Perovskite Solar Cells in Building-Integrated Photovoltaic Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite BIPV Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering a potential revolution in solar energy harvesting. The integration of these cells into building-integrated photovoltaic (BIPV) systems represents a significant step towards sustainable urban development and energy-efficient architecture. This research aims to explore the application of perovskite solar cells in BIPV systems, addressing the growing need for renewable energy solutions in the built environment.

The development of perovskite solar cells can be traced back to 2009 when they were first used as sensitizers in dye-sensitized solar cells. Since then, rapid advancements have been made, with power conversion efficiencies increasing from 3.8% to over 25% in just a decade. This remarkable progress has positioned perovskite solar cells as a viable alternative to traditional silicon-based photovoltaics, particularly in the context of building integration.

BIPV systems, which incorporate photovoltaic materials into building envelopes, have gained traction as a means to generate clean energy while serving architectural functions. The marriage of perovskite technology with BIPV presents an opportunity to overcome limitations of conventional solar panels, such as weight, flexibility, and aesthetic constraints. Perovskite solar cells offer unique advantages, including tunable bandgaps, low-temperature processing, and the potential for semi-transparency, making them ideal candidates for diverse BIPV applications.

The primary objective of this research is to investigate the feasibility and performance of perovskite solar cells in BIPV systems. This involves examining the technical challenges associated with integrating perovskite technology into building materials, assessing long-term stability and durability under real-world conditions, and exploring innovative designs that maximize both energy generation and architectural functionality.

Furthermore, this study aims to evaluate the economic viability and environmental impact of perovskite BIPV systems. By analyzing the cost-effectiveness, energy payback time, and life cycle assessment of these systems, we seek to provide a comprehensive understanding of their potential to contribute to sustainable urban development and meet global energy demands.

As the world moves towards net-zero energy buildings and smart cities, the role of integrated renewable energy technologies becomes increasingly crucial. This research endeavors to contribute to the body of knowledge that will shape the future of solar energy in the built environment, paving the way for widespread adoption of perovskite-based BIPV systems and accelerating the transition to a more sustainable and energy-efficient urban landscape.

The development of perovskite solar cells can be traced back to 2009 when they were first used as sensitizers in dye-sensitized solar cells. Since then, rapid advancements have been made, with power conversion efficiencies increasing from 3.8% to over 25% in just a decade. This remarkable progress has positioned perovskite solar cells as a viable alternative to traditional silicon-based photovoltaics, particularly in the context of building integration.

BIPV systems, which incorporate photovoltaic materials into building envelopes, have gained traction as a means to generate clean energy while serving architectural functions. The marriage of perovskite technology with BIPV presents an opportunity to overcome limitations of conventional solar panels, such as weight, flexibility, and aesthetic constraints. Perovskite solar cells offer unique advantages, including tunable bandgaps, low-temperature processing, and the potential for semi-transparency, making them ideal candidates for diverse BIPV applications.

The primary objective of this research is to investigate the feasibility and performance of perovskite solar cells in BIPV systems. This involves examining the technical challenges associated with integrating perovskite technology into building materials, assessing long-term stability and durability under real-world conditions, and exploring innovative designs that maximize both energy generation and architectural functionality.

Furthermore, this study aims to evaluate the economic viability and environmental impact of perovskite BIPV systems. By analyzing the cost-effectiveness, energy payback time, and life cycle assessment of these systems, we seek to provide a comprehensive understanding of their potential to contribute to sustainable urban development and meet global energy demands.

As the world moves towards net-zero energy buildings and smart cities, the role of integrated renewable energy technologies becomes increasingly crucial. This research endeavors to contribute to the body of knowledge that will shape the future of solar energy in the built environment, paving the way for widespread adoption of perovskite-based BIPV systems and accelerating the transition to a more sustainable and energy-efficient urban landscape.

