Enhancing Adhesive Bonding with Barium Hydroxide in Automotive Production

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Adhesive Tech Evolution

The evolution of adhesive technology in the automotive industry has been marked by significant advancements, particularly in the realm of enhancing bonding strength and durability. The journey began with simple mechanical fasteners and progressed through various stages of chemical adhesives, each offering improved performance characteristics.

In the early days of automotive manufacturing, mechanical fasteners such as rivets and bolts were the primary means of joining components. However, as vehicle designs became more complex and weight reduction became a priority, the industry began to explore alternative joining methods. This led to the introduction of basic adhesives, which offered advantages in terms of weight savings and stress distribution.

The 1950s and 1960s saw the emergence of synthetic adhesives, including epoxies and acrylics, which provided stronger bonds and greater versatility. These adhesives allowed for the joining of dissimilar materials, a crucial factor in the increasingly diverse material compositions of modern vehicles. As environmental concerns grew, the 1970s and 1980s witnessed the development of water-based adhesives, reducing the reliance on solvent-based formulations.

The 1990s marked a significant leap forward with the introduction of structural adhesives capable of withstanding high loads and harsh environmental conditions. These adhesives became integral to vehicle assembly, particularly in areas requiring high strength and durability. Concurrently, advancements in surface preparation techniques and primer technologies further enhanced bond strength and longevity.

The turn of the millennium brought about a focus on multi-material bonding solutions, addressing the automotive industry's shift towards lightweight materials such as aluminum and composites. This period also saw the rise of smart adhesives, capable of self-healing or indicating bond integrity through color changes.

Recent years have witnessed a surge in research aimed at improving adhesive performance under extreme conditions and enhancing overall vehicle safety. The integration of nanotechnology has led to adhesives with superior strength-to-weight ratios and improved thermal and electrical properties. Additionally, the development of fast-curing adhesives has significantly reduced assembly times, meeting the demands of high-volume production.

The latest frontier in adhesive technology involves the exploration of bio-based and environmentally friendly formulations, aligning with the industry's sustainability goals. This includes the investigation of novel compounds, such as barium hydroxide, to enhance bonding strength while minimizing environmental impact.

In the early days of automotive manufacturing, mechanical fasteners such as rivets and bolts were the primary means of joining components. However, as vehicle designs became more complex and weight reduction became a priority, the industry began to explore alternative joining methods. This led to the introduction of basic adhesives, which offered advantages in terms of weight savings and stress distribution.

The 1950s and 1960s saw the emergence of synthetic adhesives, including epoxies and acrylics, which provided stronger bonds and greater versatility. These adhesives allowed for the joining of dissimilar materials, a crucial factor in the increasingly diverse material compositions of modern vehicles. As environmental concerns grew, the 1970s and 1980s witnessed the development of water-based adhesives, reducing the reliance on solvent-based formulations.

The 1990s marked a significant leap forward with the introduction of structural adhesives capable of withstanding high loads and harsh environmental conditions. These adhesives became integral to vehicle assembly, particularly in areas requiring high strength and durability. Concurrently, advancements in surface preparation techniques and primer technologies further enhanced bond strength and longevity.

The turn of the millennium brought about a focus on multi-material bonding solutions, addressing the automotive industry's shift towards lightweight materials such as aluminum and composites. This period also saw the rise of smart adhesives, capable of self-healing or indicating bond integrity through color changes.

Recent years have witnessed a surge in research aimed at improving adhesive performance under extreme conditions and enhancing overall vehicle safety. The integration of nanotechnology has led to adhesives with superior strength-to-weight ratios and improved thermal and electrical properties. Additionally, the development of fast-curing adhesives has significantly reduced assembly times, meeting the demands of high-volume production.

The latest frontier in adhesive technology involves the exploration of bio-based and environmentally friendly formulations, aligning with the industry's sustainability goals. This includes the investigation of novel compounds, such as barium hydroxide, to enhance bonding strength while minimizing environmental impact.

