Key Techniques for Ferrofluid Application in Environmental Science

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant technological evolution over the past six decades. Initially conceived for controlling fluids in zero gravity, these magnetic nanofluids have found diverse applications in environmental science, marking key milestones in their development trajectory.

The 1970s saw the first commercial applications of ferrofluids, primarily in sealing and damping technologies. This period laid the groundwork for understanding the fundamental properties of ferrofluids, including their response to magnetic fields and their stability in various environments.

In the 1980s and 1990s, advancements in nanoparticle synthesis techniques led to the production of more stable and uniform ferrofluids. This era witnessed the exploration of ferrofluids in environmental remediation, particularly in oil spill cleanup. The magnetic properties of ferrofluids were harnessed to separate oil from water, showcasing their potential in environmental applications.

The turn of the millennium brought about a surge in research focused on enhancing the properties of ferrofluids for specific environmental applications. Scientists developed ferrofluids with improved magnetic susceptibility and environmental compatibility. This period also saw the integration of ferrofluids with other materials, such as polymers and ceramics, expanding their functionality in environmental sensing and remediation.

From 2010 onwards, the focus shifted towards developing "smart" ferrofluids capable of responding to multiple stimuli beyond magnetic fields. These advanced materials found applications in water purification, where they could be used to remove heavy metals and organic pollutants with high efficiency. The development of biocompatible ferrofluids also opened up new avenues in environmental monitoring and biosensing.

Recent years have witnessed a convergence of ferrofluid technology with other emerging fields such as nanotechnology and artificial intelligence. This synergy has led to the creation of intelligent ferrofluid systems capable of autonomous operation in environmental remediation tasks. Additionally, the advent of 3D printing technology has enabled the fabrication of complex ferrofluid-based structures with enhanced functionalities for environmental applications.

Looking ahead, the evolution of ferrofluid technology in environmental science is poised to continue its rapid pace. Emerging trends include the development of biodegradable ferrofluids for eco-friendly applications, the integration of ferrofluids with renewable energy systems for enhanced efficiency, and the exploration of ferrofluid-based solutions for climate change mitigation strategies.

The 1970s saw the first commercial applications of ferrofluids, primarily in sealing and damping technologies. This period laid the groundwork for understanding the fundamental properties of ferrofluids, including their response to magnetic fields and their stability in various environments.

In the 1980s and 1990s, advancements in nanoparticle synthesis techniques led to the production of more stable and uniform ferrofluids. This era witnessed the exploration of ferrofluids in environmental remediation, particularly in oil spill cleanup. The magnetic properties of ferrofluids were harnessed to separate oil from water, showcasing their potential in environmental applications.

The turn of the millennium brought about a surge in research focused on enhancing the properties of ferrofluids for specific environmental applications. Scientists developed ferrofluids with improved magnetic susceptibility and environmental compatibility. This period also saw the integration of ferrofluids with other materials, such as polymers and ceramics, expanding their functionality in environmental sensing and remediation.

From 2010 onwards, the focus shifted towards developing "smart" ferrofluids capable of responding to multiple stimuli beyond magnetic fields. These advanced materials found applications in water purification, where they could be used to remove heavy metals and organic pollutants with high efficiency. The development of biocompatible ferrofluids also opened up new avenues in environmental monitoring and biosensing.

Recent years have witnessed a convergence of ferrofluid technology with other emerging fields such as nanotechnology and artificial intelligence. This synergy has led to the creation of intelligent ferrofluid systems capable of autonomous operation in environmental remediation tasks. Additionally, the advent of 3D printing technology has enabled the fabrication of complex ferrofluid-based structures with enhanced functionalities for environmental applications.

Looking ahead, the evolution of ferrofluid technology in environmental science is poised to continue its rapid pace. Emerging trends include the development of biodegradable ferrofluids for eco-friendly applications, the integration of ferrofluids with renewable energy systems for enhanced efficiency, and the exploration of ferrofluid-based solutions for climate change mitigation strategies.

Environmental Market Needs

The environmental market has shown a growing demand for innovative solutions to address pressing ecological challenges. Ferrofluids, with their unique magnetic properties and versatility, are emerging as a promising technology in environmental science applications. The market needs for ferrofluid-based solutions span across various sectors, including water treatment, soil remediation, and air purification.

