Investigating sensor integration within submersible pumps.

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Sensor Integration Background

Submersible pumps have been a cornerstone of fluid handling systems for decades, particularly in applications where traditional surface-mounted pumps are impractical or inefficient. These pumps are designed to operate while fully submerged in the fluid they are pumping, making them ideal for deep well extraction, wastewater management, and various industrial processes.

The integration of sensors within submersible pumps represents a significant technological advancement in this field. This development is driven by the increasing demand for real-time monitoring, improved efficiency, and predictive maintenance capabilities in pump systems. The evolution of sensor technology, coupled with the miniaturization of electronic components, has made it feasible to incorporate sophisticated sensing capabilities directly into the pump assembly.

Historically, submersible pumps operated with minimal instrumentation, relying on external monitoring systems or periodic manual inspections. However, the advent of smart sensors and Internet of Things (IoT) technologies has opened up new possibilities for enhancing pump performance and reliability. These integrated sensors can monitor various parameters such as temperature, pressure, vibration, and flow rate, providing valuable data for pump operation and maintenance.

The primary objectives of sensor integration in submersible pumps include improving operational efficiency, reducing downtime, and extending equipment lifespan. By continuously monitoring critical parameters, operators can detect potential issues before they escalate into major problems, allowing for proactive maintenance and minimizing costly repairs or replacements.

Furthermore, sensor integration aligns with the broader trend of digitalization in industrial processes. The data collected by these sensors can be leveraged for advanced analytics, enabling predictive maintenance strategies and optimizing pump performance based on real-time conditions. This shift towards data-driven decision-making represents a significant leap forward in pump technology and management.

The development of sensor-integrated submersible pumps has been influenced by advancements in materials science, particularly in the creation of robust, waterproof enclosures for electronic components. Additionally, progress in wireless communication technologies has facilitated the transmission of sensor data from submerged pumps to surface-level control systems, overcoming the challenges of data retrieval in underwater environments.

As the technology continues to evolve, the integration of sensors in submersible pumps is expected to play a crucial role in enhancing the efficiency, reliability, and sustainability of fluid handling systems across various industries. This technological progression sets the stage for more intelligent, autonomous pump systems capable of self-diagnosis and adaptive operation in response to changing environmental conditions.

The integration of sensors within submersible pumps represents a significant technological advancement in this field. This development is driven by the increasing demand for real-time monitoring, improved efficiency, and predictive maintenance capabilities in pump systems. The evolution of sensor technology, coupled with the miniaturization of electronic components, has made it feasible to incorporate sophisticated sensing capabilities directly into the pump assembly.

Historically, submersible pumps operated with minimal instrumentation, relying on external monitoring systems or periodic manual inspections. However, the advent of smart sensors and Internet of Things (IoT) technologies has opened up new possibilities for enhancing pump performance and reliability. These integrated sensors can monitor various parameters such as temperature, pressure, vibration, and flow rate, providing valuable data for pump operation and maintenance.

The primary objectives of sensor integration in submersible pumps include improving operational efficiency, reducing downtime, and extending equipment lifespan. By continuously monitoring critical parameters, operators can detect potential issues before they escalate into major problems, allowing for proactive maintenance and minimizing costly repairs or replacements.

Furthermore, sensor integration aligns with the broader trend of digitalization in industrial processes. The data collected by these sensors can be leveraged for advanced analytics, enabling predictive maintenance strategies and optimizing pump performance based on real-time conditions. This shift towards data-driven decision-making represents a significant leap forward in pump technology and management.

The development of sensor-integrated submersible pumps has been influenced by advancements in materials science, particularly in the creation of robust, waterproof enclosures for electronic components. Additionally, progress in wireless communication technologies has facilitated the transmission of sensor data from submerged pumps to surface-level control systems, overcoming the challenges of data retrieval in underwater environments.

As the technology continues to evolve, the integration of sensors in submersible pumps is expected to play a crucial role in enhancing the efficiency, reliability, and sustainability of fluid handling systems across various industries. This technological progression sets the stage for more intelligent, autonomous pump systems capable of self-diagnosis and adaptive operation in response to changing environmental conditions.