Automotive Bonding Demand

The automotive industry has witnessed a significant surge in demand for advanced adhesive bonding solutions, driven by the need for lightweight construction, improved fuel efficiency, and enhanced vehicle safety. As manufacturers strive to meet stringent environmental regulations and consumer expectations, the role of adhesive bonding in automotive production has become increasingly critical.

The market for automotive adhesives is experiencing robust growth, with a particular focus on high-performance bonding solutions that can withstand the rigorous demands of modern vehicle assembly. This demand is fueled by the industry's shift towards electric vehicles and the integration of new materials such as composites and advanced alloys, which require specialized bonding techniques.

Adhesive bonding offers several advantages over traditional joining methods like welding or mechanical fastening. It allows for the joining of dissimilar materials, provides more uniform stress distribution, and contributes to weight reduction without compromising structural integrity. These benefits align perfectly with the automotive industry's goals of producing lighter, more fuel-efficient vehicles while maintaining or improving safety standards.

The demand for adhesive bonding solutions extends across various automotive applications, including body-in-white assembly, interior trim attachment, powertrain components, and electronics integration. Manufacturers are seeking adhesives that not only provide strong and durable bonds but also offer additional functionalities such as noise and vibration damping, thermal management, and corrosion resistance.

In recent years, there has been a growing interest in environmentally friendly adhesive solutions, reflecting the industry's commitment to sustainability. This has led to increased demand for water-based and solvent-free adhesives that reduce volatile organic compound (VOC) emissions during the manufacturing process.

The automotive sector's push towards automation and Industry 4.0 principles has also influenced adhesive bonding demand. There is a rising need for adhesives that are compatible with automated application systems and can be integrated into smart manufacturing processes, offering features such as real-time curing monitoring and quality control.

As vehicle designs become more complex and incorporate a wider range of materials, the demand for versatile adhesive solutions capable of bonding multiple substrates continues to grow. This trend is particularly evident in the electric vehicle segment, where battery pack assembly and thermal management systems require specialized bonding technologies.

The exploration of novel adhesive formulations, such as those incorporating barium hydroxide, represents a response to the industry's evolving needs. These innovative solutions aim to address specific challenges in automotive production, such as improving bond strength, enhancing durability under extreme conditions, and optimizing production efficiency.

The market for automotive adhesives is experiencing robust growth, with a particular focus on high-performance bonding solutions that can withstand the rigorous demands of modern vehicle assembly. This demand is fueled by the industry's shift towards electric vehicles and the integration of new materials such as composites and advanced alloys, which require specialized bonding techniques.

Adhesive bonding offers several advantages over traditional joining methods like welding or mechanical fastening. It allows for the joining of dissimilar materials, provides more uniform stress distribution, and contributes to weight reduction without compromising structural integrity. These benefits align perfectly with the automotive industry's goals of producing lighter, more fuel-efficient vehicles while maintaining or improving safety standards.

The demand for adhesive bonding solutions extends across various automotive applications, including body-in-white assembly, interior trim attachment, powertrain components, and electronics integration. Manufacturers are seeking adhesives that not only provide strong and durable bonds but also offer additional functionalities such as noise and vibration damping, thermal management, and corrosion resistance.

In recent years, there has been a growing interest in environmentally friendly adhesive solutions, reflecting the industry's commitment to sustainability. This has led to increased demand for water-based and solvent-free adhesives that reduce volatile organic compound (VOC) emissions during the manufacturing process.

The automotive sector's push towards automation and Industry 4.0 principles has also influenced adhesive bonding demand. There is a rising need for adhesives that are compatible with automated application systems and can be integrated into smart manufacturing processes, offering features such as real-time curing monitoring and quality control.

As vehicle designs become more complex and incorporate a wider range of materials, the demand for versatile adhesive solutions capable of bonding multiple substrates continues to grow. This trend is particularly evident in the electric vehicle segment, where battery pack assembly and thermal management systems require specialized bonding technologies.