In the water treatment sector, there is a significant demand for more efficient and cost-effective methods to remove contaminants from both industrial wastewater and drinking water sources. Ferrofluids offer potential advantages in this area, particularly in the removal of heavy metals, organic pollutants, and microplastics. The ability of ferrofluids to be manipulated by external magnetic fields allows for targeted and controlled treatment processes, which could lead to more effective and less resource-intensive water purification systems.

Soil remediation is another critical area where ferrofluid technology shows promise. With increasing concerns about soil pollution from industrial activities, agriculture, and urban development, there is a growing market need for innovative soil cleanup techniques. Ferrofluids could potentially be used to extract contaminants from soil more efficiently than traditional methods, offering a less invasive and more sustainable approach to soil restoration.

Air purification is also a sector where ferrofluid applications are gaining attention. As air quality concerns continue to rise in urban areas and industrial zones, there is a demand for advanced filtration and purification technologies. Ferrofluids could be incorporated into air filtration systems to enhance the capture of fine particulate matter and other airborne pollutants, potentially improving indoor and outdoor air quality.

The environmental monitoring market is another area where ferrofluid technology could meet growing needs. There is an increasing demand for more sensitive and accurate sensors to detect and measure various environmental parameters. Ferrofluid-based sensors could offer improved sensitivity and reliability in detecting pollutants in water, soil, and air, supporting more effective environmental management and regulatory compliance.

Furthermore, the push towards sustainable and green technologies is driving market demand for environmentally friendly materials and processes. Ferrofluids, when developed and applied responsibly, could contribute to this trend by offering more efficient and less harmful alternatives to traditional environmental remediation and monitoring techniques. This aligns with the growing emphasis on circular economy principles and the need for technologies that minimize environmental impact while maximizing resource efficiency.

As environmental regulations become more stringent worldwide, industries are seeking innovative solutions to meet compliance requirements. This regulatory landscape is creating a favorable market environment for ferrofluid applications in environmental science, as companies look for advanced technologies to address their environmental challenges more effectively and economically.

In the water treatment sector, there is a significant demand for more efficient and cost-effective methods to remove contaminants from both industrial wastewater and drinking water sources. Ferrofluids offer potential advantages in this area, particularly in the removal of heavy metals, organic pollutants, and microplastics. The ability of ferrofluids to be manipulated by external magnetic fields allows for targeted and controlled treatment processes, which could lead to more effective and less resource-intensive water purification systems.

Soil remediation is another critical area where ferrofluid technology shows promise. With increasing concerns about soil pollution from industrial activities, agriculture, and urban development, there is a growing market need for innovative soil cleanup techniques. Ferrofluids could potentially be used to extract contaminants from soil more efficiently than traditional methods, offering a less invasive and more sustainable approach to soil restoration.

Air purification is also a sector where ferrofluid applications are gaining attention. As air quality concerns continue to rise in urban areas and industrial zones, there is a demand for advanced filtration and purification technologies. Ferrofluids could be incorporated into air filtration systems to enhance the capture of fine particulate matter and other airborne pollutants, potentially improving indoor and outdoor air quality.

The environmental monitoring market is another area where ferrofluid technology could meet growing needs. There is an increasing demand for more sensitive and accurate sensors to detect and measure various environmental parameters. Ferrofluid-based sensors could offer improved sensitivity and reliability in detecting pollutants in water, soil, and air, supporting more effective environmental management and regulatory compliance.

Furthermore, the push towards sustainable and green technologies is driving market demand for environmentally friendly materials and processes. Ferrofluids, when developed and applied responsibly, could contribute to this trend by offering more efficient and less harmful alternatives to traditional environmental remediation and monitoring techniques. This aligns with the growing emphasis on circular economy principles and the need for technologies that minimize environmental impact while maximizing resource efficiency.

