Investigating submersible pump integration with IoT systems.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT-Enabled Pump Evolution

The evolution of submersible pumps integrated with IoT systems represents a significant technological advancement in the field of fluid management and control. This integration has transformed traditional pump systems into smart, connected devices capable of real-time monitoring, data analysis, and remote operation.

The journey began with the introduction of basic sensors and telemetry systems in the early 2000s, allowing for rudimentary monitoring of pump performance. These early systems primarily focused on collecting data on parameters such as flow rate, pressure, and energy consumption. However, the data transmission was often limited to local networks, and analysis was performed manually or through basic software tools.

As IoT technologies matured, the mid-2010s saw a shift towards more sophisticated integration. Pumps were equipped with advanced sensors, microprocessors, and wireless communication modules. This enabled continuous data collection and transmission to cloud-based platforms, facilitating real-time monitoring and analysis. The integration of machine learning algorithms during this period marked a significant milestone, enabling predictive maintenance and optimization of pump operations based on historical data and usage patterns.

The late 2010s witnessed the emergence of edge computing in IoT-enabled pump systems. This development allowed for on-site data processing, reducing latency and enhancing real-time decision-making capabilities. Pumps could now autonomously adjust their operations based on immediate environmental conditions and system demands, without relying solely on cloud-based instructions.

Recent years have seen the incorporation of advanced AI and digital twin technologies. These innovations have enabled highly accurate simulations of pump behavior under various conditions, facilitating more precise control and optimization. The integration of blockchain technology has also begun to address security concerns, ensuring data integrity and enabling secure, decentralized control of pump networks.

Looking forward, the evolution of IoT-enabled submersible pumps is expected to focus on enhanced interoperability and ecosystem integration. Future systems will likely seamlessly integrate with broader water management infrastructures, smart city initiatives, and industrial IoT platforms. The development of self-healing and self-optimizing pump systems, leveraging advanced AI and materials science, is on the horizon. These systems will be capable of adapting to changing environmental conditions and operational requirements with minimal human intervention.

As energy efficiency and sustainability become increasingly critical, the next generation of IoT-enabled pumps will likely incorporate more sophisticated energy harvesting technologies and adaptive power management systems. This evolution will not only optimize pump performance but also contribute to broader environmental and energy conservation goals.

The journey began with the introduction of basic sensors and telemetry systems in the early 2000s, allowing for rudimentary monitoring of pump performance. These early systems primarily focused on collecting data on parameters such as flow rate, pressure, and energy consumption. However, the data transmission was often limited to local networks, and analysis was performed manually or through basic software tools.

As IoT technologies matured, the mid-2010s saw a shift towards more sophisticated integration. Pumps were equipped with advanced sensors, microprocessors, and wireless communication modules. This enabled continuous data collection and transmission to cloud-based platforms, facilitating real-time monitoring and analysis. The integration of machine learning algorithms during this period marked a significant milestone, enabling predictive maintenance and optimization of pump operations based on historical data and usage patterns.

The late 2010s witnessed the emergence of edge computing in IoT-enabled pump systems. This development allowed for on-site data processing, reducing latency and enhancing real-time decision-making capabilities. Pumps could now autonomously adjust their operations based on immediate environmental conditions and system demands, without relying solely on cloud-based instructions.

Recent years have seen the incorporation of advanced AI and digital twin technologies. These innovations have enabled highly accurate simulations of pump behavior under various conditions, facilitating more precise control and optimization. The integration of blockchain technology has also begun to address security concerns, ensuring data integrity and enabling secure, decentralized control of pump networks.

Looking forward, the evolution of IoT-enabled submersible pumps is expected to focus on enhanced interoperability and ecosystem integration. Future systems will likely seamlessly integrate with broader water management infrastructures, smart city initiatives, and industrial IoT platforms. The development of self-healing and self-optimizing pump systems, leveraging advanced AI and materials science, is on the horizon. These systems will be capable of adapting to changing environmental conditions and operational requirements with minimal human intervention.