The exploration of novel adhesive formulations, such as those incorporating barium hydroxide, represents a response to the industry's evolving needs. These innovative solutions aim to address specific challenges in automotive production, such as improving bond strength, enhancing durability under extreme conditions, and optimizing production efficiency.

Barium Hydroxide Challenges

The integration of barium hydroxide in automotive adhesive bonding processes presents several significant challenges that need to be addressed for successful implementation. One of the primary concerns is the potential health and safety risks associated with barium compounds. Barium hydroxide is classified as a hazardous substance, and prolonged exposure can lead to respiratory issues, skin irritation, and other health problems. This necessitates stringent safety protocols and protective measures in manufacturing environments, potentially increasing operational costs and complexity.

Another challenge lies in the chemical reactivity of barium hydroxide. Its strong alkaline nature can interfere with certain adhesive formulations, potentially altering their curing processes or compromising their long-term stability. This requires extensive research and development to create compatible adhesive systems that can maintain their performance characteristics when combined with barium hydroxide.

The environmental impact of barium hydroxide usage is also a significant concern. Improper disposal or accidental release can lead to soil and water contamination, posing risks to ecosystems and human health. Automotive manufacturers must implement robust waste management and recycling processes to mitigate these environmental risks, which may require substantial investments in infrastructure and training.

From a production standpoint, incorporating barium hydroxide into existing manufacturing processes presents logistical challenges. The compound's sensitivity to moisture and carbon dioxide in the air necessitates careful handling and storage procedures. This may require modifications to production lines, including the installation of specialized equipment for dispensing and mixing, as well as climate-controlled storage facilities.

Quality control and consistency in adhesive performance are critical in automotive manufacturing. The addition of barium hydroxide introduces new variables that need to be carefully monitored and controlled. Variations in barium hydroxide concentration or purity can significantly impact bond strength and durability, requiring the development of precise measurement and mixing techniques to ensure consistent results across large-scale production.

Regulatory compliance is another hurdle in the adoption of barium hydroxide in automotive adhesives. Different regions and countries may have varying regulations regarding the use of barium compounds in manufacturing processes. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly, potentially delaying product launches or limiting market access.

Lastly, the cost implications of incorporating barium hydroxide into adhesive formulations must be carefully evaluated. While it may offer performance benefits, the additional expenses associated with sourcing, handling, and processing barium hydroxide could impact the overall cost-effectiveness of the adhesive solution. Manufacturers must weigh these costs against the potential improvements in bond strength and durability to determine the economic viability of this approach.

Another challenge lies in the chemical reactivity of barium hydroxide. Its strong alkaline nature can interfere with certain adhesive formulations, potentially altering their curing processes or compromising their long-term stability. This requires extensive research and development to create compatible adhesive systems that can maintain their performance characteristics when combined with barium hydroxide.

The environmental impact of barium hydroxide usage is also a significant concern. Improper disposal or accidental release can lead to soil and water contamination, posing risks to ecosystems and human health. Automotive manufacturers must implement robust waste management and recycling processes to mitigate these environmental risks, which may require substantial investments in infrastructure and training.

From a production standpoint, incorporating barium hydroxide into existing manufacturing processes presents logistical challenges. The compound's sensitivity to moisture and carbon dioxide in the air necessitates careful handling and storage procedures. This may require modifications to production lines, including the installation of specialized equipment for dispensing and mixing, as well as climate-controlled storage facilities.

Quality control and consistency in adhesive performance are critical in automotive manufacturing. The addition of barium hydroxide introduces new variables that need to be carefully monitored and controlled. Variations in barium hydroxide concentration or purity can significantly impact bond strength and durability, requiring the development of precise measurement and mixing techniques to ensure consistent results across large-scale production.

