Novel Electrode Materials for Enhancing Perovskite Solar Cell Performance

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Solar Cell Evolution and Objectives

Perovskite solar cells have emerged as a revolutionary technology in the field of photovoltaics, offering the potential for high-efficiency, low-cost solar energy conversion. The evolution of perovskite solar cells can be traced back to 2009 when they were first introduced as a novel photovoltaic material. Since then, the technology has undergone rapid development, with power conversion efficiencies increasing from an initial 3.8% to over 25% in just a decade.

The primary objective in the field of perovskite solar cells is to enhance their performance, stability, and scalability. Researchers aim to develop novel electrode materials that can improve charge extraction, reduce interfacial recombination, and enhance overall device efficiency. Additionally, there is a focus on addressing the long-term stability issues associated with perovskite solar cells, particularly their sensitivity to moisture and thermal stress.

One of the key goals is to optimize the interface between the perovskite absorber layer and the charge transport layers. This involves developing new electrode materials that can effectively collect and transport charge carriers while minimizing energy losses. Researchers are exploring various materials, including organic semiconductors, metal oxides, and two-dimensional materials, to serve as efficient electron and hole transport layers.

Another important objective is to improve the scalability of perovskite solar cells. While high efficiencies have been achieved in small-scale laboratory devices, translating these results to large-area modules remains a challenge. The development of novel electrode materials and deposition techniques that are compatible with large-scale manufacturing processes is crucial for the commercialization of perovskite solar cell technology.

Furthermore, there is a growing emphasis on developing lead-free perovskite materials to address environmental concerns associated with lead-based perovskites. Researchers are investigating alternative metal cations, such as tin, bismuth, and antimony, to create lead-free perovskite compositions that maintain high efficiency and stability.

The ultimate goal of perovskite solar cell research is to create a technology that can compete with and potentially surpass the performance of traditional silicon-based solar cells. This involves not only improving efficiency but also addressing issues of long-term stability, environmental impact, and cost-effectiveness. By focusing on novel electrode materials and innovative device architectures, researchers aim to unlock the full potential of perovskite solar cells and pave the way for their widespread adoption in the renewable energy sector.

The primary objective in the field of perovskite solar cells is to enhance their performance, stability, and scalability. Researchers aim to develop novel electrode materials that can improve charge extraction, reduce interfacial recombination, and enhance overall device efficiency. Additionally, there is a focus on addressing the long-term stability issues associated with perovskite solar cells, particularly their sensitivity to moisture and thermal stress.

One of the key goals is to optimize the interface between the perovskite absorber layer and the charge transport layers. This involves developing new electrode materials that can effectively collect and transport charge carriers while minimizing energy losses. Researchers are exploring various materials, including organic semiconductors, metal oxides, and two-dimensional materials, to serve as efficient electron and hole transport layers.

Another important objective is to improve the scalability of perovskite solar cells. While high efficiencies have been achieved in small-scale laboratory devices, translating these results to large-area modules remains a challenge. The development of novel electrode materials and deposition techniques that are compatible with large-scale manufacturing processes is crucial for the commercialization of perovskite solar cell technology.

Furthermore, there is a growing emphasis on developing lead-free perovskite materials to address environmental concerns associated with lead-based perovskites. Researchers are investigating alternative metal cations, such as tin, bismuth, and antimony, to create lead-free perovskite compositions that maintain high efficiency and stability.

The ultimate goal of perovskite solar cell research is to create a technology that can compete with and potentially surpass the performance of traditional silicon-based solar cells. This involves not only improving efficiency but also addressing issues of long-term stability, environmental impact, and cost-effectiveness. By focusing on novel electrode materials and innovative device architectures, researchers aim to unlock the full potential of perovskite solar cells and pave the way for their widespread adoption in the renewable energy sector.

Market Analysis for High-Efficiency Solar Cells

The global market for high-efficiency solar cells has been experiencing significant growth in recent years, driven by increasing demand for renewable energy sources and advancements in photovoltaic technologies. Perovskite solar cells, in particular, have emerged as a promising candidate for next-generation solar technology due to their potential for high efficiency and low production costs.

The market for perovskite solar cells is expected to expand rapidly in the coming years, with a projected compound annual growth rate (CAGR) exceeding 30% between 2021 and 2026. This growth is fueled by ongoing research and development efforts to improve cell efficiency, stability, and scalability, as well as increasing investments from both private and public sectors.

Key market drivers include government initiatives promoting clean energy adoption, declining costs of solar panel production, and growing environmental awareness among consumers. Additionally, the integration of perovskite solar cells into building-integrated photovoltaics (BIPV) and portable electronic devices is opening up new market opportunities.

