Barium Hydroxide’s Integration into High-Performance Photovoltaic Devices

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide PV Integration Background

Barium hydroxide has emerged as a promising material for integration into high-performance photovoltaic devices, marking a significant advancement in solar energy technology. The exploration of this compound in the context of photovoltaics stems from the ongoing quest for more efficient and cost-effective solar cells. Historically, the development of photovoltaic technology has been characterized by a continuous search for materials that can enhance light absorption, charge separation, and overall energy conversion efficiency.

The integration of barium hydroxide into photovoltaic devices represents a novel approach to addressing some of the persistent challenges in solar cell technology. This compound, with its unique chemical and physical properties, has shown potential to improve various aspects of solar cell performance. The interest in barium hydroxide is part of a broader trend in the photovoltaic industry towards exploring unconventional materials and innovative device architectures to push the boundaries of solar cell efficiency.

The background of this technological development is rooted in the limitations of traditional silicon-based solar cells and the need for alternative materials that can overcome these constraints. Researchers have been investigating a wide range of compounds, including perovskites, quantum dots, and various metal oxides, to enhance the performance of photovoltaic devices. Barium hydroxide's integration into this field represents a convergence of materials science, chemistry, and photovoltaic engineering.

The motivation behind incorporating barium hydroxide into photovoltaic devices is multifaceted. It is driven by the potential to improve key performance metrics such as power conversion efficiency, stability, and manufacturability. Additionally, there is a growing emphasis on developing environmentally friendly and sustainable solar technologies, which has led to increased interest in materials that can be produced and utilized with minimal environmental impact.

As the global demand for renewable energy continues to rise, the pressure to develop more efficient and cost-effective solar technologies intensifies. The integration of barium hydroxide into high-performance photovoltaic devices is a response to this demand, aiming to contribute to the broader goal of making solar energy a more viable and widespread alternative to fossil fuels. This technological direction aligns with international efforts to mitigate climate change and transition towards cleaner energy sources.

The integration of barium hydroxide into photovoltaic devices represents a novel approach to addressing some of the persistent challenges in solar cell technology. This compound, with its unique chemical and physical properties, has shown potential to improve various aspects of solar cell performance. The interest in barium hydroxide is part of a broader trend in the photovoltaic industry towards exploring unconventional materials and innovative device architectures to push the boundaries of solar cell efficiency.

The background of this technological development is rooted in the limitations of traditional silicon-based solar cells and the need for alternative materials that can overcome these constraints. Researchers have been investigating a wide range of compounds, including perovskites, quantum dots, and various metal oxides, to enhance the performance of photovoltaic devices. Barium hydroxide's integration into this field represents a convergence of materials science, chemistry, and photovoltaic engineering.

The motivation behind incorporating barium hydroxide into photovoltaic devices is multifaceted. It is driven by the potential to improve key performance metrics such as power conversion efficiency, stability, and manufacturability. Additionally, there is a growing emphasis on developing environmentally friendly and sustainable solar technologies, which has led to increased interest in materials that can be produced and utilized with minimal environmental impact.

As the global demand for renewable energy continues to rise, the pressure to develop more efficient and cost-effective solar technologies intensifies. The integration of barium hydroxide into high-performance photovoltaic devices is a response to this demand, aiming to contribute to the broader goal of making solar energy a more viable and widespread alternative to fossil fuels. This technological direction aligns with international efforts to mitigate climate change and transition towards cleaner energy sources.

Market Analysis for Ba(OH)2 Enhanced Solar Cells

The integration of barium hydroxide (Ba(OH)2) into high-performance photovoltaic devices represents a significant advancement in solar cell technology, with substantial market implications. The global solar energy market has been experiencing robust growth, driven by increasing environmental concerns and the push for renewable energy sources. As of 2023, the solar photovoltaic market was valued at approximately $170 billion, with projections indicating continued expansion.

The introduction of Ba(OH)2 enhanced solar cells addresses several key market demands. Firstly, there is a growing need for higher efficiency photovoltaic devices to maximize energy output from limited space. Ba(OH)2 integration has shown potential to increase solar cell efficiency by several percentage points, which translates to significant improvements in power generation capacity.

Cost-effectiveness is another crucial factor driving market demand. While traditional high-performance solar cells often come with premium price tags, Ba(OH)2 enhanced cells offer the promise of improved efficiency without substantially increasing production costs. This balance of performance and affordability is particularly attractive to both residential and commercial consumers looking to optimize their return on investment in solar technology.

