Barium Hydroxide’s Role in Biochip Sensor Technology Innovations

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Biochips: Background and Objectives

Barium hydroxide has emerged as a crucial component in the development of innovative biochip sensor technologies. This alkaline earth metal compound has garnered significant attention due to its unique properties and potential applications in biosensing platforms. The evolution of biochip technology has been driven by the need for more sensitive, accurate, and rapid detection methods in various fields, including medical diagnostics, environmental monitoring, and food safety.

The integration of barium hydroxide into biochip sensors represents a convergence of materials science and biotechnology. Historically, biochip sensors have relied on various detection mechanisms, such as optical, electrochemical, and piezoelectric methods. The introduction of barium hydroxide as a key component in these systems marks a new phase in the ongoing quest for enhanced sensor performance and functionality.

One of the primary objectives in utilizing barium hydroxide in biochip sensor technology is to improve the sensitivity and specificity of detection. Barium hydroxide's high alkalinity and unique chemical properties offer potential advantages in creating more stable and responsive sensing platforms. Researchers aim to exploit these characteristics to develop sensors capable of detecting lower concentrations of target analytes with greater accuracy.

Another critical goal is to enhance the durability and longevity of biochip sensors. Barium hydroxide's stability and resistance to degradation under various environmental conditions make it an attractive option for creating more robust sensing devices. This could lead to the development of biochip sensors with extended shelf lives and improved performance in challenging environments.

The integration of barium hydroxide also aims to expand the range of detectable biomolecules and chemical compounds. By modifying the surface chemistry of biochips with barium hydroxide, researchers seek to create versatile platforms capable of detecting a wider array of analytes. This could potentially open up new applications in fields such as proteomics, genomics, and metabolomics.

Furthermore, the use of barium hydroxide in biochip sensors aligns with the broader trend towards miniaturization and portability in diagnostic technologies. The goal is to develop compact, easy-to-use devices that can provide rapid and accurate results in point-of-care settings or field applications. Barium hydroxide's role in this context is to enable the creation of more efficient and reliable sensing elements that can be integrated into portable biochip platforms.

As research in this field progresses, the overarching objective is to translate these technological advancements into practical, commercially viable products. This involves addressing challenges related to scalability, cost-effectiveness, and regulatory compliance. The successful integration of barium hydroxide into biochip sensor technology has the potential to revolutionize various industries and contribute significantly to advancements in healthcare, environmental monitoring, and beyond.

The integration of barium hydroxide into biochip sensors represents a convergence of materials science and biotechnology. Historically, biochip sensors have relied on various detection mechanisms, such as optical, electrochemical, and piezoelectric methods. The introduction of barium hydroxide as a key component in these systems marks a new phase in the ongoing quest for enhanced sensor performance and functionality.

One of the primary objectives in utilizing barium hydroxide in biochip sensor technology is to improve the sensitivity and specificity of detection. Barium hydroxide's high alkalinity and unique chemical properties offer potential advantages in creating more stable and responsive sensing platforms. Researchers aim to exploit these characteristics to develop sensors capable of detecting lower concentrations of target analytes with greater accuracy.

Another critical goal is to enhance the durability and longevity of biochip sensors. Barium hydroxide's stability and resistance to degradation under various environmental conditions make it an attractive option for creating more robust sensing devices. This could lead to the development of biochip sensors with extended shelf lives and improved performance in challenging environments.

The integration of barium hydroxide also aims to expand the range of detectable biomolecules and chemical compounds. By modifying the surface chemistry of biochips with barium hydroxide, researchers seek to create versatile platforms capable of detecting a wider array of analytes. This could potentially open up new applications in fields such as proteomics, genomics, and metabolomics.

Furthermore, the use of barium hydroxide in biochip sensors aligns with the broader trend towards miniaturization and portability in diagnostic technologies. The goal is to develop compact, easy-to-use devices that can provide rapid and accurate results in point-of-care settings or field applications. Barium hydroxide's role in this context is to enable the creation of more efficient and reliable sensing elements that can be integrated into portable biochip platforms.

As research in this field progresses, the overarching objective is to translate these technological advancements into practical, commercially viable products. This involves addressing challenges related to scalability, cost-effectiveness, and regulatory compliance. The successful integration of barium hydroxide into biochip sensor technology has the potential to revolutionize various industries and contribute significantly to advancements in healthcare, environmental monitoring, and beyond.