Market Demand Analysis

The integration of sensors within submersible pumps has witnessed a significant surge in market demand, driven by the increasing need for efficient and reliable pump operations across various industries. This technology convergence addresses critical challenges in pump performance monitoring, predictive maintenance, and overall system optimization.

The oil and gas sector represents a primary market for sensor-integrated submersible pumps, particularly in offshore and deep-sea operations. As exploration and production activities extend to more challenging environments, the demand for robust, intelligent pumping systems continues to grow. The ability to monitor real-time performance metrics, such as temperature, pressure, and flow rates, enables operators to optimize production and minimize downtime, resulting in substantial cost savings and improved operational efficiency.

In the water and wastewater management industry, there is a rising demand for smart pumping solutions that can adapt to varying load conditions and environmental factors. Municipalities and water utilities are increasingly investing in sensor-equipped submersible pumps to enhance water distribution networks, reduce energy consumption, and prevent system failures. The integration of sensors allows for precise control of pump operations, leading to improved water quality management and reduced maintenance costs.

The mining sector presents another significant market opportunity for sensor-integrated submersible pumps. As mining operations delve deeper and face more complex dewatering challenges, the need for intelligent pumping systems becomes paramount. Sensors that can detect changes in fluid composition, sediment levels, and pump wear enable mining companies to maintain optimal extraction rates while minimizing equipment damage and environmental impact.

In the realm of agriculture and irrigation, the demand for sensor-integrated submersible pumps is driven by the need for precision farming and water conservation. Farmers and agricultural businesses are adopting smart irrigation systems that can adjust water delivery based on soil moisture levels, weather conditions, and crop requirements. This technology integration not only improves crop yields but also contributes to sustainable water management practices.

The industrial manufacturing sector is another key market for sensor-equipped submersible pumps, particularly in chemical processing, food and beverage production, and pharmaceutical manufacturing. These industries require precise control over fluid handling processes and stringent quality assurance measures. Sensor integration enables real-time monitoring of critical parameters such as viscosity, pH levels, and contamination, ensuring product consistency and regulatory compliance.

Market analysis indicates that the global demand for sensor-integrated submersible pumps is expected to grow steadily over the next decade. This growth is fueled by factors such as increasing industrial automation, the adoption of Internet of Things (IoT) technologies in pump systems, and the push for energy-efficient solutions across all sectors. As sensor technologies continue to advance and become more cost-effective, their integration into submersible pumps is likely to become a standard feature rather than a premium option.

The oil and gas sector represents a primary market for sensor-integrated submersible pumps, particularly in offshore and deep-sea operations. As exploration and production activities extend to more challenging environments, the demand for robust, intelligent pumping systems continues to grow. The ability to monitor real-time performance metrics, such as temperature, pressure, and flow rates, enables operators to optimize production and minimize downtime, resulting in substantial cost savings and improved operational efficiency.

In the water and wastewater management industry, there is a rising demand for smart pumping solutions that can adapt to varying load conditions and environmental factors. Municipalities and water utilities are increasingly investing in sensor-equipped submersible pumps to enhance water distribution networks, reduce energy consumption, and prevent system failures. The integration of sensors allows for precise control of pump operations, leading to improved water quality management and reduced maintenance costs.

The mining sector presents another significant market opportunity for sensor-integrated submersible pumps. As mining operations delve deeper and face more complex dewatering challenges, the need for intelligent pumping systems becomes paramount. Sensors that can detect changes in fluid composition, sediment levels, and pump wear enable mining companies to maintain optimal extraction rates while minimizing equipment damage and environmental impact.

In the realm of agriculture and irrigation, the demand for sensor-integrated submersible pumps is driven by the need for precision farming and water conservation. Farmers and agricultural businesses are adopting smart irrigation systems that can adjust water delivery based on soil moisture levels, weather conditions, and crop requirements. This technology integration not only improves crop yields but also contributes to sustainable water management practices.

The industrial manufacturing sector is another key market for sensor-equipped submersible pumps, particularly in chemical processing, food and beverage production, and pharmaceutical manufacturing. These industries require precise control over fluid handling processes and stringent quality assurance measures. Sensor integration enables real-time monitoring of critical parameters such as viscosity, pH levels, and contamination, ensuring product consistency and regulatory compliance.

