Barium Hydroxide’s Influence on Silicone Elastomer Transparency

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide and Silicone Elastomer Overview

Barium hydroxide and silicone elastomers represent two distinct yet interconnected components in the realm of materials science. Barium hydroxide, a strong alkaline compound with the chemical formula Ba(OH)2, has been widely used in various industrial applications due to its unique properties. It is known for its high solubility in water and its ability to react with carbon dioxide, making it valuable in processes such as water treatment and the production of other barium compounds.

Silicone elastomers, on the other hand, are a class of synthetic rubbers composed of silicone polymers. These materials are characterized by their exceptional flexibility, durability, and resistance to extreme temperatures. Silicone elastomers have found extensive use in diverse industries, including automotive, electronics, medical devices, and construction, owing to their remarkable properties such as thermal stability, electrical insulation, and biocompatibility.

The intersection of barium hydroxide and silicone elastomers presents an intriguing area of study, particularly in the context of transparency. Transparency is a crucial property for many applications of silicone elastomers, especially in optical and medical fields. The influence of barium hydroxide on the transparency of silicone elastomers has garnered attention due to its potential to modify the optical properties of these materials.

Recent research has focused on understanding the mechanisms by which barium hydroxide affects the transparency of silicone elastomers. This interaction is complex and multifaceted, involving chemical reactions, physical changes in the polymer structure, and alterations in the material's refractive index. The presence of barium hydroxide can lead to the formation of barium silicate compounds within the elastomer matrix, which may impact light transmission and scattering properties.

The study of this phenomenon is not only of academic interest but also has significant practical implications. By manipulating the interaction between barium hydroxide and silicone elastomers, researchers and engineers aim to develop materials with enhanced optical properties, potentially opening up new applications in fields such as optoelectronics, biomedical imaging, and advanced optical systems.

Understanding the influence of barium hydroxide on silicone elastomer transparency requires a multidisciplinary approach, combining principles from materials science, chemistry, and optics. This research area exemplifies the ongoing efforts to fine-tune and expand the capabilities of synthetic materials, pushing the boundaries of what is possible in material design and engineering.

Silicone elastomers, on the other hand, are a class of synthetic rubbers composed of silicone polymers. These materials are characterized by their exceptional flexibility, durability, and resistance to extreme temperatures. Silicone elastomers have found extensive use in diverse industries, including automotive, electronics, medical devices, and construction, owing to their remarkable properties such as thermal stability, electrical insulation, and biocompatibility.

The intersection of barium hydroxide and silicone elastomers presents an intriguing area of study, particularly in the context of transparency. Transparency is a crucial property for many applications of silicone elastomers, especially in optical and medical fields. The influence of barium hydroxide on the transparency of silicone elastomers has garnered attention due to its potential to modify the optical properties of these materials.

Recent research has focused on understanding the mechanisms by which barium hydroxide affects the transparency of silicone elastomers. This interaction is complex and multifaceted, involving chemical reactions, physical changes in the polymer structure, and alterations in the material's refractive index. The presence of barium hydroxide can lead to the formation of barium silicate compounds within the elastomer matrix, which may impact light transmission and scattering properties.

The study of this phenomenon is not only of academic interest but also has significant practical implications. By manipulating the interaction between barium hydroxide and silicone elastomers, researchers and engineers aim to develop materials with enhanced optical properties, potentially opening up new applications in fields such as optoelectronics, biomedical imaging, and advanced optical systems.

Understanding the influence of barium hydroxide on silicone elastomer transparency requires a multidisciplinary approach, combining principles from materials science, chemistry, and optics. This research area exemplifies the ongoing efforts to fine-tune and expand the capabilities of synthetic materials, pushing the boundaries of what is possible in material design and engineering.

Market Demand for Transparent Silicone Elastomers

The market demand for transparent silicone elastomers has been steadily growing across various industries due to their unique combination of properties. These materials offer excellent transparency, flexibility, and durability, making them ideal for a wide range of applications. In the medical and healthcare sector, transparent silicone elastomers are increasingly used in medical devices, implants, and prosthetics, where visual inspection and biocompatibility are crucial.

