How Barium Hydroxide Assists in Smart Window Technology

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Window Tech Evolution

Smart window technology has undergone significant evolution since its inception in the 1970s. Initially, these windows relied on simple electrochromic materials that could change their optical properties when an electric current was applied. The early versions were limited in their functionality and efficiency, often suffering from slow response times and poor durability.

In the 1980s and 1990s, research focused on improving the performance of electrochromic materials. Scientists explored various metal oxides, such as tungsten oxide and nickel oxide, to enhance the color-changing capabilities and longevity of smart windows. This period also saw the introduction of suspended particle devices (SPDs) and polymer dispersed liquid crystals (PDLCs) as alternative technologies for smart glazing.

The turn of the millennium marked a significant leap in smart window technology. Researchers began investigating the potential of nanostructured materials to improve the optical and electrical properties of smart windows. This led to the development of more efficient and faster-responding electrochromic devices. Concurrently, the integration of smart windows with building management systems started gaining traction, allowing for automated control based on environmental conditions.

The 2010s witnessed a surge in the commercialization of smart window technologies. Companies like View, Inc. and SageGlass brought large-scale production of electrochromic windows to the market, making them more accessible for commercial and residential applications. This period also saw advancements in energy efficiency, with smart windows becoming an integral part of green building design strategies.

In recent years, the focus has shifted towards multifunctional smart windows. Researchers are exploring ways to combine energy-harvesting capabilities with dynamic tinting, creating windows that not only control light and heat but also generate electricity. The integration of transparent solar cells and thermoelectric materials into smart window designs represents a promising direction for future development.

The role of barium hydroxide in smart window technology emerged as a significant innovation in the late 2010s. Researchers discovered that incorporating barium hydroxide into the electrolyte layer of electrochromic devices could dramatically improve their performance. This compound enhances the stability of the electrolyte, leading to faster switching times, improved durability, and a wider range of optical modulation.

Looking ahead, the evolution of smart window technology is likely to continue along several paths. These include the development of more environmentally friendly materials, further improvements in energy efficiency, and the integration of artificial intelligence for predictive control. The ongoing research into novel materials and fabrication techniques promises to yield smart windows with even greater functionality and performance in the coming years.

In the 1980s and 1990s, research focused on improving the performance of electrochromic materials. Scientists explored various metal oxides, such as tungsten oxide and nickel oxide, to enhance the color-changing capabilities and longevity of smart windows. This period also saw the introduction of suspended particle devices (SPDs) and polymer dispersed liquid crystals (PDLCs) as alternative technologies for smart glazing.

The turn of the millennium marked a significant leap in smart window technology. Researchers began investigating the potential of nanostructured materials to improve the optical and electrical properties of smart windows. This led to the development of more efficient and faster-responding electrochromic devices. Concurrently, the integration of smart windows with building management systems started gaining traction, allowing for automated control based on environmental conditions.

The 2010s witnessed a surge in the commercialization of smart window technologies. Companies like View, Inc. and SageGlass brought large-scale production of electrochromic windows to the market, making them more accessible for commercial and residential applications. This period also saw advancements in energy efficiency, with smart windows becoming an integral part of green building design strategies.

In recent years, the focus has shifted towards multifunctional smart windows. Researchers are exploring ways to combine energy-harvesting capabilities with dynamic tinting, creating windows that not only control light and heat but also generate electricity. The integration of transparent solar cells and thermoelectric materials into smart window designs represents a promising direction for future development.

The role of barium hydroxide in smart window technology emerged as a significant innovation in the late 2010s. Researchers discovered that incorporating barium hydroxide into the electrolyte layer of electrochromic devices could dramatically improve their performance. This compound enhances the stability of the electrolyte, leading to faster switching times, improved durability, and a wider range of optical modulation.

Looking ahead, the evolution of smart window technology is likely to continue along several paths. These include the development of more environmentally friendly materials, further improvements in energy efficiency, and the integration of artificial intelligence for predictive control. The ongoing research into novel materials and fabrication techniques promises to yield smart windows with even greater functionality and performance in the coming years.

Market Demand Analysis

The market demand for smart window technology incorporating barium hydroxide is experiencing significant growth, driven by increasing awareness of energy efficiency and sustainability in building design. Smart windows, which can dynamically control light transmission and heat flow, are becoming increasingly popular in both commercial and residential sectors.

In the commercial building market, there is a strong demand for smart windows that can reduce energy consumption and improve occupant comfort. Large office buildings, hotels, and shopping centers are prime targets for this technology, as they seek to minimize cooling costs and enhance the overall user experience. The ability of barium hydroxide-assisted smart windows to regulate indoor temperature and reduce glare makes them particularly attractive for these applications.

