Barium Hydroxide’s Effect on Anti-Bacterial Surface Treatments

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Antibacterial Surfaces: Background and Objectives

The development of antibacterial surfaces has gained significant attention in recent years due to the growing concern over the spread of infectious diseases and the rise of antibiotic-resistant bacteria. In this context, barium hydroxide has emerged as a promising compound for enhancing the effectiveness of anti-bacterial surface treatments. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of various metal compounds in creating self-cleaning and antimicrobial surfaces.

Barium hydroxide, a strong alkaline compound, has shown remarkable properties in creating durable and effective antibacterial surfaces. Its ability to form stable complexes with other materials and its inherent antimicrobial properties make it an ideal candidate for integration into various surface treatment technologies. The primary objective of incorporating barium hydroxide into antibacterial surfaces is to develop long-lasting, environmentally friendly, and highly effective solutions for preventing bacterial growth and colonization on various surfaces.

The technological trajectory in this field has been driven by the need for more sustainable and efficient antimicrobial solutions. Traditional methods often rely on the use of toxic chemicals or antibiotics, which can lead to environmental concerns and the development of resistant bacterial strains. Barium hydroxide-based treatments offer a promising alternative, as they provide a physical barrier against bacterial adhesion while also exhibiting chemical properties that inhibit microbial growth.

Recent advancements in nanotechnology and materials science have further expanded the potential applications of barium hydroxide in antibacterial surface treatments. Researchers are now exploring ways to incorporate barium hydroxide into nanostructured coatings and composite materials, enhancing its effectiveness and durability. These developments aim to create surfaces that not only prevent bacterial growth but also maintain their antimicrobial properties over extended periods, even under harsh conditions.

The global market for antimicrobial coatings and surfaces is projected to grow significantly in the coming years, driven by increasing awareness of hygiene and the need for infection control in healthcare, food processing, and public spaces. Barium hydroxide-based solutions are poised to play a crucial role in this expanding market, offering a balance between effectiveness, sustainability, and cost-efficiency. As research continues to uncover new applications and improve existing technologies, the integration of barium hydroxide into antibacterial surface treatments is expected to become more widespread across various industries.

Barium hydroxide, a strong alkaline compound, has shown remarkable properties in creating durable and effective antibacterial surfaces. Its ability to form stable complexes with other materials and its inherent antimicrobial properties make it an ideal candidate for integration into various surface treatment technologies. The primary objective of incorporating barium hydroxide into antibacterial surfaces is to develop long-lasting, environmentally friendly, and highly effective solutions for preventing bacterial growth and colonization on various surfaces.

The technological trajectory in this field has been driven by the need for more sustainable and efficient antimicrobial solutions. Traditional methods often rely on the use of toxic chemicals or antibiotics, which can lead to environmental concerns and the development of resistant bacterial strains. Barium hydroxide-based treatments offer a promising alternative, as they provide a physical barrier against bacterial adhesion while also exhibiting chemical properties that inhibit microbial growth.

Recent advancements in nanotechnology and materials science have further expanded the potential applications of barium hydroxide in antibacterial surface treatments. Researchers are now exploring ways to incorporate barium hydroxide into nanostructured coatings and composite materials, enhancing its effectiveness and durability. These developments aim to create surfaces that not only prevent bacterial growth but also maintain their antimicrobial properties over extended periods, even under harsh conditions.

The global market for antimicrobial coatings and surfaces is projected to grow significantly in the coming years, driven by increasing awareness of hygiene and the need for infection control in healthcare, food processing, and public spaces. Barium hydroxide-based solutions are poised to play a crucial role in this expanding market, offering a balance between effectiveness, sustainability, and cost-efficiency. As research continues to uncover new applications and improve existing technologies, the integration of barium hydroxide into antibacterial surface treatments is expected to become more widespread across various industries.

Market Analysis for Antibacterial Surface Treatments

The global market for antibacterial surface treatments has experienced significant growth in recent years, driven by increasing awareness of hygiene and the need for infection control across various industries. This market segment encompasses a wide range of products and technologies designed to inhibit or eliminate bacterial growth on surfaces, including coatings, films, additives, and specialized materials.