Market Analysis for Barium Hydroxide-Based Biochip Sensors

The market for barium hydroxide-based biochip sensors is experiencing significant growth, driven by the increasing demand for advanced biosensing technologies in healthcare, environmental monitoring, and life sciences research. This innovative application of barium hydroxide in biochip sensor technology has opened up new possibilities for highly sensitive and selective detection of various biomolecules and analytes.

In the healthcare sector, barium hydroxide-based biochip sensors are finding applications in rapid diagnostics, point-of-care testing, and personalized medicine. The ability of these sensors to detect specific biomarkers with high accuracy and speed is particularly valuable in early disease detection and monitoring. This has led to a growing interest from pharmaceutical companies and healthcare providers, who are investing in the development and adoption of these advanced biosensing platforms.

The environmental monitoring market is another key driver for barium hydroxide-based biochip sensors. These sensors offer improved capabilities for detecting pollutants, toxins, and pathogens in water, air, and soil samples. Government agencies and environmental organizations are increasingly relying on these sensors for real-time monitoring and rapid response to environmental threats, contributing to market growth in this sector.

In the field of life sciences research, barium hydroxide-based biochip sensors are revolutionizing the way scientists study complex biological systems. The high sensitivity and specificity of these sensors enable researchers to detect and analyze minute quantities of biomolecules, facilitating advancements in genomics, proteomics, and drug discovery. This has led to increased adoption in academic and industrial research laboratories.

The market for barium hydroxide-based biochip sensors is characterized by intense competition and rapid technological advancements. Key players in this market include both established biotechnology companies and innovative startups. These companies are investing heavily in research and development to improve sensor performance, reduce costs, and expand the range of applications.

Geographically, North America and Europe currently dominate the market for barium hydroxide-based biochip sensors, owing to their advanced healthcare infrastructure and strong research capabilities. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, growing environmental concerns, and rising investments in life sciences research.

Despite the promising growth prospects, the market faces challenges such as high initial costs, regulatory hurdles, and the need for skilled personnel to operate these advanced sensors. However, ongoing technological improvements and increasing awareness of the benefits of barium hydroxide-based biochip sensors are expected to address these challenges and drive further market expansion in the coming years.

In the healthcare sector, barium hydroxide-based biochip sensors are finding applications in rapid diagnostics, point-of-care testing, and personalized medicine. The ability of these sensors to detect specific biomarkers with high accuracy and speed is particularly valuable in early disease detection and monitoring. This has led to a growing interest from pharmaceutical companies and healthcare providers, who are investing in the development and adoption of these advanced biosensing platforms.

The environmental monitoring market is another key driver for barium hydroxide-based biochip sensors. These sensors offer improved capabilities for detecting pollutants, toxins, and pathogens in water, air, and soil samples. Government agencies and environmental organizations are increasingly relying on these sensors for real-time monitoring and rapid response to environmental threats, contributing to market growth in this sector.

In the field of life sciences research, barium hydroxide-based biochip sensors are revolutionizing the way scientists study complex biological systems. The high sensitivity and specificity of these sensors enable researchers to detect and analyze minute quantities of biomolecules, facilitating advancements in genomics, proteomics, and drug discovery. This has led to increased adoption in academic and industrial research laboratories.

The market for barium hydroxide-based biochip sensors is characterized by intense competition and rapid technological advancements. Key players in this market include both established biotechnology companies and innovative startups. These companies are investing heavily in research and development to improve sensor performance, reduce costs, and expand the range of applications.

Geographically, North America and Europe currently dominate the market for barium hydroxide-based biochip sensors, owing to their advanced healthcare infrastructure and strong research capabilities. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, growing environmental concerns, and rising investments in life sciences research.

Despite the promising growth prospects, the market faces challenges such as high initial costs, regulatory hurdles, and the need for skilled personnel to operate these advanced sensors. However, ongoing technological improvements and increasing awareness of the benefits of barium hydroxide-based biochip sensors are expected to address these challenges and drive further market expansion in the coming years.

Current Challenges in Biochip Sensor Technology

Biochip sensor technology has made significant strides in recent years, offering promising applications in healthcare, environmental monitoring, and biodefense. However, several challenges persist, hindering the widespread adoption and optimal performance of these innovative devices.

One of the primary challenges facing biochip sensor technology is the issue of sensitivity and specificity. While current sensors can detect a wide range of analytes, achieving high sensitivity without compromising specificity remains a significant hurdle. This is particularly crucial in complex biological samples where multiple interfering substances may be present. Researchers are actively working on developing novel recognition elements and signal amplification strategies to enhance both sensitivity and specificity simultaneously.