As energy efficiency and sustainability become increasingly critical, the next generation of IoT-enabled pumps will likely incorporate more sophisticated energy harvesting technologies and adaptive power management systems. This evolution will not only optimize pump performance but also contribute to broader environmental and energy conservation goals.

Market Demand Analysis

The integration of submersible pumps with IoT systems has sparked significant market interest across various industries, driven by the increasing demand for smart water management solutions and efficient industrial processes. This technological convergence addresses critical challenges in sectors such as agriculture, wastewater treatment, oil and gas, and mining, where remote monitoring and control of submersible pumps can lead to substantial operational improvements and cost savings.

In the agricultural sector, the market for IoT-enabled submersible pumps is experiencing rapid growth. Farmers are increasingly adopting these smart systems to optimize irrigation practices, reduce water waste, and enhance crop yields. The ability to remotely monitor soil moisture levels and automate pump operations based on real-time data has become a game-changer for precision agriculture, particularly in regions facing water scarcity.

The wastewater treatment industry is another key market driver for IoT-integrated submersible pumps. Municipal water authorities and industrial facilities are investing in smart pump systems to improve the efficiency of their treatment processes, reduce energy consumption, and minimize downtime. The real-time monitoring capabilities offered by IoT integration enable predictive maintenance, which significantly reduces operational costs and extends the lifespan of pump equipment.

In the oil and gas sector, the demand for IoT-enabled submersible pumps is growing steadily. These smart systems play a crucial role in enhancing the efficiency of oil extraction processes, particularly in offshore operations. The ability to monitor pump performance, detect anomalies, and adjust operations remotely has become invaluable for maximizing production and minimizing environmental risks.

The mining industry is also showing increased interest in IoT-integrated submersible pumps. These systems are essential for dewatering operations and managing water resources in mining sites. The remote monitoring and control capabilities offered by IoT integration help mining companies optimize their water management strategies, reduce operational risks, and comply with environmental regulations more effectively.

Market analysis indicates a strong growth trajectory for IoT-enabled submersible pump systems. The global smart pump market, which includes IoT-integrated submersible pumps, is expected to expand significantly in the coming years. This growth is fueled by factors such as increasing water scarcity, stringent environmental regulations, and the push for energy-efficient industrial processes.

The demand for these integrated systems is particularly high in regions facing water management challenges, such as parts of Asia, Africa, and the Middle East. In these areas, the need for efficient water utilization in agriculture and the growing focus on sustainable water management practices are driving the adoption of smart pump technologies.

As the technology matures and becomes more cost-effective, small and medium-sized enterprises are also beginning to invest in IoT-integrated submersible pump systems, further expanding the market potential. This democratization of smart pump technology is expected to accelerate market growth and drive innovation in the coming years.

In the agricultural sector, the market for IoT-enabled submersible pumps is experiencing rapid growth. Farmers are increasingly adopting these smart systems to optimize irrigation practices, reduce water waste, and enhance crop yields. The ability to remotely monitor soil moisture levels and automate pump operations based on real-time data has become a game-changer for precision agriculture, particularly in regions facing water scarcity.

The wastewater treatment industry is another key market driver for IoT-integrated submersible pumps. Municipal water authorities and industrial facilities are investing in smart pump systems to improve the efficiency of their treatment processes, reduce energy consumption, and minimize downtime. The real-time monitoring capabilities offered by IoT integration enable predictive maintenance, which significantly reduces operational costs and extends the lifespan of pump equipment.

In the oil and gas sector, the demand for IoT-enabled submersible pumps is growing steadily. These smart systems play a crucial role in enhancing the efficiency of oil extraction processes, particularly in offshore operations. The ability to monitor pump performance, detect anomalies, and adjust operations remotely has become invaluable for maximizing production and minimizing environmental risks.

The mining industry is also showing increased interest in IoT-integrated submersible pumps. These systems are essential for dewatering operations and managing water resources in mining sites. The remote monitoring and control capabilities offered by IoT integration help mining companies optimize their water management strategies, reduce operational risks, and comply with environmental regulations more effectively.