Regulatory compliance is another hurdle in the adoption of barium hydroxide in automotive adhesives. Different regions and countries may have varying regulations regarding the use of barium compounds in manufacturing processes. Navigating these regulatory landscapes and obtaining necessary approvals can be time-consuming and costly, potentially delaying product launches or limiting market access.

Lastly, the cost implications of incorporating barium hydroxide into adhesive formulations must be carefully evaluated. While it may offer performance benefits, the additional expenses associated with sourcing, handling, and processing barium hydroxide could impact the overall cost-effectiveness of the adhesive solution. Manufacturers must weigh these costs against the potential improvements in bond strength and durability to determine the economic viability of this approach.

Current Barium Hydroxide Use

01 Use of barium hydroxide in adhesive compositions

Barium hydroxide is utilized as a key component in adhesive formulations, particularly for bonding applications. It can enhance the adhesive properties and improve the overall performance of the bonding material. The incorporation of barium hydroxide can lead to stronger and more durable adhesive bonds in various industrial applications.- Use of barium hydroxide in adhesive compositions: Barium hydroxide is utilized as a key component in adhesive formulations, particularly for bonding applications. It can enhance the adhesive properties and improve the overall performance of the bonding material. The incorporation of barium hydroxide can lead to stronger and more durable adhesive bonds in various industrial applications.

- Barium hydroxide as a curing agent: Barium hydroxide serves as an effective curing agent in adhesive systems. It can initiate and accelerate the curing process, leading to faster bond formation and improved adhesion strength. The use of barium hydroxide as a curing agent can be particularly beneficial in applications requiring rapid bonding or assembly.

- Barium hydroxide in high-temperature adhesive applications: Barium hydroxide is employed in the development of high-temperature resistant adhesives. Its incorporation can enhance the thermal stability of the adhesive, making it suitable for applications involving elevated temperatures. This property is particularly valuable in industries such as aerospace, automotive, and electronics.

- Combination of barium hydroxide with other compounds: The combination of barium hydroxide with other compounds can lead to synergistic effects in adhesive formulations. These combinations can enhance various properties such as bond strength, chemical resistance, and durability. The specific compounds used in conjunction with barium hydroxide can be tailored to meet the requirements of different bonding applications.

- Barium hydroxide in specialized bonding applications: Barium hydroxide finds use in specialized bonding applications, such as in the production of abrasive materials, ceramic bonding, and glass-to-metal seals. Its unique properties make it suitable for these niche applications where conventional adhesives may not perform adequately. The use of barium hydroxide in these specialized areas can lead to improved product performance and durability.

02 Barium hydroxide as a curing agent

Barium hydroxide serves as an effective curing agent in adhesive systems. It can initiate and accelerate the curing process, leading to faster bond formation and improved adhesion strength. The use of barium hydroxide as a curing agent can be particularly beneficial in applications requiring rapid bonding or assembly.Expand Specific Solutions03 Barium hydroxide in high-temperature adhesive applications

Barium hydroxide is employed in adhesive formulations designed for high-temperature applications. It can enhance the thermal stability of the adhesive, allowing it to maintain its bonding properties under elevated temperature conditions. This makes it suitable for use in industries such as automotive, aerospace, and electronics manufacturing.Expand Specific Solutions04 Combination of barium hydroxide with other additives

Barium hydroxide is often combined with other additives to create synergistic effects in adhesive formulations. These combinations can lead to improved adhesion, increased bond strength, or enhanced resistance to environmental factors. The specific additives used may vary depending on the intended application and desired properties of the adhesive.Expand Specific Solutions05 Barium hydroxide in specialty adhesive applications

Barium hydroxide finds use in specialty adhesive applications, such as in the production of optical adhesives, dental adhesives, or adhesives for specific industrial processes. Its unique properties can contribute to the development of adhesives with tailored characteristics for these specialized applications, offering advantages over conventional adhesive formulations.Expand Specific Solutions