The residential sector is also showing growing interest in smart window technology. Homeowners are increasingly looking for ways to reduce their energy bills and create more comfortable living spaces. Smart windows offer a solution that can automatically adjust to changing light conditions throughout the day, potentially leading to significant energy savings and improved home comfort.

The automotive industry represents another significant market for smart window technology. Luxury car manufacturers are exploring the integration of smart windows to enhance passenger comfort and vehicle energy efficiency. The ability to control light transmission and heat flow is particularly valuable in electric vehicles, where energy management is crucial for maximizing range.

Geographically, North America and Europe are currently the leading markets for smart window technology, with Asia-Pacific showing rapid growth potential. This is largely due to stringent energy efficiency regulations in these regions and increasing awareness of the benefits of smart building technologies.

The market for smart windows is expected to expand as the technology becomes more affordable and accessible. As production scales up and manufacturing processes improve, the cost of smart windows is likely to decrease, making them a more viable option for a broader range of applications.

Furthermore, the growing focus on green building certifications, such as LEED (Leadership in Energy and Environmental Design), is driving demand for energy-efficient building components, including smart windows. Many developers and building owners are seeking these certifications to demonstrate their commitment to sustainability and to attract environmentally conscious tenants or buyers.

In conclusion, the market demand for barium hydroxide-assisted smart window technology is robust and multifaceted, spanning various sectors and geographical regions. As energy efficiency and sustainability continue to be prioritized in construction and transportation, the demand for this innovative technology is expected to grow steadily in the coming years.

In the commercial building market, there is a strong demand for smart windows that can reduce energy consumption and improve occupant comfort. Large office buildings, hotels, and shopping centers are prime targets for this technology, as they seek to minimize cooling costs and enhance the overall user experience. The ability of barium hydroxide-assisted smart windows to regulate indoor temperature and reduce glare makes them particularly attractive for these applications.

The residential sector is also showing growing interest in smart window technology. Homeowners are increasingly looking for ways to reduce their energy bills and create more comfortable living spaces. Smart windows offer a solution that can automatically adjust to changing light conditions throughout the day, potentially leading to significant energy savings and improved home comfort.

The automotive industry represents another significant market for smart window technology. Luxury car manufacturers are exploring the integration of smart windows to enhance passenger comfort and vehicle energy efficiency. The ability to control light transmission and heat flow is particularly valuable in electric vehicles, where energy management is crucial for maximizing range.

Geographically, North America and Europe are currently the leading markets for smart window technology, with Asia-Pacific showing rapid growth potential. This is largely due to stringent energy efficiency regulations in these regions and increasing awareness of the benefits of smart building technologies.

The market for smart windows is expected to expand as the technology becomes more affordable and accessible. As production scales up and manufacturing processes improve, the cost of smart windows is likely to decrease, making them a more viable option for a broader range of applications.

Furthermore, the growing focus on green building certifications, such as LEED (Leadership in Energy and Environmental Design), is driving demand for energy-efficient building components, including smart windows. Many developers and building owners are seeking these certifications to demonstrate their commitment to sustainability and to attract environmentally conscious tenants or buyers.

In conclusion, the market demand for barium hydroxide-assisted smart window technology is robust and multifaceted, spanning various sectors and geographical regions. As energy efficiency and sustainability continue to be prioritized in construction and transportation, the demand for this innovative technology is expected to grow steadily in the coming years.

Barium Hydroxide Challenges

While barium hydroxide shows promise in smart window technology, several challenges need to be addressed for its widespread adoption and optimal performance. One of the primary concerns is the stability of barium hydroxide in various environmental conditions. Exposure to carbon dioxide in the air can lead to the formation of barium carbonate, potentially reducing the effectiveness of the smart window over time. This carbonation process may alter the optical and thermal properties of the window, compromising its ability to regulate light and heat transmission.

Another significant challenge is the potential toxicity of barium compounds. Barium hydroxide is classified as a hazardous substance, and proper handling and disposal procedures must be implemented to ensure safety throughout the manufacturing, installation, and end-of-life stages of smart windows. This necessitates the development of robust encapsulation methods to prevent any leakage or exposure during the product's lifecycle.

The integration of barium hydroxide into existing window manufacturing processes presents technical hurdles. The material's reactivity with certain substrates and sealants may require the development of new compatible materials or modification of current production techniques. Additionally, ensuring uniform distribution and consistent performance across large window surfaces remains a challenge, particularly for commercial-scale applications.

Durability and longevity of barium hydroxide-based smart windows are also areas of concern. The repeated cycling between transparent and opaque states may lead to material fatigue or degradation over time. Research is needed to improve the long-term stability and maintain consistent performance throughout the expected lifespan of the windows.