The healthcare sector remains the primary driver of demand for antibacterial surface treatments, with hospitals, clinics, and long-term care facilities seeking innovative solutions to reduce healthcare-associated infections. The COVID-19 pandemic has further accelerated this trend, heightening public awareness of the importance of surface hygiene in preventing disease transmission.

Beyond healthcare, other sectors contributing to market growth include food processing, packaging, consumer goods, and public transportation. These industries are increasingly adopting antibacterial surface treatments to enhance product safety, extend shelf life, and improve consumer confidence.

The market is characterized by ongoing technological advancements, with a focus on developing more effective, long-lasting, and environmentally friendly solutions. Nanotechnology-based treatments and bio-based antimicrobial agents are gaining traction, offering improved performance and sustainability compared to traditional chemical-based treatments.

Geographically, North America and Europe currently dominate the market, owing to stringent regulations, advanced healthcare infrastructure, and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing concerns over food safety.

Key market players include global chemical companies, specialty coating manufacturers, and innovative startups. These companies are investing heavily in research and development to gain a competitive edge and expand their product portfolios.

Challenges facing the market include regulatory hurdles, concerns over the potential development of antimicrobial resistance, and the need for cost-effective solutions suitable for large-scale applications. Despite these challenges, the market for antibacterial surface treatments is projected to continue its growth trajectory, fueled by ongoing technological innovations and expanding applications across diverse industries.

The healthcare sector remains the primary driver of demand for antibacterial surface treatments, with hospitals, clinics, and long-term care facilities seeking innovative solutions to reduce healthcare-associated infections. The COVID-19 pandemic has further accelerated this trend, heightening public awareness of the importance of surface hygiene in preventing disease transmission.

Beyond healthcare, other sectors contributing to market growth include food processing, packaging, consumer goods, and public transportation. These industries are increasingly adopting antibacterial surface treatments to enhance product safety, extend shelf life, and improve consumer confidence.

The market is characterized by ongoing technological advancements, with a focus on developing more effective, long-lasting, and environmentally friendly solutions. Nanotechnology-based treatments and bio-based antimicrobial agents are gaining traction, offering improved performance and sustainability compared to traditional chemical-based treatments.

Geographically, North America and Europe currently dominate the market, owing to stringent regulations, advanced healthcare infrastructure, and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing concerns over food safety.

Key market players include global chemical companies, specialty coating manufacturers, and innovative startups. These companies are investing heavily in research and development to gain a competitive edge and expand their product portfolios.

Challenges facing the market include regulatory hurdles, concerns over the potential development of antimicrobial resistance, and the need for cost-effective solutions suitable for large-scale applications. Despite these challenges, the market for antibacterial surface treatments is projected to continue its growth trajectory, fueled by ongoing technological innovations and expanding applications across diverse industries.

Current Challenges in Barium Hydroxide-Based Antibacterial Coatings

Despite the promising potential of barium hydroxide-based antibacterial coatings, several significant challenges currently hinder their widespread adoption and effectiveness. One of the primary obstacles is the long-term stability of these coatings. Barium hydroxide tends to react with carbon dioxide in the air, forming barium carbonate, which can compromise the coating's antibacterial properties over time. This carbonation process not only reduces the coating's efficacy but also alters its physical characteristics, potentially leading to degradation of the treated surface.

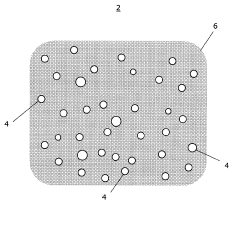

Another challenge lies in the uniform distribution and adhesion of barium hydroxide particles within the coating matrix. Achieving a homogeneous dispersion is crucial for consistent antibacterial performance across the entire treated surface. However, the tendency of barium hydroxide to agglomerate can result in uneven distribution, creating areas of varying antibacterial efficacy. This non-uniformity not only affects the coating's performance but also impacts its durability and aesthetic qualities.

