Material Innovations to Reduce Toxicity in Perovskite Solar Cells

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Toxicity Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the presence of toxic elements, particularly lead, in these devices has raised significant environmental and health concerns. This toxicity issue has become a major obstacle in the widespread adoption and commercialization of perovskite solar cells.

The development of perovskite solar cells can be traced back to 2009 when they were first introduced as a novel photovoltaic technology. Since then, rapid progress has been made in improving their efficiency, with current record efficiencies exceeding 25%. This remarkable performance, coupled with the potential for low-cost production, has positioned perovskite solar cells as a promising alternative to traditional silicon-based solar cells.

Despite these advantages, the presence of lead in the most efficient perovskite compositions has become a critical issue. Lead is known for its toxicity and potential environmental hazards, raising concerns about the long-term sustainability and safety of perovskite solar cells. This has led to increased research efforts focused on developing lead-free or lead-reduced perovskite materials that maintain high efficiency and stability.

The primary objective of current research in this field is to identify and develop alternative materials that can replace or reduce the amount of lead in perovskite solar cells without compromising their performance. This involves exploring various strategies, such as partial substitution of lead with less toxic elements, development of entirely new perovskite compositions, and investigation of alternative device architectures that minimize the risk of lead leakage.

Another important goal is to enhance the stability and durability of perovskite solar cells, as the degradation of these materials can lead to the release of toxic components into the environment. Researchers are working on improving encapsulation techniques and developing more robust perovskite compositions to address this issue.

Furthermore, there is a growing focus on understanding the environmental impact and toxicity profiles of alternative materials being considered as replacements for lead. This includes comprehensive life cycle assessments and toxicological studies to ensure that proposed solutions do not introduce new environmental or health risks.

As the field progresses, it is expected that material innovations will play a crucial role in addressing the toxicity concerns associated with perovskite solar cells. The ultimate aim is to develop a new generation of perovskite solar cells that combine high efficiency, low cost, and environmental sustainability, paving the way for their widespread adoption in the global renewable energy landscape.

The development of perovskite solar cells can be traced back to 2009 when they were first introduced as a novel photovoltaic technology. Since then, rapid progress has been made in improving their efficiency, with current record efficiencies exceeding 25%. This remarkable performance, coupled with the potential for low-cost production, has positioned perovskite solar cells as a promising alternative to traditional silicon-based solar cells.

Despite these advantages, the presence of lead in the most efficient perovskite compositions has become a critical issue. Lead is known for its toxicity and potential environmental hazards, raising concerns about the long-term sustainability and safety of perovskite solar cells. This has led to increased research efforts focused on developing lead-free or lead-reduced perovskite materials that maintain high efficiency and stability.

The primary objective of current research in this field is to identify and develop alternative materials that can replace or reduce the amount of lead in perovskite solar cells without compromising their performance. This involves exploring various strategies, such as partial substitution of lead with less toxic elements, development of entirely new perovskite compositions, and investigation of alternative device architectures that minimize the risk of lead leakage.

Another important goal is to enhance the stability and durability of perovskite solar cells, as the degradation of these materials can lead to the release of toxic components into the environment. Researchers are working on improving encapsulation techniques and developing more robust perovskite compositions to address this issue.

Furthermore, there is a growing focus on understanding the environmental impact and toxicity profiles of alternative materials being considered as replacements for lead. This includes comprehensive life cycle assessments and toxicological studies to ensure that proposed solutions do not introduce new environmental or health risks.

As the field progresses, it is expected that material innovations will play a crucial role in addressing the toxicity concerns associated with perovskite solar cells. The ultimate aim is to develop a new generation of perovskite solar cells that combine high efficiency, low cost, and environmental sustainability, paving the way for their widespread adoption in the global renewable energy landscape.

Market Analysis for Eco-friendly Solar Cells

The market for eco-friendly solar cells, particularly those based on perovskite technology, is experiencing rapid growth and attracting significant attention from investors, researchers, and industry players. This surge in interest is driven by the increasing global demand for sustainable energy solutions and the potential of perovskite solar cells to offer higher efficiency and lower production costs compared to traditional silicon-based photovoltaics.

The global solar energy market is projected to reach substantial value in the coming years, with perovskite solar cells expected to capture an increasing share. The push for renewable energy sources, coupled with government incentives and environmental regulations, is creating a favorable environment for the adoption of eco-friendly solar technologies.

