Nichrome Applications in High-Security Electronics

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Tech Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has undergone significant technological evolution in its applications within high-security electronics. The journey of nichrome in this field began in the mid-20th century when its unique properties were first recognized for potential use in sensitive electronic components.

In the 1960s and 1970s, nichrome found its initial applications in high-security electronics as a resistive element in precision resistors. Its stability at high temperatures and resistance to oxidation made it an ideal choice for critical circuits where reliability was paramount. During this period, the focus was on refining the composition and manufacturing processes to achieve consistent electrical properties.

The 1980s marked a turning point in nichrome's evolution, as miniaturization trends in electronics demanded more compact and efficient components. Researchers developed thin-film deposition techniques that allowed for the creation of ultra-thin nichrome layers, enabling the production of smaller, more precise resistors and heating elements. This advancement significantly expanded nichrome's use in secure communication devices and early encryption hardware.

Throughout the 1990s, the increasing sophistication of electronic warfare and surveillance technologies drove further innovation in nichrome applications. The alloy's low thermal EMF (electromotive force) properties were exploited to create sensors and detectors that were highly resistant to electromagnetic interference, a crucial feature in maintaining the integrity of classified electronic systems.

The early 2000s saw a surge in the development of tamper-evident and self-destructing electronics, where nichrome played a pivotal role. Its rapid heating capabilities when subjected to electrical current were utilized to design circuits that could quickly destroy sensitive data or render devices inoperable if unauthorized access was detected. This period also witnessed the integration of nichrome elements in advanced biometric security systems, leveraging its precise temperature control for fingerprint and retinal scanners.

In the past decade, the focus has shifted towards enhancing the material properties of nichrome for even more specialized applications. Researchers have experimented with doping the alloy with rare earth elements to improve its electrical characteristics and develop new functionalities. These advancements have led to the creation of nichrome-based components that can operate reliably in extreme environments, making them ideal for use in secure satellite communications and deep-sea data transmission systems.

The most recent developments in nichrome technology for high-security electronics involve its application in quantum-resistant cryptographic hardware. As the threat of quantum computing to traditional encryption methods grows, nichrome's unique properties are being harnessed to create physical unclonable functions (PUFs) and true random number generators (TRNGs) that form the backbone of next-generation secure communication devices.

In the 1960s and 1970s, nichrome found its initial applications in high-security electronics as a resistive element in precision resistors. Its stability at high temperatures and resistance to oxidation made it an ideal choice for critical circuits where reliability was paramount. During this period, the focus was on refining the composition and manufacturing processes to achieve consistent electrical properties.

The 1980s marked a turning point in nichrome's evolution, as miniaturization trends in electronics demanded more compact and efficient components. Researchers developed thin-film deposition techniques that allowed for the creation of ultra-thin nichrome layers, enabling the production of smaller, more precise resistors and heating elements. This advancement significantly expanded nichrome's use in secure communication devices and early encryption hardware.

Throughout the 1990s, the increasing sophistication of electronic warfare and surveillance technologies drove further innovation in nichrome applications. The alloy's low thermal EMF (electromotive force) properties were exploited to create sensors and detectors that were highly resistant to electromagnetic interference, a crucial feature in maintaining the integrity of classified electronic systems.

The early 2000s saw a surge in the development of tamper-evident and self-destructing electronics, where nichrome played a pivotal role. Its rapid heating capabilities when subjected to electrical current were utilized to design circuits that could quickly destroy sensitive data or render devices inoperable if unauthorized access was detected. This period also witnessed the integration of nichrome elements in advanced biometric security systems, leveraging its precise temperature control for fingerprint and retinal scanners.

In the past decade, the focus has shifted towards enhancing the material properties of nichrome for even more specialized applications. Researchers have experimented with doping the alloy with rare earth elements to improve its electrical characteristics and develop new functionalities. These advancements have led to the creation of nichrome-based components that can operate reliably in extreme environments, making them ideal for use in secure satellite communications and deep-sea data transmission systems.