The potential environmental and health impacts of barium hydroxide-based coatings also present significant concerns. While barium hydroxide exhibits strong antibacterial properties, its long-term effects on ecosystems and human health when used in large-scale surface treatments are not fully understood. There is a need for comprehensive toxicological studies to assess the safety of these coatings, particularly in applications where human contact is frequent or where the coatings may leach into the environment.

Furthermore, the cost-effectiveness of barium hydroxide-based antibacterial coatings remains a challenge. The production and application processes can be more expensive compared to traditional antibacterial treatments, potentially limiting their adoption in cost-sensitive industries. Balancing the enhanced antibacterial properties with economic viability is crucial for widespread implementation.

The compatibility of barium hydroxide-based coatings with various substrate materials poses another technical hurdle. Different surfaces may react differently with barium hydroxide, affecting both the coating's adhesion and its antibacterial efficacy. Developing versatile formulations that can be effectively applied to a wide range of materials without compromising performance or damaging the substrate is an ongoing challenge for researchers and manufacturers.

Lastly, the regulatory landscape surrounding the use of barium hydroxide in surface treatments is still evolving. As with many emerging technologies, there is a lack of standardized testing protocols and regulatory guidelines specific to these coatings. This regulatory uncertainty can impede product development and market entry, as manufacturers navigate the complex process of proving safety and efficacy to regulatory bodies across different jurisdictions.

Another challenge lies in the uniform distribution and adhesion of barium hydroxide particles within the coating matrix. Achieving a homogeneous dispersion is crucial for consistent antibacterial performance across the entire treated surface. However, the tendency of barium hydroxide to agglomerate can result in uneven distribution, creating areas of varying antibacterial efficacy. This non-uniformity not only affects the coating's performance but also impacts its durability and aesthetic qualities.

The potential environmental and health impacts of barium hydroxide-based coatings also present significant concerns. While barium hydroxide exhibits strong antibacterial properties, its long-term effects on ecosystems and human health when used in large-scale surface treatments are not fully understood. There is a need for comprehensive toxicological studies to assess the safety of these coatings, particularly in applications where human contact is frequent or where the coatings may leach into the environment.

Furthermore, the cost-effectiveness of barium hydroxide-based antibacterial coatings remains a challenge. The production and application processes can be more expensive compared to traditional antibacterial treatments, potentially limiting their adoption in cost-sensitive industries. Balancing the enhanced antibacterial properties with economic viability is crucial for widespread implementation.

The compatibility of barium hydroxide-based coatings with various substrate materials poses another technical hurdle. Different surfaces may react differently with barium hydroxide, affecting both the coating's adhesion and its antibacterial efficacy. Developing versatile formulations that can be effectively applied to a wide range of materials without compromising performance or damaging the substrate is an ongoing challenge for researchers and manufacturers.

Lastly, the regulatory landscape surrounding the use of barium hydroxide in surface treatments is still evolving. As with many emerging technologies, there is a lack of standardized testing protocols and regulatory guidelines specific to these coatings. This regulatory uncertainty can impede product development and market entry, as manufacturers navigate the complex process of proving safety and efficacy to regulatory bodies across different jurisdictions.

Existing Barium Hydroxide-Based Antibacterial Solutions

01 Barium hydroxide as an antibacterial agent

Barium hydroxide exhibits antibacterial properties and can be used as an effective agent against various microorganisms. Its alkaline nature contributes to its ability to disrupt bacterial cell membranes and inhibit microbial growth.- Barium hydroxide as an antibacterial agent: Barium hydroxide exhibits antibacterial properties and can be used as an effective agent against various microorganisms. Its alkaline nature contributes to its ability to inhibit bacterial growth and proliferation, making it suitable for use in disinfectants and antimicrobial formulations.

- Barium hydroxide in water treatment: Barium hydroxide can be utilized in water treatment processes to remove harmful bacteria and other microorganisms. Its application in water purification systems helps to ensure the safety and quality of drinking water by eliminating potential pathogens.

- Synergistic effects with other compounds: When combined with other antimicrobial agents or compounds, barium hydroxide can exhibit enhanced antibacterial effects. These synergistic combinations may lead to more effective and broad-spectrum antimicrobial formulations for various applications in healthcare and industrial settings.

