Application of Barium Hydroxide in Sustainable Structural Material Recycling

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Recycling: Background and Objectives

Barium hydroxide has emerged as a promising agent in the field of sustainable structural material recycling, marking a significant advancement in environmental conservation efforts. This technology has evolved from initial laboratory experiments to practical applications in various industrial sectors over the past few decades. The primary objective of utilizing barium hydroxide in recycling processes is to enhance the efficiency and effectiveness of material recovery while minimizing environmental impact.

The development of this technology can be traced back to the growing global concern over resource depletion and waste management. As traditional recycling methods often proved inadequate in dealing with complex structural materials, researchers began exploring alternative chemical processes. Barium hydroxide, with its unique properties, was identified as a potential solution due to its ability to react with and separate various components in composite materials.

The evolution of barium hydroxide application in recycling has been driven by several key factors. Firstly, the increasing scarcity of raw materials has necessitated more efficient recycling techniques. Secondly, stricter environmental regulations have pushed industries to adopt more sustainable practices. Lastly, advancements in chemical engineering and material science have enabled the refinement of barium hydroxide-based recycling processes.

The primary technical goal in this field is to develop a comprehensive and scalable system for recycling structural materials using barium hydroxide. This involves optimizing the chemical reactions to achieve higher recovery rates of valuable materials, reducing energy consumption in the process, and minimizing the generation of secondary waste. Additionally, there is a focus on improving the purity of recovered materials to enhance their reusability in high-quality applications.

Another crucial objective is to broaden the range of materials that can be effectively recycled using this technology. While initial applications focused on specific types of composites, ongoing research aims to extend the use of barium hydroxide to a wider variety of structural materials, including those used in construction, automotive, and aerospace industries.

Furthermore, there is a growing emphasis on integrating barium hydroxide-based recycling processes into existing industrial systems. This integration aims to create closed-loop recycling systems, where materials can be continuously recycled without significant loss of quality or value. Such an approach aligns with the principles of circular economy, which is increasingly becoming a priority in global sustainability efforts.

The development of this technology can be traced back to the growing global concern over resource depletion and waste management. As traditional recycling methods often proved inadequate in dealing with complex structural materials, researchers began exploring alternative chemical processes. Barium hydroxide, with its unique properties, was identified as a potential solution due to its ability to react with and separate various components in composite materials.

The evolution of barium hydroxide application in recycling has been driven by several key factors. Firstly, the increasing scarcity of raw materials has necessitated more efficient recycling techniques. Secondly, stricter environmental regulations have pushed industries to adopt more sustainable practices. Lastly, advancements in chemical engineering and material science have enabled the refinement of barium hydroxide-based recycling processes.

The primary technical goal in this field is to develop a comprehensive and scalable system for recycling structural materials using barium hydroxide. This involves optimizing the chemical reactions to achieve higher recovery rates of valuable materials, reducing energy consumption in the process, and minimizing the generation of secondary waste. Additionally, there is a focus on improving the purity of recovered materials to enhance their reusability in high-quality applications.

Another crucial objective is to broaden the range of materials that can be effectively recycled using this technology. While initial applications focused on specific types of composites, ongoing research aims to extend the use of barium hydroxide to a wider variety of structural materials, including those used in construction, automotive, and aerospace industries.

Furthermore, there is a growing emphasis on integrating barium hydroxide-based recycling processes into existing industrial systems. This integration aims to create closed-loop recycling systems, where materials can be continuously recycled without significant loss of quality or value. Such an approach aligns with the principles of circular economy, which is increasingly becoming a priority in global sustainability efforts.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market has been experiencing significant growth in recent years, driven by increasing environmental awareness, stringent regulations, and the push for circular economy practices. The global market for sustainable construction materials was valued at $199.98 billion in 2020 and is projected to reach $403.88 billion by 2030, growing at a CAGR of 7.3% from 2021 to 2030.

Within this market, the recycling of structural materials plays a crucial role. The construction and demolition waste (C&D waste) recycling market, a key segment of sustainable construction materials, is expected to grow from $126.9 billion in 2021 to $174.3 billion by 2026, at a CAGR of 6.5%. This growth is fueled by the increasing focus on resource efficiency and the need to reduce the environmental impact of construction activities.