Cost-effectiveness is another hurdle to overcome. While barium hydroxide itself is relatively inexpensive, the additional processing and safety measures required may increase the overall production costs. Balancing these costs with the energy-saving benefits of smart windows is crucial for market acceptance and widespread adoption.

Lastly, the environmental impact of barium hydroxide production and disposal must be carefully considered. Sustainable sourcing of raw materials and development of recycling processes for end-of-life smart windows are essential to minimize the ecological footprint of this technology. Addressing these challenges will be critical in realizing the full potential of barium hydroxide in smart window applications and ensuring its viability as a sustainable solution for energy-efficient buildings.

Another significant challenge is the potential toxicity of barium compounds. Barium hydroxide is classified as a hazardous substance, and proper handling and disposal procedures must be implemented to ensure safety throughout the manufacturing, installation, and end-of-life stages of smart windows. This necessitates the development of robust encapsulation methods to prevent any leakage or exposure during the product's lifecycle.

The integration of barium hydroxide into existing window manufacturing processes presents technical hurdles. The material's reactivity with certain substrates and sealants may require the development of new compatible materials or modification of current production techniques. Additionally, ensuring uniform distribution and consistent performance across large window surfaces remains a challenge, particularly for commercial-scale applications.

Durability and longevity of barium hydroxide-based smart windows are also areas of concern. The repeated cycling between transparent and opaque states may lead to material fatigue or degradation over time. Research is needed to improve the long-term stability and maintain consistent performance throughout the expected lifespan of the windows.

Cost-effectiveness is another hurdle to overcome. While barium hydroxide itself is relatively inexpensive, the additional processing and safety measures required may increase the overall production costs. Balancing these costs with the energy-saving benefits of smart windows is crucial for market acceptance and widespread adoption.

Lastly, the environmental impact of barium hydroxide production and disposal must be carefully considered. Sustainable sourcing of raw materials and development of recycling processes for end-of-life smart windows are essential to minimize the ecological footprint of this technology. Addressing these challenges will be critical in realizing the full potential of barium hydroxide in smart window applications and ensuring its viability as a sustainable solution for energy-efficient buildings.

Current Barium Hydroxide Solutions

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes involve different raw materials, reaction conditions, and purification steps to obtain high-quality barium hydroxide for industrial applications.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes involve different raw materials and techniques to obtain high-quality barium hydroxide, which is used in various industrial applications.

- Use of barium hydroxide in chemical reactions: Barium hydroxide is utilized in various chemical reactions as a reagent or catalyst. It plays a role in processes such as neutralization, precipitation, and synthesis of other barium compounds.

- Applications in water treatment and environmental processes: Barium hydroxide finds applications in water treatment and environmental processes. It is used for removing impurities, adjusting pH, and in various purification techniques for industrial and municipal water systems.

- Use in the production of other barium compounds: Barium hydroxide serves as a precursor for the synthesis of other barium compounds. It is used in the manufacturing process of various barium salts and materials used in different industries.

- Industrial applications and processing techniques: Various industrial applications and processing techniques involving barium hydroxide are described. These include its use in specific manufacturing processes, as well as methods for handling, storing, and utilizing barium hydroxide in industrial settings.

02 Applications of barium hydroxide in chemical processes

Barium hydroxide is utilized in various chemical processes, including the production of other barium compounds, water treatment, and as a reagent in organic synthesis. Its alkaline properties make it suitable for neutralization reactions and pH adjustment in industrial settings.Expand Specific Solutions03 Use of barium hydroxide in material manufacturing

Barium hydroxide plays a role in the manufacturing of various materials, such as ceramics, glass, and specialty chemicals. It is used as an additive or precursor to improve material properties or facilitate specific reactions during production processes.Expand Specific Solutions04 Environmental and safety considerations for barium hydroxide

The handling, storage, and disposal of barium hydroxide require specific safety measures due to its alkaline nature and potential environmental impact. Proper containment, personal protective equipment, and waste management protocols are essential when working with this compound.Expand Specific Solutions05 Analytical methods for barium hydroxide

Various analytical techniques are employed to determine the purity, concentration, and properties of barium hydroxide. These methods include titration, spectroscopy, and chromatography, which are crucial for quality control and research purposes in industries using barium hydroxide.Expand Specific Solutions

Key Industry Players

The smart window technology market, incorporating barium hydroxide, is in a growth phase with increasing adoption across commercial and residential sectors. The market size is expanding rapidly, driven by energy efficiency demands and sustainable building trends. Technological maturity is advancing, with companies like Haier Smart Home, LG Chem, and BOE Technology Group leading innovation. These firms are developing advanced electrochromic and thermochromic solutions, improving durability and performance. Research institutions such as the National Institute for Materials Science and universities like Zhejiang University are contributing to fundamental advancements in materials science, pushing the boundaries of smart window capabilities and efficiency.