One of the key drivers for the market growth of eco-friendly perovskite solar cells is the ongoing research and development efforts to address the toxicity concerns associated with lead-based perovskites. This focus on material innovations to reduce toxicity aligns with the growing consumer and regulatory demand for safer, more environmentally friendly energy solutions.

The market for perovskite solar cells is segmented based on structure type, application, and end-use industry. Residential, commercial, and utility-scale applications are all potential growth areas, with each sector presenting unique opportunities and challenges. The residential market, in particular, shows promise due to increasing awareness of environmental issues and the desire for clean energy solutions at the household level.

Geographically, Asia-Pacific is expected to dominate the perovskite solar cell market, with China leading in terms of production and adoption. Europe and North America are also significant markets, driven by strong environmental policies and investment in renewable energy infrastructure.

The competitive landscape of the eco-friendly solar cell market is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to overcome the technical challenges associated with perovskite solar cells, including stability, scalability, and toxicity reduction.

Market trends indicate a growing interest in tandem solar cell technologies, which combine perovskite layers with traditional silicon cells to achieve higher efficiencies. This hybrid approach could potentially accelerate market adoption by leveraging existing manufacturing infrastructure while introducing the benefits of perovskite technology.

As material innovations continue to address toxicity concerns, the market for eco-friendly perovskite solar cells is expected to expand rapidly. The successful development of non-toxic or less toxic alternatives to lead-based perovskites could be a game-changer, potentially opening up new market segments and accelerating widespread adoption of this promising technology.

The global solar energy market is projected to reach substantial value in the coming years, with perovskite solar cells expected to capture an increasing share. The push for renewable energy sources, coupled with government incentives and environmental regulations, is creating a favorable environment for the adoption of eco-friendly solar technologies.

One of the key drivers for the market growth of eco-friendly perovskite solar cells is the ongoing research and development efforts to address the toxicity concerns associated with lead-based perovskites. This focus on material innovations to reduce toxicity aligns with the growing consumer and regulatory demand for safer, more environmentally friendly energy solutions.

The market for perovskite solar cells is segmented based on structure type, application, and end-use industry. Residential, commercial, and utility-scale applications are all potential growth areas, with each sector presenting unique opportunities and challenges. The residential market, in particular, shows promise due to increasing awareness of environmental issues and the desire for clean energy solutions at the household level.

Geographically, Asia-Pacific is expected to dominate the perovskite solar cell market, with China leading in terms of production and adoption. Europe and North America are also significant markets, driven by strong environmental policies and investment in renewable energy infrastructure.

The competitive landscape of the eco-friendly solar cell market is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to overcome the technical challenges associated with perovskite solar cells, including stability, scalability, and toxicity reduction.

Market trends indicate a growing interest in tandem solar cell technologies, which combine perovskite layers with traditional silicon cells to achieve higher efficiencies. This hybrid approach could potentially accelerate market adoption by leveraging existing manufacturing infrastructure while introducing the benefits of perovskite technology.

As material innovations continue to address toxicity concerns, the market for eco-friendly perovskite solar cells is expected to expand rapidly. The successful development of non-toxic or less toxic alternatives to lead-based perovskites could be a game-changer, potentially opening up new market segments and accelerating widespread adoption of this promising technology.

Current Challenges in Perovskite Toxicity Reduction

Despite the promising potential of perovskite solar cells, their widespread adoption faces significant challenges due to toxicity concerns. The primary issue stems from the presence of lead (Pb) in the most efficient perovskite compositions. Lead toxicity poses serious environmental and health risks, particularly during manufacturing, deployment, and end-of-life disposal of these solar cells.

One of the main challenges in reducing perovskite toxicity is finding suitable alternatives to lead that maintain or improve the cell's efficiency. While lead-free perovskites have been developed, they often suffer from lower power conversion efficiencies and reduced stability compared to their lead-based counterparts. This trade-off between performance and toxicity remains a significant hurdle for researchers and manufacturers.

Another critical challenge is the long-term stability of perovskite materials. Many lead-free alternatives exhibit poor stability under operational conditions, leading to rapid degradation and reduced lifespan of the solar cells. This instability not only affects the cell's performance but also increases the risk of toxic material leakage into the environment over time.