The Asia-Pacific region, particularly China and Japan, is leading the market in terms of production and adoption of high-efficiency solar cells. Europe and North America are also significant players, with strong research and development capabilities and supportive regulatory environments.

However, the market faces challenges such as the need for improved long-term stability of perovskite solar cells and concerns about the use of lead in some perovskite formulations. These issues are driving research into lead-free alternatives and more stable electrode materials.

The competitive landscape is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to gain a competitive edge in this rapidly evolving market.

Novel electrode materials play a crucial role in enhancing the performance of perovskite solar cells. The development of new electrode materials that can improve charge transport, reduce recombination losses, and enhance overall cell stability is a key focus area for researchers and manufacturers alike.

As the technology matures and production scales up, the cost of perovskite solar cells is expected to decrease, making them increasingly competitive with traditional silicon-based solar cells. This cost reduction, coupled with improvements in efficiency and stability, is likely to drive wider adoption across various applications, from large-scale solar farms to consumer electronics.

The market for perovskite solar cells is expected to expand rapidly in the coming years, with a projected compound annual growth rate (CAGR) exceeding 30% between 2021 and 2026. This growth is fueled by ongoing research and development efforts to improve cell efficiency, stability, and scalability, as well as increasing investments from both private and public sectors.

Key market drivers include government initiatives promoting clean energy adoption, declining costs of solar panel production, and growing environmental awareness among consumers. Additionally, the integration of perovskite solar cells into building-integrated photovoltaics (BIPV) and portable electronic devices is opening up new market opportunities.

The Asia-Pacific region, particularly China and Japan, is leading the market in terms of production and adoption of high-efficiency solar cells. Europe and North America are also significant players, with strong research and development capabilities and supportive regulatory environments.

However, the market faces challenges such as the need for improved long-term stability of perovskite solar cells and concerns about the use of lead in some perovskite formulations. These issues are driving research into lead-free alternatives and more stable electrode materials.

The competitive landscape is characterized by a mix of established photovoltaic manufacturers and innovative startups. Major players are investing heavily in research and development to gain a competitive edge in this rapidly evolving market.

Novel electrode materials play a crucial role in enhancing the performance of perovskite solar cells. The development of new electrode materials that can improve charge transport, reduce recombination losses, and enhance overall cell stability is a key focus area for researchers and manufacturers alike.

As the technology matures and production scales up, the cost of perovskite solar cells is expected to decrease, making them increasingly competitive with traditional silicon-based solar cells. This cost reduction, coupled with improvements in efficiency and stability, is likely to drive wider adoption across various applications, from large-scale solar farms to consumer electronics.

Current Electrode Materials and Limitations

Perovskite solar cells have shown remarkable progress in recent years, with their efficiency rapidly approaching that of traditional silicon-based photovoltaics. However, the performance of these devices is heavily dependent on the electrode materials used. Currently, the most common electrode materials for perovskite solar cells are transparent conductive oxides (TCOs) for the front electrode and metals for the back electrode.

Indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) are the predominant TCO materials used as front electrodes. These materials offer high transparency and good electrical conductivity, which are crucial for efficient light transmission and charge collection. However, they face limitations in terms of cost, particularly in the case of ITO due to the scarcity of indium. Additionally, their brittleness can lead to cracking during the fabrication process, potentially compromising device performance.

For back electrodes, metals such as gold, silver, and aluminum are commonly employed. Gold is favored for its high work function and stability but is expensive for large-scale production. Silver, while more cost-effective, can react with halide ions from the perovskite layer, leading to degradation over time. Aluminum is the most economical option but suffers from poor stability in ambient conditions and can easily oxidize.

One of the major limitations of current electrode materials is their compatibility with the perovskite layer. The interface between the electrode and the perovskite is critical for efficient charge extraction and minimizing recombination losses. Many electrode materials require additional buffer layers to achieve optimal contact, which adds complexity to the device structure and manufacturing process.

Stability is another significant challenge, particularly for the back electrode. The susceptibility of some metals to corrosion or reaction with the perovskite layer can lead to degradation of device performance over time. This issue is exacerbated by the sensitivity of perovskite materials to moisture and oxygen, requiring robust encapsulation strategies.

Scalability and manufacturing considerations also pose limitations for current electrode materials. The high-temperature processing often required for TCOs can be detrimental to the underlying perovskite layer, necessitating careful process optimization. Similarly, vacuum deposition techniques commonly used for metal electrodes can be costly and challenging to scale up for large-area production.