Durability and longevity of solar panels are also key considerations for consumers. Ba(OH)2 integration has demonstrated potential to enhance the stability of perovskite solar cells, addressing one of the major challenges in commercializing this promising technology. Improved stability translates to longer-lasting solar panels, reducing replacement costs and improving the overall value proposition for end-users.

Market analysis indicates that the demand for Ba(OH)2 enhanced solar cells is likely to be particularly strong in regions with high solar irradiance and ambitious renewable energy targets. Countries in the Middle East, North Africa, and parts of Asia and Australia are prime candidates for early adoption. Additionally, developed markets in Europe and North America, where there is a strong focus on technological innovation and sustainability, are expected to show significant interest in this advanced solar technology.

The commercial and utility-scale solar sectors are projected to be the primary drivers of demand for Ba(OH)2 enhanced solar cells. These sectors prioritize efficiency and long-term performance, making them ideal markets for this technology. However, as production scales up and costs decrease, the residential sector is also expected to become a significant market segment for these advanced solar cells.

In conclusion, the market potential for Ba(OH)2 enhanced solar cells is substantial, driven by the global push for more efficient, cost-effective, and durable photovoltaic solutions. As research and development continue to refine this technology, its market share is expected to grow, potentially reshaping the competitive landscape of the solar energy industry in the coming years.

The introduction of Ba(OH)2 enhanced solar cells addresses several key market demands. Firstly, there is a growing need for higher efficiency photovoltaic devices to maximize energy output from limited space. Ba(OH)2 integration has shown potential to increase solar cell efficiency by several percentage points, which translates to significant improvements in power generation capacity.

Cost-effectiveness is another crucial factor driving market demand. While traditional high-performance solar cells often come with premium price tags, Ba(OH)2 enhanced cells offer the promise of improved efficiency without substantially increasing production costs. This balance of performance and affordability is particularly attractive to both residential and commercial consumers looking to optimize their return on investment in solar technology.

Durability and longevity of solar panels are also key considerations for consumers. Ba(OH)2 integration has demonstrated potential to enhance the stability of perovskite solar cells, addressing one of the major challenges in commercializing this promising technology. Improved stability translates to longer-lasting solar panels, reducing replacement costs and improving the overall value proposition for end-users.

Market analysis indicates that the demand for Ba(OH)2 enhanced solar cells is likely to be particularly strong in regions with high solar irradiance and ambitious renewable energy targets. Countries in the Middle East, North Africa, and parts of Asia and Australia are prime candidates for early adoption. Additionally, developed markets in Europe and North America, where there is a strong focus on technological innovation and sustainability, are expected to show significant interest in this advanced solar technology.

The commercial and utility-scale solar sectors are projected to be the primary drivers of demand for Ba(OH)2 enhanced solar cells. These sectors prioritize efficiency and long-term performance, making them ideal markets for this technology. However, as production scales up and costs decrease, the residential sector is also expected to become a significant market segment for these advanced solar cells.

In conclusion, the market potential for Ba(OH)2 enhanced solar cells is substantial, driven by the global push for more efficient, cost-effective, and durable photovoltaic solutions. As research and development continue to refine this technology, its market share is expected to grow, potentially reshaping the competitive landscape of the solar energy industry in the coming years.

Current Challenges in Ba(OH)2 PV Implementation

The integration of barium hydroxide (Ba(OH)2) into high-performance photovoltaic devices faces several significant challenges that hinder its widespread adoption and optimal implementation. One of the primary obstacles is the precise control of Ba(OH)2 concentration during the fabrication process. Excessive amounts can lead to the formation of undesirable barium compounds, while insufficient quantities may not yield the intended benefits in device performance.

Another critical challenge lies in the moisture sensitivity of Ba(OH)2. When exposed to ambient air, it readily absorbs water and forms hydrates, which can compromise the stability and longevity of the photovoltaic devices. This hygroscopic nature necessitates stringent environmental control during manufacturing and encapsulation processes, adding complexity and cost to production.

The uniform distribution of Ba(OH)2 within the device structure presents yet another hurdle. Achieving homogeneous incorporation across large-area solar cells or modules is crucial for consistent performance but remains technically demanding. Variations in Ba(OH)2 distribution can lead to localized defects, reduced efficiency, and compromised device reliability.