National Institute for Materials Science IAI

Technical Solution: NIMS has developed an innovative smart window technology utilizing barium hydroxide as a key component. Their approach involves incorporating barium hydroxide into a gel-like polymer matrix, which can reversibly switch between transparent and opaque states in response to electrical stimuli[1]. The barium hydroxide acts as an ion conductor, facilitating the movement of ions within the polymer matrix. When an electric field is applied, the barium ions migrate, causing a change in the optical properties of the window[3]. This technology allows for precise control over light transmission and heat regulation, making it highly suitable for energy-efficient building applications[5].

Strengths: Precise control over optical properties, energy-efficient, and potentially long-lasting. Weaknesses: May require specialized manufacturing processes and could be more expensive than traditional windows.

The Regents of the University of California

Technical Solution: The University of California has developed a smart window technology that utilizes barium hydroxide in conjunction with other materials to create a dynamic glazing system. Their approach involves a multi-layer structure where barium hydroxide is used as an electrolyte layer sandwiched between two electrochromic layers[2]. When a low voltage is applied, ions from the barium hydroxide layer move into the electrochromic layers, causing a change in their optical properties. This allows the window to switch between transparent and tinted states, effectively controlling light transmission and solar heat gain[4]. The use of barium hydroxide enhances the ion conductivity and stability of the system, leading to faster switching times and improved durability compared to other electrolytes[6].

Strengths: Fast switching times, improved durability, and effective control of light and heat. Weaknesses: Complexity of the multi-layer structure may lead to higher production costs.