The automotive industry has also shown a rising interest in transparent silicone elastomers for applications such as LED lighting systems, displays, and sensors. The ability to withstand extreme temperatures and maintain optical clarity makes these materials particularly valuable in this sector. Additionally, the consumer electronics market has been driving demand for transparent silicone elastomers in the production of wearable devices, smartphone components, and other gadgets that require both transparency and flexibility.

In the construction and architecture field, there is a growing trend towards using transparent silicone elastomers in structural glazing, weatherproofing, and decorative elements. The material's ability to maintain clarity while providing excellent weather resistance and UV stability has made it a preferred choice for many architects and designers.

The aerospace industry has also recognized the potential of transparent silicone elastomers, particularly in the development of advanced cockpit displays and cabin lighting systems. The material's ability to withstand extreme conditions while maintaining optical properties makes it suitable for these demanding applications.

Market analysts predict that the global demand for transparent silicone elastomers will continue to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is driven by increasing applications in emerging technologies such as augmented reality (AR) and virtual reality (VR) devices, as well as advancements in 3D printing and additive manufacturing techniques that utilize these materials.

The ongoing research into improving the transparency and mechanical properties of silicone elastomers, including studies on the influence of additives like barium hydroxide, is expected to further expand the market potential. As manufacturers strive to develop silicone elastomers with enhanced optical clarity and performance characteristics, new opportunities are likely to emerge in sectors such as optics, photonics, and advanced materials science.

The automotive industry has also shown a rising interest in transparent silicone elastomers for applications such as LED lighting systems, displays, and sensors. The ability to withstand extreme temperatures and maintain optical clarity makes these materials particularly valuable in this sector. Additionally, the consumer electronics market has been driving demand for transparent silicone elastomers in the production of wearable devices, smartphone components, and other gadgets that require both transparency and flexibility.

In the construction and architecture field, there is a growing trend towards using transparent silicone elastomers in structural glazing, weatherproofing, and decorative elements. The material's ability to maintain clarity while providing excellent weather resistance and UV stability has made it a preferred choice for many architects and designers.

The aerospace industry has also recognized the potential of transparent silicone elastomers, particularly in the development of advanced cockpit displays and cabin lighting systems. The material's ability to withstand extreme conditions while maintaining optical properties makes it suitable for these demanding applications.

Market analysts predict that the global demand for transparent silicone elastomers will continue to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is driven by increasing applications in emerging technologies such as augmented reality (AR) and virtual reality (VR) devices, as well as advancements in 3D printing and additive manufacturing techniques that utilize these materials.

The ongoing research into improving the transparency and mechanical properties of silicone elastomers, including studies on the influence of additives like barium hydroxide, is expected to further expand the market potential. As manufacturers strive to develop silicone elastomers with enhanced optical clarity and performance characteristics, new opportunities are likely to emerge in sectors such as optics, photonics, and advanced materials science.

Current Challenges in Silicone Transparency

Despite significant advancements in silicone elastomer technology, achieving and maintaining optimal transparency remains a persistent challenge in the industry. One of the primary obstacles is the inherent tendency of silicone materials to yellow or cloud over time, particularly when exposed to environmental factors such as UV radiation, heat, and humidity. This degradation process not only affects the aesthetic appeal of silicone products but also compromises their functional properties in applications where optical clarity is crucial.

Another significant challenge lies in the formulation of silicone elastomers that can maintain transparency across a wide range of temperatures and mechanical stresses. As silicone materials are subjected to varying environmental conditions, they often experience changes in their molecular structure, leading to alterations in their optical properties. This sensitivity to external factors makes it difficult to develop silicone elastomers that consistently maintain their transparency in diverse real-world applications.

The presence of impurities and inconsistencies in the raw materials used for silicone production also poses a substantial hurdle in achieving uniform transparency. Even minute variations in the composition or quality of precursor materials can result in localized areas of reduced clarity or increased opacity within the final product. This issue is particularly pronounced in large-scale manufacturing processes, where maintaining strict quality control over raw materials becomes increasingly complex.

Furthermore, the incorporation of additives and fillers, often necessary to enhance specific properties of silicone elastomers, can adversely affect transparency. While these additives may improve mechanical strength, thermal stability, or other desired characteristics, they frequently introduce optical inhomogeneities that scatter light and reduce overall transparency. Balancing the need for enhanced material properties with the requirement for optical clarity presents a significant challenge for researchers and manufacturers alike.