The most recent developments in nichrome technology for high-security electronics involve its application in quantum-resistant cryptographic hardware. As the threat of quantum computing to traditional encryption methods grows, nichrome's unique properties are being harnessed to create physical unclonable functions (PUFs) and true random number generators (TRNGs) that form the backbone of next-generation secure communication devices.

High-Security Market Needs

The high-security electronics market has witnessed a significant surge in demand for advanced materials and components that can withstand extreme conditions while maintaining optimal performance. Nichrome, an alloy of nickel and chromium, has emerged as a crucial material in this sector due to its unique properties and versatile applications. The market needs for high-security electronics incorporating nichrome are driven by several key factors.

Firstly, there is an increasing requirement for components that can operate reliably in harsh environments. High-security applications often involve exposure to extreme temperatures, corrosive substances, and electromagnetic interference. Nichrome's excellent resistance to heat and corrosion makes it an ideal choice for such demanding conditions, ensuring the longevity and reliability of critical electronic systems.

Secondly, the miniaturization trend in electronics has created a demand for materials that can maintain their properties even at reduced scales. Nichrome's ability to be fabricated into thin films and fine wires without compromising its electrical and mechanical characteristics aligns perfectly with this market need. This property is particularly valuable in the development of compact, high-performance security devices.

The growing emphasis on energy efficiency in electronic systems has also contributed to the demand for nichrome in high-security applications. The alloy's high electrical resistivity allows for the design of precise and efficient heating elements, which are essential in various security devices such as biometric scanners and environmental sensors. These components require accurate temperature control to function optimally, making nichrome an indispensable material.

Furthermore, the market for tamper-resistant and tamper-evident electronics has expanded rapidly. Nichrome's unique properties make it suitable for creating intricate security features that can detect and respond to unauthorized access attempts. Its use in thin-film resistors and fuse elements enables the development of self-destructing circuits and secure memory devices, addressing the critical need for data protection in high-security environments.

The aerospace and defense sectors, in particular, have shown a strong demand for nichrome-based components in their high-security electronic systems. These industries require materials that can withstand extreme g-forces, radiation exposure, and rapid temperature fluctuations while maintaining consistent electrical properties. Nichrome's stability under such conditions makes it a preferred choice for mission-critical applications in satellites, aircraft, and military equipment.

Lastly, the increasing focus on cybersecurity has created a need for hardware-based security solutions. Nichrome's role in developing physically unclonable functions (PUFs) and secure element chips addresses this market demand by providing a foundation for creating unique, tamper-resistant identifiers for electronic devices. This application is crucial in preventing counterfeiting and unauthorized access to sensitive systems in various high-security domains.

Firstly, there is an increasing requirement for components that can operate reliably in harsh environments. High-security applications often involve exposure to extreme temperatures, corrosive substances, and electromagnetic interference. Nichrome's excellent resistance to heat and corrosion makes it an ideal choice for such demanding conditions, ensuring the longevity and reliability of critical electronic systems.

Secondly, the miniaturization trend in electronics has created a demand for materials that can maintain their properties even at reduced scales. Nichrome's ability to be fabricated into thin films and fine wires without compromising its electrical and mechanical characteristics aligns perfectly with this market need. This property is particularly valuable in the development of compact, high-performance security devices.

The growing emphasis on energy efficiency in electronic systems has also contributed to the demand for nichrome in high-security applications. The alloy's high electrical resistivity allows for the design of precise and efficient heating elements, which are essential in various security devices such as biometric scanners and environmental sensors. These components require accurate temperature control to function optimally, making nichrome an indispensable material.

Furthermore, the market for tamper-resistant and tamper-evident electronics has expanded rapidly. Nichrome's unique properties make it suitable for creating intricate security features that can detect and respond to unauthorized access attempts. Its use in thin-film resistors and fuse elements enables the development of self-destructing circuits and secure memory devices, addressing the critical need for data protection in high-security environments.

The aerospace and defense sectors, in particular, have shown a strong demand for nichrome-based components in their high-security electronic systems. These industries require materials that can withstand extreme g-forces, radiation exposure, and rapid temperature fluctuations while maintaining consistent electrical properties. Nichrome's stability under such conditions makes it a preferred choice for mission-critical applications in satellites, aircraft, and military equipment.