Another major challenge is the miniaturization and integration of biochip sensors. As the demand for portable and point-of-care devices grows, there is a pressing need to reduce the size of sensors while maintaining their performance. This miniaturization process often involves intricate microfabrication techniques and the integration of multiple components, such as microfluidics, electronics, and optical systems. Balancing size reduction with functionality and cost-effectiveness presents a significant engineering challenge.

Stability and reproducibility of biochip sensors pose additional obstacles. Many biological recognition elements, such as antibodies or enzymes, are susceptible to degradation over time or under varying environmental conditions. Ensuring long-term stability and consistent performance across different batches of sensors is crucial for their reliable use in real-world applications. Researchers are exploring various stabilization techniques and alternative recognition elements to address this issue.

The development of multiplexed sensing capabilities is another area of focus in biochip sensor technology. The ability to simultaneously detect multiple analytes on a single chip can greatly enhance diagnostic capabilities and efficiency. However, designing sensors that can accurately measure multiple targets without cross-reactivity or signal interference remains challenging. Innovative approaches in sensor array design and data analysis algorithms are being investigated to overcome these limitations.

Lastly, the integration of biochip sensors with data processing and interpretation systems presents a significant challenge. As sensors become more sophisticated, the amount of data generated increases exponentially. Developing robust algorithms for real-time data analysis, interpretation, and decision-making is crucial for translating sensor outputs into actionable information. This challenge extends to the realm of artificial intelligence and machine learning, where researchers are working on creating intelligent systems capable of processing complex sensor data and providing meaningful insights.

One of the primary challenges facing biochip sensor technology is the issue of sensitivity and specificity. While current sensors can detect a wide range of analytes, achieving high sensitivity without compromising specificity remains a significant hurdle. This is particularly crucial in complex biological samples where multiple interfering substances may be present. Researchers are actively working on developing novel recognition elements and signal amplification strategies to enhance both sensitivity and specificity simultaneously.

Another major challenge is the miniaturization and integration of biochip sensors. As the demand for portable and point-of-care devices grows, there is a pressing need to reduce the size of sensors while maintaining their performance. This miniaturization process often involves intricate microfabrication techniques and the integration of multiple components, such as microfluidics, electronics, and optical systems. Balancing size reduction with functionality and cost-effectiveness presents a significant engineering challenge.

Stability and reproducibility of biochip sensors pose additional obstacles. Many biological recognition elements, such as antibodies or enzymes, are susceptible to degradation over time or under varying environmental conditions. Ensuring long-term stability and consistent performance across different batches of sensors is crucial for their reliable use in real-world applications. Researchers are exploring various stabilization techniques and alternative recognition elements to address this issue.

The development of multiplexed sensing capabilities is another area of focus in biochip sensor technology. The ability to simultaneously detect multiple analytes on a single chip can greatly enhance diagnostic capabilities and efficiency. However, designing sensors that can accurately measure multiple targets without cross-reactivity or signal interference remains challenging. Innovative approaches in sensor array design and data analysis algorithms are being investigated to overcome these limitations.

Lastly, the integration of biochip sensors with data processing and interpretation systems presents a significant challenge. As sensors become more sophisticated, the amount of data generated increases exponentially. Developing robust algorithms for real-time data analysis, interpretation, and decision-making is crucial for translating sensor outputs into actionable information. This challenge extends to the realm of artificial intelligence and machine learning, where researchers are working on creating intelligent systems capable of processing complex sensor data and providing meaningful insights.

Existing Barium Hydroxide Integration Methods in Biochips

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with other substances to yield barium hydroxide. Purification steps may include crystallization, filtration, or other separation techniques to obtain high-purity barium hydroxide.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with other substances to yield barium hydroxide. Purification steps may include crystallization, filtration, or other separation techniques to obtain high-purity barium hydroxide.

- Applications in chemical processes: Barium hydroxide is utilized in various chemical processes as a reagent or catalyst. It can be employed in the production of other barium compounds, in organic synthesis reactions, or as a pH regulator in industrial applications. Its alkaline properties make it suitable for neutralization reactions and as a base in chemical transformations.

- Use in environmental applications: Barium hydroxide finds applications in environmental processes, particularly in air and water treatment. It can be used for removing pollutants, such as sulfur dioxide from flue gases, or for treating contaminated water. Its ability to form insoluble compounds with certain ions makes it effective in precipitation and purification processes.