As environmental regulations become more stringent worldwide, industries are seeking innovative solutions to meet compliance requirements. This regulatory landscape is creating a favorable market environment for ferrofluid applications in environmental science, as companies look for advanced technologies to address their environmental challenges more effectively and economically.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in environmental science applications, several significant challenges hinder their widespread adoption and effectiveness. One of the primary obstacles is the long-term stability of ferrofluids in complex environmental matrices. When exposed to diverse pollutants, varying pH levels, and biological components present in natural systems, ferrofluids may experience aggregation, oxidation, or loss of magnetic properties, compromising their performance and reusability.

Another critical challenge lies in the controlled manipulation of ferrofluids in environmental settings. While magnetic fields can guide ferrofluids, achieving precise control over their movement and distribution in heterogeneous environmental media, such as soil or water bodies, remains difficult. This limitation impacts the efficiency of pollutant capture and removal processes, particularly in large-scale applications.

The potential environmental and health impacts of ferrofluids themselves pose a significant concern. As nanoparticle-based materials, the long-term effects of ferrofluids on ecosystems and human health are not fully understood. There is a need for comprehensive toxicological studies to assess their bioaccumulation, persistence, and potential adverse effects on various organisms and food chains.

Scalability and cost-effectiveness present additional hurdles in the application of ferrofluids for environmental remediation. While laboratory-scale demonstrations have shown promise, translating these results to field-scale operations involves significant engineering challenges. The production of large quantities of high-quality ferrofluids, as well as the development of robust and economically viable systems for their deployment and recovery, remain areas requiring substantial research and development efforts.

Furthermore, the selectivity of ferrofluids in targeting specific pollutants in complex environmental matrices needs improvement. Enhancing the specificity of ferrofluids to capture particular contaminants without affecting beneficial components of the ecosystem is crucial for their practical application in environmental science.

Lastly, the integration of ferrofluid technology with existing environmental remediation and monitoring systems presents a challenge. Developing standardized protocols and equipment compatible with current environmental management practices is essential for the widespread adoption of ferrofluid-based solutions in the field.

Another critical challenge lies in the controlled manipulation of ferrofluids in environmental settings. While magnetic fields can guide ferrofluids, achieving precise control over their movement and distribution in heterogeneous environmental media, such as soil or water bodies, remains difficult. This limitation impacts the efficiency of pollutant capture and removal processes, particularly in large-scale applications.

The potential environmental and health impacts of ferrofluids themselves pose a significant concern. As nanoparticle-based materials, the long-term effects of ferrofluids on ecosystems and human health are not fully understood. There is a need for comprehensive toxicological studies to assess their bioaccumulation, persistence, and potential adverse effects on various organisms and food chains.

Scalability and cost-effectiveness present additional hurdles in the application of ferrofluids for environmental remediation. While laboratory-scale demonstrations have shown promise, translating these results to field-scale operations involves significant engineering challenges. The production of large quantities of high-quality ferrofluids, as well as the development of robust and economically viable systems for their deployment and recovery, remain areas requiring substantial research and development efforts.

Furthermore, the selectivity of ferrofluids in targeting specific pollutants in complex environmental matrices needs improvement. Enhancing the specificity of ferrofluids to capture particular contaminants without affecting beneficial components of the ecosystem is crucial for their practical application in environmental science.

Lastly, the integration of ferrofluid technology with existing environmental remediation and monitoring systems presents a challenge. Developing standardized protocols and equipment compatible with current environmental management practices is essential for the widespread adoption of ferrofluid-based solutions in the field.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and the ability to be directed by magnetic fields, making them useful in applications such as heat sinks and thermal interfaces for electronic components.

- Damping and vibration control: The viscoelastic properties of ferrofluids make them suitable for damping applications. They can be used in shock absorbers, vibration isolators, and other mechanical systems to reduce unwanted oscillations and improve system stability.