Key Adhesive Manufacturers

The automotive adhesive bonding market utilizing barium hydroxide is in a growth phase, driven by increasing demand for lightweight vehicles and improved fuel efficiency. The market size is expanding, with major players like 3M, Henkel, and Dow Global Technologies leading innovation. These companies, along with others such as Sika Technology and BASF, are advancing the technology's maturity through continuous research and development. The competitive landscape is characterized by a mix of established chemical companies and specialized adhesive manufacturers, each striving to enhance bond strength, durability, and environmental compatibility in automotive applications.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a proprietary adhesive system that utilizes barium hydroxide as a key component to enhance bonding in automotive applications. Their technology involves a modified epoxy-based adhesive with barium hydroxide nanoparticles dispersed throughout the matrix. This formulation creates a more robust interfacial layer between the adhesive and substrate, significantly improving bond strength and resistance to environmental factors[2]. Henkel's approach also incorporates a unique curing mechanism that is activated by the presence of barium hydroxide, allowing for faster assembly times in automotive production lines[4]. Additionally, their system includes specialized primers designed to work synergistically with the barium hydroxide-enhanced adhesive, further improving adhesion to a wide range of automotive materials[6].

Strengths: Enhanced bond strength, improved resistance to environmental factors, and faster production times. Weaknesses: May require specialized application equipment and careful control of nanoparticle dispersion.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has innovated in the field of adhesive bonding for automotive production by developing a barium hydroxide-enhanced structural adhesive system. Their technology incorporates barium hydroxide into a modified epoxy resin matrix, creating a network of ionic crosslinks that significantly enhance the adhesive's mechanical properties and durability[13]. Toyota's approach also includes a novel curing process that utilizes the alkaline nature of barium hydroxide to catalyze the adhesive polymerization, resulting in faster bonding times and improved production efficiency[15]. Furthermore, their system features a smart adhesive formulation that can adapt its properties based on the specific requirements of different vehicle components, providing optimal performance across various applications within the automotive assembly process[17].

Strengths: Enhanced mechanical properties, faster curing times, and adaptability to different automotive applications. Weaknesses: May require specialized handling and storage procedures for the barium hydroxide-containing adhesive components.

Barium Hydroxide Innovations

Production of barium hydroxide monohydrate

PatentInactiveUS3661520A

Innovation

- Heating barium hydroxide monohydrate particles to 100-140°C and passing an inert sweep gas to remove excess water, increasing the Ba(OH)2·H2O assay to at least 99% and eliminating higher hydrates, preventing agglomeration.

Method for manufacturing joined body

PatentWO2025018333A1

Innovation

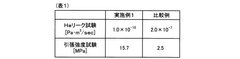

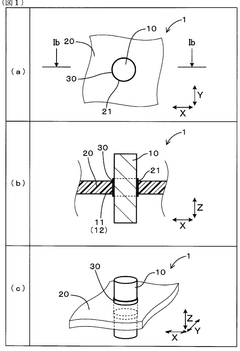

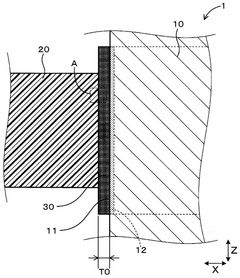

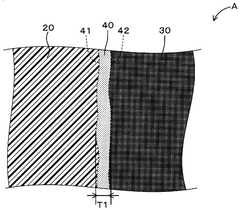

- A manufacturing method involving an adhesive layer formed by electrodeposition coating, where a compatible layer is created between the resin member and the adhesive layer, and the adhesive layer is heated to an uncured state to ensure proper bonding and subsequent reheating to enhance airtightness, achieving a helium leakage rate of 1×10⁻¹⁰ Pa·m³/sec or less.

Environmental Impact Analysis

The use of barium hydroxide in enhancing adhesive bonding for automotive production raises significant environmental considerations. This process, while potentially improving vehicle manufacturing efficiency, necessitates a thorough analysis of its ecological footprint.