The encapsulation of perovskite solar cells presents another challenge in toxicity reduction. Effective encapsulation is crucial to prevent the leaching of toxic materials, but current encapsulation techniques often struggle to provide long-term protection while maintaining cell efficiency. Developing advanced encapsulation methods that can withstand various environmental stressors without compromising performance is an ongoing area of research.

Scalability and cost-effectiveness of toxicity reduction strategies pose additional challenges. Many promising lead-free or low-toxicity perovskite compositions involve rare or expensive elements, making large-scale production economically unfeasible. Balancing material costs with performance and environmental safety remains a complex optimization problem for the industry.

Regulatory compliance and standardization present further obstacles. As awareness of the potential environmental impacts of perovskite solar cells grows, stricter regulations are likely to be implemented. Developing materials and manufacturing processes that meet these evolving standards while remaining competitive in the market is a significant challenge for researchers and manufacturers alike.

Lastly, the challenge of public perception and acceptance cannot be overlooked. Even with significant advancements in toxicity reduction, overcoming the stigma associated with potentially hazardous materials in solar cells will require extensive education and outreach efforts. Building consumer trust in the safety and sustainability of perovskite solar technology is crucial for its widespread adoption and commercial success.

One of the main challenges in reducing perovskite toxicity is finding suitable alternatives to lead that maintain or improve the cell's efficiency. While lead-free perovskites have been developed, they often suffer from lower power conversion efficiencies and reduced stability compared to their lead-based counterparts. This trade-off between performance and toxicity remains a significant hurdle for researchers and manufacturers.

Another critical challenge is the long-term stability of perovskite materials. Many lead-free alternatives exhibit poor stability under operational conditions, leading to rapid degradation and reduced lifespan of the solar cells. This instability not only affects the cell's performance but also increases the risk of toxic material leakage into the environment over time.

The encapsulation of perovskite solar cells presents another challenge in toxicity reduction. Effective encapsulation is crucial to prevent the leaching of toxic materials, but current encapsulation techniques often struggle to provide long-term protection while maintaining cell efficiency. Developing advanced encapsulation methods that can withstand various environmental stressors without compromising performance is an ongoing area of research.

Scalability and cost-effectiveness of toxicity reduction strategies pose additional challenges. Many promising lead-free or low-toxicity perovskite compositions involve rare or expensive elements, making large-scale production economically unfeasible. Balancing material costs with performance and environmental safety remains a complex optimization problem for the industry.

Regulatory compliance and standardization present further obstacles. As awareness of the potential environmental impacts of perovskite solar cells grows, stricter regulations are likely to be implemented. Developing materials and manufacturing processes that meet these evolving standards while remaining competitive in the market is a significant challenge for researchers and manufacturers alike.

Lastly, the challenge of public perception and acceptance cannot be overlooked. Even with significant advancements in toxicity reduction, overcoming the stigma associated with potentially hazardous materials in solar cells will require extensive education and outreach efforts. Building consumer trust in the safety and sustainability of perovskite solar technology is crucial for its widespread adoption and commercial success.

Existing Solutions for Reducing Perovskite Toxicity

01 Lead-free perovskite materials for solar cells

Research focuses on developing lead-free perovskite materials for solar cells to address toxicity concerns. These alternative materials aim to maintain high efficiency while eliminating the use of toxic lead compounds, potentially improving the environmental safety and commercial viability of perovskite solar cells.- Lead-free perovskite materials for solar cells: Development of lead-free perovskite materials for solar cells to address toxicity concerns. These alternative materials aim to maintain high efficiency while eliminating the use of toxic lead compounds, potentially improving the environmental safety and commercial viability of perovskite solar cells.

- Encapsulation techniques for perovskite solar cells: Implementation of advanced encapsulation methods to prevent the leakage of potentially toxic materials from perovskite solar cells. These techniques aim to improve the long-term stability and safety of the cells, reducing the risk of environmental contamination and human exposure to harmful substances.

- Toxicity assessment and mitigation strategies: Development of comprehensive toxicity assessment protocols and mitigation strategies for perovskite solar cells. This includes studying the potential environmental and health impacts of perovskite materials throughout their lifecycle, and developing methods to minimize or neutralize any toxic effects.

