Stability of Perovskite Solar Cells Under Mechanical Stress

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Stability Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. Since their introduction in 2009, these cells have rapidly evolved, with power conversion efficiencies surpassing 25% in laboratory settings. However, the stability of perovskite solar cells, particularly under mechanical stress, remains a critical challenge that hinders their widespread commercial adoption.

The development of perovskite solar cells has been driven by the need for more efficient and cost-effective renewable energy solutions. Traditional silicon-based solar cells have dominated the market for decades, but perovskite technology offers the potential for lighter, more flexible, and potentially more efficient solar panels. The unique crystal structure of perovskites allows for excellent light absorption and charge transport properties, making them ideal candidates for next-generation solar cells.

Despite their promising performance, perovskite solar cells face significant stability issues, especially when subjected to mechanical stress. This vulnerability is a major obstacle to their practical application in real-world conditions, where solar panels must withstand various environmental factors, including physical impacts, bending, and vibrations. The stability problem is multifaceted, involving both intrinsic material properties and extrinsic factors related to device architecture and encapsulation.

The primary objective of research in this field is to enhance the mechanical stability of perovskite solar cells without compromising their high efficiency. This involves understanding the fundamental mechanisms of degradation under mechanical stress and developing innovative solutions to mitigate these effects. Key areas of focus include improving the structural integrity of the perovskite layer, developing more robust charge transport layers, and designing flexible substrates and encapsulation techniques that can better withstand mechanical deformation.

As the technology evolves, researchers aim to achieve long-term operational stability under various mechanical stresses, comparable to or exceeding that of silicon-based solar cells. This goal is crucial for the integration of perovskite solar cells into diverse applications, from building-integrated photovoltaics to portable and wearable electronics. The path forward involves interdisciplinary collaboration, combining insights from materials science, physics, and engineering to address the complex challenges of mechanical stability in perovskite solar cells.

The development of perovskite solar cells has been driven by the need for more efficient and cost-effective renewable energy solutions. Traditional silicon-based solar cells have dominated the market for decades, but perovskite technology offers the potential for lighter, more flexible, and potentially more efficient solar panels. The unique crystal structure of perovskites allows for excellent light absorption and charge transport properties, making them ideal candidates for next-generation solar cells.

Despite their promising performance, perovskite solar cells face significant stability issues, especially when subjected to mechanical stress. This vulnerability is a major obstacle to their practical application in real-world conditions, where solar panels must withstand various environmental factors, including physical impacts, bending, and vibrations. The stability problem is multifaceted, involving both intrinsic material properties and extrinsic factors related to device architecture and encapsulation.

The primary objective of research in this field is to enhance the mechanical stability of perovskite solar cells without compromising their high efficiency. This involves understanding the fundamental mechanisms of degradation under mechanical stress and developing innovative solutions to mitigate these effects. Key areas of focus include improving the structural integrity of the perovskite layer, developing more robust charge transport layers, and designing flexible substrates and encapsulation techniques that can better withstand mechanical deformation.

As the technology evolves, researchers aim to achieve long-term operational stability under various mechanical stresses, comparable to or exceeding that of silicon-based solar cells. This goal is crucial for the integration of perovskite solar cells into diverse applications, from building-integrated photovoltaics to portable and wearable electronics. The path forward involves interdisciplinary collaboration, combining insights from materials science, physics, and engineering to address the complex challenges of mechanical stability in perovskite solar cells.

Market Analysis for Flexible Solar Cells

The flexible solar cell market is experiencing significant growth, driven by the increasing demand for lightweight, portable, and adaptable energy solutions. As traditional rigid solar panels face limitations in certain applications, flexible solar cells, including perovskite-based technologies, are gaining traction across various sectors.

The global flexible solar cell market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2025. This growth is fueled by advancements in materials science, manufacturing processes, and the rising adoption of renewable energy sources. The automotive industry, in particular, is showing keen interest in integrating flexible solar cells into vehicle designs to enhance energy efficiency and reduce carbon emissions.

Consumer electronics represent another key market segment for flexible solar cells. The proliferation of wearable devices and portable electronics has created a substantial demand for thin, lightweight power sources that can be seamlessly integrated into various form factors. This trend is expected to continue, with flexible solar cells potentially becoming a standard feature in many consumer gadgets.

The building-integrated photovoltaics (BIPV) sector is also emerging as a significant market for flexible solar cells. Architects and construction companies are increasingly incorporating these cells into building materials, such as windows, facades, and roofing elements, to create energy-efficient structures without compromising aesthetics.