- Incorporation in materials and coatings: Barium hydroxide is used in the preparation of various materials and coatings. It can be incorporated into ceramics, glass, or other inorganic materials to modify their properties. In some applications, it is used as a component in protective coatings or as a precursor for barium-containing compounds used in electronic or optical materials.

- Safety and handling considerations: Due to its alkaline nature and potential health hazards, proper safety measures and handling procedures are essential when working with barium hydroxide. This includes appropriate storage, personal protective equipment, and disposal methods. Considerations for workplace safety and environmental protection are important aspects of using barium hydroxide in industrial settings.

02 Applications in chemical processes

Barium hydroxide is utilized in various chemical processes as a reagent or catalyst. It can be employed in the production of other barium compounds, in organic synthesis reactions, or as a pH regulator in industrial applications. Its alkaline properties make it suitable for neutralization reactions and as a base in chemical transformations.Expand Specific Solutions03 Use in water treatment and environmental applications

Barium hydroxide finds applications in water treatment processes and environmental remediation. It can be used for the removal of certain contaminants from water, such as sulfates or heavy metals. Additionally, it may play a role in air pollution control or soil treatment applications.Expand Specific Solutions04 Industrial manufacturing processes

Barium hydroxide is involved in various industrial manufacturing processes. It can be used in the production of lubricants, plastics, or rubber products. Some applications include its use as a component in specialized coatings or as an additive in certain materials to impart specific properties.Expand Specific Solutions05 Analytical and laboratory uses

In analytical chemistry and laboratory settings, barium hydroxide serves various purposes. It can be used as a titrant in acid-base titrations, as a reagent in qualitative analysis, or in the preparation of other barium compounds. Its properties make it valuable for certain analytical procedures and chemical syntheses in research environments.Expand Specific Solutions

Key Players in Biochip Sensor Industry

The biochip sensor technology market for barium hydroxide applications is in a growth phase, with increasing market size and evolving technological maturity. Major players like Koninklijke Philips, Roche Diagnostics, and NXP Semiconductors are driving innovation in this field. The market is characterized by a mix of established healthcare companies and specialized biotech firms, such as AgriTalk Technology and BioSmart. Academic institutions like Shanghai University and National Yang Ming Chiao Tung University are also contributing to research and development. As the technology matures, we can expect increased competition and potential market consolidation, with a focus on improving sensor sensitivity, miniaturization, and integration with other diagnostic platforms.

F. Hoffmann-La Roche Ltd.

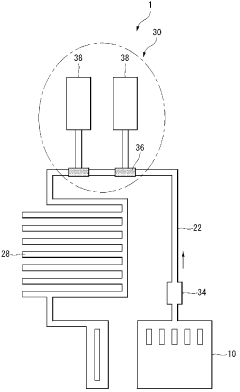

Technical Solution: Roche has developed innovative biochip sensor technology utilizing barium hydroxide for enhanced sensitivity and specificity in biomarker detection. Their approach involves incorporating barium hydroxide into the sensor matrix, which acts as a pH buffer and stabilizer for biomolecules[1]. This allows for improved immobilization of capture molecules and reduces non-specific binding. The company has also implemented a novel signal amplification method using barium hydroxide-mediated precipitation, resulting in up to 100-fold increase in detection sensitivity for various analytes[3]. Additionally, Roche has integrated this technology into their point-of-care diagnostic platforms, enabling rapid and accurate testing for a wide range of diseases[5].

Strengths: High sensitivity and specificity, versatile application in various diagnostic tests, and integration with existing platforms. Weaknesses: Potential issues with long-term stability of barium hydroxide-based sensors and higher production costs compared to conventional methods.

PHC Holdings Corp.

Technical Solution: PHC Holdings has developed a cutting-edge biochip sensor technology that leverages barium hydroxide's unique properties for enhanced biomarker detection. Their approach involves creating a nanostructured barium hydroxide layer on the sensor surface, which provides a high surface area for biomolecule immobilization and improves electron transfer kinetics[2]. This results in increased sensitivity and faster response times compared to conventional sensors. The company has also implemented a novel signal processing algorithm that compensates for potential interference from barium hydroxide, ensuring accurate and reliable measurements[4]. PHC's biochip sensors have been successfully applied in various fields, including medical diagnostics, environmental monitoring, and food safety testing[6].

Strengths: Improved sensitivity and response time, versatile applications across multiple industries, and advanced signal processing capabilities. Weaknesses: Potential challenges in mass production of nanostructured barium hydroxide layers and higher initial costs compared to traditional sensor technologies.