Market analysis indicates that the global demand for sensor-integrated submersible pumps is expected to grow steadily over the next decade. This growth is fueled by factors such as increasing industrial automation, the adoption of Internet of Things (IoT) technologies in pump systems, and the push for energy-efficient solutions across all sectors. As sensor technologies continue to advance and become more cost-effective, their integration into submersible pumps is likely to become a standard feature rather than a premium option.

Current Challenges in Underwater Sensing

The integration of sensors within submersible pumps presents several significant challenges in underwater sensing. One of the primary obstacles is the harsh and corrosive nature of underwater environments. Saltwater, in particular, can rapidly degrade sensor components, leading to reduced accuracy and shortened lifespan. This necessitates the development of robust, corrosion-resistant materials and protective coatings for sensors, which adds complexity and cost to the manufacturing process.

Another major challenge is maintaining reliable communication between sensors and control systems. Water's high density and conductivity can severely attenuate electromagnetic signals, making traditional wireless communication methods ineffective. This limitation often requires the use of specialized acoustic communication techniques or hardwired connections, both of which have their own set of drawbacks in terms of data transmission speed, range, and reliability.

Power supply and management pose additional hurdles in underwater sensing applications. Batteries used in submersible pumps must be capable of withstanding high pressures and providing long-term power in a sealed environment. The need for regular battery replacement or recharging can be particularly problematic in deep-sea or remote locations, necessitating the development of more efficient power management systems or alternative energy harvesting methods.

Sensor calibration and accuracy maintenance in dynamic underwater conditions represent another significant challenge. Fluctuations in temperature, pressure, and salinity can affect sensor readings, requiring sophisticated calibration techniques and adaptive algorithms to ensure consistent and reliable data collection. This is particularly crucial for applications that demand high precision, such as environmental monitoring or underwater navigation.

The physical integration of sensors into submersible pumps without compromising pump performance or efficiency is also a complex task. Sensors must be positioned to collect accurate data without interfering with the pump's hydraulic flow or mechanical operation. This often requires innovative design solutions and careful consideration of fluid dynamics to optimize both sensor placement and pump functionality.

Lastly, data processing and interpretation in real-time underwater environments present unique challenges. The volume and complexity of data generated by multiple integrated sensors can be substantial, requiring advanced onboard processing capabilities or efficient data transmission methods for surface-level analysis. Developing algorithms that can quickly interpret sensor data and make autonomous decisions in underwater settings is an ongoing area of research and development in this field.

Another major challenge is maintaining reliable communication between sensors and control systems. Water's high density and conductivity can severely attenuate electromagnetic signals, making traditional wireless communication methods ineffective. This limitation often requires the use of specialized acoustic communication techniques or hardwired connections, both of which have their own set of drawbacks in terms of data transmission speed, range, and reliability.

Power supply and management pose additional hurdles in underwater sensing applications. Batteries used in submersible pumps must be capable of withstanding high pressures and providing long-term power in a sealed environment. The need for regular battery replacement or recharging can be particularly problematic in deep-sea or remote locations, necessitating the development of more efficient power management systems or alternative energy harvesting methods.

Sensor calibration and accuracy maintenance in dynamic underwater conditions represent another significant challenge. Fluctuations in temperature, pressure, and salinity can affect sensor readings, requiring sophisticated calibration techniques and adaptive algorithms to ensure consistent and reliable data collection. This is particularly crucial for applications that demand high precision, such as environmental monitoring or underwater navigation.

The physical integration of sensors into submersible pumps without compromising pump performance or efficiency is also a complex task. Sensors must be positioned to collect accurate data without interfering with the pump's hydraulic flow or mechanical operation. This often requires innovative design solutions and careful consideration of fluid dynamics to optimize both sensor placement and pump functionality.

Lastly, data processing and interpretation in real-time underwater environments present unique challenges. The volume and complexity of data generated by multiple integrated sensors can be substantial, requiring advanced onboard processing capabilities or efficient data transmission methods for surface-level analysis. Developing algorithms that can quickly interpret sensor data and make autonomous decisions in underwater settings is an ongoing area of research and development in this field.