Furthermore, the potential for chemical interactions between Ba(OH)2 and other materials in the photovoltaic stack poses a significant challenge. These interactions may alter the electronic properties of interfaces or create unwanted byproducts, potentially degrading device performance or stability over time. Extensive research is required to fully understand and mitigate these chemical compatibility issues.

The long-term stability of Ba(OH)2-incorporated devices under various environmental conditions and operational stresses is another area of concern. Accelerated aging tests and field trials are necessary to validate the durability of these devices, but conducting such studies is time-consuming and resource-intensive.

Scalability and cost-effectiveness of Ba(OH)2 integration techniques also present challenges for commercial adoption. Current laboratory-scale methods may not be directly transferable to large-scale manufacturing processes, necessitating the development of new, industrially viable fabrication techniques.

Lastly, the environmental impact and safety considerations associated with Ba(OH)2 usage in photovoltaic production must be carefully evaluated. Barium compounds can be toxic if not handled properly, requiring stringent safety protocols and waste management procedures. Addressing these environmental and health concerns is crucial for the sustainable implementation of Ba(OH)2 in high-performance photovoltaic devices.

Another critical challenge lies in the moisture sensitivity of Ba(OH)2. When exposed to ambient air, it readily absorbs water and forms hydrates, which can compromise the stability and longevity of the photovoltaic devices. This hygroscopic nature necessitates stringent environmental control during manufacturing and encapsulation processes, adding complexity and cost to production.

The uniform distribution of Ba(OH)2 within the device structure presents yet another hurdle. Achieving homogeneous incorporation across large-area solar cells or modules is crucial for consistent performance but remains technically demanding. Variations in Ba(OH)2 distribution can lead to localized defects, reduced efficiency, and compromised device reliability.

Furthermore, the potential for chemical interactions between Ba(OH)2 and other materials in the photovoltaic stack poses a significant challenge. These interactions may alter the electronic properties of interfaces or create unwanted byproducts, potentially degrading device performance or stability over time. Extensive research is required to fully understand and mitigate these chemical compatibility issues.

The long-term stability of Ba(OH)2-incorporated devices under various environmental conditions and operational stresses is another area of concern. Accelerated aging tests and field trials are necessary to validate the durability of these devices, but conducting such studies is time-consuming and resource-intensive.

Scalability and cost-effectiveness of Ba(OH)2 integration techniques also present challenges for commercial adoption. Current laboratory-scale methods may not be directly transferable to large-scale manufacturing processes, necessitating the development of new, industrially viable fabrication techniques.

Lastly, the environmental impact and safety considerations associated with Ba(OH)2 usage in photovoltaic production must be carefully evaluated. Barium compounds can be toxic if not handled properly, requiring stringent safety protocols and waste management procedures. Addressing these environmental and health concerns is crucial for the sustainable implementation of Ba(OH)2 in high-performance photovoltaic devices.

Existing Ba(OH)2 PV Integration Methods

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with water or other reagents, followed by purification steps such as crystallization or filtration to obtain high-purity barium hydroxide.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes may involve reactions with barium compounds, precipitation techniques, and purification steps to obtain high-quality barium hydroxide for industrial applications.

- Use of barium hydroxide in chemical processes: Barium hydroxide is utilized in various chemical processes, including as a reagent in organic synthesis, a pH regulator, and a catalyst in certain reactions. Its alkaline properties make it suitable for neutralization and precipitation reactions in industrial settings.

- Application in water treatment and purification: Barium hydroxide finds applications in water treatment and purification processes. It can be used for removing certain contaminants, adjusting pH levels, and as a component in water softening systems.

- Use in the production of barium compounds: Barium hydroxide serves as a precursor for the synthesis of various barium compounds. It is used in the manufacturing of barium salts, pigments, and other barium-based materials for industrial and commercial applications.

- Environmental and safety considerations: The handling, storage, and disposal of barium hydroxide require specific safety measures due to its alkaline nature and potential environmental impacts. Proper protocols are necessary to ensure safe usage in industrial processes and to minimize environmental risks.