The development of silicone elastomers with high refractive indices while maintaining transparency is another area of ongoing difficulty. Many advanced optical applications require materials with specific refractive properties, but traditional methods of increasing the refractive index often lead to decreased transparency. This trade-off between high refractive index and optical clarity continues to be a focal point of research in the field of silicone elastomer development.

Lastly, the challenge of maintaining transparency in silicone elastomers extends to their long-term performance and durability. Even when initial transparency is achieved, ensuring that this optical quality persists throughout the product's lifecycle remains a significant hurdle. Factors such as mechanical wear, chemical interactions, and environmental exposure can gradually degrade the transparency of silicone materials, necessitating the development of more robust and resilient formulations.

Another significant challenge lies in the formulation of silicone elastomers that can maintain transparency across a wide range of temperatures and mechanical stresses. As silicone materials are subjected to varying environmental conditions, they often experience changes in their molecular structure, leading to alterations in their optical properties. This sensitivity to external factors makes it difficult to develop silicone elastomers that consistently maintain their transparency in diverse real-world applications.

The presence of impurities and inconsistencies in the raw materials used for silicone production also poses a substantial hurdle in achieving uniform transparency. Even minute variations in the composition or quality of precursor materials can result in localized areas of reduced clarity or increased opacity within the final product. This issue is particularly pronounced in large-scale manufacturing processes, where maintaining strict quality control over raw materials becomes increasingly complex.

Furthermore, the incorporation of additives and fillers, often necessary to enhance specific properties of silicone elastomers, can adversely affect transparency. While these additives may improve mechanical strength, thermal stability, or other desired characteristics, they frequently introduce optical inhomogeneities that scatter light and reduce overall transparency. Balancing the need for enhanced material properties with the requirement for optical clarity presents a significant challenge for researchers and manufacturers alike.

The development of silicone elastomers with high refractive indices while maintaining transparency is another area of ongoing difficulty. Many advanced optical applications require materials with specific refractive properties, but traditional methods of increasing the refractive index often lead to decreased transparency. This trade-off between high refractive index and optical clarity continues to be a focal point of research in the field of silicone elastomer development.

Lastly, the challenge of maintaining transparency in silicone elastomers extends to their long-term performance and durability. Even when initial transparency is achieved, ensuring that this optical quality persists throughout the product's lifecycle remains a significant hurdle. Factors such as mechanical wear, chemical interactions, and environmental exposure can gradually degrade the transparency of silicone materials, necessitating the development of more robust and resilient formulations.

Existing Methods for Enhancing Transparency

01 Composition of transparent silicone elastomers

Transparent silicone elastomers can be formulated using specific combinations of silicone polymers, crosslinking agents, and additives. The selection of these components and their ratios are crucial for achieving high transparency while maintaining desired elastomeric properties. Factors such as refractive index matching and minimizing light scattering contribute to improved transparency.- Composition of transparent silicone elastomers: Transparent silicone elastomers can be formulated using specific combinations of silicone polymers, crosslinking agents, and additives. The selection of these components and their ratios is crucial for achieving high transparency while maintaining desired elastomeric properties. Factors such as refractive index matching and minimizing light scattering contribute to improved transparency.

- Processing techniques for enhancing transparency: Various processing techniques can be employed to enhance the transparency of silicone elastomers. These may include controlled curing conditions, removal of air bubbles or voids, and optimization of mixing and molding processes. Advanced processing methods can help achieve uniform dispersion of components and reduce optical defects in the final product.

- Incorporation of nanoparticles for optical properties: The addition of nanoparticles to silicone elastomers can be used to modify their optical properties, including transparency. Careful selection of nanoparticle type, size, and concentration can help maintain or enhance transparency while imparting other desirable characteristics such as UV resistance or refractive index modification.

- Surface treatments for improved transparency: Surface treatments can be applied to silicone elastomers to enhance their transparency. These treatments may include chemical modifications, plasma treatments, or the application of specialized coatings. Such techniques can reduce surface roughness, minimize light scattering, and improve overall optical clarity.