Existing Sensor Integration Solutions

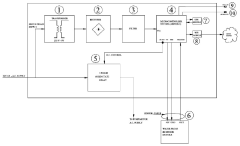

01 Integration of sensors for monitoring pump performance

Submersible pumps can be equipped with various sensors to monitor performance parameters such as pressure, temperature, vibration, and flow rate. These sensors provide real-time data on pump operation, enabling early detection of issues and optimizing performance.- Integration of sensors for monitoring pump performance: Submersible pumps can be equipped with various sensors to monitor performance parameters such as pressure, temperature, vibration, and flow rate. These sensors provide real-time data on pump operation, enabling early detection of issues and optimizing performance. The integration of sensors allows for predictive maintenance and improved efficiency of submersible pump systems.

- Wireless communication systems for sensor data transmission: Wireless communication technologies are implemented to transmit sensor data from submersible pumps to surface control systems. This allows for remote monitoring and control of pump operations without the need for physical connections. The wireless systems can use various protocols and may include data encryption for secure transmission in challenging environments.

- Smart control systems for pump operation based on sensor feedback: Advanced control systems utilize sensor data to automatically adjust pump operations. These smart systems can optimize pump speed, detect and respond to abnormal conditions, and manage power consumption. The integration of artificial intelligence and machine learning algorithms enhances the decision-making capabilities of these control systems, leading to improved pump efficiency and longevity.

- Sensor integration for environmental and fluid property monitoring: Sensors are integrated into submersible pumps to monitor environmental conditions and fluid properties. These may include sensors for detecting the presence of sand, gas, or other contaminants in the pumped fluid, as well as sensors for measuring fluid viscosity, density, and composition. This information is crucial for maintaining pump performance and protecting the equipment from damage due to adverse operating conditions.

- Energy harvesting and power management for sensor systems: To support the operation of integrated sensors in submersible pumps, energy harvesting technologies are employed. These systems capture energy from the pump's operation or surrounding environment to power the sensors and communication devices. Advanced power management techniques are used to optimize energy consumption, ensuring long-term operation of the sensor systems without the need for frequent battery replacements or external power sources.

02 Wireless communication systems for sensor data transmission

Wireless communication technologies are implemented to transmit sensor data from submersible pumps to surface control systems. This allows for remote monitoring and control of pump operations, reducing the need for physical inspections and improving overall efficiency.Expand Specific Solutions03 Smart control systems for pump operation

Advanced control systems utilize sensor data to automatically adjust pump operations based on changing conditions. These systems can optimize energy consumption, prevent pump damage, and extend equipment lifespan by responding to real-time sensor inputs.Expand Specific Solutions04 Sensor integration for downhole fluid analysis

Specialized sensors are integrated into submersible pumps to analyze downhole fluid properties such as composition, density, and viscosity. This information helps in optimizing production strategies and identifying potential issues in oil and gas wells.Expand Specific Solutions05 Sensor-based predictive maintenance systems

Predictive maintenance systems use machine learning algorithms to analyze sensor data from submersible pumps. These systems can forecast potential failures, schedule maintenance activities, and reduce downtime by identifying wear patterns and anomalies in pump performance.Expand Specific Solutions

Key Players in Submersible Pump Sensor Industry

The integration of sensors within submersible pumps is currently in a growth phase, with the market expanding rapidly due to increasing demand for smart and efficient pump systems across various industries. The global market size for smart pumps, including sensor-integrated submersible pumps, is projected to reach significant figures in the coming years. Technologically, the field is advancing quickly, with companies like Schlumberger Technologies, Baker Hughes, and Grundfos leading innovation. These firms are developing sophisticated sensor technologies that enhance pump performance, efficiency, and predictive maintenance capabilities. Other players such as KSB SE & Co. KGaA and SPX FLOW are also contributing to the technological maturity of the sector, focusing on integrating IoT and AI capabilities into their pump systems.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced sensor integration systems for submersible pumps, particularly in the oil and gas industry. Their technology includes the Lift IQ production life cycle management service, which incorporates real-time monitoring and control capabilities[1]. This system integrates various sensors such as pressure, temperature, and vibration sensors directly into the submersible pump assembly. The data collected is processed using advanced algorithms to optimize pump performance, predict maintenance needs, and prevent failures[2]. Schlumberger's approach also includes the use of fiber optic sensing technology, allowing for distributed temperature and acoustic sensing along the entire length of the wellbore, providing unprecedented insight into pump and reservoir conditions[3].