- Recycling and disposal methods for perovskite solar cells: Innovation in recycling and safe disposal methods for perovskite solar cells to address end-of-life toxicity concerns. These methods aim to recover valuable materials and prevent the release of potentially harmful substances into the environment, promoting a more sustainable lifecycle for perovskite solar technology.

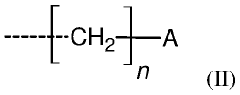

- Bio-inspired and organic perovskite alternatives: Exploration of bio-inspired and organic perovskite alternatives to reduce toxicity in solar cells. This research focuses on developing materials that mimic the structure and efficiency of traditional perovskites while using non-toxic, environmentally friendly components, potentially revolutionizing the safety profile of next-generation solar technologies.

02 Encapsulation techniques for perovskite solar cells

Various encapsulation methods are being developed to prevent the leaching of toxic components from perovskite solar cells. These techniques aim to improve the stability and safety of the cells by creating protective barriers that contain potentially harmful materials within the device structure.Expand Specific Solutions03 Environmental impact assessment of perovskite solar cells

Studies are being conducted to evaluate the full life-cycle environmental impact of perovskite solar cells, including their production, use, and disposal. These assessments aim to quantify the potential ecological and health risks associated with perovskite solar technology and compare them to traditional photovoltaic systems.Expand Specific Solutions04 Recycling and disposal methods for perovskite solar cells

Research is ongoing to develop efficient recycling and safe disposal methods for perovskite solar cells at the end of their life cycle. These efforts focus on recovering valuable materials and minimizing the release of toxic components into the environment, addressing long-term sustainability concerns.Expand Specific Solutions05 Toxicity mitigation strategies in perovskite solar cell manufacturing

Innovative manufacturing processes and material handling techniques are being explored to mitigate toxicity risks during the production of perovskite solar cells. These strategies aim to reduce worker exposure to hazardous materials and minimize environmental contamination in the manufacturing phase.Expand Specific Solutions

Key Players in Perovskite Solar Cell Industry

The field of material innovations to reduce toxicity in perovskite solar cells is in a rapidly evolving phase, characterized by intense research and development efforts. The market for perovskite solar cells is expanding, driven by the growing demand for efficient and sustainable energy solutions. While the technology is promising, it is still in the early stages of commercialization, with various challenges to overcome. Key players in this field include academic institutions like Soochow University, Huazhong University of Science & Technology, and École Polytechnique Fédérale de Lausanne, which are at the forefront of research. Companies such as FUJIFILM Corp. and LG Chem Ltd. are also investing in this technology, indicating its potential for industrial applications. The involvement of both academic and industrial entities suggests a collaborative approach to advancing the technology's maturity and addressing toxicity concerns.

École Polytechnique Fédérale de Lausanne

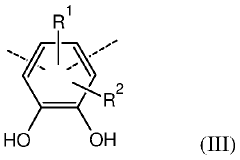

Technical Solution: EPFL has developed a novel approach to reduce toxicity in perovskite solar cells by replacing lead with tin. They have created a double-perovskite material using tin halide perovskites, which achieves a power conversion efficiency of 9.1%[1]. The team has also implemented a layer-by-layer deposition technique to improve the stability and performance of these lead-free perovskite solar cells[2]. Additionally, EPFL researchers have explored the use of 2D/3D hybrid perovskite structures to enhance the moisture stability of the cells, addressing one of the key challenges in perovskite technology[3].

Strengths: Lead-free composition reduces environmental impact; improved stability through innovative structures. Weaknesses: Lower efficiency compared to lead-based perovskites; potential high production costs for novel materials.

Northwestern University

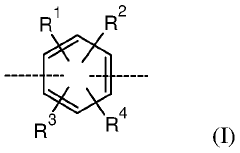

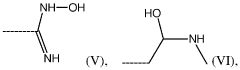

Technical Solution: Northwestern University has made significant strides in reducing toxicity in perovskite solar cells through material innovations. They have developed a new class of 2D perovskites using bulky organic cations, which demonstrate improved stability and reduced toxicity[4]. The team has also explored the use of layered perovskites with optimized organic spacers to enhance moisture resistance and thermal stability[5]. Furthermore, Northwestern researchers have implemented a molecular engineering approach to design low-toxicity hole-transport materials, which play a crucial role in perovskite solar cell performance and longevity[6].