The application of barium hydroxide in sustainable structural material recycling represents a niche but promising segment within this market. Barium hydroxide has shown potential in improving the recycling process of concrete and other cementitious materials, enhancing their properties and extending their lifecycle. This aligns with the growing demand for innovative recycling technologies that can produce high-quality recycled materials suitable for structural applications.

Regionally, Europe leads the sustainable construction materials market, followed by North America and Asia-Pacific. The European Union's Circular Economy Action Plan and stringent waste management regulations have been key drivers in this region. In North America, the U.S. Green Building Council's LEED certification program has significantly influenced the adoption of sustainable materials. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid urbanization and increasing government initiatives promoting sustainable construction practices.

The market for sustainable structural material recycling is characterized by a high degree of fragmentation, with numerous local and regional players. However, there is a growing trend of consolidation as larger companies seek to expand their capabilities in sustainable materials. Key market players are investing heavily in research and development to improve recycling technologies and develop new sustainable materials.

Challenges in the market include the higher initial costs of sustainable materials compared to traditional ones, inconsistent quality of recycled materials, and the need for standardization in recycling processes. However, these challenges are gradually being addressed through technological advancements and supportive government policies.

Within this market, the recycling of structural materials plays a crucial role. The construction and demolition waste (C&D waste) recycling market, a key segment of sustainable construction materials, is expected to grow from $126.9 billion in 2021 to $174.3 billion by 2026, at a CAGR of 6.5%. This growth is fueled by the increasing focus on resource efficiency and the need to reduce the environmental impact of construction activities.

The application of barium hydroxide in sustainable structural material recycling represents a niche but promising segment within this market. Barium hydroxide has shown potential in improving the recycling process of concrete and other cementitious materials, enhancing their properties and extending their lifecycle. This aligns with the growing demand for innovative recycling technologies that can produce high-quality recycled materials suitable for structural applications.

Regionally, Europe leads the sustainable construction materials market, followed by North America and Asia-Pacific. The European Union's Circular Economy Action Plan and stringent waste management regulations have been key drivers in this region. In North America, the U.S. Green Building Council's LEED certification program has significantly influenced the adoption of sustainable materials. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid urbanization and increasing government initiatives promoting sustainable construction practices.

The market for sustainable structural material recycling is characterized by a high degree of fragmentation, with numerous local and regional players. However, there is a growing trend of consolidation as larger companies seek to expand their capabilities in sustainable materials. Key market players are investing heavily in research and development to improve recycling technologies and develop new sustainable materials.

Challenges in the market include the higher initial costs of sustainable materials compared to traditional ones, inconsistent quality of recycled materials, and the need for standardization in recycling processes. However, these challenges are gradually being addressed through technological advancements and supportive government policies.

Current Challenges in Structural Material Recycling

The recycling of structural materials presents several significant challenges in the current landscape of sustainable construction and waste management. One of the primary obstacles is the heterogeneous nature of construction and demolition waste, which often contains a complex mixture of materials including concrete, steel, wood, plastics, and various contaminants. This diversity makes it difficult to implement efficient sorting and separation processes, leading to reduced recycling rates and increased costs.

Another major challenge is the degradation of material properties during the recycling process. For instance, recycled concrete aggregates often exhibit lower strength and durability compared to virgin materials, limiting their applications in high-performance structural elements. This quality issue is particularly pronounced in the recycling of composite materials, such as fiber-reinforced polymers, where the separation of fibers from the matrix without significant damage remains a technical hurdle.

The presence of hazardous substances in structural materials poses both environmental and health risks during the recycling process. Asbestos, lead-based paints, and certain chemical treatments used in older buildings require specialized handling and disposal methods, further complicating the recycling efforts and increasing associated costs.

Economic viability remains a significant barrier to widespread adoption of structural material recycling. The costs associated with collection, transportation, processing, and quality control of recycled materials often exceed those of virgin materials, particularly when oil prices are low. This economic disadvantage is exacerbated by the lack of consistent demand for recycled materials in the construction industry, partly due to concerns about their performance and regulatory restrictions.

Technological limitations in the recycling processes themselves present another set of challenges. Current methods for concrete recycling, for example, often focus on downcycling into lower-value applications rather than fully recovering the original material properties. The development of more advanced, efficient, and cost-effective recycling technologies is crucial for improving the quality and economic viability of recycled structural materials.