Market Analysis for BIPV Perovskite Solutions

The market for Building-Integrated Photovoltaic (BIPV) perovskite solutions is experiencing significant growth and transformation. As the global focus on sustainable construction and renewable energy intensifies, BIPV systems are gaining traction in both residential and commercial sectors. Perovskite solar cells, with their unique properties and potential for high efficiency, are emerging as a promising technology in this space.

The BIPV market is projected to expand rapidly in the coming years, driven by factors such as increasing environmental awareness, government incentives for green building practices, and the growing demand for energy-efficient structures. Perovskite-based BIPV solutions are particularly attractive due to their potential for low-cost production, lightweight nature, and flexibility in application.

In the residential sector, homeowners are showing increased interest in aesthetically pleasing solar solutions that can seamlessly integrate with building facades, roofs, and windows. Perovskite BIPV products offer the advantage of customization in terms of color and transparency, making them more appealing to architects and homeowners alike.

The commercial and industrial sectors present significant opportunities for BIPV perovskite solutions. Large-scale buildings, such as office complexes, shopping centers, and factories, have extensive surface areas that can be utilized for power generation. The ability of perovskite solar cells to perform well under low-light conditions and at various angles makes them suitable for vertical installations on building facades.

Geographically, Europe and North America are currently leading the BIPV market, with countries like Germany, France, and the United States at the forefront. However, rapid urbanization and increasing energy demands in Asia-Pacific regions, particularly in China and India, are expected to drive substantial growth in these markets.

Despite the promising outlook, several challenges need to be addressed for widespread adoption of BIPV perovskite solutions. These include improving the long-term stability of perovskite cells, scaling up production processes, and addressing potential environmental concerns related to lead-based perovskites. Overcoming these hurdles will be crucial for market penetration and consumer acceptance.

The competitive landscape is evolving, with both established solar companies and startups investing in perovskite BIPV technology. Collaborations between material scientists, solar cell manufacturers, and construction companies are becoming more common, aiming to develop integrated solutions that meet both energy generation and building requirements.

As the technology matures and production costs decrease, the market for BIPV perovskite solutions is expected to expand significantly. This growth will likely be supported by evolving building codes and energy regulations that promote on-site renewable energy generation in new constructions and retrofits.

The BIPV market is projected to expand rapidly in the coming years, driven by factors such as increasing environmental awareness, government incentives for green building practices, and the growing demand for energy-efficient structures. Perovskite-based BIPV solutions are particularly attractive due to their potential for low-cost production, lightweight nature, and flexibility in application.

In the residential sector, homeowners are showing increased interest in aesthetically pleasing solar solutions that can seamlessly integrate with building facades, roofs, and windows. Perovskite BIPV products offer the advantage of customization in terms of color and transparency, making them more appealing to architects and homeowners alike.

The commercial and industrial sectors present significant opportunities for BIPV perovskite solutions. Large-scale buildings, such as office complexes, shopping centers, and factories, have extensive surface areas that can be utilized for power generation. The ability of perovskite solar cells to perform well under low-light conditions and at various angles makes them suitable for vertical installations on building facades.

Geographically, Europe and North America are currently leading the BIPV market, with countries like Germany, France, and the United States at the forefront. However, rapid urbanization and increasing energy demands in Asia-Pacific regions, particularly in China and India, are expected to drive substantial growth in these markets.

Despite the promising outlook, several challenges need to be addressed for widespread adoption of BIPV perovskite solutions. These include improving the long-term stability of perovskite cells, scaling up production processes, and addressing potential environmental concerns related to lead-based perovskites. Overcoming these hurdles will be crucial for market penetration and consumer acceptance.

The competitive landscape is evolving, with both established solar companies and startups investing in perovskite BIPV technology. Collaborations between material scientists, solar cell manufacturers, and construction companies are becoming more common, aiming to develop integrated solutions that meet both energy generation and building requirements.

As the technology matures and production costs decrease, the market for BIPV perovskite solutions is expected to expand significantly. This growth will likely be supported by evolving building codes and energy regulations that promote on-site renewable energy generation in new constructions and retrofits.