Strengths: Enhanced stability and reduced toxicity through molecular engineering; potential for scalable production. Weaknesses: Possible trade-offs between stability and efficiency; complexity in material synthesis.

Core Innovations in Non-toxic Perovskite Materials

New hybrid material, non-toxic, efficient for photovoltaic application

PatentActiveMA54885A1

Innovation

- Development of a new hybrid material CH3NH3TiP3 for photovoltaic applications, addressing toxicity and stability issues of traditional perovskites.

- The material demonstrates unique properties that make it competitive with both hybrid perovskite and silicon-based solar cells.

- Utilization of CH3NH3TiP3 as an absorber layer in solar cells, potentially offering a non-toxic alternative to lead-based perovskites.

Perovskite solar cell provided with an adsorbent material for adsorbing toxic materials

PatentWO2021122851A1

Innovation

- Integration of a Metal Organic Framework (MOF)/polymer composite material within the solar cell module to act as an adsorbent, capturing and trapping lead in case of damage or leakage, thereby reducing the environmental impact of toxic material release.

Environmental Impact Assessment

The environmental impact assessment of material innovations to reduce toxicity in perovskite solar cells is a critical aspect of their development and potential widespread adoption. Perovskite solar cells have shown remarkable potential in terms of efficiency and cost-effectiveness, but concerns about their environmental impact, particularly due to the presence of lead, have been a significant barrier to their commercialization.

Recent material innovations have focused on reducing or eliminating the use of toxic elements in perovskite solar cells. These efforts have led to the development of lead-free perovskite materials, such as tin-based and bismuth-based perovskites. While these alternatives show promise in terms of reduced toxicity, their environmental impact must be thoroughly assessed across the entire lifecycle of the solar cells.

One key consideration is the production phase of these new materials. The extraction and processing of alternative elements like tin and bismuth may have different environmental implications compared to lead. For instance, tin mining can lead to soil erosion and water pollution, while bismuth extraction often occurs as a byproduct of lead, copper, and tin mining, potentially offsetting some of the environmental benefits.

The manufacturing process of these new perovskite materials also requires scrutiny. Energy consumption, chemical waste generation, and emissions during production must be evaluated and compared to traditional perovskite and silicon-based solar cells. Initial studies suggest that the production of lead-free perovskites may require less energy and produce fewer emissions than their lead-based counterparts, but more comprehensive lifecycle assessments are needed to confirm these findings.

The operational phase of solar cells made with these new materials presents another area for environmental impact assessment. While the reduced toxicity during operation is a clear benefit, factors such as durability, degradation patterns, and potential leaching of materials under various environmental conditions must be thoroughly investigated. The longevity of these new materials compared to traditional perovskites and silicon solar cells will significantly influence their overall environmental impact.

End-of-life considerations are equally important in the environmental assessment. The recyclability and disposal methods for these new materials must be developed and evaluated. If the new perovskite materials can be more easily recycled or safely disposed of compared to lead-based perovskites or silicon solar cells, this could represent a significant environmental advantage.

Lastly, the potential for these material innovations to accelerate the adoption of solar energy must be factored into the overall environmental impact assessment. If lead-free perovskite solar cells can overcome regulatory hurdles and public concerns more easily than their lead-based counterparts, they could contribute to a faster transition to renewable energy sources, potentially offsetting their production-related environmental impacts through reduced reliance on fossil fuels.

Recent material innovations have focused on reducing or eliminating the use of toxic elements in perovskite solar cells. These efforts have led to the development of lead-free perovskite materials, such as tin-based and bismuth-based perovskites. While these alternatives show promise in terms of reduced toxicity, their environmental impact must be thoroughly assessed across the entire lifecycle of the solar cells.

One key consideration is the production phase of these new materials. The extraction and processing of alternative elements like tin and bismuth may have different environmental implications compared to lead. For instance, tin mining can lead to soil erosion and water pollution, while bismuth extraction often occurs as a byproduct of lead, copper, and tin mining, potentially offsetting some of the environmental benefits.