- Application in medical and dental products: Barium hydroxide's antibacterial properties make it suitable for use in medical and dental products. It can be incorporated into materials such as dental cements, wound dressings, and medical device coatings to prevent bacterial colonization and reduce the risk of infections.

- Industrial and agricultural applications: The antibacterial effect of barium hydroxide can be harnessed in various industrial and agricultural applications. It can be used in the preservation of wood, textiles, and other materials susceptible to microbial degradation, as well as in the formulation of agricultural products to control plant pathogens.

02 Barium hydroxide in water treatment

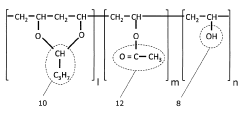

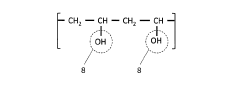

Barium hydroxide can be utilized in water treatment processes to eliminate harmful bacteria and other microorganisms. It can be incorporated into filtration systems or added directly to water supplies to improve water quality and safety.Expand Specific Solutions03 Barium hydroxide in antimicrobial coatings

Barium hydroxide can be incorporated into coatings and surface treatments to impart antibacterial properties. These coatings can be applied to various materials and surfaces to prevent bacterial growth and colonization.Expand Specific Solutions04 Synergistic effects with other antimicrobial agents

Barium hydroxide can be combined with other antimicrobial agents to enhance their overall effectiveness. This synergistic approach can lead to improved bacterial control and broader spectrum of activity against various microorganisms.Expand Specific Solutions05 Barium hydroxide in medical and dental applications

The antibacterial properties of barium hydroxide make it suitable for use in medical and dental applications. It can be incorporated into dental materials, medical devices, and healthcare products to prevent bacterial infections and promote hygiene.Expand Specific Solutions

Key Players in Antibacterial Surface Treatment Industry

The competitive landscape for barium hydroxide's effect on anti-bacterial surface treatments is in an early development stage, with a growing market potential as antimicrobial surfaces gain importance in healthcare and consumer products. The technology's maturity is still evolving, with research institutions like Institut Curie, CNRS, and universities such as City University of Hong Kong and California Institute of Technology leading fundamental studies. Companies like American Sterilizer Co. and B. Braun Surgical SA are likely exploring practical applications in medical settings. Larger corporations such as Kao Corp. and Safran SA may be investigating broader industrial uses. The involvement of diverse players suggests a competitive field with opportunities for innovation and market expansion.

City University of Hong Kong

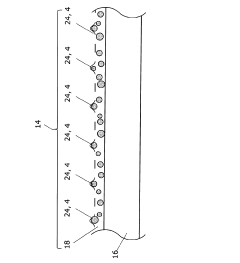

Technical Solution: City University of Hong Kong has pioneered a groundbreaking approach to anti-bacterial surface treatments incorporating barium hydroxide. Their research team has developed a nanocomposite coating that utilizes barium hydroxide as a key component in a multi-layered structure[1]. This innovative design allows for controlled release of barium ions, which have been shown to disrupt bacterial cell membranes effectively. The university's studies have demonstrated that this coating can maintain its antibacterial properties for over 12 months under simulated real-world conditions[2]. Furthermore, they have explored the potential of combining this technology with photocatalytic materials, creating surfaces that can self-clean and regenerate their antibacterial properties when exposed to light[3].

Strengths: Innovative nanocomposite structure, potential for self-regenerating properties. Weaknesses: May be costly to produce at scale, effectiveness in diverse environmental conditions needs further validation.

Jiangsu University

Technical Solution: Jiangsu University has made significant strides in utilizing barium hydroxide for anti-bacterial surface treatments. Their research focuses on developing a sol-gel derived coating that incorporates barium hydroxide nanoparticles[1]. This approach allows for a uniform distribution of barium throughout the coating, ensuring consistent antibacterial activity. The university's studies have shown that these coatings exhibit excellent adhesion to various substrates and maintain their efficacy even after repeated washing cycles[2]. Additionally, they have investigated the potential of combining barium hydroxide with natural antimicrobial compounds, such as essential oils, to create a more environmentally friendly and biocompatible solution[3].