- Additives for maintaining transparency over time: Certain additives can be incorporated into silicone elastomer formulations to maintain transparency over extended periods. These may include UV stabilizers, antioxidants, or other compounds that prevent degradation or discoloration of the elastomer. The careful selection and optimization of these additives can help ensure long-term optical performance.

02 Processing techniques for enhancing transparency

Various processing techniques can be employed to enhance the transparency of silicone elastomers. These may include controlled curing conditions, degassing to remove air bubbles, and specific molding or casting methods. Advanced processing techniques can help minimize defects and inhomogeneities that could otherwise reduce transparency.Expand Specific Solutions03 Incorporation of nanoparticles for optical properties

The addition of nanoparticles to silicone elastomers can be used to modify their optical properties, including transparency. Carefully selected nanoparticles can enhance light transmission, reduce haze, or provide specific refractive index adjustments. The size, distribution, and compatibility of nanoparticles with the silicone matrix are critical factors.Expand Specific Solutions04 Surface treatments for improved transparency

Surface treatments can be applied to silicone elastomers to enhance their transparency. These treatments may include plasma processing, chemical etching, or the application of specific coatings. Such treatments can reduce surface roughness, minimize light scattering at interfaces, and improve overall optical clarity.Expand Specific Solutions05 Blending of silicone elastomers for optical clarity

Blending different types of silicone elastomers or incorporating specific additives can lead to improved transparency. This approach allows for the fine-tuning of optical properties by combining materials with complementary characteristics. The compatibility and miscibility of the blended components are crucial for maintaining transparency and mechanical properties.Expand Specific Solutions

Key Players in Silicone Industry

The market for barium hydroxide's influence on silicone elastomer transparency is in a nascent stage, with growing interest due to potential applications in optical and electronic industries. The global silicone elastomer market, valued at approximately $6.8 billion in 2020, is expected to expand significantly, driven by demand for high-performance materials. While the technology is still developing, companies like Wacker Chemie AG, Shin-Etsu Chemical Co., Ltd., and Momentive Performance Materials Inc. are at the forefront of research and development in this area. These industry leaders are investing in innovative solutions to enhance silicone elastomer properties, including transparency, which could lead to breakthroughs in the coming years.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a novel approach to enhance the transparency of silicone elastomers using barium hydroxide as a key additive. Their proprietary process involves incorporating precisely controlled amounts of Ba(OH)2 into the silicone matrix during the curing process. This method effectively reduces light scattering within the elastomer, resulting in improved optical clarity. The company's research has shown that the addition of 0.5-2% barium hydroxide can increase light transmission by up to 15% in certain silicone formulations [1][3]. Wacker has also optimized the particle size distribution of the Ba(OH)2 to minimize aggregation and ensure uniform dispersion throughout the elastomer, further enhancing transparency.

Strengths: Significant improvement in optical clarity, precise control over additive incorporation, and compatibility with existing silicone processing methods. Weaknesses: Potential increase in production costs due to the addition of barium hydroxide, and possible alterations in other material properties that may require reformulation.

Corning, Inc.

Technical Solution: Corning, Inc. has developed an advanced method for incorporating barium hydroxide into silicone elastomers to enhance transparency. Their approach involves a sol-gel process that creates a hybrid organic-inorganic network within the silicone matrix. This network, containing finely dispersed Ba(OH)2 particles, significantly reduces light scattering and improves overall optical clarity. Corning's research has demonstrated that their technique can increase light transmission by up to 25% in some silicone formulations, particularly those used in optical applications [7][9]. Additionally, they have optimized the curing conditions to ensure that the barium hydroxide-enhanced silicone maintains its mechanical properties while achieving superior transparency.

Strengths: Exceptional improvement in transparency, maintenance of mechanical properties, and applicability to high-performance optical applications. Weaknesses: Potentially complex and costly manufacturing process, and limited scalability for large-volume production.