Perovskite BIPV: Current Status and Challenges

Perovskite solar cells have emerged as a promising technology for building-integrated photovoltaics (BIPV) due to their unique properties and potential for high efficiency. However, the current status of perovskite BIPV systems faces several challenges that need to be addressed for widespread adoption.

One of the primary advantages of perovskite solar cells is their high power conversion efficiency, which has rapidly increased from 3.8% in 2009 to over 25% in recent years. This remarkable progress has positioned perovskites as a competitive alternative to traditional silicon-based solar cells. Additionally, perovskite solar cells offer excellent flexibility and lightweight characteristics, making them ideal for integration into building materials.

Despite these promising attributes, perovskite BIPV systems face significant stability issues. The perovskite material is highly sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cells. This instability poses a major challenge for long-term performance in real-world building applications, where exposure to environmental factors is inevitable.

Another critical challenge is the scalability of perovskite solar cell production. While lab-scale devices have shown impressive efficiencies, translating these results to large-area modules suitable for BIPV applications remains difficult. Issues such as uniformity, defect control, and maintaining high efficiency at larger scales need to be addressed.

The toxicity of lead, a common component in high-performance perovskite solar cells, raises environmental and health concerns. Research efforts are ongoing to develop lead-free alternatives, but these typically show lower efficiencies and stability compared to their lead-based counterparts. Balancing performance with environmental safety is crucial for the widespread adoption of perovskite BIPV systems.

Integration of perovskite solar cells into building materials presents unique challenges. Ensuring compatibility with existing construction materials and processes, as well as meeting building codes and safety standards, requires further research and development. Additionally, the aesthetic requirements of BIPV systems necessitate innovations in color tuning and transparency control of perovskite solar cells.

The long-term durability and performance of perovskite BIPV systems under real-world conditions remain largely unknown. Accelerated aging tests and field trials are necessary to assess the technology's viability for building applications, where a lifespan of 20-25 years is typically expected.

In conclusion, while perovskite solar cells show great promise for BIPV applications, significant challenges in stability, scalability, toxicity, integration, and long-term performance need to be overcome. Addressing these issues requires collaborative efforts between materials scientists, engineers, and the construction industry to realize the full potential of perovskite BIPV technology.

One of the primary advantages of perovskite solar cells is their high power conversion efficiency, which has rapidly increased from 3.8% in 2009 to over 25% in recent years. This remarkable progress has positioned perovskites as a competitive alternative to traditional silicon-based solar cells. Additionally, perovskite solar cells offer excellent flexibility and lightweight characteristics, making them ideal for integration into building materials.

Despite these promising attributes, perovskite BIPV systems face significant stability issues. The perovskite material is highly sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cells. This instability poses a major challenge for long-term performance in real-world building applications, where exposure to environmental factors is inevitable.

Another critical challenge is the scalability of perovskite solar cell production. While lab-scale devices have shown impressive efficiencies, translating these results to large-area modules suitable for BIPV applications remains difficult. Issues such as uniformity, defect control, and maintaining high efficiency at larger scales need to be addressed.

The toxicity of lead, a common component in high-performance perovskite solar cells, raises environmental and health concerns. Research efforts are ongoing to develop lead-free alternatives, but these typically show lower efficiencies and stability compared to their lead-based counterparts. Balancing performance with environmental safety is crucial for the widespread adoption of perovskite BIPV systems.

Integration of perovskite solar cells into building materials presents unique challenges. Ensuring compatibility with existing construction materials and processes, as well as meeting building codes and safety standards, requires further research and development. Additionally, the aesthetic requirements of BIPV systems necessitate innovations in color tuning and transparency control of perovskite solar cells.

The long-term durability and performance of perovskite BIPV systems under real-world conditions remain largely unknown. Accelerated aging tests and field trials are necessary to assess the technology's viability for building applications, where a lifespan of 20-25 years is typically expected.