- Sensing and measurement applications: Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them useful in applications such as accelerometers, inclinometers, and pressure sensors. They can also be used in magnetic field visualization and measurement tools.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields, making them valuable in applications such as computer cooling systems and power electronics.Expand Specific Solutions04 Damping and vibration control

The viscoelastic properties of ferrofluids make them useful in damping applications. They can be used to control vibrations in mechanical systems, improve the performance of shock absorbers, and enhance the stability of structures subject to dynamic loads.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position allows for the development of sensors for acceleration, tilt, and fluid level measurement. They are also used in specialized optical systems and magnetic resonance imaging.Expand Specific Solutions

Key Industry Players

The ferrofluid application in environmental science is in an emerging stage, with a growing market driven by increasing environmental concerns and technological advancements. The global market size for ferrofluid applications is expanding, though still relatively niche. Technologically, the field is progressing rapidly, with varying levels of maturity across different applications. Key players like Yale University, CEA, and Lanzhou University of Technology are at the forefront of research, while companies such as Koninklijke Philips NV and Western Digital Corp. are exploring commercial applications. The involvement of diverse institutions, from academic to industrial, indicates a competitive landscape with potential for significant breakthroughs in environmental applications of ferrofluids.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has applied ferrofluid technology to environmental challenges in the oil and gas industry. They have developed ferrofluid-based solutions for enhanced oil recovery (EOR) that can potentially reduce the environmental impact of extraction processes. Their approach involves using magnetically guided ferrofluids to improve sweep efficiency in reservoirs, potentially reducing the amount of water used in oil recovery[10]. Halliburton has also explored using ferrofluids for wellbore cleaning and remediation, which can help in reducing the use of harsh chemicals in these processes[11]. Additionally, they have investigated ferrofluid applications in produced water treatment, aiming to improve the efficiency of oil-water separation[12].

Strengths: Practical applications in the oil and gas industry, potential for reducing environmental impact of extraction processes. Weaknesses: Limited to specific industry applications, potential environmental concerns related to ferrofluid use in subsurface environments.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid technologies for environmental applications. Their approach involves using nanoparticle-based ferrofluids for water treatment and pollutant removal. The company has engineered ferrofluids with enhanced magnetic properties and surface functionalization to target specific contaminants[1]. Their technology allows for efficient separation of pollutants from water using magnetic fields, with reported removal efficiencies of up to 99% for certain heavy metals[2]. Ferrotec has also explored the use of ferrofluids in oil spill remediation, where the magnetic properties are utilized to contain and recover oil from water surfaces[3].

Strengths: Highly efficient contaminant removal, versatile applications in water treatment. Weaknesses: Potential for nanoparticle leaching, scalability challenges for large-scale environmental remediation.