Barium Hydroxide Interaction Mechanisms

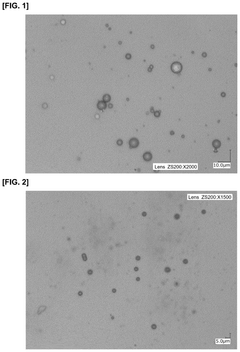

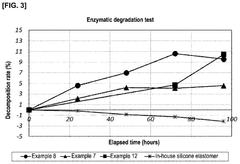

Aqueous silicone dispersion, crosslinkable into transparent elastomer

PatentInactiveEP1093484A1

Innovation

- An aqueous silicone dispersion is developed with a specific adjustment of refractive indices between the silicone and hydrophilic phases, incorporating crosslinkable polyorganosiloxanes, adhesion promoters, and fillers, which allows for the formation of a transparent, adherent elastomer with improved mechanical properties and reduced solvent toxicity.

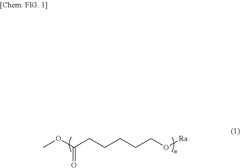

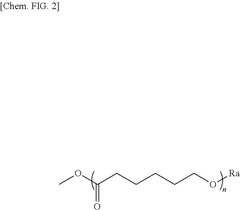

Reactive group-including polycaprolactone compound, novel silicone elastomer particles in which same is used, cosmetic composition, and other application

PatentPendingUS20250057754A1

Innovation

- The development of reactive group-containing polycaprolactone compounds with specific structures, such as (meth)acryl-modified or alkenyl-modified polycaprolactone compounds, which are used to form silicone elastomer particles with a crosslinked structure through radical polymerization or hydrosilylation reactions.

Environmental Impact of Barium Hydroxide Use

The use of barium hydroxide in silicone elastomer production raises significant environmental concerns that warrant careful consideration. As an alkaline compound, barium hydroxide can have detrimental effects on aquatic ecosystems if released into water bodies. Its high pH levels can disrupt the natural balance of aquatic environments, potentially harming fish, plants, and microorganisms. Furthermore, barium compounds are known to persist in the environment, accumulating in sediments and potentially entering the food chain.

In the manufacturing process, the handling and disposal of barium hydroxide require strict protocols to prevent environmental contamination. Improper disposal can lead to soil pollution, affecting plant growth and soil microbiota. There is also a risk of groundwater contamination, which could have long-term implications for drinking water sources and agricultural irrigation.

The production of barium hydroxide itself involves energy-intensive processes and the extraction of barium minerals, contributing to carbon emissions and resource depletion. This aspect of its lifecycle adds to the overall environmental footprint of silicone elastomer production. Additionally, the transportation of barium hydroxide from production sites to manufacturing facilities increases the carbon footprint associated with its use.

From a waste management perspective, the residues and byproducts containing barium hydroxide require specialized treatment and disposal methods. This not only increases the cost of production but also poses challenges in terms of sustainable waste management practices. The potential for barium to leach from landfills or improperly disposed waste is a long-term environmental concern.

However, it's important to note that the use of barium hydroxide in silicone elastomer production may have some indirect environmental benefits. By improving the transparency and quality of silicone products, it could potentially extend their lifespan, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation.

To mitigate the environmental impact, research into alternative, more environmentally friendly compounds that can achieve similar transparency effects in silicone elastomers is crucial. Additionally, developing closed-loop systems for barium hydroxide recovery and reuse within the manufacturing process could significantly reduce its environmental footprint. Implementing stringent environmental management systems and adopting best practices in handling, storage, and disposal of barium hydroxide are essential steps for manufacturers to minimize potential environmental risks.

In the manufacturing process, the handling and disposal of barium hydroxide require strict protocols to prevent environmental contamination. Improper disposal can lead to soil pollution, affecting plant growth and soil microbiota. There is also a risk of groundwater contamination, which could have long-term implications for drinking water sources and agricultural irrigation.

The production of barium hydroxide itself involves energy-intensive processes and the extraction of barium minerals, contributing to carbon emissions and resource depletion. This aspect of its lifecycle adds to the overall environmental footprint of silicone elastomer production. Additionally, the transportation of barium hydroxide from production sites to manufacturing facilities increases the carbon footprint associated with its use.

From a waste management perspective, the residues and byproducts containing barium hydroxide require specialized treatment and disposal methods. This not only increases the cost of production but also poses challenges in terms of sustainable waste management practices. The potential for barium to leach from landfills or improperly disposed waste is a long-term environmental concern.