In conclusion, while perovskite solar cells show great promise for BIPV applications, significant challenges in stability, scalability, toxicity, integration, and long-term performance need to be overcome. Addressing these issues requires collaborative efforts between materials scientists, engineers, and the construction industry to realize the full potential of perovskite BIPV technology.

Existing Perovskite BIPV Integration Methods

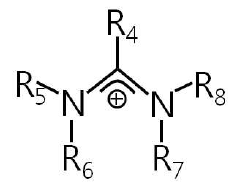

01 Perovskite material composition and structure

Research focuses on optimizing the composition and crystal structure of perovskite materials to enhance solar cell efficiency and stability. This includes exploring various cations, anions, and dopants to fine-tune the material properties and improve performance.- Perovskite material composition and structure: Research focuses on optimizing the composition and crystal structure of perovskite materials to enhance solar cell efficiency and stability. This includes exploring various cations, anions, and dopants to improve light absorption, charge transport, and resistance to environmental factors.

- Fabrication techniques for perovskite layers: Advanced manufacturing methods are being developed to create high-quality, uniform perovskite layers. These techniques aim to control film morphology, reduce defects, and improve scalability for large-area production of perovskite solar cells.

- Interface engineering and charge transport layers: Innovations in interface engineering focus on developing efficient charge transport layers and optimizing the interfaces between perovskite and other layers. This includes exploring new materials and structures to reduce recombination losses and enhance overall device performance.

- Stability and encapsulation strategies: Research efforts are directed towards improving the long-term stability of perovskite solar cells. This involves developing effective encapsulation methods, moisture-resistant materials, and strategies to mitigate degradation under various environmental conditions.

- Tandem and multi-junction perovskite solar cells: Advanced architectures such as tandem and multi-junction configurations are being explored to surpass the theoretical efficiency limits of single-junction cells. These designs combine perovskite with other photovoltaic materials to harvest a broader spectrum of solar energy.

02 Fabrication techniques for perovskite solar cells

Advanced manufacturing methods are being developed to improve the quality and scalability of perovskite solar cells. These techniques aim to enhance film uniformity, reduce defects, and increase production efficiency for large-scale commercialization.Expand Specific Solutions03 Stability and encapsulation strategies

Researchers are developing innovative encapsulation methods and materials to protect perovskite solar cells from environmental factors, improving their long-term stability and operational lifetime under various conditions.Expand Specific Solutions04 Tandem and multi-junction perovskite solar cells

Integration of perovskite materials with other photovoltaic technologies to create tandem or multi-junction solar cells is being explored. This approach aims to surpass the theoretical efficiency limits of single-junction cells and maximize power conversion efficiency.Expand Specific Solutions05 Charge transport layers and interfaces

Optimization of charge transport layers and interfaces between different materials in perovskite solar cells is crucial for improving charge extraction and reducing recombination losses, ultimately enhancing overall device performance.Expand Specific Solutions

Key Players in Perovskite BIPV Industry

The research on perovskite solar cells in building-integrated photovoltaic systems is in a rapidly evolving phase, with significant market potential and growing technological maturity. The global market for this technology is expanding, driven by increasing demand for sustainable energy solutions in urban environments. Key players like Trina Solar, Oxford Photovoltaics, and EneCoat Technologies are at the forefront, developing innovative perovskite-based products. Academic institutions such as MIT, Xidian University, and the University of Oxford are contributing crucial research. The involvement of major energy companies like Eni SpA and Siemens Energy indicates the technology's commercial viability. While still emerging, perovskite solar cells are progressing towards wider adoption in building-integrated applications.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has been actively researching perovskite solar cells for BIPV applications. They have developed a proprietary perovskite-silicon tandem cell technology that has achieved a record efficiency of 24.8% for a large-area (> 200 cm²) cell [4]. Their approach focuses on integrating perovskite top cells with their high-efficiency silicon cells to create cost-effective tandem structures. Trina Solar is also working on developing semi-transparent perovskite cells specifically for BIPV applications, aiming to balance power generation with daylighting requirements in buildings [5]. They have invested in pilot production lines to scale up perovskite technology and are collaborating with research institutions to address stability and encapsulation challenges [6].