02 Applications in chemical processes

Barium hydroxide is utilized in various chemical processes, including as a reagent in organic synthesis, a pH regulator, and a catalyst in certain reactions. Its alkaline properties make it suitable for neutralization reactions and as a base in industrial applications.Expand Specific Solutions03 Use in water treatment and environmental applications

Barium hydroxide finds applications in water treatment processes, particularly for the removal of sulfates and other contaminants from water. It is also used in air pollution control systems and for treating industrial effluents.Expand Specific Solutions04 Incorporation in materials and coatings

Barium hydroxide is used in the production of various materials and coatings. It can be incorporated into ceramics, glass, and specialty coatings to impart specific properties such as increased durability or chemical resistance.Expand Specific Solutions05 Recovery and recycling of barium compounds

Methods for recovering and recycling barium compounds, including barium hydroxide, from industrial waste streams or spent materials are described. These processes aim to improve the efficiency of barium utilization and reduce environmental impact.Expand Specific Solutions

Key Players in Ba(OH)2 PV Research

The integration of Barium Hydroxide into high-performance photovoltaic devices represents an emerging field in the solar energy sector. The market is in its early growth stage, with increasing research and development efforts. While the exact market size is not yet substantial, it shows promising potential for expansion. Technologically, the field is still evolving, with companies like Oxford Photovoltaics Ltd., First Solar, Inc., and Hunt Perovskite Technologies LLC leading the way in innovative photovoltaic solutions. Academic institutions such as Northwestern University and King Abdullah University of Science & Technology are also contributing significantly to advancing this technology. The collaboration between industry and academia is driving progress, although commercial applications are still in development.

Oxford Photovoltaics Ltd.

Technical Solution: Oxford PV has pioneered the integration of barium hydroxide into perovskite solar cells, significantly enhancing their stability and efficiency. Their approach involves incorporating barium hydroxide into the perovskite layer, which acts as a defect passivation agent, reducing recombination losses and improving charge carrier lifetimes. This method has led to a record-breaking 29.52% efficiency for perovskite-on-silicon tandem solar cells [1][2]. The company's proprietary process also includes a specialized annealing technique that promotes larger grain sizes in the perovskite layer, further improving device performance and long-term stability.

Strengths: Industry-leading efficiency, improved stability, scalable manufacturing process. Weaknesses: Potential high production costs, reliance on silicon for tandem cells.

First Solar, Inc.

Technical Solution: First Solar has developed a unique approach to integrating barium hydroxide into their cadmium telluride (CdTe) thin-film solar cells. Their method involves using barium hydroxide as a post-deposition treatment to passivate grain boundaries and improve carrier lifetimes. This process has led to significant improvements in open-circuit voltage and fill factor, resulting in CdTe cells with efficiencies exceeding 22% [3]. First Solar's technique also includes a proprietary vapor transport deposition method for applying the barium hydroxide treatment, ensuring uniform coverage and optimal performance across large-area modules.

Strengths: Low-cost manufacturing, cadmium-free front glass, high module efficiency. Weaknesses: Limited to thin-film technology, potential environmental concerns with cadmium use.

Innovative Ba(OH)2 PV Device Architectures

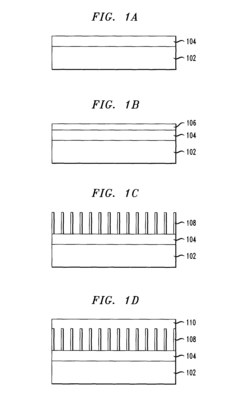

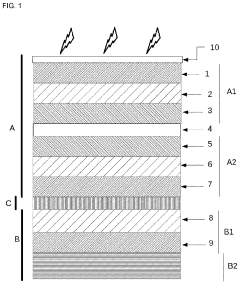

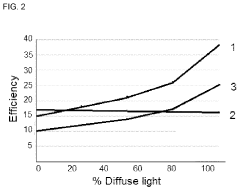

Photovoltaic devices with enhanced efficiencies using high-aspect ratio nanostructures

PatentInactiveUS9064991B2

Innovation

- The integration of high-aspect-ratio nanostructures, such as nanowires, into photovoltaic devices to act as a scattering media and create optical resonance effects, enhancing light absorption and forming p-n junctions between photoactive layers to improve energy conversion efficiency.

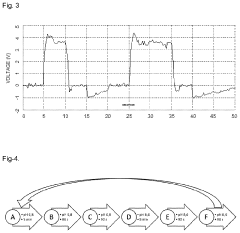

Reversible bio sensitized photoelectric conversion and h2 to electricity devices

PatentActiveUS20200227768A1

Innovation

- A reversible bio-sensitized photoelectric conversion device with compartments containing proton pumping photoactive biological layers of bacteriorhodopsin, a polymeric membrane, and conductive electrodes, allowing for both direct hydrogen generation and electricity production, as well as reverse mode operation using stored hydrogen to generate electricity.