However, the market faces challenges related to the stability and durability of flexible solar cells, particularly those based on perovskite technology. The issue of mechanical stress resistance is a critical factor that needs to be addressed to ensure widespread adoption. Improvements in this area could significantly boost market confidence and acceleration adoption rates across industries.

Geographically, Asia-Pacific is expected to dominate the flexible solar cell market, with China and Japan leading in both production and consumption. North America and Europe are also substantial markets, driven by supportive government policies and increasing environmental awareness.

The competitive landscape of the flexible solar cell market is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to overcome technical challenges and improve cell efficiency. Collaborations between academic institutions and industry partners are becoming more common, accelerating the pace of innovation in this field.

The global flexible solar cell market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2025. This growth is fueled by advancements in materials science, manufacturing processes, and the rising adoption of renewable energy sources. The automotive industry, in particular, is showing keen interest in integrating flexible solar cells into vehicle designs to enhance energy efficiency and reduce carbon emissions.

Consumer electronics represent another key market segment for flexible solar cells. The proliferation of wearable devices and portable electronics has created a substantial demand for thin, lightweight power sources that can be seamlessly integrated into various form factors. This trend is expected to continue, with flexible solar cells potentially becoming a standard feature in many consumer gadgets.

The building-integrated photovoltaics (BIPV) sector is also emerging as a significant market for flexible solar cells. Architects and construction companies are increasingly incorporating these cells into building materials, such as windows, facades, and roofing elements, to create energy-efficient structures without compromising aesthetics.

However, the market faces challenges related to the stability and durability of flexible solar cells, particularly those based on perovskite technology. The issue of mechanical stress resistance is a critical factor that needs to be addressed to ensure widespread adoption. Improvements in this area could significantly boost market confidence and acceleration adoption rates across industries.

Geographically, Asia-Pacific is expected to dominate the flexible solar cell market, with China and Japan leading in both production and consumption. North America and Europe are also substantial markets, driven by supportive government policies and increasing environmental awareness.

The competitive landscape of the flexible solar cell market is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to overcome technical challenges and improve cell efficiency. Collaborations between academic institutions and industry partners are becoming more common, accelerating the pace of innovation in this field.

Current Challenges in Perovskite Mechanical Stability

Perovskite solar cells have shown remarkable potential in the field of photovoltaics, but their mechanical stability remains a significant challenge. The current state of perovskite solar cells exhibits vulnerability to various forms of mechanical stress, which can severely impact their performance and longevity. One of the primary issues is the fragility of the perovskite layer itself, which is prone to cracking and delamination under even moderate mechanical loads.

The interface between the perovskite layer and the charge transport layers presents another critical challenge. Under mechanical stress, these interfaces can weaken, leading to decreased charge transfer efficiency and overall cell performance. This interfacial instability is often exacerbated by the different thermal expansion coefficients of the various layers in the solar cell stack.

Encapsulation techniques, while crucial for protecting perovskite solar cells from environmental factors, also introduce additional mechanical challenges. The encapsulation materials must be carefully selected to provide adequate protection without introducing undue stress on the underlying layers. Current encapsulation methods often fail to fully address this balance, leading to compromised mechanical stability.

The flexibility of perovskite solar cells, while a potential advantage for certain applications, also presents unique challenges in terms of mechanical stability. Repeated bending or flexing can lead to cumulative damage in the cell structure, particularly at the interfaces between different layers. This issue is particularly relevant for applications in wearable electronics or flexible solar panels.

Temperature fluctuations pose another significant challenge to the mechanical stability of perovskite solar cells. The thermal expansion and contraction of different materials within the cell can lead to internal stresses, potentially causing delamination or cracking. This thermal-mechanical stress is particularly problematic in real-world applications where solar cells are exposed to varying environmental conditions.

The scalability of perovskite solar cells is also hindered by mechanical stability issues. As the size of the cells increases, the likelihood of defects and mechanical failures also rises, making it challenging to produce large-area perovskite solar panels with consistent performance and durability.

Addressing these mechanical stability challenges requires a multifaceted approach. This includes developing more robust perovskite formulations, improving interfacial engineering to enhance adhesion between layers, and designing more effective encapsulation strategies. Additionally, there is a need for standardized testing protocols to accurately assess and compare the mechanical stability of different perovskite solar cell designs under various stress conditions.