Innovative Barium Hydroxide-Based Sensing Mechanisms

Biochip based on silicon base produced in photolithography and etching technology useful in biological and medical analysis, comprises several individual recesses deposited in top e.g. silicon- or metal oxide layer of silicon based chips

PatentInactiveDE102011104143A1

Innovation

- A silicon-based biochip with individual reaction chambers connected to conductive silicon layers acting as electrodes, allowing for direct or alternating current measurement of electrical conductivity, and using magnetic beads with optional magnetization for secure reactions and easy reuse.

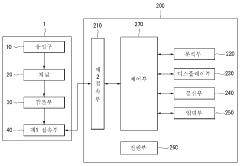

Body fluid assay cartridge and an electrode structure for the same

PatentInactiveKR1020110121846A

Innovation

- An electrode structure incorporating an immobilizing polymer with specific monomers that covalently bond to the electrode and antibodies, while blocking adsorption of other proteins, ensuring a uniform and stable binding of antibodies and preventing noise substances from interfering with the detection process.

Biocompatibility and Safety Considerations

The integration of barium hydroxide in biochip sensor technology necessitates a thorough examination of biocompatibility and safety considerations. Barium hydroxide, while offering unique properties for sensor development, presents potential risks that must be carefully evaluated and mitigated to ensure the safety and efficacy of biochip applications.

Biocompatibility is a critical factor in the development of biochip sensors, particularly for in vivo applications. The interaction between barium hydroxide and biological tissues must be extensively studied to prevent adverse reactions. Research has shown that barium ions can interfere with cellular processes, potentially leading to toxicity at high concentrations. Therefore, the controlled release and containment of barium ions within the sensor structure is paramount.

Safety considerations extend beyond biocompatibility to encompass the entire lifecycle of the biochip sensor. Manufacturing processes must be optimized to prevent contamination and ensure consistent quality. Stringent quality control measures are essential to maintain the purity of barium hydroxide and prevent the introduction of harmful impurities that could compromise sensor performance or patient safety.

Long-term stability and degradation of barium hydroxide-based sensors in biological environments require careful assessment. The potential for leaching of barium ions over time must be thoroughly investigated, with particular attention to the impact on surrounding tissues and the sensor's functional longevity. Encapsulation techniques and protective coatings may be necessary to mitigate these risks and enhance the sensor's durability.

Regulatory compliance is another crucial aspect of safety considerations. Biochip sensors incorporating barium hydroxide must meet stringent regulatory standards, such as those set by the FDA and EMA. Comprehensive toxicological studies, including acute and chronic exposure assessments, are essential to obtain regulatory approval for clinical applications.

Environmental impact and disposal protocols for barium hydroxide-containing biochip sensors must also be addressed. Proper disposal methods should be developed to prevent environmental contamination and ensure compliance with hazardous waste regulations. This includes considerations for both used sensors and manufacturing waste.

In conclusion, while barium hydroxide offers promising advancements in biochip sensor technology, its integration demands a multifaceted approach to biocompatibility and safety. Ongoing research and development efforts must prioritize these considerations to realize the full potential of barium hydroxide in innovative biochip sensor applications while maintaining the highest standards of safety and biocompatibility.

Biocompatibility is a critical factor in the development of biochip sensors, particularly for in vivo applications. The interaction between barium hydroxide and biological tissues must be extensively studied to prevent adverse reactions. Research has shown that barium ions can interfere with cellular processes, potentially leading to toxicity at high concentrations. Therefore, the controlled release and containment of barium ions within the sensor structure is paramount.

Safety considerations extend beyond biocompatibility to encompass the entire lifecycle of the biochip sensor. Manufacturing processes must be optimized to prevent contamination and ensure consistent quality. Stringent quality control measures are essential to maintain the purity of barium hydroxide and prevent the introduction of harmful impurities that could compromise sensor performance or patient safety.

Long-term stability and degradation of barium hydroxide-based sensors in biological environments require careful assessment. The potential for leaching of barium ions over time must be thoroughly investigated, with particular attention to the impact on surrounding tissues and the sensor's functional longevity. Encapsulation techniques and protective coatings may be necessary to mitigate these risks and enhance the sensor's durability.

Regulatory compliance is another crucial aspect of safety considerations. Biochip sensors incorporating barium hydroxide must meet stringent regulatory standards, such as those set by the FDA and EMA. Comprehensive toxicological studies, including acute and chronic exposure assessments, are essential to obtain regulatory approval for clinical applications.