As research in perovskite solar cells continues to advance, there is a growing need for electrode materials that can address these limitations while maintaining or improving device performance. Novel electrode materials that offer enhanced stability, better interfacial properties, and more cost-effective manufacturing processes are crucial for the commercial viability of perovskite solar technology.

Indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) are the predominant TCO materials used as front electrodes. These materials offer high transparency and good electrical conductivity, which are crucial for efficient light transmission and charge collection. However, they face limitations in terms of cost, particularly in the case of ITO due to the scarcity of indium. Additionally, their brittleness can lead to cracking during the fabrication process, potentially compromising device performance.

For back electrodes, metals such as gold, silver, and aluminum are commonly employed. Gold is favored for its high work function and stability but is expensive for large-scale production. Silver, while more cost-effective, can react with halide ions from the perovskite layer, leading to degradation over time. Aluminum is the most economical option but suffers from poor stability in ambient conditions and can easily oxidize.

One of the major limitations of current electrode materials is their compatibility with the perovskite layer. The interface between the electrode and the perovskite is critical for efficient charge extraction and minimizing recombination losses. Many electrode materials require additional buffer layers to achieve optimal contact, which adds complexity to the device structure and manufacturing process.

Stability is another significant challenge, particularly for the back electrode. The susceptibility of some metals to corrosion or reaction with the perovskite layer can lead to degradation of device performance over time. This issue is exacerbated by the sensitivity of perovskite materials to moisture and oxygen, requiring robust encapsulation strategies.

Scalability and manufacturing considerations also pose limitations for current electrode materials. The high-temperature processing often required for TCOs can be detrimental to the underlying perovskite layer, necessitating careful process optimization. Similarly, vacuum deposition techniques commonly used for metal electrodes can be costly and challenging to scale up for large-area production.

As research in perovskite solar cells continues to advance, there is a growing need for electrode materials that can address these limitations while maintaining or improving device performance. Novel electrode materials that offer enhanced stability, better interfacial properties, and more cost-effective manufacturing processes are crucial for the commercial viability of perovskite solar technology.

Existing Electrode Material Solutions

01 Improved perovskite material composition

Enhancing the performance of perovskite solar cells through optimized material composition. This includes developing new perovskite formulations, doping strategies, and mixed-cation or mixed-halide perovskites to improve stability, efficiency, and bandgap tunability.- Perovskite material composition optimization: Improving the performance of perovskite solar cells through optimization of the perovskite material composition. This includes exploring different cation and anion combinations, as well as incorporating additives to enhance stability and efficiency. Researchers are focusing on developing lead-free perovskites and mixed-cation perovskites to achieve better performance and environmental sustainability.

- Interface engineering: Enhancing the performance of perovskite solar cells by optimizing the interfaces between different layers. This includes developing novel electron and hole transport materials, as well as implementing passivation strategies to reduce recombination losses at interfaces. Researchers are exploring various materials and deposition techniques to improve charge extraction and reduce interfacial defects.

- Tandem solar cell architectures: Developing tandem solar cell structures that combine perovskite with other photovoltaic materials to achieve higher efficiencies. This approach allows for better utilization of the solar spectrum by stacking cells with complementary absorption ranges. Researchers are working on perovskite/silicon and all-perovskite tandem cells to push the limits of solar cell efficiency.

- Stability and encapsulation techniques: Improving the long-term stability of perovskite solar cells through advanced encapsulation techniques and material modifications. This includes developing moisture-resistant perovskite formulations, implementing effective barrier layers, and exploring novel encapsulation materials. Researchers are focusing on enhancing the operational lifetime of perovskite solar cells under various environmental conditions.

- Scalable fabrication methods: Developing scalable and cost-effective fabrication methods for perovskite solar cells to enable large-scale production. This includes exploring solution-based deposition techniques, roll-to-roll processing, and other high-throughput manufacturing methods. Researchers are working on optimizing process parameters and developing new equipment to improve the uniformity and reproducibility of large-area perovskite solar cells.