Strengths: Strong manufacturing capabilities, experience in commercializing solar technologies, and progress in large-area cells. Weaknesses: Relatively new to perovskite technology compared to some competitors.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation Ltd. has developed advanced perovskite solar cell technologies for building-integrated photovoltaic (BIPV) systems. Their approach focuses on improving the stability and efficiency of perovskite cells through novel material engineering and device architectures. They have achieved power conversion efficiencies exceeding 23% in laboratory settings [1], and are working on scaling up production for commercial applications. Their research includes the development of tandem perovskite-silicon cells, which have the potential to surpass the theoretical efficiency limits of single-junction silicon cells [2]. Additionally, they are exploring the use of 2D/3D perovskite structures to enhance long-term stability and moisture resistance, critical for BIPV applications [3].

Strengths: High efficiency, potential for low-cost production, and expertise in tandem cell technology. Weaknesses: Challenges in long-term stability and scaling up for commercial production.

Core Innovations in Perovskite BIPV Technology

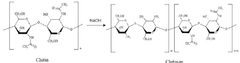

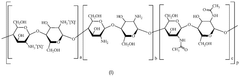

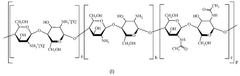

Perovskite-based photovoltaic cells and preparation process thereof

PatentWO2024194758A1

Innovation

- Incorporating a salified chitosan with a specific general formula into the perovskite photoactive layer, allowing for better solubility and processing in an uncontrolled atmosphere, enhancing the power conversion efficiency and maintaining good photoelectric properties suitable for large-area photovoltaic cells.

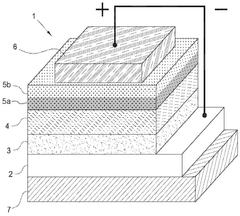

Assembled Structure for Perovskite Solar Cell, Perovskite Solar Cell Having Improved Photo-stability and the Fabrication Method thereof

PatentActiveKR1020190037463A

Innovation

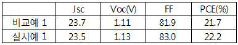

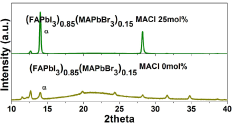

- Incorporating a chlorine source into the active layer of the perovskite solar cell structure, which thermally decomposes to supply chlorine to the electron carrier and perovskite compound, enhancing the photostability and maintaining high efficiency over extended light exposure.

Environmental Impact of Perovskite BIPV Systems

The environmental impact of perovskite Building-Integrated Photovoltaic (BIPV) systems is a critical consideration in the development and deployment of this emerging technology. As perovskite solar cells gain traction in the BIPV sector, it is essential to assess their ecological footprint throughout their lifecycle.

One of the primary environmental advantages of perovskite BIPV systems is their potential to reduce carbon emissions. By integrating solar energy generation directly into building materials, these systems can significantly decrease reliance on fossil fuels for electricity production. This reduction in greenhouse gas emissions contributes to mitigating climate change and improving air quality in urban environments.

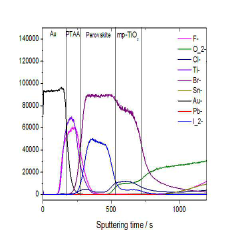

However, the production of perovskite solar cells raises some environmental concerns. The synthesis of perovskite materials often involves the use of lead-based compounds, which can pose risks to human health and ecosystems if not properly managed. Researchers are actively exploring lead-free alternatives and developing encapsulation techniques to minimize potential environmental hazards.

The manufacturing process of perovskite BIPV systems also requires careful consideration. While perovskite solar cells can be produced using low-temperature processes, which are less energy-intensive than traditional silicon-based solar cells, the overall environmental impact of production still needs to be thoroughly assessed. This includes evaluating the sourcing of raw materials, energy consumption during manufacturing, and potential emissions or waste products.