The manufacturing process of these new perovskite materials also requires scrutiny. Energy consumption, chemical waste generation, and emissions during production must be evaluated and compared to traditional perovskite and silicon-based solar cells. Initial studies suggest that the production of lead-free perovskites may require less energy and produce fewer emissions than their lead-based counterparts, but more comprehensive lifecycle assessments are needed to confirm these findings.

The operational phase of solar cells made with these new materials presents another area for environmental impact assessment. While the reduced toxicity during operation is a clear benefit, factors such as durability, degradation patterns, and potential leaching of materials under various environmental conditions must be thoroughly investigated. The longevity of these new materials compared to traditional perovskites and silicon solar cells will significantly influence their overall environmental impact.

End-of-life considerations are equally important in the environmental assessment. The recyclability and disposal methods for these new materials must be developed and evaluated. If the new perovskite materials can be more easily recycled or safely disposed of compared to lead-based perovskites or silicon solar cells, this could represent a significant environmental advantage.

Lastly, the potential for these material innovations to accelerate the adoption of solar energy must be factored into the overall environmental impact assessment. If lead-free perovskite solar cells can overcome regulatory hurdles and public concerns more easily than their lead-based counterparts, they could contribute to a faster transition to renewable energy sources, potentially offsetting their production-related environmental impacts through reduced reliance on fossil fuels.

Regulatory Framework for Solar Cell Materials

The regulatory framework for solar cell materials plays a crucial role in ensuring the safety, environmental sustainability, and market acceptance of perovskite solar cells. As concerns about toxicity in these innovative photovoltaic devices grow, regulatory bodies worldwide are developing and refining guidelines to address potential risks associated with their production, use, and disposal.

In the United States, the Environmental Protection Agency (EPA) has taken the lead in establishing regulations for solar cell materials under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new chemical substances, including those used in perovskite solar cells. This process allows the agency to assess potential risks and implement necessary restrictions or reporting requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in solar cell production. Under REACH, manufacturers must register chemicals produced or imported in quantities over one tonne per year and provide safety data. For perovskite solar cells, this includes lead-based compounds, which are subject to strict controls due to their toxicity.

In China, the Ministry of Environmental Protection has issued guidelines for the management of new chemical substances, which impact the development and production of perovskite solar cells. These regulations require manufacturers to conduct risk assessments and obtain approval before introducing new materials into the market.

International standards organizations, such as the International Electrotechnical Commission (IEC), are developing specific standards for perovskite solar cell materials. These standards aim to establish uniform testing methods and performance criteria, which will facilitate global trade and ensure consistent quality and safety across different markets.

As the technology evolves, regulatory frameworks are adapting to address emerging concerns. For instance, there is a growing focus on end-of-life management and recycling of solar cell materials. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive now includes photovoltaic panels, mandating proper disposal and recycling procedures.

To promote innovation while ensuring safety, some regulatory bodies are implementing fast-track approval processes for less toxic alternatives in perovskite solar cells. These initiatives aim to accelerate the adoption of safer materials without compromising the rigorous safety standards required for market entry.

In the United States, the Environmental Protection Agency (EPA) has taken the lead in establishing regulations for solar cell materials under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new chemical substances, including those used in perovskite solar cells. This process allows the agency to assess potential risks and implement necessary restrictions or reporting requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in solar cell production. Under REACH, manufacturers must register chemicals produced or imported in quantities over one tonne per year and provide safety data. For perovskite solar cells, this includes lead-based compounds, which are subject to strict controls due to their toxicity.

In China, the Ministry of Environmental Protection has issued guidelines for the management of new chemical substances, which impact the development and production of perovskite solar cells. These regulations require manufacturers to conduct risk assessments and obtain approval before introducing new materials into the market.

International standards organizations, such as the International Electrotechnical Commission (IEC), are developing specific standards for perovskite solar cell materials. These standards aim to establish uniform testing methods and performance criteria, which will facilitate global trade and ensure consistent quality and safety across different markets.

As the technology evolves, regulatory frameworks are adapting to address emerging concerns. For instance, there is a growing focus on end-of-life management and recycling of solar cell materials. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive now includes photovoltaic panels, mandating proper disposal and recycling procedures.

To promote innovation while ensuring safety, some regulatory bodies are implementing fast-track approval processes for less toxic alternatives in perovskite solar cells. These initiatives aim to accelerate the adoption of safer materials without compromising the rigorous safety standards required for market entry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!