Barium Hydroxide Innovations

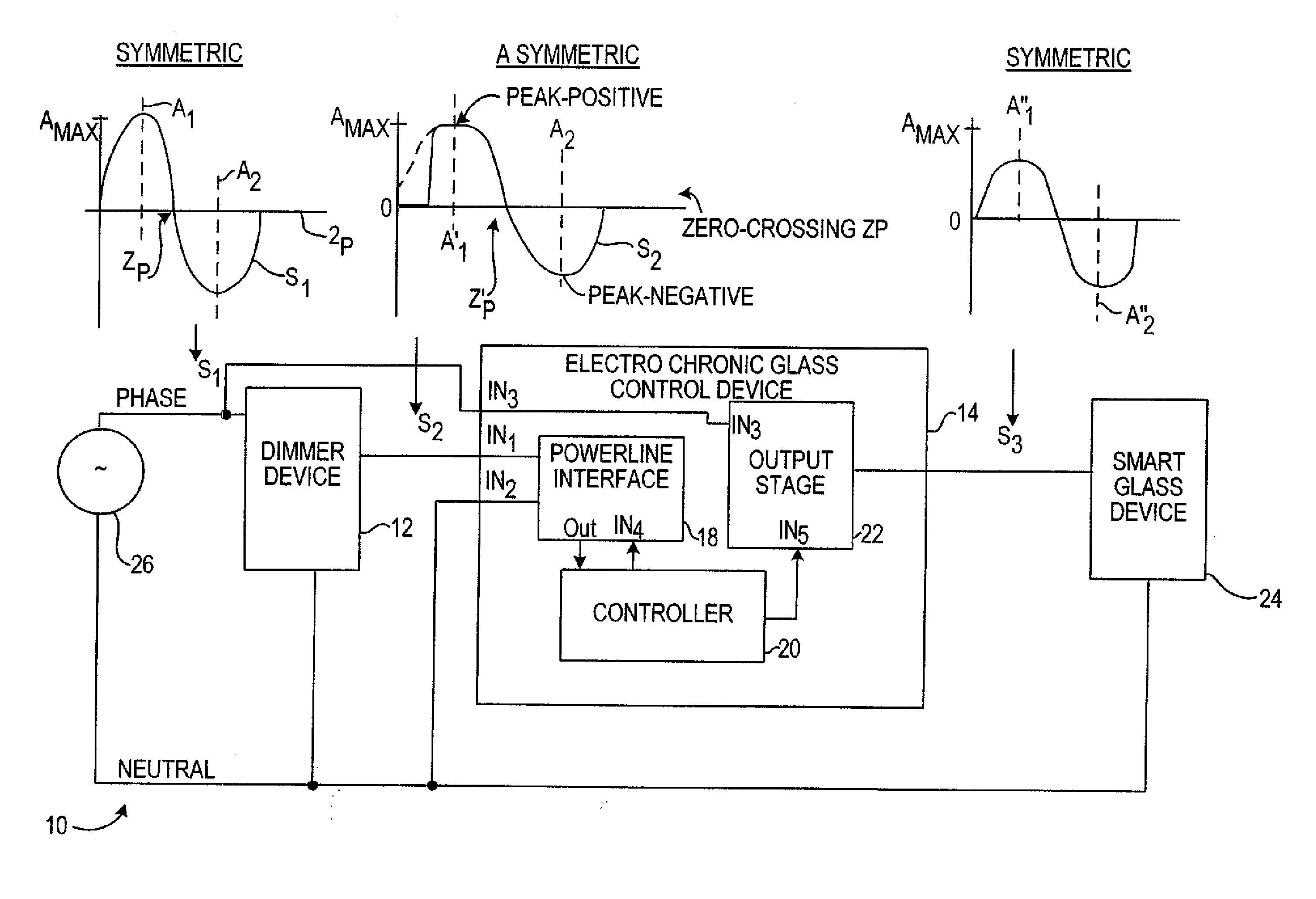

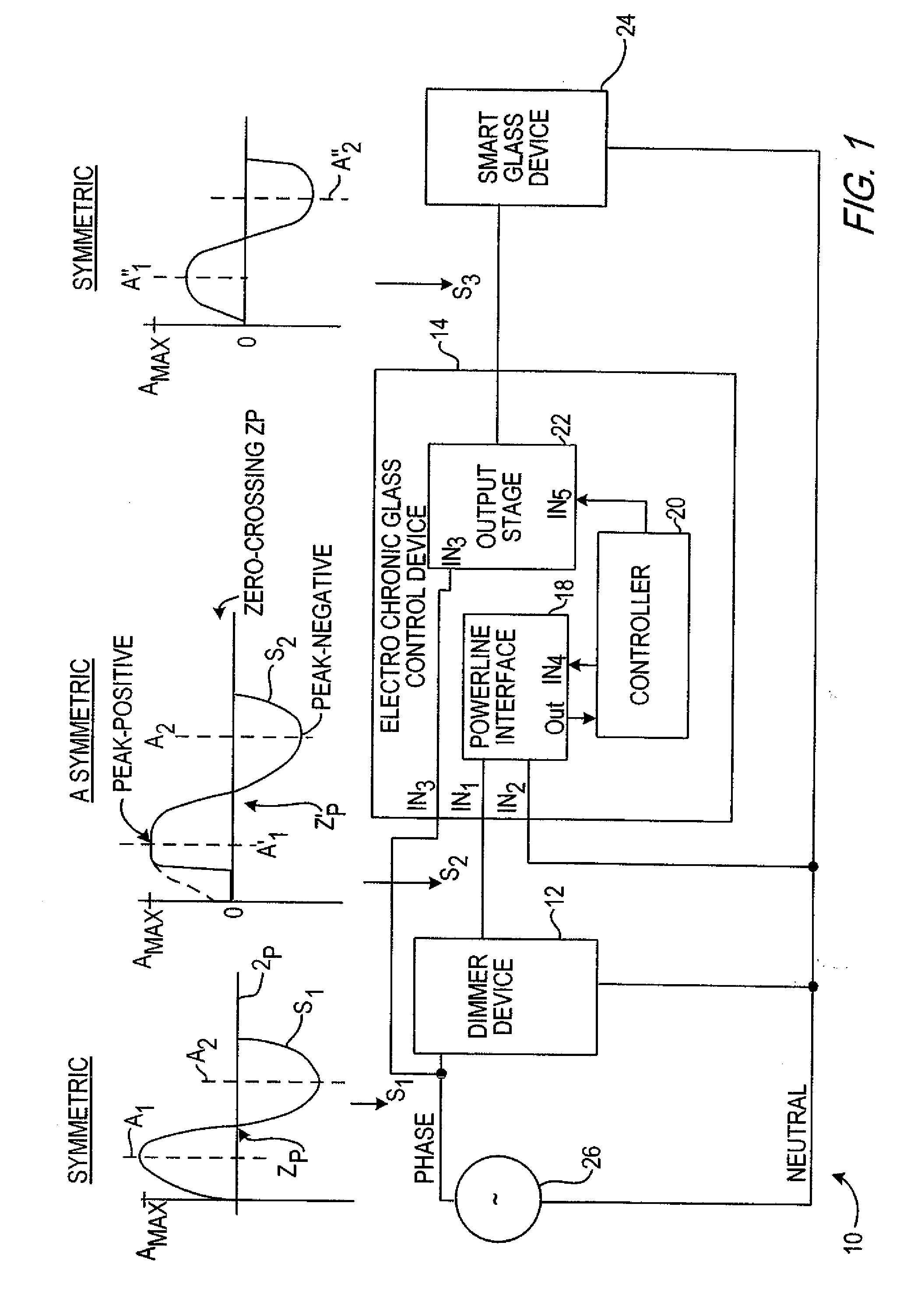

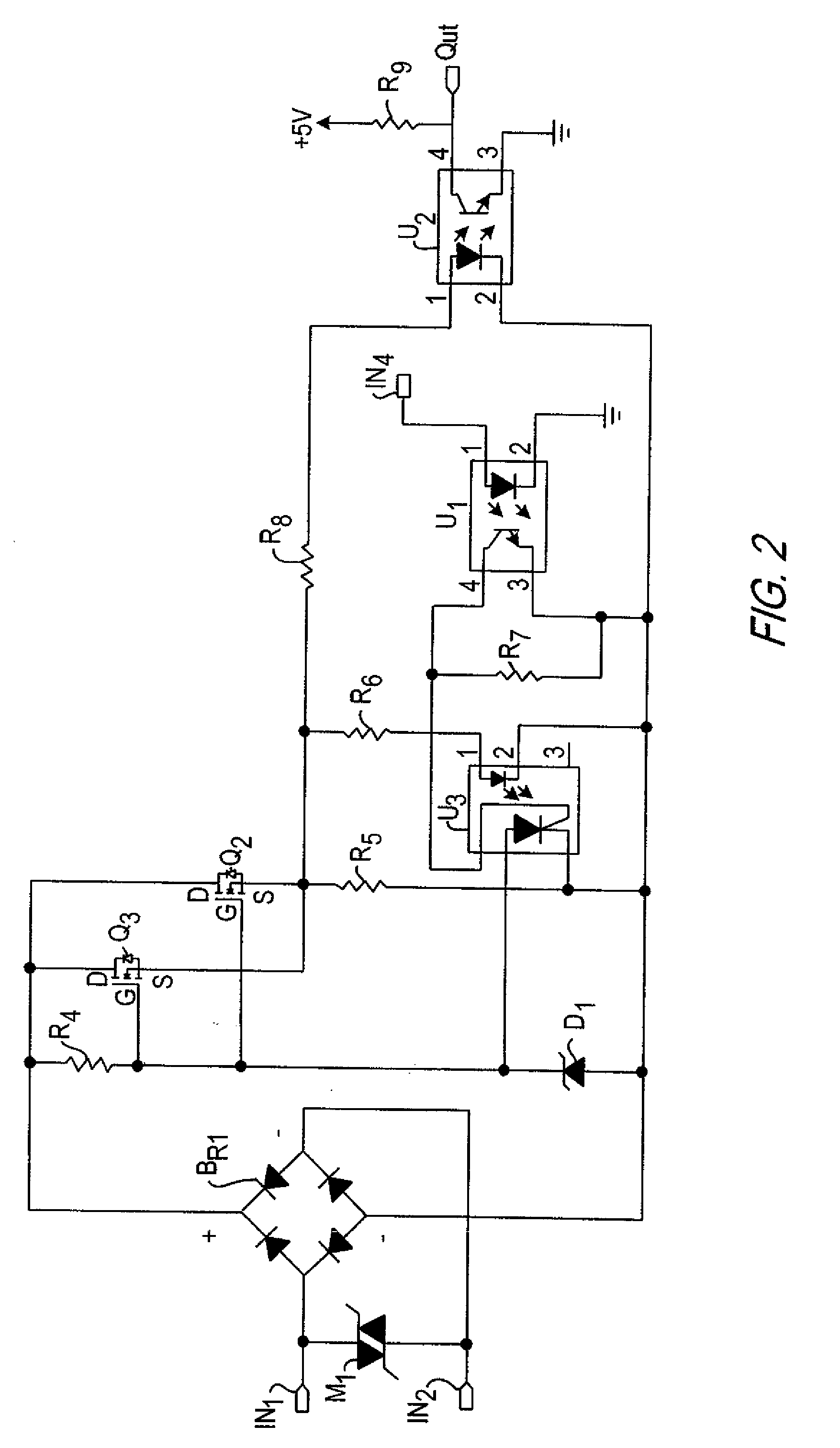

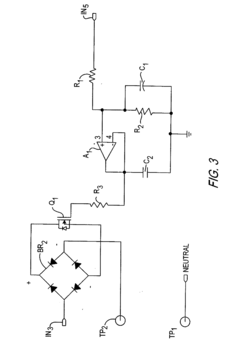

Electrochromic glass control device

PatentInactiveUS20070097484A1

Innovation

- An electrochromic glass control device that converts asymmetric AC power signals from standard dimmers into symmetric, amplitude-controlled AC signals, using a controllable semiconductor load to interface with smart-glass devices, reducing heat and chatter issues.