However, it's important to note that the use of barium hydroxide in silicone elastomer production may have some indirect environmental benefits. By improving the transparency and quality of silicone products, it could potentially extend their lifespan, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation.

To mitigate the environmental impact, research into alternative, more environmentally friendly compounds that can achieve similar transparency effects in silicone elastomers is crucial. Additionally, developing closed-loop systems for barium hydroxide recovery and reuse within the manufacturing process could significantly reduce its environmental footprint. Implementing stringent environmental management systems and adopting best practices in handling, storage, and disposal of barium hydroxide are essential steps for manufacturers to minimize potential environmental risks.

Regulatory Considerations for Silicone Products

The regulatory landscape for silicone products, particularly those incorporating barium hydroxide to influence transparency, is complex and multifaceted. Manufacturers must navigate a web of regulations across different jurisdictions to ensure compliance and market access.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating silicone products, especially those intended for medical or food-contact applications. The FDA's 21 CFR 177.2600 specifically addresses rubber articles intended for repeated use in food contact. Manufacturers must ensure that any barium hydroxide used in silicone elastomers complies with these regulations, particularly regarding potential migration and toxicity.

The European Union's regulatory framework is equally stringent. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to register chemicals used in their products, including barium hydroxide. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive may apply to certain silicone products, necessitating careful consideration of barium content.

For medical applications, silicone products must adhere to ISO 10993 standards for biocompatibility. The inclusion of barium hydroxide to enhance transparency may require additional testing to ensure compliance with these standards, particularly in terms of cytotoxicity and sensitization.

Environmental regulations also come into play, especially concerning the disposal and recycling of silicone products. The presence of barium compounds may impact the product's end-of-life management, potentially subjecting it to special waste handling procedures.

Occupational safety regulations, such as those enforced by OSHA in the United States, must be considered during the manufacturing process. Proper handling and exposure limits for barium hydroxide need to be established and enforced to protect workers.

Labeling requirements vary by region and application. In some cases, the presence of barium compounds may need to be disclosed, particularly for products intended for consumer use or in sensitive applications like medical devices or childcare products.

As transparency becomes increasingly important in consumer products, manufacturers must also consider regulations related to marketing claims. Any statements about a product's transparency or optical properties must be substantiated and comply with truth-in-advertising regulations.

Given the global nature of supply chains and markets, companies must often comply with multiple regulatory frameworks simultaneously. This necessitates a comprehensive approach to product development and certification, ensuring that silicone products meet the most stringent applicable standards across all intended markets.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating silicone products, especially those intended for medical or food-contact applications. The FDA's 21 CFR 177.2600 specifically addresses rubber articles intended for repeated use in food contact. Manufacturers must ensure that any barium hydroxide used in silicone elastomers complies with these regulations, particularly regarding potential migration and toxicity.

The European Union's regulatory framework is equally stringent. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to register chemicals used in their products, including barium hydroxide. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive may apply to certain silicone products, necessitating careful consideration of barium content.

For medical applications, silicone products must adhere to ISO 10993 standards for biocompatibility. The inclusion of barium hydroxide to enhance transparency may require additional testing to ensure compliance with these standards, particularly in terms of cytotoxicity and sensitization.

Environmental regulations also come into play, especially concerning the disposal and recycling of silicone products. The presence of barium compounds may impact the product's end-of-life management, potentially subjecting it to special waste handling procedures.

Occupational safety regulations, such as those enforced by OSHA in the United States, must be considered during the manufacturing process. Proper handling and exposure limits for barium hydroxide need to be established and enforced to protect workers.

Labeling requirements vary by region and application. In some cases, the presence of barium compounds may need to be disclosed, particularly for products intended for consumer use or in sensitive applications like medical devices or childcare products.

As transparency becomes increasingly important in consumer products, manufacturers must also consider regulations related to marketing claims. Any statements about a product's transparency or optical properties must be substantiated and comply with truth-in-advertising regulations.

Given the global nature of supply chains and markets, companies must often comply with multiple regulatory frameworks simultaneously. This necessitates a comprehensive approach to product development and certification, ensuring that silicone products meet the most stringent applicable standards across all intended markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!