functional coatings incorporating barium hydroxide are crucial for sustainable product design. Developing effective recycling and disposal methods for these coatings is essential to prevent the release of barium compounds into ecosystems. Innovations in coating removal techniques and material recovery processes are areas of active research to address this challenge.

From a broader sustainability perspective, the enhanced performance of multi-functional coatings enabled by barium hydroxide can contribute to energy efficiency in various applications. For instance, in building materials, these coatings can improve thermal insulation properties, potentially reducing energy consumption for heating and cooling.

As environmental regulations become more stringent, manufacturers are exploring alternatives to barium-based compounds in coating formulations. This drive towards greener chemistry is spurring innovation in eco-friendly coating technologies. However, any substitute must match or exceed the performance characteristics provided by barium hydroxide to ensure widespread adoption.

In conclusion, while barium hydroxide plays a significant role in advancing multi-functional coating technology, its environmental impact necessitates a holistic approach to sustainability. Balancing the benefits of improved coating performance with responsible production, application, and disposal practices is crucial for the long-term viability of this technology in an increasingly environmentally conscious market.

During the production phase, the extraction and processing of barium compounds can lead to potential environmental issues. Mining activities may result in habitat disruption and soil contamination if not properly managed. Additionally, the energy-intensive nature of barium hydroxide production contributes to greenhouse gas emissions. However, advancements in cleaner production technologies and stricter regulations are helping to mitigate these impacts.

In the application of multi-functional coatings, barium hydroxide's role in enhancing durability and resistance properties can indirectly contribute to sustainability. Coatings with improved longevity reduce the frequency of reapplication, thereby decreasing overall material consumption and waste generation. This extended lifespan of coated surfaces aligns with principles of resource efficiency and circular economy.

The potential leaching of barium compounds from coatings into the environment is a concern that requires ongoing research and monitoring. While barium hydroxide itself has low solubility, the long-term behavior of barium-containing coatings under various environmental conditions needs thorough investigation to ensure minimal ecological impact.

End-of-life considerations for multi-functional coatings incorporating barium hydroxide are crucial for sustainable product design. Developing effective recycling and disposal methods for these coatings is essential to prevent the release of barium compounds into ecosystems. Innovations in coating removal techniques and material recovery processes are areas of active research to address this challenge.

From a broader sustainability perspective, the enhanced performance of multi-functional coatings enabled by barium hydroxide can contribute to energy efficiency in various applications. For instance, in building materials, these coatings can improve thermal insulation properties, potentially reducing energy consumption for heating and cooling.

As environmental regulations become more stringent, manufacturers are exploring alternatives to barium-based compounds in coating formulations. This drive towards greener chemistry is spurring innovation in eco-friendly coating technologies. However, any substitute must match or exceed the performance characteristics provided by barium hydroxide to ensure widespread adoption.

In conclusion, while barium hydroxide plays a significant role in advancing multi-functional coating technology, its environmental impact necessitates a holistic approach to sustainability. Balancing the benefits of improved coating performance with responsible production, application, and disposal practices is crucial for the long-term viability of this technology in an increasingly environmentally conscious market.

Regulatory Framework for Chemical Coatings

The regulatory framework for chemical coatings plays a crucial role in ensuring the safe and responsible use of barium hydroxide in multi-functional coating development. Governments and international organizations have established comprehensive guidelines and standards to address potential health and environmental risks associated with chemical coatings.

In the United States, the Environmental Protection Agency (EPA) regulates chemical coatings under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including those used in coatings. Barium hydroxide, as a component in multi-functional coatings, falls under this regulatory purview. The EPA assesses the potential risks and may require additional testing or impose restrictions on its use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers must register chemical substances, including those used in coatings, with the European Chemicals Agency (ECHA). Barium hydroxide and its applications in multi-functional coatings are subject to these registration requirements, ensuring a thorough evaluation of their safety and environmental impact.

Occupational safety regulations also govern the use of barium hydroxide in coating applications. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for barium compounds in the workplace. Similarly, the European Agency for Safety and Health at Work (EU-OSHA) provides guidelines for handling barium-containing substances in industrial settings.

International standards, such as those developed by the International Organization for Standardization (ISO), provide guidelines for testing and evaluating chemical coatings. ISO 12944, for instance, outlines standards for corrosion protection of steel structures by protective paint systems, which may include barium hydroxide-based coatings.

The regulatory landscape also addresses environmental concerns. Many countries have implemented volatile organic compound (VOC) regulations to limit emissions from coatings. While barium hydroxide itself is not a VOC, its use in multi-functional coatings must comply with these regulations. The development of low-VOC and water-based coatings has been driven in part by these environmental regulations.

As research into barium hydroxide's role in multi-functional coatings progresses, regulatory frameworks continue to evolve. Manufacturers and researchers must stay informed about changes in regulations and ensure compliance throughout the development and application of these innovative coating technologies.

In the United States, the Environmental Protection Agency (EPA) regulates chemical coatings under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including those used in coatings. Barium hydroxide, as a component in multi-functional coatings, falls under this regulatory purview. The EPA assesses the potential risks and may require additional testing or impose restrictions on its use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers must register chemical substances, including those used in coatings, with the European Chemicals Agency (ECHA). Barium hydroxide and its applications in multi-functional coatings are subject to these registration requirements, ensuring a thorough evaluation of their safety and environmental impact.

Occupational safety regulations also govern the use of barium hydroxide in coating applications. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for barium compounds in the workplace. Similarly, the European Agency for Safety and Health at Work (EU-OSHA) provides guidelines for handling barium-containing substances in industrial settings.

International standards, such as those developed by the International Organization for Standardization (ISO), provide guidelines for testing and evaluating chemical coatings. ISO 12944, for instance, outlines standards for corrosion protection of steel structures by protective paint systems, which may include barium hydroxide-based coatings.

The regulatory landscape also addresses environmental concerns. Many countries have implemented volatile organic compound (VOC) regulations to limit emissions from coatings. While barium hydroxide itself is not a VOC, its use in multi-functional coatings must comply with these regulations. The development of low-VOC and water-based coatings has been driven in part by these environmental regulations.

As research into barium hydroxide's role in multi-functional coatings progresses, regulatory frameworks continue to evolve. Manufacturers and researchers must stay informed about changes in regulations and ensure compliance throughout the development and application of these innovative coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!