Market analysis indicates a strong growth trajectory for IoT-enabled submersible pump systems. The global smart pump market, which includes IoT-integrated submersible pumps, is expected to expand significantly in the coming years. This growth is fueled by factors such as increasing water scarcity, stringent environmental regulations, and the push for energy-efficient industrial processes.

The demand for these integrated systems is particularly high in regions facing water management challenges, such as parts of Asia, Africa, and the Middle East. In these areas, the need for efficient water utilization in agriculture and the growing focus on sustainable water management practices are driving the adoption of smart pump technologies.

As the technology matures and becomes more cost-effective, small and medium-sized enterprises are also beginning to invest in IoT-integrated submersible pump systems, further expanding the market potential. This democratization of smart pump technology is expected to accelerate market growth and drive innovation in the coming years.

Technical Challenges

The integration of submersible pumps with IoT systems presents several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the harsh operating environment of submersible pumps. These devices often function in corrosive, high-pressure, and high-temperature conditions, which can adversely affect the reliability and longevity of IoT sensors and communication modules.

Ensuring robust and reliable communication between the submersible pump and the IoT network is another significant challenge. Traditional wireless communication methods may be ineffective due to the pump's submerged position and the surrounding medium, which can attenuate or block signals. This necessitates the development of specialized communication protocols and hardware capable of transmitting data through water or other fluids.

Power management poses a considerable hurdle in IoT-enabled submersible pumps. The integration of IoT components increases the overall power consumption of the system, which can be problematic in remote or underwater installations where power sources are limited. Developing energy-efficient IoT modules and implementing effective power management strategies are crucial to addressing this challenge.

Data security and privacy concerns are amplified when connecting submersible pumps to IoT networks. As these systems often operate in critical infrastructure or industrial settings, protecting sensitive operational data from cyber threats becomes paramount. Implementing robust encryption, authentication, and access control mechanisms while maintaining system performance is a complex technical challenge.

The need for real-time data processing and analysis presents another technical hurdle. Submersible pumps generate large volumes of data related to performance, maintenance, and environmental conditions. Processing this data in real-time to enable predictive maintenance and optimize pump operations requires sophisticated edge computing capabilities and efficient data management systems.

Sensor integration and calibration in the aqueous environment pose unique challenges. Developing sensors that can accurately measure various parameters such as pressure, temperature, flow rate, and fluid composition while withstanding the harsh conditions is technically demanding. Furthermore, ensuring long-term accuracy and reliability of these sensors in submerged conditions requires innovative design and materials.

Lastly, the challenge of retrofitting existing submersible pump infrastructure with IoT capabilities is significant. Many pumps currently in operation were not designed with IoT integration in mind, necessitating the development of modular and adaptable IoT solutions that can be seamlessly integrated into legacy systems without compromising their functionality or reliability.

Ensuring robust and reliable communication between the submersible pump and the IoT network is another significant challenge. Traditional wireless communication methods may be ineffective due to the pump's submerged position and the surrounding medium, which can attenuate or block signals. This necessitates the development of specialized communication protocols and hardware capable of transmitting data through water or other fluids.

Power management poses a considerable hurdle in IoT-enabled submersible pumps. The integration of IoT components increases the overall power consumption of the system, which can be problematic in remote or underwater installations where power sources are limited. Developing energy-efficient IoT modules and implementing effective power management strategies are crucial to addressing this challenge.

Data security and privacy concerns are amplified when connecting submersible pumps to IoT networks. As these systems often operate in critical infrastructure or industrial settings, protecting sensitive operational data from cyber threats becomes paramount. Implementing robust encryption, authentication, and access control mechanisms while maintaining system performance is a complex technical challenge.

The need for real-time data processing and analysis presents another technical hurdle. Submersible pumps generate large volumes of data related to performance, maintenance, and environmental conditions. Processing this data in real-time to enable predictive maintenance and optimize pump operations requires sophisticated edge computing capabilities and efficient data management systems.