Core Ferrofluid Innovations

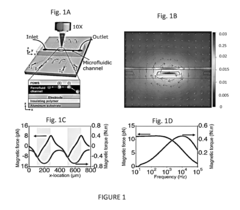

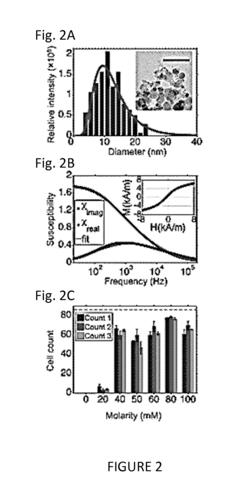

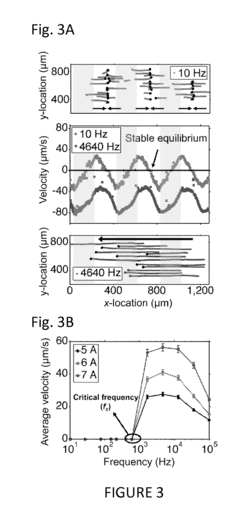

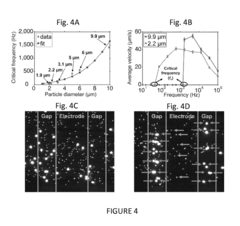

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

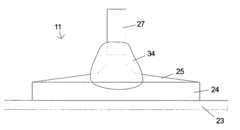

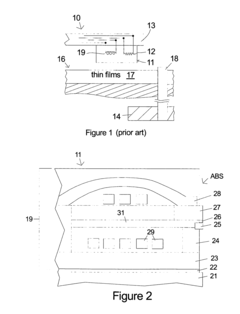

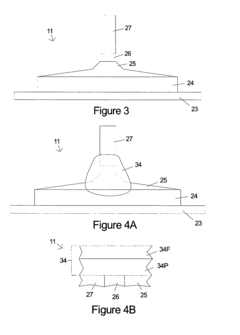

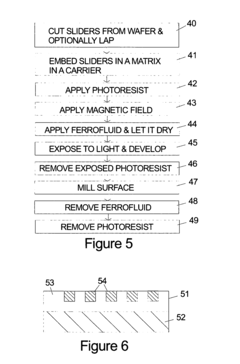

Method for fabricating a magnetic head using a ferrofluid mask

PatentInactiveUS20070220739A1

Innovation

- A method involving the application of a positive photoresist and ferrofluid on the air-bearing surface of magnetic heads, utilizing a perpendicular magnetic field to concentrate ferrofluid around the write gap, creating an optical mask that prevents exposure and allows for precise milling of recessed surfaces, thereby reducing the fly height and improving write head design.

Environmental Regulations

The application of ferrofluids in environmental science is subject to a complex web of regulations that vary across jurisdictions. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the use of nanomaterials, including ferrofluids, in environmental applications. The EPA's approach is guided by the Toxic Substances Control Act (TSCA), which requires manufacturers to provide safety data on new chemical substances before they are introduced into the market.

At the European level, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of nanomaterials, including ferrofluids. REACH mandates that companies register substances manufactured or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA). This process involves providing detailed information on the properties, hazards, and safe use of the substance.

Environmental regulations also focus on the potential ecological impacts of ferrofluids. The Water Framework Directive in the EU and the Clean Water Act in the US set standards for water quality and regulate the discharge of pollutants into water bodies. As ferrofluids may be used in water treatment applications, their use must comply with these regulations to prevent any adverse effects on aquatic ecosystems.

The disposal of ferrofluids and ferrofluid-containing devices is another area of regulatory concern. Many countries have specific regulations for the disposal of hazardous waste, which may apply to ferrofluids depending on their composition and concentration. For instance, the Resource Conservation and Recovery Act (RCRA) in the US provides guidelines for the management of hazardous waste from cradle to grave.

Occupational health and safety regulations also come into play when working with ferrofluids in environmental applications. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) set standards for handling nanomaterials in the workplace. These regulations typically require proper risk assessment, use of personal protective equipment, and implementation of engineering controls to minimize exposure.

As the field of ferrofluid applications in environmental science continues to evolve, regulatory frameworks are likely to adapt. Many countries are developing specific guidelines for nanomaterials, which will impact the use of ferrofluids. Researchers and industry professionals must stay informed about these evolving regulations to ensure compliance and responsible development of ferrofluid technologies for environmental applications.

At the European level, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of nanomaterials, including ferrofluids. REACH mandates that companies register substances manufactured or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA). This process involves providing detailed information on the properties, hazards, and safe use of the substance.

Environmental regulations also focus on the potential ecological impacts of ferrofluids. The Water Framework Directive in the EU and the Clean Water Act in the US set standards for water quality and regulate the discharge of pollutants into water bodies. As ferrofluids may be used in water treatment applications, their use must comply with these regulations to prevent any adverse effects on aquatic ecosystems.

The disposal of ferrofluids and ferrofluid-containing devices is another area of regulatory concern. Many countries have specific regulations for the disposal of hazardous waste, which may apply to ferrofluids depending on their composition and concentration. For instance, the Resource Conservation and Recovery Act (RCRA) in the US provides guidelines for the management of hazardous waste from cradle to grave.

Occupational health and safety regulations also come into play when working with ferrofluids in environmental applications. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) set standards for handling nanomaterials in the workplace. These regulations typically require proper risk assessment, use of personal protective equipment, and implementation of engineering controls to minimize exposure.

As the field of ferrofluid applications in environmental science continues to evolve, regulatory frameworks are likely to adapt. Many countries are developing specific guidelines for nanomaterials, which will impact the use of ferrofluids. Researchers and industry professionals must stay informed about these evolving regulations to ensure compliance and responsible development of ferrofluid technologies for environmental applications.

Eco-friendly Ferrofluid Design

Eco-friendly ferrofluid design is a critical aspect of advancing the application of ferrofluids in environmental science. The development of environmentally benign ferrofluids requires careful consideration of the materials used and their potential impact on ecosystems.