02 Advanced fabrication techniques

Implementing innovative fabrication methods to enhance perovskite solar cell performance. This involves developing new deposition techniques, controlling crystal growth, and optimizing layer thicknesses to improve film quality, reduce defects, and increase overall device efficiency.Expand Specific Solutions03 Interface engineering

Focusing on the optimization of interfaces between different layers in perovskite solar cells. This includes developing novel electron and hole transport materials, passivation layers, and buffer layers to reduce recombination losses and improve charge extraction.Expand Specific Solutions04 Stability enhancement strategies

Developing methods to improve the long-term stability of perovskite solar cells. This involves addressing issues such as moisture sensitivity, thermal instability, and ion migration through encapsulation techniques, compositional engineering, and the use of additives or protective layers.Expand Specific Solutions05 Tandem and multi-junction architectures

Exploring tandem and multi-junction solar cell configurations incorporating perovskite materials. This approach aims to surpass the theoretical efficiency limits of single-junction cells by combining perovskites with other photovoltaic materials, such as silicon or other thin-film technologies.Expand Specific Solutions

Key Players in Perovskite Solar Cell Industry

The development of novel electrode materials for enhancing perovskite solar cell performance is in a dynamic growth phase, with significant market potential and ongoing technological advancements. The global perovskite solar cell market is expanding rapidly, driven by the increasing demand for efficient and cost-effective renewable energy solutions. Key players like Trina Solar, Oxford Photovoltaics, and CSEM are at the forefront of research and commercialization efforts. While the technology is still evolving, substantial progress has been made in improving efficiency and stability. Collaborations between academic institutions such as MIT, KAUST, and IIT Bombay, and industry leaders are accelerating innovation in this field, indicating a promising future for perovskite-based photovoltaics.

Oxford Photovoltaics Ltd.

Technical Solution: Oxford PV has developed a perovskite-on-silicon tandem solar cell technology that significantly enhances the performance of traditional silicon solar cells. Their approach involves depositing a thin layer of perovskite material onto conventional silicon solar cells, creating a tandem structure that can better utilize the solar spectrum. This technology has achieved a world record efficiency of 29.52% for a perovskite-silicon tandem solar cell in 2020[1]. The company uses a proprietary perovskite composition and has optimized the interface between the perovskite and silicon layers to minimize losses and maximize power output. They have also developed scalable manufacturing processes for their perovskite solar technology, including a pilot line capable of producing full-size 156 mm x 156 mm perovskite-silicon tandem solar cells[2].

Strengths: High efficiency, potential for low-cost manufacturing, compatibility with existing silicon PV infrastructure. Weaknesses: Stability and long-term durability of perovskite materials still need to be proven at commercial scale.

King Abdullah University of Science & Technology

Technical Solution: KAUST has made significant advancements in perovskite solar cell technology, particularly in the development of novel electrode materials. Their research focuses on improving charge transport and collection at the interfaces between the perovskite layer and the electrodes. One of their key innovations is the use of two-dimensional (2D) materials as interlayers or electrodes. For instance, they have developed graphene-based transparent electrodes that exhibit excellent conductivity and transparency[3]. Additionally, KAUST researchers have explored the use of metal-organic frameworks (MOFs) as electron transport layers, which have shown improved stability and efficiency compared to traditional materials[4]. They have also investigated the use of carbon-based materials, such as carbon nanotubes and graphene quantum dots, as hole transport layers to enhance charge extraction and reduce recombination losses[5].

Strengths: Cutting-edge research in 2D materials and MOFs for electrode applications, potential for improved stability and efficiency. Weaknesses: Some of the advanced materials may be challenging to scale up for commercial production.