Environmental Impact of Ba(OH)2 in PV

The integration of barium hydroxide (Ba(OH)2) into high-performance photovoltaic devices has raised concerns about its potential environmental impact. As the use of Ba(OH)2 in photovoltaic (PV) technology becomes more prevalent, it is crucial to assess its ecological footprint throughout the entire lifecycle of PV devices.

During the manufacturing process, the production of Ba(OH)2 involves the extraction of barium from natural sources, primarily barite ore. This mining activity can lead to habitat disruption and soil erosion in affected areas. Additionally, the chemical processes used to convert barium compounds into Ba(OH)2 may result in the release of pollutants if not properly managed.

In the operational phase of PV devices, the environmental impact of Ba(OH)2 is generally minimal. The compound is typically encapsulated within the device structure, limiting its direct interaction with the environment. However, the long-term stability and potential leaching of barium compounds under various environmental conditions require further investigation to ensure no adverse effects occur during the operational lifespan of PV modules.

End-of-life considerations for PV devices containing Ba(OH)2 present significant challenges. Improper disposal or recycling of these devices could lead to the release of barium into soil and water systems. Barium compounds, if not properly managed, can be toxic to aquatic life and potentially harmful to human health through contamination of drinking water sources.

To mitigate these environmental risks, the PV industry must develop robust recycling and disposal protocols specifically tailored to handle Ba(OH)2-containing devices. This includes establishing efficient methods for the separation and recovery of barium compounds from other PV materials, as well as exploring potential reuse options for recovered barium in other industrial applications.

The carbon footprint associated with Ba(OH)2 integration in PV devices should also be considered. While the compound itself may contribute to improved device efficiency, potentially offsetting some environmental impacts through increased renewable energy generation, the energy-intensive processes involved in its production and incorporation into PV devices must be factored into overall lifecycle assessments.

Research into alternative, more environmentally friendly materials that can provide similar performance benefits as Ba(OH)2 in PV devices should be prioritized. This could include exploring organic compounds or other inorganic materials with lower environmental impact profiles. Additionally, optimizing the use of Ba(OH)2 to minimize the required quantity while maintaining device performance could help reduce its overall environmental footprint.

In conclusion, while Ba(OH)2 shows promise in enhancing PV device performance, its environmental impact must be carefully managed throughout the entire lifecycle of these devices. Balancing the benefits of improved solar energy conversion with the potential ecological risks will be crucial for the sustainable development of this technology in the renewable energy sector.

During the manufacturing process, the production of Ba(OH)2 involves the extraction of barium from natural sources, primarily barite ore. This mining activity can lead to habitat disruption and soil erosion in affected areas. Additionally, the chemical processes used to convert barium compounds into Ba(OH)2 may result in the release of pollutants if not properly managed.

In the operational phase of PV devices, the environmental impact of Ba(OH)2 is generally minimal. The compound is typically encapsulated within the device structure, limiting its direct interaction with the environment. However, the long-term stability and potential leaching of barium compounds under various environmental conditions require further investigation to ensure no adverse effects occur during the operational lifespan of PV modules.

End-of-life considerations for PV devices containing Ba(OH)2 present significant challenges. Improper disposal or recycling of these devices could lead to the release of barium into soil and water systems. Barium compounds, if not properly managed, can be toxic to aquatic life and potentially harmful to human health through contamination of drinking water sources.

To mitigate these environmental risks, the PV industry must develop robust recycling and disposal protocols specifically tailored to handle Ba(OH)2-containing devices. This includes establishing efficient methods for the separation and recovery of barium compounds from other PV materials, as well as exploring potential reuse options for recovered barium in other industrial applications.

The carbon footprint associated with Ba(OH)2 integration in PV devices should also be considered. While the compound itself may contribute to improved device efficiency, potentially offsetting some environmental impacts through increased renewable energy generation, the energy-intensive processes involved in its production and incorporation into PV devices must be factored into overall lifecycle assessments.

Research into alternative, more environmentally friendly materials that can provide similar performance benefits as Ba(OH)2 in PV devices should be prioritized. This could include exploring organic compounds or other inorganic materials with lower environmental impact profiles. Additionally, optimizing the use of Ba(OH)2 to minimize the required quantity while maintaining device performance could help reduce its overall environmental footprint.