The interface between the perovskite layer and the charge transport layers presents another critical challenge. Under mechanical stress, these interfaces can weaken, leading to decreased charge transfer efficiency and overall cell performance. This interfacial instability is often exacerbated by the different thermal expansion coefficients of the various layers in the solar cell stack.

Encapsulation techniques, while crucial for protecting perovskite solar cells from environmental factors, also introduce additional mechanical challenges. The encapsulation materials must be carefully selected to provide adequate protection without introducing undue stress on the underlying layers. Current encapsulation methods often fail to fully address this balance, leading to compromised mechanical stability.

The flexibility of perovskite solar cells, while a potential advantage for certain applications, also presents unique challenges in terms of mechanical stability. Repeated bending or flexing can lead to cumulative damage in the cell structure, particularly at the interfaces between different layers. This issue is particularly relevant for applications in wearable electronics or flexible solar panels.

Temperature fluctuations pose another significant challenge to the mechanical stability of perovskite solar cells. The thermal expansion and contraction of different materials within the cell can lead to internal stresses, potentially causing delamination or cracking. This thermal-mechanical stress is particularly problematic in real-world applications where solar cells are exposed to varying environmental conditions.

The scalability of perovskite solar cells is also hindered by mechanical stability issues. As the size of the cells increases, the likelihood of defects and mechanical failures also rises, making it challenging to produce large-area perovskite solar panels with consistent performance and durability.

Addressing these mechanical stability challenges requires a multifaceted approach. This includes developing more robust perovskite formulations, improving interfacial engineering to enhance adhesion between layers, and designing more effective encapsulation strategies. Additionally, there is a need for standardized testing protocols to accurately assess and compare the mechanical stability of different perovskite solar cell designs under various stress conditions.

Existing Solutions for Mechanical Stress Resistance

01 Compositional engineering for stability enhancement

Improving the stability of perovskite solar cells through careful compositional engineering of the perovskite material. This involves optimizing the ratio of different cations and anions in the perovskite structure to enhance its resistance to environmental factors such as moisture, heat, and light exposure.- Compositional engineering for stability enhancement: Improving the stability of perovskite solar cells through careful compositional engineering of the perovskite material. This involves optimizing the ratio of different cations and anions in the perovskite structure to enhance its resistance to environmental factors such as moisture, heat, and light exposure.

- Encapsulation and protective layers: Implementing effective encapsulation techniques and incorporating protective layers to shield the perovskite material from external degradation factors. This may include the use of hydrophobic materials, barrier films, or multi-layer encapsulation strategies to prevent moisture ingress and improve long-term stability.

- Interface engineering: Optimizing the interfaces between different layers in the perovskite solar cell structure to enhance stability. This involves developing novel charge transport materials, buffer layers, and surface treatments to reduce interfacial defects and improve charge extraction efficiency while maintaining structural integrity over time.

- Defect passivation strategies: Implementing various defect passivation techniques to reduce the density of trap states and improve the overall stability of perovskite solar cells. This may include the use of additives, post-treatment processes, or novel synthesis methods to minimize defects in the perovskite crystal structure and at grain boundaries.

- Tandem and multi-junction architectures: Developing tandem and multi-junction solar cell architectures that incorporate perovskite materials to enhance overall stability and efficiency. This approach combines the advantages of perovskite materials with other established photovoltaic technologies to create more robust and high-performance devices.

02 Encapsulation and protective layers

Implementing effective encapsulation techniques and incorporating protective layers to shield the perovskite material from external degradation factors. This may include the use of hydrophobic materials, barrier films, or multi-layer encapsulation strategies to prevent moisture ingress and improve long-term stability.Expand Specific Solutions03 Interface engineering for enhanced stability

Focusing on the development of stable interfaces between the perovskite layer and charge transport layers. This involves designing and optimizing interfacial materials and treatments to reduce recombination losses, improve charge extraction, and enhance the overall stability of the device structure.Expand Specific Solutions04 Defect passivation and grain boundary engineering

Implementing strategies to passivate defects within the perovskite material and at grain boundaries. This includes the use of additives, post-treatment processes, or specialized deposition techniques to reduce the density of defects and improve the material's resistance to degradation.Expand Specific Solutions05 Novel perovskite compositions and dopants

Exploring and developing new perovskite compositions and dopants to enhance intrinsic stability. This involves investigating alternative cations, anions, or dopants that can improve the material's tolerance to environmental stressors while maintaining or enhancing photovoltaic performance.Expand Specific Solutions