Strengths: Industry-leading expertise in oil and gas applications, comprehensive data analytics capabilities, and global service network. Weaknesses: High implementation costs and potential over-reliance on proprietary systems.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed the CENtrilift™ ESP monitoring system for submersible pumps, which integrates multiple sensors to provide real-time data on pump performance and well conditions[4]. Their system includes advanced downhole sensors that measure parameters such as intake pressure, motor temperature, and vibration. The data is transmitted to the surface using high-speed telemetry systems and analyzed using proprietary software to optimize pump operation and predict potential issues[5]. Baker Hughes has also introduced the TransCoil™ rigless deployed ESP system, which incorporates sensor technology for easier deployment and retrieval of submersible pumps, reducing operational costs and risks[6].

Strengths: Innovative deployment solutions, extensive experience in harsh environments, and strong focus on cost-effective operations. Weaknesses: May have limited applications outside of oil and gas industry.

Core Innovations in Underwater Sensing

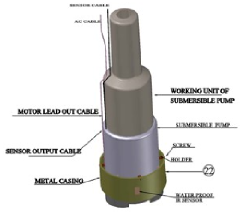

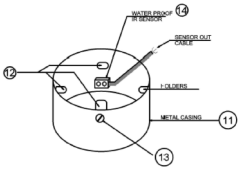

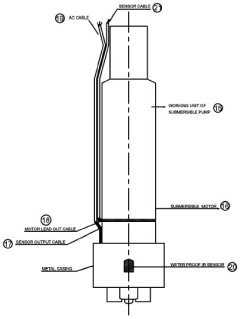

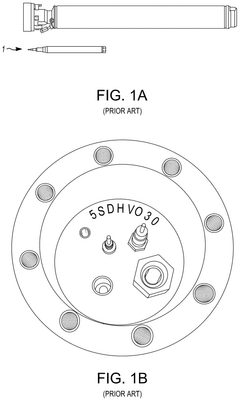

An Intelligent Sensor for Submersible Pump

PatentActiveIN201741035240A

Innovation

- A waterproof IR sensor module with a microcontroller-based control circuit and GSM/WiFi modules that use infrared sensing to detect water levels, sending alerts and controlling the pump's operation to prevent dry running, integrated with a solid state relay for efficient and reliable pump management.

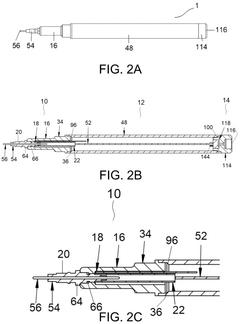

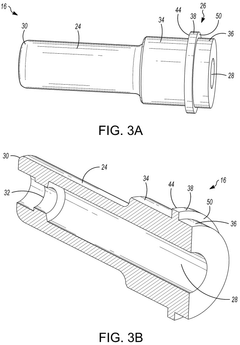

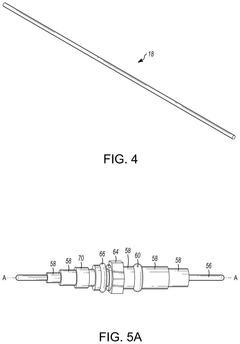

Integrated electrically submersible pump sensor device

PatentActiveUS12104589B2

Innovation

- A compact integrated ESP sensor device featuring an integrated temperature sensor and electrical feedthrough assembly, electronics assembly, and pressure assembly, which includes a probe body housing the temperature sensor, electrical feedthrough, and high voltage insulator, allowing for consistent temperature measurements and reduced component count, thereby minimizing size and manufacturing costs.