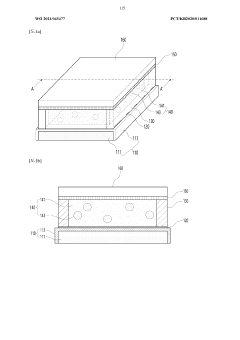

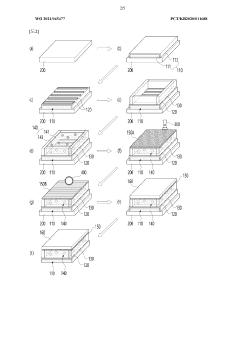

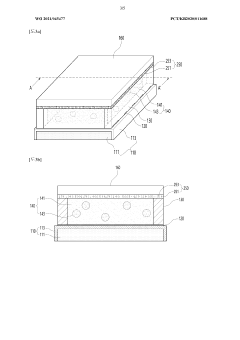

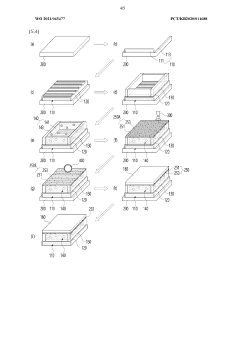

Light transmission control device, smart window having same, and manufacturing method therefor

PatentWO2021045477A1

Innovation

- A light transmission control device with a cap thickness of 0.02 to 1.1 μm, incorporating a hydrophilic photocurable composition and transparent conductive material, and a second transparent electrode that functions as an extension of the first electrode, allowing for increased flexibility and reduced driving voltage, while the hydrophilic cap is formed using UV irradiation to minimize process time.

Environmental Impact Assessment

The integration of barium hydroxide in smart window technology presents both environmental benefits and potential concerns that warrant careful consideration. On the positive side, smart windows incorporating barium hydroxide can significantly reduce energy consumption in buildings by dynamically controlling solar heat gain and visible light transmission. This leads to decreased reliance on heating, cooling, and artificial lighting systems, thereby lowering overall energy demand and associated greenhouse gas emissions.

The production process of barium hydroxide, however, requires careful environmental management. Mining and processing of barium ores can lead to soil disturbance, water pollution, and habitat disruption if not properly controlled. Manufacturers must implement stringent measures to mitigate these impacts, including dust suppression, water treatment, and land reclamation practices.

In terms of lifecycle assessment, smart windows utilizing barium hydroxide generally demonstrate a net positive environmental impact. The energy savings achieved throughout the operational life of these windows typically offset the environmental costs associated with their production and installation. However, the longevity and durability of these windows are crucial factors in determining their overall environmental footprint.

End-of-life considerations for smart windows containing barium hydroxide are an important aspect of their environmental impact. Proper recycling and disposal protocols must be established to prevent the release of barium compounds into the environment. While barium is not considered highly toxic, improper disposal could lead to soil and water contamination.

The use of barium hydroxide in smart windows may also contribute to improved indoor environmental quality. By optimizing natural light and heat transmission, these windows can enhance occupant comfort and well-being, potentially reducing the need for artificial lighting and HVAC systems that may introduce pollutants or allergens into indoor spaces.

From a broader perspective, the widespread adoption of smart window technology incorporating barium hydroxide could contribute to urban heat island mitigation. By reducing the heat absorption and reflection from building facades, these windows may help lower ambient temperatures in densely built urban areas, leading to improved microclimate conditions and reduced strain on urban ecosystems.

The production process of barium hydroxide, however, requires careful environmental management. Mining and processing of barium ores can lead to soil disturbance, water pollution, and habitat disruption if not properly controlled. Manufacturers must implement stringent measures to mitigate these impacts, including dust suppression, water treatment, and land reclamation practices.

In terms of lifecycle assessment, smart windows utilizing barium hydroxide generally demonstrate a net positive environmental impact. The energy savings achieved throughout the operational life of these windows typically offset the environmental costs associated with their production and installation. However, the longevity and durability of these windows are crucial factors in determining their overall environmental footprint.

End-of-life considerations for smart windows containing barium hydroxide are an important aspect of their environmental impact. Proper recycling and disposal protocols must be established to prevent the release of barium compounds into the environment. While barium is not considered highly toxic, improper disposal could lead to soil and water contamination.

The use of barium hydroxide in smart windows may also contribute to improved indoor environmental quality. By optimizing natural light and heat transmission, these windows can enhance occupant comfort and well-being, potentially reducing the need for artificial lighting and HVAC systems that may introduce pollutants or allergens into indoor spaces.

From a broader perspective, the widespread adoption of smart window technology incorporating barium hydroxide could contribute to urban heat island mitigation. By reducing the heat absorption and reflection from building facades, these windows may help lower ambient temperatures in densely built urban areas, leading to improved microclimate conditions and reduced strain on urban ecosystems.