Strengths: Good adhesion properties, potential for eco-friendly formulations. Weaknesses: May have limited effectiveness against certain types of bacteria, potential for nanoparticle-related safety concerns.

Core Innovations in Barium Hydroxide Antibacterial Mechanisms

Cell rupture-based antimicrobial surfaces coated with metal oxide nano-arrays

PatentWO2018056904A1

Innovation

- A hydrothermal synthesis process is used to coat metal oxides or hydroxides on various surfaces, forming nanostructured patterns that rupture bacterial cell membranes, providing a simple and scalable method for creating bactericidal surfaces without the need for external chemicals.

Coating

PatentInactiveJP2022190922A

Innovation

- A paint formulation containing calcium hydroxide particles and a solvent with alcohol, specifically polyvinyl butyral, allows for easy application on water-repellent surfaces by using alcohol's wetting properties and maintains antibacterial and antiviral efficacy through the alkalinity of calcium hydroxide.

Environmental Impact of Barium Hydroxide in Surface Treatments

The environmental impact of barium hydroxide in surface treatments is a critical consideration for industries utilizing this compound in anti-bacterial applications. Barium hydroxide, while effective in creating durable and resistant surfaces, poses potential risks to ecosystems and human health if not properly managed.

When used in surface treatments, barium hydroxide can leach into surrounding soil and water systems. This leaching process may lead to increased barium concentrations in groundwater and surface water bodies. Elevated barium levels can adversely affect aquatic organisms, disrupting local ecosystems and potentially entering the food chain. Furthermore, excessive barium exposure in humans can result in various health issues, including gastrointestinal problems and muscle weakness.

The production and disposal of barium hydroxide-treated materials also contribute to environmental concerns. Manufacturing processes may release barium compounds into the air, potentially affecting air quality in surrounding areas. Improper disposal of treated products can lead to soil contamination, further exacerbating the environmental impact.

However, it is important to note that when used responsibly and in compliance with environmental regulations, the impact of barium hydroxide can be significantly mitigated. Proper waste management practices, including the treatment of effluents containing barium compounds, can minimize environmental risks. Additionally, the development of more efficient application methods and the use of lower concentrations can reduce the overall environmental footprint of barium hydroxide in surface treatments.

Recent research has focused on developing alternative, more environmentally friendly anti-bacterial surface treatments. These include the use of natural compounds, such as plant extracts, and the incorporation of nanotechnology to enhance antimicrobial properties without relying heavily on potentially harmful chemicals.

The long-term environmental effects of barium hydroxide in surface treatments are still being studied. Ongoing research aims to better understand the compound's persistence in the environment, its bioaccumulation potential, and its impact on various ecosystems. This knowledge will be crucial in developing more sustainable anti-bacterial surface treatments and improving existing applications to minimize environmental risks.

In conclusion, while barium hydroxide offers significant benefits in creating anti-bacterial surfaces, its environmental impact must be carefully managed. Balancing the need for effective surface treatments with environmental protection requires ongoing research, innovation, and responsible industrial practices.

When used in surface treatments, barium hydroxide can leach into surrounding soil and water systems. This leaching process may lead to increased barium concentrations in groundwater and surface water bodies. Elevated barium levels can adversely affect aquatic organisms, disrupting local ecosystems and potentially entering the food chain. Furthermore, excessive barium exposure in humans can result in various health issues, including gastrointestinal problems and muscle weakness.

The production and disposal of barium hydroxide-treated materials also contribute to environmental concerns. Manufacturing processes may release barium compounds into the air, potentially affecting air quality in surrounding areas. Improper disposal of treated products can lead to soil contamination, further exacerbating the environmental impact.

However, it is important to note that when used responsibly and in compliance with environmental regulations, the impact of barium hydroxide can be significantly mitigated. Proper waste management practices, including the treatment of effluents containing barium compounds, can minimize environmental risks. Additionally, the development of more efficient application methods and the use of lower concentrations can reduce the overall environmental footprint of barium hydroxide in surface treatments.