Environmental Impact Assessment

The integration of sensors within submersible pumps has significant environmental implications that warrant careful consideration. These advanced pumping systems, equipped with sophisticated sensing technologies, offer potential benefits for environmental monitoring and resource management. However, their deployment also raises concerns about potential ecological impacts.

One of the primary environmental advantages of sensor-integrated submersible pumps is their ability to enhance water resource management. By providing real-time data on water quality, flow rates, and pump performance, these systems enable more efficient and sustainable water extraction practices. This can lead to reduced energy consumption and minimized water waste, contributing to overall conservation efforts.

Furthermore, the continuous monitoring capabilities of these pumps can aid in early detection of environmental issues such as contamination or changes in water table levels. This proactive approach allows for timely interventions, potentially preventing or mitigating ecological damage. In sensitive aquatic ecosystems, such as wetlands or protected marine areas, this level of monitoring can be crucial for maintaining ecological balance.

However, the introduction of sensor-integrated pumps into aquatic environments also presents potential risks. The materials used in sensor construction and the electronic components may introduce new elements into the ecosystem. While modern sensors are designed to be environmentally inert, long-term studies on their impact on aquatic flora and fauna are still limited. There is a need for ongoing research to ensure that these devices do not leach harmful substances or interfere with local species.

The installation and maintenance of these advanced pump systems may also cause temporary disturbances to aquatic habitats. Care must be taken during deployment to minimize physical disruption to the surrounding environment. Additionally, the increased human activity associated with maintenance and data collection could potentially stress local ecosystems if not managed properly.

From an energy perspective, while sensor-integrated pumps can lead to more efficient operations, they also introduce additional power requirements for the sensing and data transmission components. This increased energy demand must be balanced against the potential energy savings from improved pump efficiency. Ideally, renewable energy sources should be considered for powering these systems to minimize their carbon footprint.

In conclusion, the environmental impact of sensor integration within submersible pumps is multifaceted. While offering significant potential for improved environmental monitoring and resource management, careful consideration must be given to the ecological implications of their deployment. Ongoing research, responsible implementation practices, and continuous monitoring of long-term effects are essential to ensure that the benefits of this technology outweigh any potential environmental risks.

One of the primary environmental advantages of sensor-integrated submersible pumps is their ability to enhance water resource management. By providing real-time data on water quality, flow rates, and pump performance, these systems enable more efficient and sustainable water extraction practices. This can lead to reduced energy consumption and minimized water waste, contributing to overall conservation efforts.

Furthermore, the continuous monitoring capabilities of these pumps can aid in early detection of environmental issues such as contamination or changes in water table levels. This proactive approach allows for timely interventions, potentially preventing or mitigating ecological damage. In sensitive aquatic ecosystems, such as wetlands or protected marine areas, this level of monitoring can be crucial for maintaining ecological balance.

However, the introduction of sensor-integrated pumps into aquatic environments also presents potential risks. The materials used in sensor construction and the electronic components may introduce new elements into the ecosystem. While modern sensors are designed to be environmentally inert, long-term studies on their impact on aquatic flora and fauna are still limited. There is a need for ongoing research to ensure that these devices do not leach harmful substances or interfere with local species.

The installation and maintenance of these advanced pump systems may also cause temporary disturbances to aquatic habitats. Care must be taken during deployment to minimize physical disruption to the surrounding environment. Additionally, the increased human activity associated with maintenance and data collection could potentially stress local ecosystems if not managed properly.

From an energy perspective, while sensor-integrated pumps can lead to more efficient operations, they also introduce additional power requirements for the sensing and data transmission components. This increased energy demand must be balanced against the potential energy savings from improved pump efficiency. Ideally, renewable energy sources should be considered for powering these systems to minimize their carbon footprint.

In conclusion, the environmental impact of sensor integration within submersible pumps is multifaceted. While offering significant potential for improved environmental monitoring and resource management, careful consideration must be given to the ecological implications of their deployment. Ongoing research, responsible implementation practices, and continuous monitoring of long-term effects are essential to ensure that the benefits of this technology outweigh any potential environmental risks.

Regulatory Compliance for Underwater Sensors

Regulatory compliance for underwater sensors in submersible pumps is a critical aspect that manufacturers and operators must address to ensure safe and legal operation. The integration of sensors within these pumps necessitates adherence to various national and international standards, which are designed to protect both the environment and human safety.