Energy Efficiency Metrics

Energy efficiency metrics play a crucial role in evaluating the performance of smart window technologies, particularly those utilizing barium hydroxide. These metrics provide quantitative measures of how effectively smart windows can reduce energy consumption in buildings, thus contributing to overall sustainability goals.

One of the primary energy efficiency metrics for smart windows is the Solar Heat Gain Coefficient (SHGC). This metric measures the fraction of incident solar radiation that enters a building through the window, either by direct transmission or as absorbed heat. Smart windows incorporating barium hydroxide can dynamically adjust their SHGC, allowing for optimal control of solar heat gain based on environmental conditions and occupant preferences.

Another important metric is the U-factor, which quantifies the rate of non-solar heat transfer through the window. Lower U-factor values indicate better insulating properties. Barium hydroxide-based smart windows can potentially achieve lower U-factors in their tinted state, enhancing thermal insulation during extreme weather conditions.

Visible Light Transmission (VLT) is a metric that measures the amount of visible light passing through the window. Smart windows must balance energy efficiency with maintaining adequate natural light levels. Barium hydroxide-assisted technologies can modulate VLT effectively, optimizing both energy performance and occupant comfort.

The switching speed of smart windows is another critical energy efficiency metric. Faster switching times allow for more responsive adaptation to changing environmental conditions, maximizing energy savings. Barium hydroxide-based systems have shown promising results in achieving rapid switching speeds, contributing to improved overall energy performance.

Energy savings potential is often quantified through simulation studies and real-world pilot projects. These assessments typically measure the reduction in heating, cooling, and lighting energy consumption compared to conventional windows. Smart windows utilizing barium hydroxide have demonstrated significant energy savings, with some studies reporting reductions of up to 20-30% in total building energy consumption.

Longevity and durability are also important considerations in energy efficiency metrics. The ability of smart windows to maintain their performance over time directly impacts their long-term energy-saving potential. Barium hydroxide-based technologies have shown promising results in terms of cycle life and resistance to degradation, ensuring sustained energy efficiency benefits throughout the window's lifespan.

Finally, embodied energy and life cycle assessment (LCA) metrics are increasingly being considered in evaluating the overall energy efficiency of smart window technologies. These metrics account for the energy consumed in the production, installation, and eventual disposal of the windows. While barium hydroxide-based smart windows may have higher initial embodied energy compared to conventional windows, their long-term energy savings potential often results in a net positive impact over the building's lifetime.

One of the primary energy efficiency metrics for smart windows is the Solar Heat Gain Coefficient (SHGC). This metric measures the fraction of incident solar radiation that enters a building through the window, either by direct transmission or as absorbed heat. Smart windows incorporating barium hydroxide can dynamically adjust their SHGC, allowing for optimal control of solar heat gain based on environmental conditions and occupant preferences.

Another important metric is the U-factor, which quantifies the rate of non-solar heat transfer through the window. Lower U-factor values indicate better insulating properties. Barium hydroxide-based smart windows can potentially achieve lower U-factors in their tinted state, enhancing thermal insulation during extreme weather conditions.

Visible Light Transmission (VLT) is a metric that measures the amount of visible light passing through the window. Smart windows must balance energy efficiency with maintaining adequate natural light levels. Barium hydroxide-assisted technologies can modulate VLT effectively, optimizing both energy performance and occupant comfort.

The switching speed of smart windows is another critical energy efficiency metric. Faster switching times allow for more responsive adaptation to changing environmental conditions, maximizing energy savings. Barium hydroxide-based systems have shown promising results in achieving rapid switching speeds, contributing to improved overall energy performance.

Energy savings potential is often quantified through simulation studies and real-world pilot projects. These assessments typically measure the reduction in heating, cooling, and lighting energy consumption compared to conventional windows. Smart windows utilizing barium hydroxide have demonstrated significant energy savings, with some studies reporting reductions of up to 20-30% in total building energy consumption.

Longevity and durability are also important considerations in energy efficiency metrics. The ability of smart windows to maintain their performance over time directly impacts their long-term energy-saving potential. Barium hydroxide-based technologies have shown promising results in terms of cycle life and resistance to degradation, ensuring sustained energy efficiency benefits throughout the window's lifespan.

Finally, embodied energy and life cycle assessment (LCA) metrics are increasingly being considered in evaluating the overall energy efficiency of smart window technologies. These metrics account for the energy consumed in the production, installation, and eventual disposal of the windows. While barium hydroxide-based smart windows may have higher initial embodied energy compared to conventional windows, their long-term energy savings potential often results in a net positive impact over the building's lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!