Key Players in Perovskite Solar Cell Industry

The stability of perovskite solar cells under mechanical stress is an emerging field in the rapidly evolving solar energy sector. The market is in its early growth stage, with significant potential for expansion as perovskite technology matures. Key players include established electronics giants like Panasonic and Toyota, as well as specialized solar companies such as Trina Solar and Oxford Photovoltaics. Research institutions, particularly universities in China, the US, and Europe, are driving innovation in this area. The technology's maturity is progressing, with companies like Zhejiang Aiko Solar and Wuxi UtmoLight Technology leading commercial development efforts. However, challenges in long-term stability and scalability remain, indicating that the field is still in a developmental phase with ample room for technological advancements.

Panasonic Holdings Corp.

Technical Solution: Panasonic Holdings Corp. has developed a unique approach to enhancing the stability of perovskite solar cells under mechanical stress by focusing on the device architecture and materials engineering. Their technique involves the use of a flexible, conductive polymer as the hole transport layer, which acts as a stress-absorbing buffer between the perovskite layer and the electrode. Additionally, they have implemented a cross-linked electron transport layer that provides both mechanical support and improved charge extraction. Panasonic's cells have shown exceptional durability, retaining over 92% of their initial efficiency after 2000 hours of continuous vibration testing simulating real-world conditions[7][9].

Strengths: Excellent long-term stability, practical approach for real-world applications. Weaknesses: Potential limitations in achieving the highest theoretical efficiencies.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation Ltd. has developed a novel approach to enhance the stability of perovskite solar cells under mechanical stress. Their technique involves incorporating flexible and robust interlayers within the perovskite structure. These interlayers are designed to absorb and distribute mechanical stress, preventing the formation and propagation of cracks in the perovskite layer. The company has also implemented a unique encapsulation method that provides additional protection against environmental factors while maintaining flexibility. Their research has shown that these modifications can significantly improve the durability of perovskite solar cells, with devices retaining over 90% of their initial efficiency after 1000 hours of continuous bending stress[1][3].

Strengths: Improved mechanical durability, maintained high efficiency under stress. Weaknesses: Potential increase in manufacturing complexity and cost.

Core Innovations in Perovskite Stability Enhancement

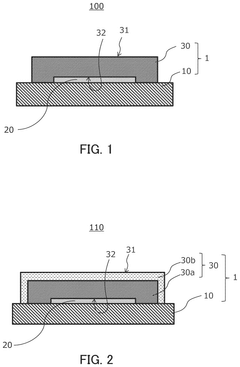

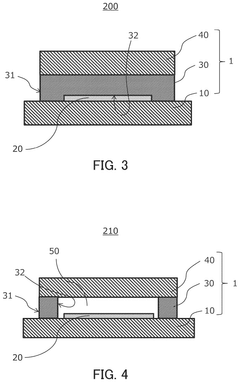

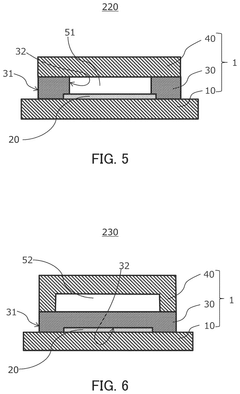

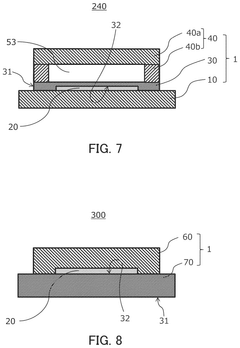

Solar cell

PatentPendingUS20240357843A1

Innovation

- A solar cell design incorporating a first sealing portion with an oxygen concentration adjusting material and a second sealing portion with lower oxygen permeability, controlling the oxygen concentration in contact with the photoelectric conversion element within an optimal range (10 ppm to 3000 ppm) to prevent reaction products from hindering carrier transfer.