Barium hydroxide, a strong base, can have substantial impacts on aquatic ecosystems if released into water bodies. Its high alkalinity may alter pH levels, potentially harming aquatic flora and fauna. Proper waste management and treatment protocols are crucial to mitigate these risks. Additionally, the production of barium hydroxide itself involves energy-intensive processes, contributing to greenhouse gas emissions and resource depletion.

However, the enhanced bonding strength achieved through this method may lead to longer-lasting automotive components, potentially reducing the need for replacements and thereby decreasing overall material consumption and waste generation in the long term. This durability factor could contribute positively to the vehicle's lifecycle assessment.

The application process of barium hydroxide in adhesive bonding may also have air quality implications. Volatile organic compounds (VOCs) and particulate matter emissions during application should be carefully monitored and controlled to ensure compliance with air quality regulations and to protect worker health.

From a circular economy perspective, the use of barium hydroxide may present challenges in end-of-life vehicle recycling. The strong bonds created might complicate the separation of materials, potentially hindering the recyclability of certain components. This aspect requires careful consideration in the vehicle design phase to ensure that the benefits of enhanced bonding do not compromise the ability to recycle or reuse materials at the end of the vehicle's life.

Energy consumption during the application process is another environmental factor to consider. While the improved bonding may reduce the need for additional fastening methods, the energy required for the barium hydroxide treatment should be evaluated against potential energy savings in other areas of the production process.

Lastly, the sourcing of barium hydroxide and its environmental impact in the supply chain should not be overlooked. Responsible sourcing practices and supplier engagement can help minimize the upstream environmental footprint associated with this material.

In conclusion, while barium hydroxide shows promise in enhancing adhesive bonding in automotive production, a comprehensive life cycle assessment is essential to fully understand and mitigate its environmental impacts. Balancing the benefits of improved vehicle durability against potential ecological risks will be crucial in determining the overall sustainability of this technology in automotive manufacturing.

Barium hydroxide, a strong base, can have substantial impacts on aquatic ecosystems if released into water bodies. Its high alkalinity may alter pH levels, potentially harming aquatic flora and fauna. Proper waste management and treatment protocols are crucial to mitigate these risks. Additionally, the production of barium hydroxide itself involves energy-intensive processes, contributing to greenhouse gas emissions and resource depletion.

However, the enhanced bonding strength achieved through this method may lead to longer-lasting automotive components, potentially reducing the need for replacements and thereby decreasing overall material consumption and waste generation in the long term. This durability factor could contribute positively to the vehicle's lifecycle assessment.

The application process of barium hydroxide in adhesive bonding may also have air quality implications. Volatile organic compounds (VOCs) and particulate matter emissions during application should be carefully monitored and controlled to ensure compliance with air quality regulations and to protect worker health.

From a circular economy perspective, the use of barium hydroxide may present challenges in end-of-life vehicle recycling. The strong bonds created might complicate the separation of materials, potentially hindering the recyclability of certain components. This aspect requires careful consideration in the vehicle design phase to ensure that the benefits of enhanced bonding do not compromise the ability to recycle or reuse materials at the end of the vehicle's life.

Energy consumption during the application process is another environmental factor to consider. While the improved bonding may reduce the need for additional fastening methods, the energy required for the barium hydroxide treatment should be evaluated against potential energy savings in other areas of the production process.

Lastly, the sourcing of barium hydroxide and its environmental impact in the supply chain should not be overlooked. Responsible sourcing practices and supplier engagement can help minimize the upstream environmental footprint associated with this material.

In conclusion, while barium hydroxide shows promise in enhancing adhesive bonding in automotive production, a comprehensive life cycle assessment is essential to fully understand and mitigate its environmental impacts. Balancing the benefits of improved vehicle durability against potential ecological risks will be crucial in determining the overall sustainability of this technology in automotive manufacturing.

Safety Regulations Compliance

In the automotive industry, safety is paramount, and the use of barium hydroxide in adhesive bonding processes must comply with stringent safety regulations. The implementation of barium hydroxide as an adhesion enhancer requires careful consideration of various safety aspects to ensure worker protection and environmental safety.