Regulatory frameworks and standards also play a critical role in the challenges faced by the structural material recycling industry. The lack of uniform, internationally recognized standards for recycled materials in construction applications creates uncertainty and hesitation among potential users. Additionally, varying regulations across different regions complicate the implementation of large-scale recycling initiatives and the cross-border movement of recycled materials.

Lastly, the carbon footprint associated with the recycling process itself is a growing concern. While recycling generally reduces overall environmental impact compared to using virgin materials, the energy-intensive nature of some recycling processes, particularly for metals and certain plastics, can partially offset these benefits. Developing more energy-efficient recycling technologies and incorporating renewable energy sources into these processes remains a significant challenge in the quest for truly sustainable structural material recycling.

Another major challenge is the degradation of material properties during the recycling process. For instance, recycled concrete aggregates often exhibit lower strength and durability compared to virgin materials, limiting their applications in high-performance structural elements. This quality issue is particularly pronounced in the recycling of composite materials, such as fiber-reinforced polymers, where the separation of fibers from the matrix without significant damage remains a technical hurdle.

The presence of hazardous substances in structural materials poses both environmental and health risks during the recycling process. Asbestos, lead-based paints, and certain chemical treatments used in older buildings require specialized handling and disposal methods, further complicating the recycling efforts and increasing associated costs.

Economic viability remains a significant barrier to widespread adoption of structural material recycling. The costs associated with collection, transportation, processing, and quality control of recycled materials often exceed those of virgin materials, particularly when oil prices are low. This economic disadvantage is exacerbated by the lack of consistent demand for recycled materials in the construction industry, partly due to concerns about their performance and regulatory restrictions.

Technological limitations in the recycling processes themselves present another set of challenges. Current methods for concrete recycling, for example, often focus on downcycling into lower-value applications rather than fully recovering the original material properties. The development of more advanced, efficient, and cost-effective recycling technologies is crucial for improving the quality and economic viability of recycled structural materials.

Regulatory frameworks and standards also play a critical role in the challenges faced by the structural material recycling industry. The lack of uniform, internationally recognized standards for recycled materials in construction applications creates uncertainty and hesitation among potential users. Additionally, varying regulations across different regions complicate the implementation of large-scale recycling initiatives and the cross-border movement of recycled materials.

Lastly, the carbon footprint associated with the recycling process itself is a growing concern. While recycling generally reduces overall environmental impact compared to using virgin materials, the energy-intensive nature of some recycling processes, particularly for metals and certain plastics, can partially offset these benefits. Developing more energy-efficient recycling technologies and incorporating renewable energy sources into these processes remains a significant challenge in the quest for truly sustainable structural material recycling.

Existing Barium Hydroxide Recycling Solutions

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with water or other reagents, followed by separation and purification steps to obtain high-quality barium hydroxide.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes often involve the reaction of barium compounds with other substances or the treatment of barium-containing materials to obtain high-purity barium hydroxide. The purification steps may include crystallization, filtration, and other separation techniques.

- Applications in chemical processes: Barium hydroxide is utilized in various chemical processes as a reagent or catalyst. It is employed in the production of other barium compounds, in organic synthesis reactions, and as a pH regulator. Its alkaline properties make it suitable for neutralization reactions and as a base in certain industrial applications.

- Use in water treatment and purification: Barium hydroxide finds applications in water treatment and purification processes. It can be used to remove certain contaminants from water, such as sulfates, and to adjust the pH of water systems. Its ability to form insoluble compounds with some ions makes it effective in water softening applications.

- Environmental and safety considerations: The handling and use of barium hydroxide require specific safety measures due to its corrosive nature and potential health hazards. Proper storage, transportation, and disposal methods are essential to minimize environmental impact and ensure worker safety. Techniques for reducing emissions and managing waste in barium hydroxide-related processes are also addressed.

- Novel applications and formulations: Emerging applications of barium hydroxide in various fields are explored. These include its use in advanced materials synthesis, energy storage technologies, and specialized industrial processes. Novel formulations and combinations with other substances are investigated to enhance its properties or create new functional materials.