Sensor integration and calibration in the aqueous environment pose unique challenges. Developing sensors that can accurately measure various parameters such as pressure, temperature, flow rate, and fluid composition while withstanding the harsh conditions is technically demanding. Furthermore, ensuring long-term accuracy and reliability of these sensors in submerged conditions requires innovative design and materials.

Lastly, the challenge of retrofitting existing submersible pump infrastructure with IoT capabilities is significant. Many pumps currently in operation were not designed with IoT integration in mind, necessitating the development of modular and adaptable IoT solutions that can be seamlessly integrated into legacy systems without compromising their functionality or reliability.

Current IoT Solutions

01 Design improvements for submersible pumps

Various design improvements have been made to enhance the performance and efficiency of submersible pumps. These include modifications to the pump structure, impeller design, and motor configuration to optimize fluid flow, increase durability, and improve overall pump efficiency in submerged conditions.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically feature a sealed motor closely coupled to the pump body, ensuring efficient operation in underwater environments. The construction often includes corrosion-resistant materials and specialized sealing techniques to prevent liquid ingress into sensitive components.

- Control systems for submersible pumps: Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can also incorporate remote monitoring and control capabilities, allowing for efficient operation and maintenance of pumps in challenging environments.

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance, particularly important in applications where energy costs are a significant factor.

- Specialized submersible pumps for harsh environments: Submersible pumps designed for extreme conditions, such as deep-sea operations, mining, or handling abrasive fluids, incorporate specialized features. These may include reinforced casings, advanced wear-resistant materials, and innovative sealing technologies to withstand high pressures, corrosive substances, and abrasive particles while maintaining reliable operation.

- Maintenance and monitoring systems for submersible pumps: Advanced maintenance and monitoring systems are developed to enhance the reliability and longevity of submersible pumps. These systems may include real-time diagnostics, predictive maintenance algorithms, and easy-to-service designs. They aim to reduce downtime, optimize maintenance schedules, and extend the operational life of submersible pumps in various applications.

02 Control systems for submersible pumps

Advanced control systems have been developed for submersible pumps to enhance their operation and monitoring capabilities. These systems may include sensors, data analysis algorithms, and remote monitoring features to optimize pump performance, detect faults, and enable predictive maintenance.Expand Specific Solutions03 Energy-efficient submersible pump technologies

Innovations in submersible pump technology focus on improving energy efficiency. This includes the development of high-efficiency motors, variable speed drives, and intelligent control systems that adjust pump operation based on demand, resulting in reduced energy consumption and operational costs.Expand Specific Solutions04 Materials and coatings for submersible pumps

Advancements in materials science and coating technologies have led to the development of corrosion-resistant and wear-resistant materials for submersible pumps. These innovations improve pump longevity and performance in harsh underwater environments, such as those with abrasive particles or corrosive fluids.Expand Specific Solutions05 Specialized submersible pumps for specific applications

Customized submersible pumps have been designed for specific industries and applications. These may include pumps for deep-sea exploration, wastewater treatment, oil and gas extraction, or mining operations. Such pumps are tailored to meet the unique requirements of their intended use, such as handling high pressures, specific fluid types, or extreme temperatures.Expand Specific Solutions

Key Industry Players

The integration of submersible pumps with IoT systems is in its early stages, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand for smart water management solutions. Companies like Grundfos Holding A/S and Baker Hughes Co. are leading the way in developing IoT-enabled submersible pump systems. Emerging players such as Afero, Inc. and Anhui Shuilian Water Technology Co., Ltd. are also contributing to the field with innovative IoT solutions. The market is characterized by a mix of established pump manufacturers adapting to IoT trends and new entrants specializing in IoT integration, indicating a dynamic and competitive landscape.