Lastly, the increasing focus on cybersecurity has created a need for hardware-based security solutions. Nichrome's role in developing physically unclonable functions (PUFs) and secure element chips addresses this market demand by providing a foundation for creating unique, tamper-resistant identifiers for electronic devices. This application is crucial in preventing counterfeiting and unauthorized access to sensitive systems in various high-security domains.

Nichrome Challenges

Nichrome, a widely used alloy in high-security electronics, faces several significant challenges that impact its application and effectiveness. One of the primary issues is the material's susceptibility to corrosion, particularly in harsh environments. This vulnerability can lead to degradation of the nichrome components over time, potentially compromising the integrity and performance of security devices.

Another challenge lies in the thermal management of nichrome-based components. While nichrome is valued for its high electrical resistance and heat-generating properties, these same characteristics can pose difficulties in maintaining optimal operating temperatures within compact electronic devices. Overheating can lead to premature failure or reduced lifespan of security components, necessitating advanced cooling solutions or thermal design considerations.

The precision required in nichrome deposition for high-security applications presents another hurdle. Achieving consistent and uniform thin-film coatings of nichrome is crucial for maintaining the reliability and accuracy of security features. However, the process of depositing nichrome with the necessary precision can be complex and costly, potentially limiting its widespread adoption in certain security applications.

Electromagnetic interference (EMI) is an additional concern when using nichrome in high-security electronics. The alloy's electrical properties can make it susceptible to external electromagnetic fields, potentially compromising the functionality or security of the devices. Shielding and isolation techniques must be carefully implemented to mitigate these risks, adding complexity to device design and manufacturing processes.

The rising cost and potential supply chain disruptions of nichrome's constituent metals, primarily nickel and chromium, pose economic challenges for manufacturers. Fluctuations in raw material prices can impact the cost-effectiveness of nichrome-based solutions, potentially driving the search for alternative materials or technologies in high-security electronics.

Lastly, the environmental impact of nichrome production and disposal is becoming an increasing concern. As sustainability becomes a more prominent factor in electronics manufacturing, the industry faces pressure to find more eco-friendly alternatives or develop improved recycling methods for nichrome-containing devices. This challenge intersects with regulatory compliance issues, as environmental regulations become more stringent globally.

Addressing these challenges requires ongoing research and development efforts, focusing on improving nichrome's properties, refining manufacturing processes, and exploring innovative applications that leverage the alloy's unique characteristics while mitigating its limitations. The future of nichrome in high-security electronics will likely depend on the industry's ability to overcome these obstacles through technological advancements and creative engineering solutions.

Another challenge lies in the thermal management of nichrome-based components. While nichrome is valued for its high electrical resistance and heat-generating properties, these same characteristics can pose difficulties in maintaining optimal operating temperatures within compact electronic devices. Overheating can lead to premature failure or reduced lifespan of security components, necessitating advanced cooling solutions or thermal design considerations.

The precision required in nichrome deposition for high-security applications presents another hurdle. Achieving consistent and uniform thin-film coatings of nichrome is crucial for maintaining the reliability and accuracy of security features. However, the process of depositing nichrome with the necessary precision can be complex and costly, potentially limiting its widespread adoption in certain security applications.

Electromagnetic interference (EMI) is an additional concern when using nichrome in high-security electronics. The alloy's electrical properties can make it susceptible to external electromagnetic fields, potentially compromising the functionality or security of the devices. Shielding and isolation techniques must be carefully implemented to mitigate these risks, adding complexity to device design and manufacturing processes.

The rising cost and potential supply chain disruptions of nichrome's constituent metals, primarily nickel and chromium, pose economic challenges for manufacturers. Fluctuations in raw material prices can impact the cost-effectiveness of nichrome-based solutions, potentially driving the search for alternative materials or technologies in high-security electronics.

Lastly, the environmental impact of nichrome production and disposal is becoming an increasing concern. As sustainability becomes a more prominent factor in electronics manufacturing, the industry faces pressure to find more eco-friendly alternatives or develop improved recycling methods for nichrome-containing devices. This challenge intersects with regulatory compliance issues, as environmental regulations become more stringent globally.