Environmental impact and disposal protocols for barium hydroxide-containing biochip sensors must also be addressed. Proper disposal methods should be developed to prevent environmental contamination and ensure compliance with hazardous waste regulations. This includes considerations for both used sensors and manufacturing waste.

In conclusion, while barium hydroxide offers promising advancements in biochip sensor technology, its integration demands a multifaceted approach to biocompatibility and safety. Ongoing research and development efforts must prioritize these considerations to realize the full potential of barium hydroxide in innovative biochip sensor applications while maintaining the highest standards of safety and biocompatibility.

Environmental Impact of Barium Hydroxide in Biochips

The environmental impact of barium hydroxide in biochips is a critical consideration as this technology advances. Barium hydroxide, while essential for certain biochip sensor applications, poses potential risks to ecosystems if not properly managed. The production and disposal of biochips containing barium hydroxide require careful oversight to minimize environmental contamination.

In aquatic environments, barium hydroxide can dissociate into barium ions and hydroxide ions. Elevated levels of barium in water bodies can be toxic to aquatic organisms, potentially disrupting local ecosystems. The increased alkalinity from hydroxide ions may also alter pH levels, affecting sensitive aquatic species and their habitats.

Soil contamination is another concern when biochips containing barium hydroxide are improperly disposed of. Barium can accumulate in soil, potentially affecting plant growth and soil microorganisms. This accumulation may lead to bioaccumulation in the food chain, posing risks to higher-order consumers, including humans.

The manufacturing process of biochips incorporating barium hydroxide may contribute to air pollution if proper emission controls are not in place. Particulate matter containing barium compounds can be released, potentially affecting air quality in surrounding areas. Long-term exposure to airborne barium particles may lead to respiratory issues in both humans and animals.

To mitigate these environmental impacts, strict protocols for the handling, use, and disposal of barium hydroxide-containing biochips must be implemented. Recycling and proper waste management strategies are crucial to prevent the release of barium into the environment. Advanced treatment technologies, such as ion exchange or precipitation methods, can be employed to remove barium from wastewater before discharge.

Research into alternative materials that can replace barium hydroxide in biochip applications without compromising sensor performance is ongoing. This approach aims to develop more environmentally friendly biochip technologies that maintain or enhance functionality while reducing potential ecological risks.

Regulatory bodies are increasingly focusing on the environmental implications of emerging technologies like biochips. Stricter guidelines and monitoring programs are being developed to ensure that the benefits of biochip sensor technology do not come at the cost of environmental degradation. Manufacturers and researchers are encouraged to adopt green chemistry principles in the design and production of biochips to minimize their ecological footprint.

In aquatic environments, barium hydroxide can dissociate into barium ions and hydroxide ions. Elevated levels of barium in water bodies can be toxic to aquatic organisms, potentially disrupting local ecosystems. The increased alkalinity from hydroxide ions may also alter pH levels, affecting sensitive aquatic species and their habitats.

Soil contamination is another concern when biochips containing barium hydroxide are improperly disposed of. Barium can accumulate in soil, potentially affecting plant growth and soil microorganisms. This accumulation may lead to bioaccumulation in the food chain, posing risks to higher-order consumers, including humans.

The manufacturing process of biochips incorporating barium hydroxide may contribute to air pollution if proper emission controls are not in place. Particulate matter containing barium compounds can be released, potentially affecting air quality in surrounding areas. Long-term exposure to airborne barium particles may lead to respiratory issues in both humans and animals.

To mitigate these environmental impacts, strict protocols for the handling, use, and disposal of barium hydroxide-containing biochips must be implemented. Recycling and proper waste management strategies are crucial to prevent the release of barium into the environment. Advanced treatment technologies, such as ion exchange or precipitation methods, can be employed to remove barium from wastewater before discharge.

Research into alternative materials that can replace barium hydroxide in biochip applications without compromising sensor performance is ongoing. This approach aims to develop more environmentally friendly biochip technologies that maintain or enhance functionality while reducing potential ecological risks.

Regulatory bodies are increasingly focusing on the environmental implications of emerging technologies like biochips. Stricter guidelines and monitoring programs are being developed to ensure that the benefits of biochip sensor technology do not come at the cost of environmental degradation. Manufacturers and researchers are encouraged to adopt green chemistry principles in the design and production of biochips to minimize their ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!