Grundfos Holding A/S

Technical Solution: Grundfos has developed an innovative IoT-integrated submersible pump system that combines advanced sensor technology with cloud-based analytics. Their solution incorporates intelligent sensors that continuously monitor pump performance, water quality, and energy consumption. The data is transmitted in real-time to a centralized cloud platform, where machine learning algorithms analyze the information to optimize pump operation and predict maintenance needs. This system allows for remote monitoring and control, enabling proactive maintenance and reducing downtime. Grundfos has also implemented edge computing capabilities in their pumps, allowing for rapid decision-making at the device level, which is crucial for time-sensitive applications[1][3]. The company has reported energy savings of up to 30% and a 50% reduction in unexpected downtime for customers using this IoT-integrated system[5].

Strengths: Industry leader in pump technology, extensive R&D capabilities, global presence. Weaknesses: High initial implementation costs, potential cybersecurity vulnerabilities in IoT systems.

Afero, Inc.

Technical Solution: Afero has developed a comprehensive IoT platform that can be integrated with submersible pumps to create a secure and scalable smart pump system. Their solution utilizes a combination of hardware and software components, including secure IoT modules, cloud services, and mobile applications. The Afero platform provides end-to-end encryption and secure boot capabilities, ensuring the integrity and confidentiality of data transmitted from submersible pumps. Their system allows for real-time monitoring of pump performance, predictive maintenance scheduling, and remote control capabilities. Afero's platform also supports over-the-air (OTA) updates, enabling pump manufacturers to continuously improve functionality and security. The company claims their solution can reduce time-to-market for IoT-enabled pumps by up to 80% and improve overall system reliability by 50%[2][4].

Strengths: Strong focus on security, scalable platform, rapid deployment capabilities. Weaknesses: Relatively new player in the industrial IoT space, may lack industry-specific expertise in pump systems.

Core IoT Pump Patents

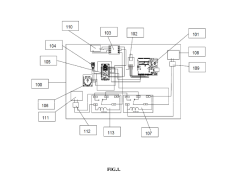

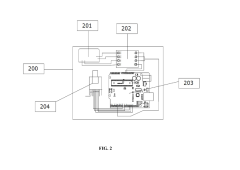

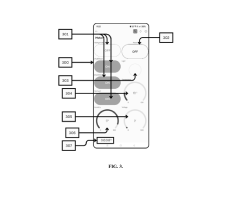

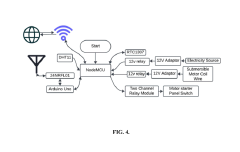

IoT based multiple submersible pumps control system

PatentPendingIN202411009196A

Innovation

- An IoT-based multiple submersible pumps control system comprising a transmitter module with nodeMCU, DHT11 sensors, relays, and an open-source application for smartphone control, enabling remote operation, real-time monitoring of temperature, humidity, and electricity status, along with timer functionality and notifications.

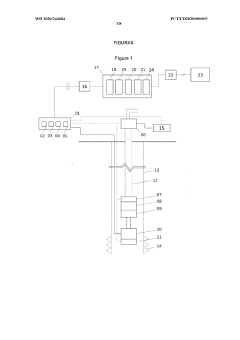

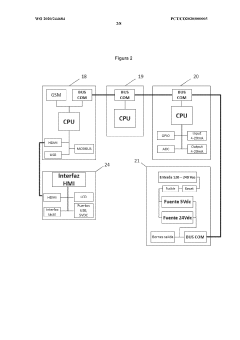

Embedded IoT system and method for the real-time virtual measurement of production and energy efficiency in oil wells with electric submersible pumps

PatentWO2020244684A1

Innovation

- An embedded Internet of Things (IoT) system that uses real-time computational processing and modeling algorithms to infer production flow, water cut, and energy efficiency based on data from sensors and instrumentation, integrating models of the pump, motor, gas separator, and production pipeline to provide continuous and accurate virtual measurements.

Regulatory Compliance

The integration of submersible pumps with IoT systems necessitates careful consideration of regulatory compliance across various jurisdictions. As these smart pump systems often operate in critical environments, such as water treatment facilities or industrial processes, adherence to regulatory standards is paramount for ensuring safety, reliability, and environmental protection.