Innovative Electrode Material Breakthroughs

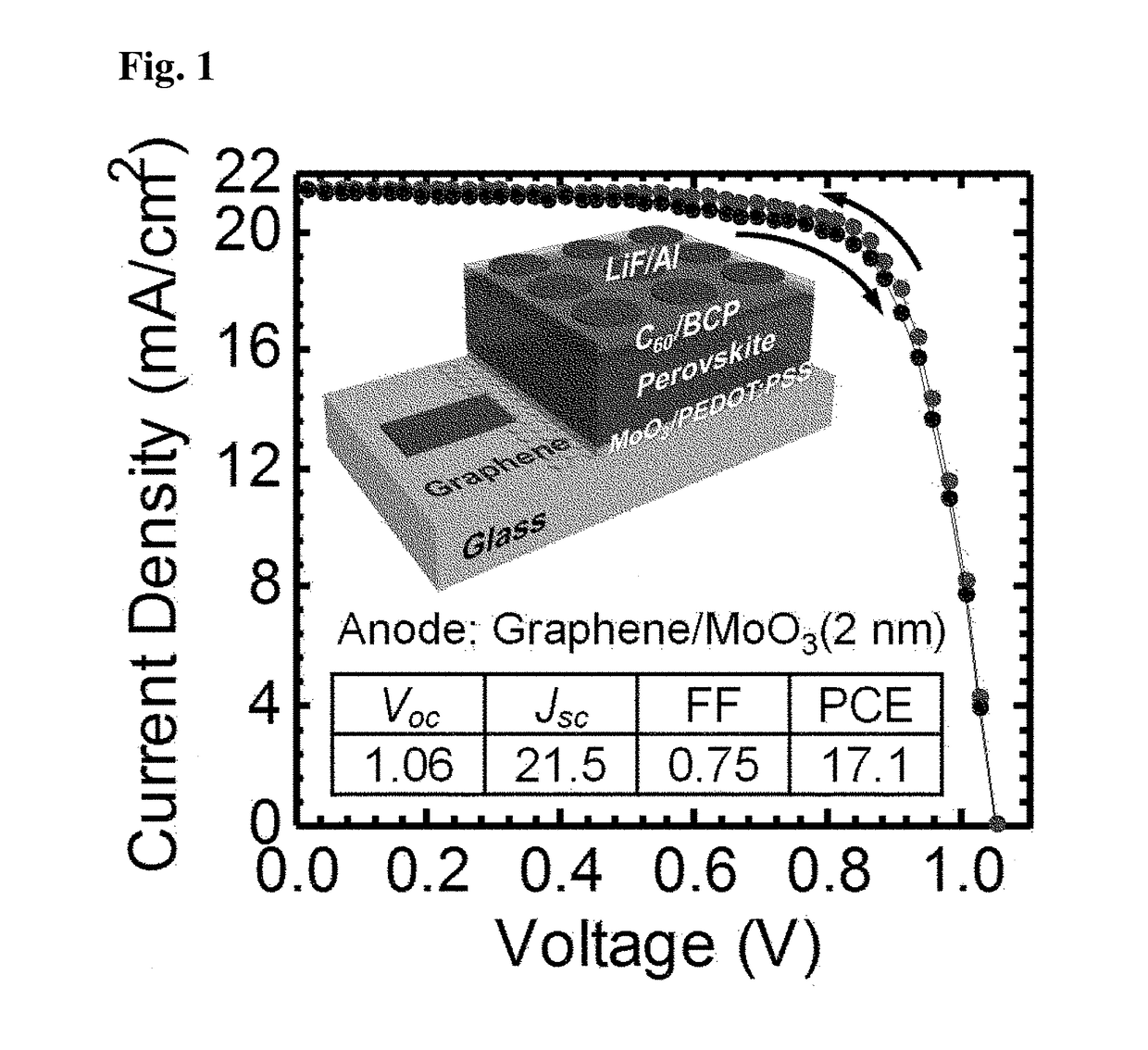

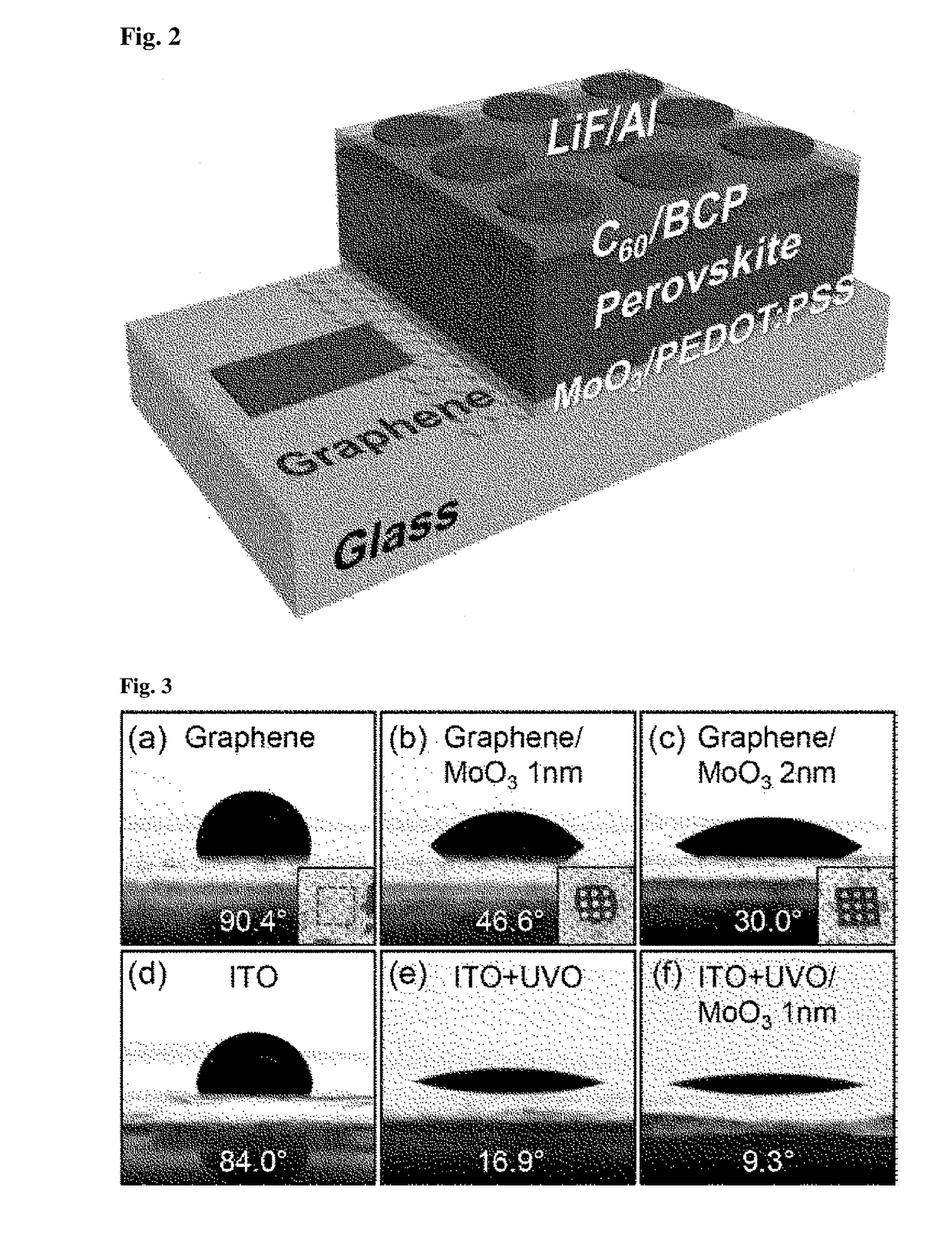

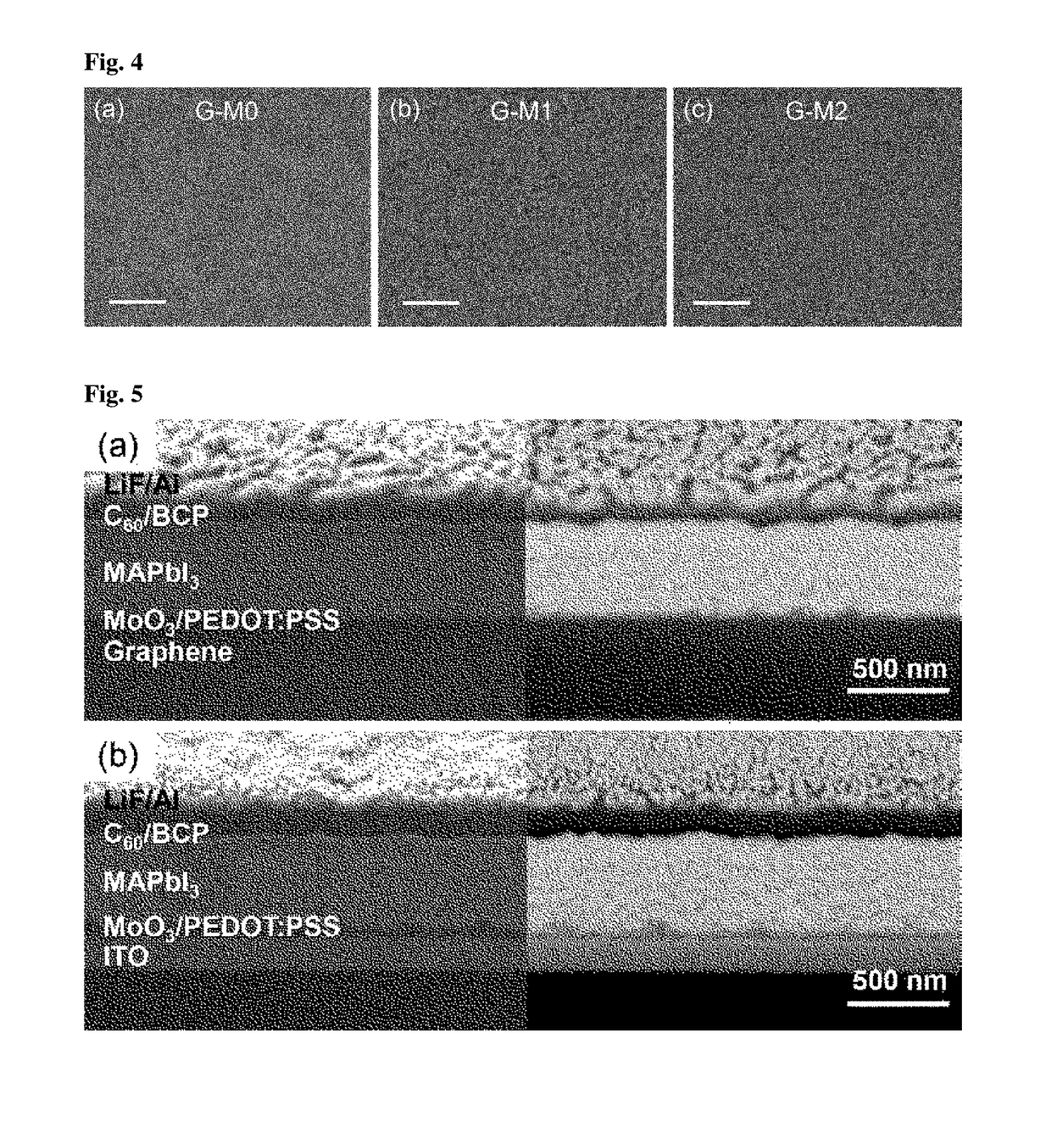

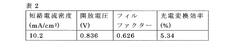

Perovskite-based solar cell using graphene as conductive transparent electrode

PatentInactiveUS20180358571A1

Innovation

- A perovskite-based solar cell design utilizing a flexible graphene electrode as a substitute for traditional transparent conducting oxide electrodes, with a structure that includes a graphene layer as a transparent conductive electrode, a hole transport layer, a perovskite layer, and a cathode, optionally with a metal oxide layer, and using a lead halide adduct for perovskite preparation, achieving efficient and flexible operation on polymer substrates.

Perovskite solar cell

PatentWO2017006839A1

Innovation

- A perovskite solar cell structure utilizing a metallic titanium negative electrode, a hole blocking layer, a mesoporous metal oxide layer, and an organic-inorganic perovskite compound as the photoelectric conversion layer, with light irradiation from the positive electrode side, enhancing photoelectric conversion efficiency and durability.

Environmental Impact of Novel Electrode Materials

The development and adoption of novel electrode materials for perovskite solar cells have significant environmental implications that warrant careful consideration. These materials, while promising for enhancing solar cell performance, may introduce new environmental challenges throughout their lifecycle.