02 Applications in chemical processes

Barium hydroxide is utilized in various chemical processes, including as a reagent in organic synthesis, a pH regulator, and a catalyst in certain reactions. Its alkaline properties make it suitable for neutralization and precipitation reactions in industrial settings.Expand Specific Solutions03 Use in water treatment and purification

Barium hydroxide finds applications in water treatment and purification processes. It can be used to remove certain contaminants, adjust pH levels, and as a component in water softening systems.Expand Specific Solutions04 Role in material synthesis and modification

Barium hydroxide is employed in the synthesis and modification of various materials, including ceramics, glasses, and specialty chemicals. It can act as a precursor for barium-containing compounds and contribute to the development of advanced materials with specific properties.Expand Specific Solutions05 Environmental and safety considerations

The use and handling of barium hydroxide require careful consideration of environmental and safety aspects. This includes proper storage, disposal methods, and safety measures to prevent exposure and mitigate potential hazards associated with its corrosive nature and toxicity.Expand Specific Solutions

Key Players in Sustainable Construction Industry

The application of barium hydroxide in sustainable structural material recycling is an emerging field in the construction and waste management industries. The market is in its early growth stage, with increasing interest driven by sustainability concerns and circular economy initiatives. While the global market size is still relatively small, it is expected to grow significantly in the coming years. The technology is advancing rapidly, with companies like Shandong Sinocera Functional Material Co., Ltd. and Binzhou Kunbao Chemical Co., Ltd. leading research and development efforts. Academic institutions such as Sichuan University and Peking University are also contributing to technological advancements. However, the technology is not yet fully mature, and further research is needed to optimize processes and improve cost-effectiveness for widespread commercial adoption.

Sichuan University

Technical Solution: Sichuan University has developed an innovative approach for sustainable structural material recycling using barium hydroxide. Their method focuses on the treatment of waste concrete, utilizing barium hydroxide to effectively extract and recover valuable components. The process involves crushing waste concrete into fine particles, then treating it with a barium hydroxide solution. This treatment facilitates the separation of cement paste from aggregates, allowing for the recovery of both materials[1]. Additionally, the university's research has shown that the recovered cement paste can be used as a supplementary cementitious material in new concrete mixtures, reducing the need for virgin cement production[2]. The process also captures CO2 during the treatment, contributing to carbon sequestration efforts[3].

Strengths: Efficient recovery of both cement paste and aggregates, reduction in virgin cement usage, and carbon sequestration. Weaknesses: Potential high costs associated with barium hydroxide and process implementation, limited large-scale application data.

Peking University

Technical Solution: Peking University has developed an advanced technique for sustainable structural material recycling using barium hydroxide. Their method focuses on the selective dissolution of calcium silicate hydrate (C-S-H) in hardened cement paste. The process involves treating crushed concrete with a barium hydroxide solution under controlled temperature and pressure conditions. This treatment selectively dissolves the C-S-H, leaving behind the aggregates and other components[1]. The dissolved C-S-H reacts with barium hydroxide to form barium silicate hydrate (Ba-S-H) and calcium hydroxide. The Ba-S-H can be further processed to recover barium hydroxide for reuse, while the calcium hydroxide can be carbonated to produce calcium carbonate, which has various industrial applications[2]. This method allows for the recovery of up to 80% of the cement paste, significantly reducing the need for new cement production[3]. Additionally, the process has been shown to effectively immobilize heavy metals present in the waste concrete, addressing environmental concerns[4].

Strengths: High recovery rate of cement paste, effective immobilization of heavy metals, potential for significant reduction in new cement production. Weaknesses: Energy-intensive process, potential scalability issues, need for careful management of barium compounds.

Innovations in Barium Hydroxide Application

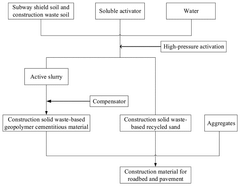

Method for preparing construction material for roadbed and pavement by using construction solid waste-based geopolymers

PatentPendingUS20250011234A1

Innovation

- A method using barium hydroxide as a main activator for high-pressure activation of construction solid wastes, combined with a compensator containing sodium, calcium, and aluminum ions, to produce a geopolymer cementitious material with a dense three-dimensional network structure, allowing for the full utilization of construction solid wastes and reducing energy consumption.