In the United States, the Environmental Protection Agency (EPA) sets forth regulations that govern the use of submersible pumps in water systems. The Safe Drinking Water Act (SDWA) and Clean Water Act (CWA) provide the regulatory framework for water quality and treatment processes. IoT-enabled submersible pumps must comply with these regulations, particularly in terms of materials used, performance standards, and monitoring capabilities.

The European Union has established the Machinery Directive (2006/42/EC) which applies to submersible pumps. This directive outlines essential health and safety requirements for machinery, including those integrated with IoT systems. Additionally, the EU's General Data Protection Regulation (GDPR) must be considered when implementing IoT solutions that collect and process data from submersible pump operations.

In the context of industrial applications, organizations must comply with industry-specific regulations. For instance, in the oil and gas sector, submersible pumps with IoT capabilities must adhere to standards set by bodies such as the American Petroleum Institute (API) or the International Organization for Standardization (ISO).

Electromagnetic compatibility (EMC) regulations are crucial for IoT-integrated submersible pumps. In the United States, the Federal Communications Commission (FCC) regulates EMC, while in Europe, the EMC Directive (2014/30/EU) applies. These regulations ensure that the IoT components of the pump system do not interfere with other electronic equipment or are not susceptible to interference themselves.

Cybersecurity regulations are becoming increasingly important as IoT systems become more prevalent. The National Institute of Standards and Technology (NIST) in the US provides guidelines for IoT device cybersecurity, which should be considered when integrating submersible pumps with IoT systems. Similarly, the EU's Cybersecurity Act aims to enhance the security of network and information systems.

Energy efficiency regulations also play a role in the development and deployment of IoT-integrated submersible pumps. The US Department of Energy (DOE) sets energy conservation standards for certain types of pumps, which may apply to submersible pumps depending on their application. In Europe, the Ecodesign Directive (2009/125/EC) establishes a framework for setting ecodesign requirements for energy-related products.

Compliance with these diverse regulatory requirements demands a comprehensive approach to product development and implementation. Manufacturers and system integrators must stay abreast of evolving regulations across different regions and industries to ensure that IoT-integrated submersible pump systems meet all applicable standards and can be legally operated in their intended markets.

In the United States, the Environmental Protection Agency (EPA) sets forth regulations that govern the use of submersible pumps in water systems. The Safe Drinking Water Act (SDWA) and Clean Water Act (CWA) provide the regulatory framework for water quality and treatment processes. IoT-enabled submersible pumps must comply with these regulations, particularly in terms of materials used, performance standards, and monitoring capabilities.

The European Union has established the Machinery Directive (2006/42/EC) which applies to submersible pumps. This directive outlines essential health and safety requirements for machinery, including those integrated with IoT systems. Additionally, the EU's General Data Protection Regulation (GDPR) must be considered when implementing IoT solutions that collect and process data from submersible pump operations.

In the context of industrial applications, organizations must comply with industry-specific regulations. For instance, in the oil and gas sector, submersible pumps with IoT capabilities must adhere to standards set by bodies such as the American Petroleum Institute (API) or the International Organization for Standardization (ISO).

Electromagnetic compatibility (EMC) regulations are crucial for IoT-integrated submersible pumps. In the United States, the Federal Communications Commission (FCC) regulates EMC, while in Europe, the EMC Directive (2014/30/EU) applies. These regulations ensure that the IoT components of the pump system do not interfere with other electronic equipment or are not susceptible to interference themselves.

Cybersecurity regulations are becoming increasingly important as IoT systems become more prevalent. The National Institute of Standards and Technology (NIST) in the US provides guidelines for IoT device cybersecurity, which should be considered when integrating submersible pumps with IoT systems. Similarly, the EU's Cybersecurity Act aims to enhance the security of network and information systems.