During the production phase, the synthesis of novel electrode materials often involves complex chemical processes and the use of rare or toxic elements. This can lead to increased energy consumption and potential environmental contamination if not properly managed. For instance, some advanced electrode materials may require high-temperature processing or the use of hazardous solvents, contributing to greenhouse gas emissions and potential air or water pollution.

The extraction of raw materials for these novel electrodes is another area of environmental concern. Rare earth elements or precious metals, often used in high-performance electrodes, are typically mined through processes that can have substantial ecological impacts, including habitat destruction, soil erosion, and water pollution. The increasing demand for these materials may exacerbate existing environmental pressures in resource-rich regions.

On the positive side, the enhanced efficiency of perovskite solar cells utilizing novel electrode materials could lead to a reduction in the overall environmental footprint of solar energy production. Higher conversion efficiencies mean that less solar panel area is required to generate the same amount of electricity, potentially reducing land use and material requirements for large-scale solar installations.

The durability and stability of these new materials also play a crucial role in their environmental impact. If novel electrodes can significantly extend the lifespan of perovskite solar cells, it would reduce the frequency of replacement and disposal, thereby minimizing waste generation and the need for raw material extraction over time.

End-of-life considerations for solar cells with novel electrode materials present both challenges and opportunities. The complex composition of these materials may complicate recycling processes, potentially leading to increased e-waste if effective recycling technologies are not developed in parallel. However, the high value of some electrode components could incentivize the development of advanced recycling techniques, promoting a more circular economy approach in the solar industry.

The environmental impact of novel electrode materials extends beyond their immediate use in solar cells. Their potential to enable more efficient and widespread adoption of solar energy could contribute significantly to global efforts in reducing reliance on fossil fuels and mitigating climate change. This broader perspective underscores the importance of holistic environmental assessment when developing and implementing new technologies in the renewable energy sector.

During the production phase, the synthesis of novel electrode materials often involves complex chemical processes and the use of rare or toxic elements. This can lead to increased energy consumption and potential environmental contamination if not properly managed. For instance, some advanced electrode materials may require high-temperature processing or the use of hazardous solvents, contributing to greenhouse gas emissions and potential air or water pollution.