Addressing these challenges requires ongoing research and development efforts, focusing on improving nichrome's properties, refining manufacturing processes, and exploring innovative applications that leverage the alloy's unique characteristics while mitigating its limitations. The future of nichrome in high-security electronics will likely depend on the industry's ability to overcome these obstacles through technological advancements and creative engineering solutions.

Current Nichrome Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Nichrome in heating elements and electrical resistors: Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and ability to withstand high temperatures. It is commonly found in appliances such as toasters, hair dryers, and electric heaters. The alloy's stability at high temperatures ensures consistent performance and long service life in these applications.

- Nichrome in thin film technology: Nichrome is utilized in thin film technology for various electronic applications. It can be deposited as a thin film using techniques such as sputtering or evaporation. These thin films are used in the production of resistors, sensors, and other microelectronic components. The stability and reliability of nichrome thin films make them valuable in precision electronics.

- Nichrome in aerospace and high-temperature applications: The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that need to withstand extreme conditions, such as in jet engines, rocket nozzles, and industrial furnaces. The alloy's ability to maintain its properties at elevated temperatures contributes to the reliability and safety of these critical systems.

- Surface treatment and coating of nichrome: Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from specific environments. These treatments can improve corrosion resistance, reduce oxidation, or modify the surface characteristics for specific applications. Coatings may include ceramic materials, precious metals, or other protective layers to extend the life and performance of nichrome components.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes aim to achieve desired physical and electrical properties while maintaining the material's structural integrity for specific applications.Expand Specific Solutions03 Applications in electronic devices and sensors

Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is commonly found in resistors, thermocouples, and strain gauges. The material's temperature coefficient of resistance makes it suitable for precise temperature measurement and control applications.Expand Specific Solutions04 Heating element applications

Nichrome is extensively used in heating elements for various industrial and consumer applications. Its high resistance to oxidation at elevated temperatures and ability to withstand repeated heating and cooling cycles make it ideal for use in electric heaters, ovens, and other heating appliances.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their performance and durability. These methods include oxidation resistance coatings, insulation layers, and protective films that improve the material's resistance to corrosion and extend its lifespan in harsh environments.Expand Specific Solutions

Key Nichrome Players

The competitive landscape for Nichrome applications in high-security electronics is characterized by a mature market with steady growth potential. The technology has reached a high level of maturity, with established players like Infineon Technologies AG, Raytheon Co., and Siemens Corp. leading the field. These companies leverage their extensive R&D capabilities and industry experience to maintain market dominance. Emerging players such as Canatu Oy and Resonac Corp. are introducing innovative solutions, potentially disrupting the market. The industry is seeing increased focus on miniaturization and enhanced performance, driving continuous technological advancements. As security concerns grow globally, the market for Nichrome-based high-security electronics is expected to expand, attracting further investment and competition.

Infineon Technologies AG

Technical Solution: Infineon has pioneered the use of nichrome in high-security microcontroller designs for smartcards and secure elements. Their approach involves integrating nichrome-based physical unclonable functions (PUFs) directly into chip designs to create unique, tamper-resistant identifiers[3]. The company has also developed nichrome-based fuse elements for one-time programmable (OTP) memory in secure ICs, providing a reliable method for storing encryption keys and other sensitive data[4]. Infineon's nichrome implementations are optimized for low power consumption and high reliability in compact form factors.

Strengths: Strong presence in secure IC market, advanced integration of nichrome in semiconductor processes. Weaknesses: Dependent on third-party foundries for some manufacturing steps.

Siemens Corp.

Technical Solution: Siemens has incorporated nichrome technology into their industrial control and automation systems for enhanced security and reliability. Their approach utilizes nichrome-based sensing elements in intrusion detection systems for critical infrastructure protection[5]. The company has also developed nichrome heating elements with precise temperature control for secure data erasure in storage devices. Siemens' nichrome applications extend to tamper-evident packaging for industrial IoT devices, leveraging the material's stable electrical properties to create circuits that irreversibly change when physically compromised[6].

Strengths: Extensive experience in industrial automation and security, global reach and resources. Weaknesses: Slower adoption in consumer electronics markets, focus primarily on industrial applications.