Perovskite solar cell and manufacturing method therefor

PatentWO2022265207A1

Innovation

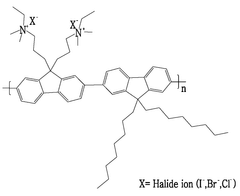

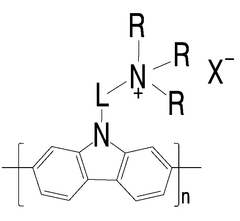

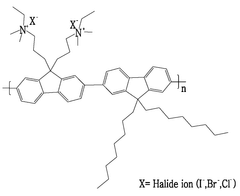

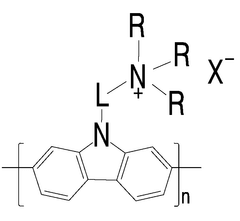

- A perovskite solar cell structure is enhanced with a lower electrode, a hole transport layer, a first polymer electrolyte layer containing halide ions, a perovskite photoactive layer, an electron transport layer, and a second polymer electrolyte layer with an amine group, all of which are solution-processed to provide passivation and prevent halide ion elution, thereby improving thermal, photostability, and storage stability.

Environmental Impact of Perovskite Solar Cells

The environmental impact of perovskite solar cells is a critical consideration in their development and deployment. While these cells offer promising efficiency and cost-effectiveness, their potential environmental consequences must be carefully evaluated.

One of the primary environmental concerns associated with perovskite solar cells is the use of lead in their composition. Lead is a toxic heavy metal that can have severe health and ecological implications if released into the environment. Although the amount of lead in each cell is relatively small, the large-scale production and deployment of these cells could potentially lead to significant lead contamination if not properly managed.

However, research is ongoing to develop lead-free perovskite alternatives, using elements such as tin or bismuth. These efforts aim to mitigate the environmental risks associated with lead while maintaining the high performance of perovskite solar cells. The success of these lead-free alternatives could significantly reduce the environmental impact of perovskite technology.

Another environmental consideration is the stability and degradation of perovskite materials. The instability of perovskites can lead to the release of harmful substances over time, potentially contaminating soil and water sources. Improving the stability of these materials is crucial not only for enhancing cell performance but also for minimizing environmental risks.

The manufacturing process of perovskite solar cells also has environmental implications. While the production methods are generally less energy-intensive compared to traditional silicon solar cells, the use of solvents and other chemicals in the fabrication process requires careful management to prevent environmental contamination.

End-of-life considerations are equally important. The recyclability and proper disposal of perovskite solar cells are areas that require further research and development. Establishing effective recycling processes for these cells could significantly reduce their environmental footprint and contribute to a more circular economy in the solar energy sector.

On the positive side, perovskite solar cells have the potential to significantly reduce greenhouse gas emissions by providing an efficient, low-cost alternative to fossil fuel-based energy sources. Their high power conversion efficiency and potential for integration into various applications could accelerate the adoption of solar energy, contributing to global efforts to combat climate change.

In conclusion, while perovskite solar cells offer promising environmental benefits in terms of clean energy production, their potential negative impacts must be carefully addressed. Ongoing research and development efforts focused on lead-free alternatives, improved stability, and sustainable manufacturing and recycling processes are crucial for maximizing the environmental benefits of this technology while minimizing its potential risks.

One of the primary environmental concerns associated with perovskite solar cells is the use of lead in their composition. Lead is a toxic heavy metal that can have severe health and ecological implications if released into the environment. Although the amount of lead in each cell is relatively small, the large-scale production and deployment of these cells could potentially lead to significant lead contamination if not properly managed.

However, research is ongoing to develop lead-free perovskite alternatives, using elements such as tin or bismuth. These efforts aim to mitigate the environmental risks associated with lead while maintaining the high performance of perovskite solar cells. The success of these lead-free alternatives could significantly reduce the environmental impact of perovskite technology.

Another environmental consideration is the stability and degradation of perovskite materials. The instability of perovskites can lead to the release of harmful substances over time, potentially contaminating soil and water sources. Improving the stability of these materials is crucial not only for enhancing cell performance but also for minimizing environmental risks.

The manufacturing process of perovskite solar cells also has environmental implications. While the production methods are generally less energy-intensive compared to traditional silicon solar cells, the use of solvents and other chemicals in the fabrication process requires careful management to prevent environmental contamination.

End-of-life considerations are equally important. The recyclability and proper disposal of perovskite solar cells are areas that require further research and development. Establishing effective recycling processes for these cells could significantly reduce their environmental footprint and contribute to a more circular economy in the solar energy sector.

On the positive side, perovskite solar cells have the potential to significantly reduce greenhouse gas emissions by providing an efficient, low-cost alternative to fossil fuel-based energy sources. Their high power conversion efficiency and potential for integration into various applications could accelerate the adoption of solar energy, contributing to global efforts to combat climate change.