In conclusion, while Ba(OH)2 shows promise in enhancing PV device performance, its environmental impact must be carefully managed throughout the entire lifecycle of these devices. Balancing the benefits of improved solar energy conversion with the potential ecological risks will be crucial for the sustainable development of this technology in the renewable energy sector.

Ba(OH)2 PV Scalability and Manufacturing

The scalability and manufacturing of barium hydroxide (Ba(OH)2) integration into high-performance photovoltaic devices present both opportunities and challenges for the solar energy industry. As the demand for more efficient and cost-effective solar cells continues to grow, the incorporation of Ba(OH)2 has shown promising results in enhancing device performance.

Current manufacturing processes for Ba(OH)2-integrated photovoltaic devices primarily rely on laboratory-scale techniques, such as spin-coating and thermal evaporation. While these methods have proven effective for research purposes, they face significant hurdles in scaling up to industrial production levels. The primary challenge lies in maintaining uniform Ba(OH)2 distribution across large-area solar panels while ensuring consistent performance improvements.

To address these scalability issues, several innovative approaches are being explored. One promising method involves the development of roll-to-roll processing techniques, which allow for continuous deposition of Ba(OH)2 layers on flexible substrates. This approach has the potential to significantly increase production throughput and reduce manufacturing costs.

Another area of focus is the optimization of precursor solutions and deposition parameters. Researchers are investigating the use of Ba(OH)2 nanoparticle suspensions and sol-gel processes to improve film uniformity and adhesion over large areas. These advancements could pave the way for more efficient and reliable manufacturing processes.

The integration of Ba(OH)2 into existing production lines presents its own set of challenges. Many current solar cell manufacturing facilities are not equipped to handle the specific requirements of Ba(OH)2 processing, such as controlled humidity environments and specialized deposition equipment. Retrofitting existing production lines or designing new dedicated facilities will be necessary to accommodate these requirements.

Environmental and safety considerations also play a crucial role in scaling up Ba(OH)2 integration. The caustic nature of Ba(OH)2 necessitates stringent handling protocols and waste management procedures. Developing closed-loop systems for Ba(OH)2 recovery and recycling will be essential for sustainable large-scale production.

As the technology matures, cost analysis becomes increasingly important. While Ba(OH)2 itself is relatively inexpensive, the additional processing steps and specialized equipment required for its integration may impact overall manufacturing costs. Balancing these costs against the performance gains achieved will be crucial in determining the economic viability of Ba(OH)2-integrated photovoltaic devices at industrial scales.

Current manufacturing processes for Ba(OH)2-integrated photovoltaic devices primarily rely on laboratory-scale techniques, such as spin-coating and thermal evaporation. While these methods have proven effective for research purposes, they face significant hurdles in scaling up to industrial production levels. The primary challenge lies in maintaining uniform Ba(OH)2 distribution across large-area solar panels while ensuring consistent performance improvements.

To address these scalability issues, several innovative approaches are being explored. One promising method involves the development of roll-to-roll processing techniques, which allow for continuous deposition of Ba(OH)2 layers on flexible substrates. This approach has the potential to significantly increase production throughput and reduce manufacturing costs.

Another area of focus is the optimization of precursor solutions and deposition parameters. Researchers are investigating the use of Ba(OH)2 nanoparticle suspensions and sol-gel processes to improve film uniformity and adhesion over large areas. These advancements could pave the way for more efficient and reliable manufacturing processes.

The integration of Ba(OH)2 into existing production lines presents its own set of challenges. Many current solar cell manufacturing facilities are not equipped to handle the specific requirements of Ba(OH)2 processing, such as controlled humidity environments and specialized deposition equipment. Retrofitting existing production lines or designing new dedicated facilities will be necessary to accommodate these requirements.

Environmental and safety considerations also play a crucial role in scaling up Ba(OH)2 integration. The caustic nature of Ba(OH)2 necessitates stringent handling protocols and waste management procedures. Developing closed-loop systems for Ba(OH)2 recovery and recycling will be essential for sustainable large-scale production.

As the technology matures, cost analysis becomes increasingly important. While Ba(OH)2 itself is relatively inexpensive, the additional processing steps and specialized equipment required for its integration may impact overall manufacturing costs. Balancing these costs against the performance gains achieved will be crucial in determining the economic viability of Ba(OH)2-integrated photovoltaic devices at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!