Occupational safety standards play a crucial role in the use of barium hydroxide. Workers handling this compound must be provided with appropriate personal protective equipment (PPE), including respiratory protection, chemical-resistant gloves, and safety goggles. Proper ventilation systems in production areas are essential to minimize exposure to barium hydroxide dust or vapors. Regular air quality monitoring and exposure assessments are necessary to ensure compliance with permissible exposure limits set by regulatory bodies such as OSHA in the United States or equivalent agencies in other countries.

Material safety data sheets (MSDS) for barium hydroxide must be readily available and regularly updated. These documents provide critical information on the compound's properties, potential hazards, and proper handling procedures. Training programs for workers involved in the adhesive bonding process should be comprehensive and include specific modules on the safe handling and use of barium hydroxide.

Environmental regulations also play a significant role in the use of barium hydroxide in automotive production. Proper waste management and disposal procedures must be implemented to prevent environmental contamination. This includes the treatment of wastewater containing barium compounds and the proper disposal of solid waste. Compliance with local and national environmental protection laws is essential, and regular audits should be conducted to ensure adherence to these regulations.

The storage and transportation of barium hydroxide must adhere to specific safety guidelines. Proper labeling, secure packaging, and controlled storage conditions are necessary to prevent accidental release or exposure. Transportation of barium hydroxide should comply with hazardous materials regulations, including proper documentation and vehicle requirements.

Risk assessment and management strategies are crucial for ensuring compliance with safety regulations. Regular safety audits, incident reporting systems, and continuous improvement processes should be implemented to identify and address potential safety issues related to the use of barium hydroxide in adhesive bonding processes.

Manufacturers must also consider product safety regulations when using barium hydroxide in automotive adhesives. The final product must meet safety standards for consumer use, including considerations for potential long-term exposure and the possibility of material degradation over time. Compliance with regulations such as REACH in the European Union or similar standards in other regions is essential for market access and consumer safety.

Occupational safety standards play a crucial role in the use of barium hydroxide. Workers handling this compound must be provided with appropriate personal protective equipment (PPE), including respiratory protection, chemical-resistant gloves, and safety goggles. Proper ventilation systems in production areas are essential to minimize exposure to barium hydroxide dust or vapors. Regular air quality monitoring and exposure assessments are necessary to ensure compliance with permissible exposure limits set by regulatory bodies such as OSHA in the United States or equivalent agencies in other countries.

Material safety data sheets (MSDS) for barium hydroxide must be readily available and regularly updated. These documents provide critical information on the compound's properties, potential hazards, and proper handling procedures. Training programs for workers involved in the adhesive bonding process should be comprehensive and include specific modules on the safe handling and use of barium hydroxide.

Environmental regulations also play a significant role in the use of barium hydroxide in automotive production. Proper waste management and disposal procedures must be implemented to prevent environmental contamination. This includes the treatment of wastewater containing barium compounds and the proper disposal of solid waste. Compliance with local and national environmental protection laws is essential, and regular audits should be conducted to ensure adherence to these regulations.

The storage and transportation of barium hydroxide must adhere to specific safety guidelines. Proper labeling, secure packaging, and controlled storage conditions are necessary to prevent accidental release or exposure. Transportation of barium hydroxide should comply with hazardous materials regulations, including proper documentation and vehicle requirements.

Risk assessment and management strategies are crucial for ensuring compliance with safety regulations. Regular safety audits, incident reporting systems, and continuous improvement processes should be implemented to identify and address potential safety issues related to the use of barium hydroxide in adhesive bonding processes.

Manufacturers must also consider product safety regulations when using barium hydroxide in automotive adhesives. The final product must meet safety standards for consumer use, including considerations for potential long-term exposure and the possibility of material degradation over time. Compliance with regulations such as REACH in the European Union or similar standards in other regions is essential for market access and consumer safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!