In conclusion, while perovskite solar cells offer promising environmental benefits in terms of clean energy production, their potential negative impacts must be carefully addressed. Ongoing research and development efforts focused on lead-free alternatives, improved stability, and sustainable manufacturing and recycling processes are crucial for maximizing the environmental benefits of this technology while minimizing its potential risks.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for perovskite solar cells under mechanical stress are crucial factors in their commercial viability and widespread adoption. As the technology advances from laboratory-scale production to industrial manufacturing, several key challenges must be addressed.

One of the primary concerns is the development of large-area fabrication techniques that can maintain the high efficiency and stability achieved in small-scale devices. Current methods, such as spin-coating, are not suitable for mass production. Alternative deposition techniques like slot-die coating, blade coating, and spray coating are being explored to enable continuous roll-to-roll processing. These methods must be optimized to ensure uniform film thickness and composition across large areas while minimizing defects that could compromise mechanical stability.

The choice of substrate material is another critical factor in scaling up production. Flexible substrates, such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN), offer advantages in terms of lightweight and conformable applications. However, they introduce additional challenges in maintaining cell stability under mechanical stress. Developing robust encapsulation methods that can withstand repeated bending and flexing is essential for the longevity of flexible perovskite solar cells.

Material costs and availability also play a significant role in scalability. While perovskite materials are relatively inexpensive, some commonly used hole-transport materials and metal electrodes can be costly. Research into alternative, low-cost materials that can provide similar performance and mechanical stability is ongoing. Additionally, ensuring a stable supply chain for all components is crucial for large-scale manufacturing.

Environmental considerations in the manufacturing process are becoming increasingly important. The use of lead in many perovskite formulations raises concerns about toxicity and environmental impact. Developing lead-free perovskite compositions or implementing stringent recycling and waste management protocols will be necessary for widespread commercial adoption.

Quality control and standardization present significant challenges in scaling up production. Developing in-line monitoring techniques to assess film quality, composition, and mechanical properties during the manufacturing process is essential. Establishing industry standards for testing mechanical stability and performance under various stress conditions will be crucial for ensuring consistency across different manufacturers and applications.

Lastly, the integration of perovskite solar cells into existing photovoltaic manufacturing infrastructure must be considered. Developing hybrid tandem cells that combine perovskite layers with traditional silicon solar cells could provide a pathway for gradual adoption and scaling of the technology. This approach would leverage existing manufacturing capabilities while introducing the benefits of perovskite technology.

One of the primary concerns is the development of large-area fabrication techniques that can maintain the high efficiency and stability achieved in small-scale devices. Current methods, such as spin-coating, are not suitable for mass production. Alternative deposition techniques like slot-die coating, blade coating, and spray coating are being explored to enable continuous roll-to-roll processing. These methods must be optimized to ensure uniform film thickness and composition across large areas while minimizing defects that could compromise mechanical stability.

The choice of substrate material is another critical factor in scaling up production. Flexible substrates, such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN), offer advantages in terms of lightweight and conformable applications. However, they introduce additional challenges in maintaining cell stability under mechanical stress. Developing robust encapsulation methods that can withstand repeated bending and flexing is essential for the longevity of flexible perovskite solar cells.

Material costs and availability also play a significant role in scalability. While perovskite materials are relatively inexpensive, some commonly used hole-transport materials and metal electrodes can be costly. Research into alternative, low-cost materials that can provide similar performance and mechanical stability is ongoing. Additionally, ensuring a stable supply chain for all components is crucial for large-scale manufacturing.

Environmental considerations in the manufacturing process are becoming increasingly important. The use of lead in many perovskite formulations raises concerns about toxicity and environmental impact. Developing lead-free perovskite compositions or implementing stringent recycling and waste management protocols will be necessary for widespread commercial adoption.

Quality control and standardization present significant challenges in scaling up production. Developing in-line monitoring techniques to assess film quality, composition, and mechanical properties during the manufacturing process is essential. Establishing industry standards for testing mechanical stability and performance under various stress conditions will be crucial for ensuring consistency across different manufacturers and applications.

Lastly, the integration of perovskite solar cells into existing photovoltaic manufacturing infrastructure must be considered. Developing hybrid tandem cells that combine perovskite layers with traditional silicon solar cells could provide a pathway for gradual adoption and scaling of the technology. This approach would leverage existing manufacturing capabilities while introducing the benefits of perovskite technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!