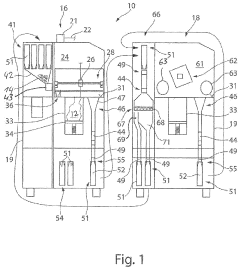

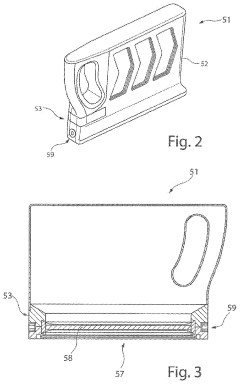

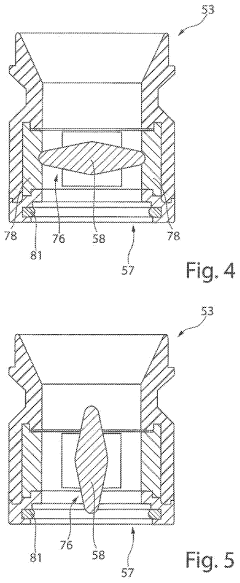

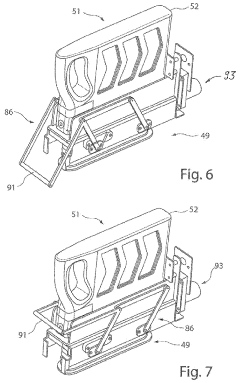

Method and plant for the recovery of processed powdered structural material, and recovery device and cartridge for a recovery device of this kind

PatentPendingUS20220402037A1

Innovation

- A recovery device and cartridge system that simplifies the recycling process by using cartridges to collect, sieve, and reutilize processed powdered structural material, minimizing staff contact and enabling cost-effective and eco-friendly recycling through a structured circuit for reintegration into the manufacturing process.

Environmental Impact Assessment

The application of barium hydroxide in sustainable structural material recycling presents both opportunities and challenges from an environmental perspective. This assessment examines the potential impacts on ecosystems, resource conservation, and overall sustainability.

Barium hydroxide's use in recycling processes can significantly reduce the environmental footprint of construction and demolition waste management. By enabling the effective recycling of concrete and other structural materials, it helps conserve natural resources and minimize the need for raw material extraction. This, in turn, reduces the environmental degradation associated with mining and quarrying activities, including habitat destruction, soil erosion, and water pollution.

The recycling process itself, when optimized with barium hydroxide, can lead to lower energy consumption compared to traditional recycling methods. This translates to reduced greenhouse gas emissions and a smaller carbon footprint for the construction industry. Additionally, the improved efficiency in material recovery means less waste ends up in landfills, addressing the growing concern of landfill capacity and associated environmental issues.

However, the use of barium hydroxide is not without potential environmental risks. Barium compounds can be toxic to aquatic life and may pose risks to soil ecosystems if not properly managed. Careful handling and disposal protocols must be implemented to prevent accidental releases into the environment. This includes proper treatment of any wastewater generated during the recycling process to remove barium residues before discharge.

The production of barium hydroxide also needs consideration in the overall environmental impact assessment. While its application in recycling offers environmental benefits, the manufacturing process of barium hydroxide itself may have associated emissions and resource requirements that need to be factored into the lifecycle analysis.

On a broader scale, the adoption of barium hydroxide in structural material recycling contributes to the circular economy model. By enhancing the recyclability and reusability of construction materials, it helps close the loop in material flows, reducing the overall environmental burden of the built environment. This aligns with global sustainability goals and supports the transition towards more environmentally responsible construction practices.

In conclusion, while the application of barium hydroxide in sustainable structural material recycling offers significant environmental benefits, particularly in resource conservation and waste reduction, it also requires careful management to mitigate potential risks. A comprehensive lifecycle assessment and strict environmental protocols are essential to ensure that the net environmental impact remains positive.

Barium hydroxide's use in recycling processes can significantly reduce the environmental footprint of construction and demolition waste management. By enabling the effective recycling of concrete and other structural materials, it helps conserve natural resources and minimize the need for raw material extraction. This, in turn, reduces the environmental degradation associated with mining and quarrying activities, including habitat destruction, soil erosion, and water pollution.

The recycling process itself, when optimized with barium hydroxide, can lead to lower energy consumption compared to traditional recycling methods. This translates to reduced greenhouse gas emissions and a smaller carbon footprint for the construction industry. Additionally, the improved efficiency in material recovery means less waste ends up in landfills, addressing the growing concern of landfill capacity and associated environmental issues.

However, the use of barium hydroxide is not without potential environmental risks. Barium compounds can be toxic to aquatic life and may pose risks to soil ecosystems if not properly managed. Careful handling and disposal protocols must be implemented to prevent accidental releases into the environment. This includes proper treatment of any wastewater generated during the recycling process to remove barium residues before discharge.