Energy efficiency regulations also play a role in the development and deployment of IoT-integrated submersible pumps. The US Department of Energy (DOE) sets energy conservation standards for certain types of pumps, which may apply to submersible pumps depending on their application. In Europe, the Ecodesign Directive (2009/125/EC) establishes a framework for setting ecodesign requirements for energy-related products.

Compliance with these diverse regulatory requirements demands a comprehensive approach to product development and implementation. Manufacturers and system integrators must stay abreast of evolving regulations across different regions and industries to ensure that IoT-integrated submersible pump systems meet all applicable standards and can be legally operated in their intended markets.

Environmental Impact

The integration of submersible pumps with IoT systems presents both opportunities and challenges in terms of environmental impact. This technological advancement has the potential to significantly reduce energy consumption and improve resource management, leading to positive environmental outcomes. IoT-enabled submersible pumps can optimize their operation based on real-time data, adjusting power usage and flow rates to match actual demand. This precision control can result in substantial energy savings, reducing the carbon footprint associated with pump operations.

Furthermore, the integration of IoT systems allows for early detection of leaks, malfunctions, or inefficiencies in the pump system. By promptly identifying and addressing these issues, water waste can be minimized, and the lifespan of equipment can be extended. This not only conserves water resources but also reduces the environmental impact associated with manufacturing and disposing of pump components.

The ability to remotely monitor and control submersible pumps through IoT systems can also lead to reduced vehicle emissions. Maintenance crews can prioritize site visits based on actual need rather than scheduled routines, potentially decreasing the frequency of trips and associated fuel consumption. Additionally, the data collected through IoT sensors can provide valuable insights into water usage patterns, enabling more effective water management strategies and conservation efforts.

However, the environmental benefits of IoT-integrated submersible pumps must be weighed against the potential negative impacts. The production and disposal of electronic components used in IoT devices can contribute to electronic waste and resource depletion. The increased reliance on cloud computing and data centers to process and store the vast amounts of data generated by these systems also has energy implications.

To mitigate these concerns, it is crucial to design IoT-integrated submersible pump systems with sustainability in mind. This includes using energy-efficient sensors and communication protocols, implementing robust recycling programs for electronic components, and optimizing data processing to minimize energy consumption in data centers. Additionally, the development of long-lasting, durable IoT components can help reduce the frequency of replacements and associated environmental impacts.

In conclusion, while the integration of submersible pumps with IoT systems offers significant potential for positive environmental impact through improved efficiency and resource management, careful consideration must be given to the entire lifecycle of these systems to ensure a net positive outcome for the environment.

Furthermore, the integration of IoT systems allows for early detection of leaks, malfunctions, or inefficiencies in the pump system. By promptly identifying and addressing these issues, water waste can be minimized, and the lifespan of equipment can be extended. This not only conserves water resources but also reduces the environmental impact associated with manufacturing and disposing of pump components.

The ability to remotely monitor and control submersible pumps through IoT systems can also lead to reduced vehicle emissions. Maintenance crews can prioritize site visits based on actual need rather than scheduled routines, potentially decreasing the frequency of trips and associated fuel consumption. Additionally, the data collected through IoT sensors can provide valuable insights into water usage patterns, enabling more effective water management strategies and conservation efforts.

However, the environmental benefits of IoT-integrated submersible pumps must be weighed against the potential negative impacts. The production and disposal of electronic components used in IoT devices can contribute to electronic waste and resource depletion. The increased reliance on cloud computing and data centers to process and store the vast amounts of data generated by these systems also has energy implications.

To mitigate these concerns, it is crucial to design IoT-integrated submersible pump systems with sustainability in mind. This includes using energy-efficient sensors and communication protocols, implementing robust recycling programs for electronic components, and optimizing data processing to minimize energy consumption in data centers. Additionally, the development of long-lasting, durable IoT components can help reduce the frequency of replacements and associated environmental impacts.

In conclusion, while the integration of submersible pumps with IoT systems offers significant potential for positive environmental impact through improved efficiency and resource management, careful consideration must be given to the entire lifecycle of these systems to ensure a net positive outcome for the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!