One of the primary focuses in eco-friendly ferrofluid design is the selection of biocompatible and biodegradable carrier fluids. Traditional carrier fluids, such as petroleum-based oils, pose environmental risks due to their persistence and potential toxicity. Researchers are exploring alternative carrier fluids derived from renewable sources, including vegetable oils and synthetic esters. These bio-based carriers offer improved biodegradability and reduced environmental impact.

The magnetic nanoparticles used in ferrofluids also play a crucial role in their environmental compatibility. Iron oxide nanoparticles, particularly magnetite (Fe3O4) and maghemite (γ-Fe2O3), are commonly used due to their magnetic properties and relative environmental safety. However, efforts are being made to further enhance their eco-friendliness through surface modifications and coatings that improve stability and reduce potential toxicity.

Surface functionalization of magnetic nanoparticles is a key technique in eco-friendly ferrofluid design. By modifying the surface of the nanoparticles with biocompatible polymers or natural compounds, researchers can improve the stability of the ferrofluid and reduce its potential environmental impact. Common surface modification agents include dextran, chitosan, and polyethylene glycol (PEG), which enhance colloidal stability and reduce nanoparticle aggregation.

Another important aspect of eco-friendly ferrofluid design is the optimization of particle size and distribution. Smaller nanoparticles generally exhibit better colloidal stability and are less likely to settle or aggregate, which can improve the overall environmental performance of the ferrofluid. However, the synthesis of uniformly sized nanoparticles with controlled magnetic properties remains a challenge.

The development of green synthesis methods for ferrofluids is also gaining attention. These approaches aim to reduce the use of harsh chemicals and energy-intensive processes in the production of magnetic nanoparticles and ferrofluids. Biogenic synthesis methods, utilizing plant extracts or microorganisms, offer promising alternatives for producing eco-friendly magnetic nanoparticles.

Lastly, the design of eco-friendly ferrofluids must consider their end-of-life management and potential for recycling or safe disposal. Developing ferrofluids that can be easily separated and recovered from environmental matrices is crucial for minimizing their long-term environmental impact. This may involve designing ferrofluids with reversible properties or incorporating features that facilitate their removal from aqueous or soil environments.

One of the primary focuses in eco-friendly ferrofluid design is the selection of biocompatible and biodegradable carrier fluids. Traditional carrier fluids, such as petroleum-based oils, pose environmental risks due to their persistence and potential toxicity. Researchers are exploring alternative carrier fluids derived from renewable sources, including vegetable oils and synthetic esters. These bio-based carriers offer improved biodegradability and reduced environmental impact.

The magnetic nanoparticles used in ferrofluids also play a crucial role in their environmental compatibility. Iron oxide nanoparticles, particularly magnetite (Fe3O4) and maghemite (γ-Fe2O3), are commonly used due to their magnetic properties and relative environmental safety. However, efforts are being made to further enhance their eco-friendliness through surface modifications and coatings that improve stability and reduce potential toxicity.

Surface functionalization of magnetic nanoparticles is a key technique in eco-friendly ferrofluid design. By modifying the surface of the nanoparticles with biocompatible polymers or natural compounds, researchers can improve the stability of the ferrofluid and reduce its potential environmental impact. Common surface modification agents include dextran, chitosan, and polyethylene glycol (PEG), which enhance colloidal stability and reduce nanoparticle aggregation.

Another important aspect of eco-friendly ferrofluid design is the optimization of particle size and distribution. Smaller nanoparticles generally exhibit better colloidal stability and are less likely to settle or aggregate, which can improve the overall environmental performance of the ferrofluid. However, the synthesis of uniformly sized nanoparticles with controlled magnetic properties remains a challenge.

The development of green synthesis methods for ferrofluids is also gaining attention. These approaches aim to reduce the use of harsh chemicals and energy-intensive processes in the production of magnetic nanoparticles and ferrofluids. Biogenic synthesis methods, utilizing plant extracts or microorganisms, offer promising alternatives for producing eco-friendly magnetic nanoparticles.

Lastly, the design of eco-friendly ferrofluids must consider their end-of-life management and potential for recycling or safe disposal. Developing ferrofluids that can be easily separated and recovered from environmental matrices is crucial for minimizing their long-term environmental impact. This may involve designing ferrofluids with reversible properties or incorporating features that facilitate their removal from aqueous or soil environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!