The production of barium hydroxide also needs consideration in the overall environmental impact assessment. While its application in recycling offers environmental benefits, the manufacturing process of barium hydroxide itself may have associated emissions and resource requirements that need to be factored into the lifecycle analysis.

On a broader scale, the adoption of barium hydroxide in structural material recycling contributes to the circular economy model. By enhancing the recyclability and reusability of construction materials, it helps close the loop in material flows, reducing the overall environmental burden of the built environment. This aligns with global sustainability goals and supports the transition towards more environmentally responsible construction practices.

In conclusion, while the application of barium hydroxide in sustainable structural material recycling offers significant environmental benefits, particularly in resource conservation and waste reduction, it also requires careful management to mitigate potential risks. A comprehensive lifecycle assessment and strict environmental protocols are essential to ensure that the net environmental impact remains positive.

Regulatory Framework for Recycled Construction Materials

The regulatory framework for recycled construction materials plays a crucial role in promoting sustainable practices within the construction industry. As the use of barium hydroxide in structural material recycling gains traction, it becomes imperative to understand and navigate the existing regulations and standards governing this process.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed guidelines for the use of recycled materials in construction. ISO 14021 and ISO 14024 provide specifications for environmental labels and declarations, which can be applied to recycled construction materials. These standards ensure that claims about recycled content are accurate and verifiable.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products. The CPR includes provisions for the use of recycled materials, requiring manufacturers to declare the performance of their products, including those containing recycled content. The European Committee for Standardization (CEN) has also developed specific standards for recycled aggregates, such as EN 12620 for concrete aggregates.

In the United States, the Environmental Protection Agency (EPA) provides guidelines for the use of recycled materials in construction through its Comprehensive Procurement Guidelines (CPG) program. The program recommends recycled-content levels for various construction products, encouraging the use of recycled materials in federal projects.

Many countries have implemented their own regulations and standards for recycled construction materials. For instance, in the United Kingdom, the WRAP (Waste and Resources Action Programme) Quality Protocol for Aggregates provides a framework for the production of aggregates from inert waste. This protocol ensures that recycled aggregates meet end-of-waste criteria and can be used without further waste regulation controls.

As the application of barium hydroxide in structural material recycling advances, it is likely that new regulations and standards will emerge to address this specific process. Currently, there are no widespread regulations explicitly governing the use of barium hydroxide in recycling construction materials. However, existing regulations on chemical use in construction, such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in the EU, may apply to the use of barium hydroxide in recycling processes.

To facilitate the adoption of barium hydroxide in sustainable structural material recycling, it will be necessary to develop new standards and potentially amend existing regulations. This process will likely involve collaboration between industry stakeholders, research institutions, and regulatory bodies to ensure that the use of barium hydroxide in recycling is safe, effective, and environmentally beneficial.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed guidelines for the use of recycled materials in construction. ISO 14021 and ISO 14024 provide specifications for environmental labels and declarations, which can be applied to recycled construction materials. These standards ensure that claims about recycled content are accurate and verifiable.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products. The CPR includes provisions for the use of recycled materials, requiring manufacturers to declare the performance of their products, including those containing recycled content. The European Committee for Standardization (CEN) has also developed specific standards for recycled aggregates, such as EN 12620 for concrete aggregates.

In the United States, the Environmental Protection Agency (EPA) provides guidelines for the use of recycled materials in construction through its Comprehensive Procurement Guidelines (CPG) program. The program recommends recycled-content levels for various construction products, encouraging the use of recycled materials in federal projects.

Many countries have implemented their own regulations and standards for recycled construction materials. For instance, in the United Kingdom, the WRAP (Waste and Resources Action Programme) Quality Protocol for Aggregates provides a framework for the production of aggregates from inert waste. This protocol ensures that recycled aggregates meet end-of-waste criteria and can be used without further waste regulation controls.

As the application of barium hydroxide in structural material recycling advances, it is likely that new regulations and standards will emerge to address this specific process. Currently, there are no widespread regulations explicitly governing the use of barium hydroxide in recycling construction materials. However, existing regulations on chemical use in construction, such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in the EU, may apply to the use of barium hydroxide in recycling processes.

To facilitate the adoption of barium hydroxide in sustainable structural material recycling, it will be necessary to develop new standards and potentially amend existing regulations. This process will likely involve collaboration between industry stakeholders, research institutions, and regulatory bodies to ensure that the use of barium hydroxide in recycling is safe, effective, and environmentally beneficial.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!