End-of-life management is another crucial aspect of the environmental impact of perovskite BIPV systems. As these systems reach the end of their operational lifespan, proper recycling and disposal methods must be developed to prevent the release of harmful materials into the environment. Research is ongoing to establish efficient recycling processes that can recover valuable materials and minimize waste.

The durability and longevity of perovskite BIPV systems also play a role in their environmental impact. While perovskite solar cells have shown promising efficiency, their long-term stability under real-world conditions is still being studied. Improving the lifespan of these systems can reduce the frequency of replacements and associated environmental costs.

Furthermore, the integration of perovskite solar cells into building materials may have indirect environmental benefits. By replacing conventional building materials with photovoltaic alternatives, the overall environmental footprint of construction can be reduced. This includes potential savings in transportation and installation costs, as well as the reduction of materials needed for separate solar panel installations.

In conclusion, while perovskite BIPV systems show great promise for sustainable energy generation in urban environments, a comprehensive lifecycle assessment is necessary to fully understand and mitigate their environmental impact. Ongoing research and development efforts are focused on addressing key environmental challenges, such as lead toxicity and end-of-life management, to ensure that perovskite BIPV technology can contribute positively to a more sustainable built environment.

One of the primary environmental advantages of perovskite BIPV systems is their potential to reduce carbon emissions. By integrating solar energy generation directly into building materials, these systems can significantly decrease reliance on fossil fuels for electricity production. This reduction in greenhouse gas emissions contributes to mitigating climate change and improving air quality in urban environments.

However, the production of perovskite solar cells raises some environmental concerns. The synthesis of perovskite materials often involves the use of lead-based compounds, which can pose risks to human health and ecosystems if not properly managed. Researchers are actively exploring lead-free alternatives and developing encapsulation techniques to minimize potential environmental hazards.

The manufacturing process of perovskite BIPV systems also requires careful consideration. While perovskite solar cells can be produced using low-temperature processes, which are less energy-intensive than traditional silicon-based solar cells, the overall environmental impact of production still needs to be thoroughly assessed. This includes evaluating the sourcing of raw materials, energy consumption during manufacturing, and potential emissions or waste products.

End-of-life management is another crucial aspect of the environmental impact of perovskite BIPV systems. As these systems reach the end of their operational lifespan, proper recycling and disposal methods must be developed to prevent the release of harmful materials into the environment. Research is ongoing to establish efficient recycling processes that can recover valuable materials and minimize waste.

The durability and longevity of perovskite BIPV systems also play a role in their environmental impact. While perovskite solar cells have shown promising efficiency, their long-term stability under real-world conditions is still being studied. Improving the lifespan of these systems can reduce the frequency of replacements and associated environmental costs.

Furthermore, the integration of perovskite solar cells into building materials may have indirect environmental benefits. By replacing conventional building materials with photovoltaic alternatives, the overall environmental footprint of construction can be reduced. This includes potential savings in transportation and installation costs, as well as the reduction of materials needed for separate solar panel installations.

In conclusion, while perovskite BIPV systems show great promise for sustainable energy generation in urban environments, a comprehensive lifecycle assessment is necessary to fully understand and mitigate their environmental impact. Ongoing research and development efforts are focused on addressing key environmental challenges, such as lead toxicity and end-of-life management, to ensure that perovskite BIPV technology can contribute positively to a more sustainable built environment.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for perovskite solar cells in building-integrated photovoltaic (BIPV) systems present both challenges and opportunities. As the demand for sustainable energy solutions in construction grows, the ability to produce perovskite solar cells at scale becomes crucial for widespread adoption.

One of the primary challenges in scaling up perovskite solar cell production is maintaining consistent performance across large areas. While laboratory-scale cells have shown impressive efficiencies, translating these results to commercial-scale manufacturing requires significant process optimization. Techniques such as slot-die coating and blade coating have shown promise for large-area deposition of perovskite layers, but further refinement is needed to ensure uniformity and reduce defects.