Recent research has focused on developing alternative, more environmentally friendly anti-bacterial surface treatments. These include the use of natural compounds, such as plant extracts, and the incorporation of nanotechnology to enhance antimicrobial properties without relying heavily on potentially harmful chemicals.

The long-term environmental effects of barium hydroxide in surface treatments are still being studied. Ongoing research aims to better understand the compound's persistence in the environment, its bioaccumulation potential, and its impact on various ecosystems. This knowledge will be crucial in developing more sustainable anti-bacterial surface treatments and improving existing applications to minimize environmental risks.

In conclusion, while barium hydroxide offers significant benefits in creating anti-bacterial surfaces, its environmental impact must be carefully managed. Balancing the need for effective surface treatments with environmental protection requires ongoing research, innovation, and responsible industrial practices.

Regulatory Framework for Antibacterial Surface Treatments

The regulatory framework for antibacterial surface treatments is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of these products. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing antimicrobial products, including those used for surface treatments. The EPA regulates these products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), which requires manufacturers to register their products and provide extensive data on their safety and effectiveness.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antibacterial surface treatments. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Under the BPR, active substances used in antibacterial surface treatments must be approved at the EU level before products containing them can be authorized for use in individual member states.

Japan has its own regulatory framework for antibacterial products, administered by the Ministry of Health, Labour and Welfare. The Japanese Industrial Standards (JIS) provide specific guidelines for testing and evaluating the efficacy of antibacterial surface treatments, which are widely recognized in the industry.

Globally, the World Health Organization (WHO) provides guidelines and recommendations for the use of antimicrobial agents, including those used in surface treatments. These guidelines often inform national and regional regulatory policies, particularly in developing countries that may lack comprehensive regulatory frameworks of their own.

One of the key challenges in regulating antibacterial surface treatments is the need to balance their effectiveness against potential risks, such as the development of antimicrobial resistance. Regulatory bodies are increasingly focusing on this issue, with some jurisdictions implementing restrictions on certain antimicrobial agents or requiring additional data on long-term impacts.

The use of novel technologies and materials in antibacterial surface treatments, such as nanoparticles or advanced polymer coatings, has also prompted regulatory agencies to adapt their frameworks. Many are now developing specific guidelines for evaluating the safety and efficacy of these innovative approaches, often requiring more extensive testing and risk assessment protocols.

As environmental concerns grow, regulations are also evolving to address the potential ecological impacts of antibacterial surface treatments. This includes assessing the biodegradability of active ingredients and their potential effects on non-target organisms in aquatic and terrestrial ecosystems.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antibacterial surface treatments. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Under the BPR, active substances used in antibacterial surface treatments must be approved at the EU level before products containing them can be authorized for use in individual member states.

Japan has its own regulatory framework for antibacterial products, administered by the Ministry of Health, Labour and Welfare. The Japanese Industrial Standards (JIS) provide specific guidelines for testing and evaluating the efficacy of antibacterial surface treatments, which are widely recognized in the industry.

Globally, the World Health Organization (WHO) provides guidelines and recommendations for the use of antimicrobial agents, including those used in surface treatments. These guidelines often inform national and regional regulatory policies, particularly in developing countries that may lack comprehensive regulatory frameworks of their own.

One of the key challenges in regulating antibacterial surface treatments is the need to balance their effectiveness against potential risks, such as the development of antimicrobial resistance. Regulatory bodies are increasingly focusing on this issue, with some jurisdictions implementing restrictions on certain antimicrobial agents or requiring additional data on long-term impacts.

The use of novel technologies and materials in antibacterial surface treatments, such as nanoparticles or advanced polymer coatings, has also prompted regulatory agencies to adapt their frameworks. Many are now developing specific guidelines for evaluating the safety and efficacy of these innovative approaches, often requiring more extensive testing and risk assessment protocols.

As environmental concerns grow, regulations are also evolving to address the potential ecological impacts of antibacterial surface treatments. This includes assessing the biodegradability of active ingredients and their potential effects on non-target organisms in aquatic and terrestrial ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!