One of the primary regulatory bodies governing underwater sensors is the International Electrotechnical Commission (IEC). The IEC 60529 standard, which defines Ingress Protection (IP) ratings, is particularly relevant for submersible pump sensors. These sensors must typically meet IP68 requirements, indicating complete protection against dust and long-term immersion in water under pressure.

In addition to IP ratings, sensors integrated into submersible pumps must comply with specific industry standards. For instance, the American Petroleum Institute (API) has established guidelines for submersible pump systems used in oil and gas extraction. These standards often include requirements for sensor accuracy, reliability, and durability in harsh underwater environments.

Environmental regulations also play a significant role in the compliance landscape for underwater sensors. In many jurisdictions, sensors used in submersible pumps must meet strict requirements for materials compatibility to prevent contamination of water sources. This often involves compliance with regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electronic equipment.

Safety certifications are another crucial aspect of regulatory compliance for underwater sensors. Organizations such as Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) provide certifications that are often required for sensors used in submersible pumps, particularly in industrial or hazardous environments. These certifications ensure that the sensors meet specific safety standards and can operate reliably under intended conditions.

For sensors used in marine environments, compliance with maritime regulations is essential. The International Maritime Organization (IMO) sets standards for equipment used in marine applications, which may apply to sensors in submersible pumps used in offshore operations or marine research. These regulations often focus on electromagnetic compatibility (EMC) to prevent interference with other marine equipment.

As the integration of smart technologies in submersible pumps advances, data privacy and cybersecurity regulations are becoming increasingly relevant. Sensors that collect and transmit data must comply with regulations such as the General Data Protection Regulation (GDPR) in the European Union or similar data protection laws in other regions, especially if the data can be linked to individuals or sensitive operations.

Manufacturers and operators must also consider the evolving nature of regulatory compliance. As technology advances and environmental concerns grow, regulations are likely to become more stringent. Staying abreast of these changes and anticipating future requirements is crucial for long-term compliance and market viability of sensor-integrated submersible pumps.

One of the primary regulatory bodies governing underwater sensors is the International Electrotechnical Commission (IEC). The IEC 60529 standard, which defines Ingress Protection (IP) ratings, is particularly relevant for submersible pump sensors. These sensors must typically meet IP68 requirements, indicating complete protection against dust and long-term immersion in water under pressure.

In addition to IP ratings, sensors integrated into submersible pumps must comply with specific industry standards. For instance, the American Petroleum Institute (API) has established guidelines for submersible pump systems used in oil and gas extraction. These standards often include requirements for sensor accuracy, reliability, and durability in harsh underwater environments.

Environmental regulations also play a significant role in the compliance landscape for underwater sensors. In many jurisdictions, sensors used in submersible pumps must meet strict requirements for materials compatibility to prevent contamination of water sources. This often involves compliance with regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electronic equipment.

Safety certifications are another crucial aspect of regulatory compliance for underwater sensors. Organizations such as Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) provide certifications that are often required for sensors used in submersible pumps, particularly in industrial or hazardous environments. These certifications ensure that the sensors meet specific safety standards and can operate reliably under intended conditions.

For sensors used in marine environments, compliance with maritime regulations is essential. The International Maritime Organization (IMO) sets standards for equipment used in marine applications, which may apply to sensors in submersible pumps used in offshore operations or marine research. These regulations often focus on electromagnetic compatibility (EMC) to prevent interference with other marine equipment.

As the integration of smart technologies in submersible pumps advances, data privacy and cybersecurity regulations are becoming increasingly relevant. Sensors that collect and transmit data must comply with regulations such as the General Data Protection Regulation (GDPR) in the European Union or similar data protection laws in other regions, especially if the data can be linked to individuals or sensitive operations.

Manufacturers and operators must also consider the evolving nature of regulatory compliance. As technology advances and environmental concerns grow, regulations are likely to become more stringent. Staying abreast of these changes and anticipating future requirements is crucial for long-term compliance and market viability of sensor-integrated submersible pumps.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!