The stability of perovskite materials under various environmental conditions remains a concern for long-term BIPV applications. Developing encapsulation methods that can protect the cells from moisture and oxygen while maintaining transparency and aesthetics is essential. Advanced barrier films and edge sealing techniques are being explored to enhance the durability of perovskite modules in building environments.

Manufacturing costs are a critical factor in the commercialization of perovskite solar cells for BIPV. Current production methods often involve high-temperature processes and expensive materials. Research into low-temperature deposition techniques and alternative, more abundant materials could significantly reduce manufacturing costs and energy payback time.

The integration of perovskite solar cells into building materials presents unique manufacturing challenges. Developing processes that allow for direct deposition or lamination of perovskite cells onto construction materials like glass or metal panels is crucial for seamless BIPV integration. This may require adapting existing manufacturing lines or creating entirely new production facilities tailored to BIPV products.

Environmental and safety considerations in manufacturing are paramount. The use of lead in many perovskite formulations raises concerns about toxicity and end-of-life disposal. Research into lead-free perovskite alternatives and the development of closed-loop recycling processes for perovskite modules are active areas of investigation to address these issues.

Scalability also depends on the availability of raw materials and the supply chain resilience. Ensuring a stable supply of high-quality precursors and identifying potential bottlenecks in material sourcing are essential for large-scale production. Developing partnerships with material suppliers and exploring alternative synthesis routes for key components can help mitigate supply chain risks.

As the technology matures, standardization of manufacturing processes and quality control measures will be crucial. Establishing industry-wide standards for perovskite BIPV products will facilitate market acceptance and regulatory approval. This includes developing reliable testing protocols that can accurately predict long-term performance and durability in real-world building applications.

One of the primary challenges in scaling up perovskite solar cell production is maintaining consistent performance across large areas. While laboratory-scale cells have shown impressive efficiencies, translating these results to commercial-scale manufacturing requires significant process optimization. Techniques such as slot-die coating and blade coating have shown promise for large-area deposition of perovskite layers, but further refinement is needed to ensure uniformity and reduce defects.

The stability of perovskite materials under various environmental conditions remains a concern for long-term BIPV applications. Developing encapsulation methods that can protect the cells from moisture and oxygen while maintaining transparency and aesthetics is essential. Advanced barrier films and edge sealing techniques are being explored to enhance the durability of perovskite modules in building environments.

Manufacturing costs are a critical factor in the commercialization of perovskite solar cells for BIPV. Current production methods often involve high-temperature processes and expensive materials. Research into low-temperature deposition techniques and alternative, more abundant materials could significantly reduce manufacturing costs and energy payback time.

The integration of perovskite solar cells into building materials presents unique manufacturing challenges. Developing processes that allow for direct deposition or lamination of perovskite cells onto construction materials like glass or metal panels is crucial for seamless BIPV integration. This may require adapting existing manufacturing lines or creating entirely new production facilities tailored to BIPV products.

Environmental and safety considerations in manufacturing are paramount. The use of lead in many perovskite formulations raises concerns about toxicity and end-of-life disposal. Research into lead-free perovskite alternatives and the development of closed-loop recycling processes for perovskite modules are active areas of investigation to address these issues.

Scalability also depends on the availability of raw materials and the supply chain resilience. Ensuring a stable supply of high-quality precursors and identifying potential bottlenecks in material sourcing are essential for large-scale production. Developing partnerships with material suppliers and exploring alternative synthesis routes for key components can help mitigate supply chain risks.

As the technology matures, standardization of manufacturing processes and quality control measures will be crucial. Establishing industry-wide standards for perovskite BIPV products will facilitate market acceptance and regulatory approval. This includes developing reliable testing protocols that can accurately predict long-term performance and durability in real-world building applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!