The extraction of raw materials for these novel electrodes is another area of environmental concern. Rare earth elements or precious metals, often used in high-performance electrodes, are typically mined through processes that can have substantial ecological impacts, including habitat destruction, soil erosion, and water pollution. The increasing demand for these materials may exacerbate existing environmental pressures in resource-rich regions.

On the positive side, the enhanced efficiency of perovskite solar cells utilizing novel electrode materials could lead to a reduction in the overall environmental footprint of solar energy production. Higher conversion efficiencies mean that less solar panel area is required to generate the same amount of electricity, potentially reducing land use and material requirements for large-scale solar installations.

The durability and stability of these new materials also play a crucial role in their environmental impact. If novel electrodes can significantly extend the lifespan of perovskite solar cells, it would reduce the frequency of replacement and disposal, thereby minimizing waste generation and the need for raw material extraction over time.

End-of-life considerations for solar cells with novel electrode materials present both challenges and opportunities. The complex composition of these materials may complicate recycling processes, potentially leading to increased e-waste if effective recycling technologies are not developed in parallel. However, the high value of some electrode components could incentivize the development of advanced recycling techniques, promoting a more circular economy approach in the solar industry.

The environmental impact of novel electrode materials extends beyond their immediate use in solar cells. Their potential to enable more efficient and widespread adoption of solar energy could contribute significantly to global efforts in reducing reliance on fossil fuels and mitigating climate change. This broader perspective underscores the importance of holistic environmental assessment when developing and implementing new technologies in the renewable energy sector.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges associated with novel electrode materials for perovskite solar cells present significant hurdles in their widespread adoption and commercialization. One of the primary obstacles is the difficulty in maintaining consistent quality and performance when scaling up production from laboratory-scale to industrial-scale manufacturing. The intricate nature of perovskite materials and their sensitivity to environmental factors make it challenging to achieve uniform deposition and crystallization across large areas.

Another critical challenge lies in the development of cost-effective and efficient manufacturing processes for these novel electrode materials. Many promising materials exhibit excellent performance in small-scale experiments but face limitations when it comes to mass production. The need for specialized equipment, controlled environments, and precise process control adds complexity and cost to the manufacturing process, potentially hindering the economic viability of perovskite solar cells.

The stability and durability of novel electrode materials also pose significant challenges in terms of scalability and manufacturing. Many advanced materials that show promising results in laboratory settings may degrade rapidly under real-world conditions or during the manufacturing process itself. This necessitates the development of robust encapsulation techniques and protective layers, further complicating the production process and potentially increasing costs.

Furthermore, the environmental impact and sustainability of manufacturing processes for novel electrode materials must be carefully considered. Some advanced materials may require rare or toxic elements, raising concerns about long-term availability and environmental consequences. Developing eco-friendly alternatives and implementing sustainable manufacturing practices are crucial for the widespread adoption of these technologies.

Lastly, the integration of novel electrode materials into existing solar cell production lines presents its own set of challenges. Adapting current manufacturing infrastructure to accommodate new materials and processes requires significant investment and may disrupt established production workflows. Balancing the benefits of improved performance with the costs and complexities of implementation remains a key consideration for manufacturers and investors in the solar energy sector.

Another critical challenge lies in the development of cost-effective and efficient manufacturing processes for these novel electrode materials. Many promising materials exhibit excellent performance in small-scale experiments but face limitations when it comes to mass production. The need for specialized equipment, controlled environments, and precise process control adds complexity and cost to the manufacturing process, potentially hindering the economic viability of perovskite solar cells.

The stability and durability of novel electrode materials also pose significant challenges in terms of scalability and manufacturing. Many advanced materials that show promising results in laboratory settings may degrade rapidly under real-world conditions or during the manufacturing process itself. This necessitates the development of robust encapsulation techniques and protective layers, further complicating the production process and potentially increasing costs.

Furthermore, the environmental impact and sustainability of manufacturing processes for novel electrode materials must be carefully considered. Some advanced materials may require rare or toxic elements, raising concerns about long-term availability and environmental consequences. Developing eco-friendly alternatives and implementing sustainable manufacturing practices are crucial for the widespread adoption of these technologies.

Lastly, the integration of novel electrode materials into existing solar cell production lines presents its own set of challenges. Adapting current manufacturing infrastructure to accommodate new materials and processes requires significant investment and may disrupt established production workflows. Balancing the benefits of improved performance with the costs and complexities of implementation remains a key consideration for manufacturers and investors in the solar energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!