Nichrome Innovations

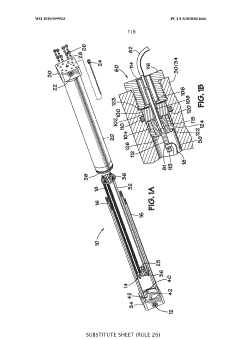

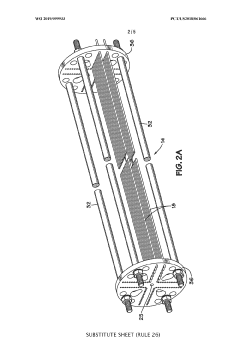

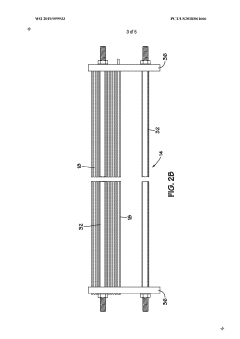

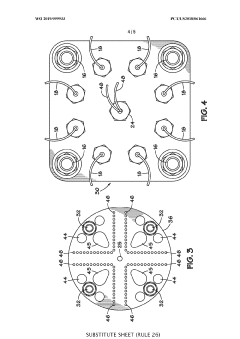

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

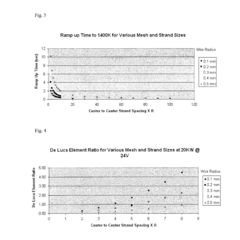

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Nichrome Supply Chain

The nichrome supply chain plays a crucial role in the production and application of high-security electronics. Nichrome, an alloy composed primarily of nickel and chromium, is sourced from various global suppliers, with major production centers located in China, India, and the United States. The supply chain begins with the extraction of raw materials, primarily nickel and chromium ores, from mines in countries such as Russia, Canada, and South Africa.

These raw materials undergo refining processes to produce high-purity nickel and chromium, which are then combined in precise ratios to create nichrome alloy. The manufacturing of nichrome wire, a common form used in electronics, involves drawing the alloy through progressively smaller dies to achieve the desired diameter and electrical properties.

The nichrome supply chain faces several challenges, including price volatility of raw materials, geopolitical tensions affecting trade, and environmental concerns associated with mining and refining processes. These factors can impact the availability and cost of nichrome for high-security electronics manufacturers.

Quality control is a critical aspect of the nichrome supply chain, particularly for applications in high-security electronics. Stringent testing and certification processes are implemented to ensure the consistency and reliability of nichrome components. This includes verifying the alloy composition, electrical properties, and mechanical characteristics of the material.

The distribution network for nichrome involves specialized metal suppliers, electronics component distributors, and direct relationships between manufacturers and end-users in the high-security electronics sector. Many companies in this field maintain strategic partnerships or long-term contracts with suppliers to ensure a stable and secure supply of nichrome materials.

In recent years, there has been a growing emphasis on supply chain transparency and traceability in the nichrome industry. This is particularly important for high-security applications, where the provenance and integrity of materials are critical. Advanced tracking systems and blockchain technology are being explored to enhance supply chain visibility and security.

The nichrome supply chain also intersects with broader trends in the electronics industry, such as the push for miniaturization and increased energy efficiency. This has led to ongoing research and development efforts to optimize nichrome alloy compositions and manufacturing processes to meet evolving requirements in high-security electronics applications.

These raw materials undergo refining processes to produce high-purity nickel and chromium, which are then combined in precise ratios to create nichrome alloy. The manufacturing of nichrome wire, a common form used in electronics, involves drawing the alloy through progressively smaller dies to achieve the desired diameter and electrical properties.

The nichrome supply chain faces several challenges, including price volatility of raw materials, geopolitical tensions affecting trade, and environmental concerns associated with mining and refining processes. These factors can impact the availability and cost of nichrome for high-security electronics manufacturers.

Quality control is a critical aspect of the nichrome supply chain, particularly for applications in high-security electronics. Stringent testing and certification processes are implemented to ensure the consistency and reliability of nichrome components. This includes verifying the alloy composition, electrical properties, and mechanical characteristics of the material.

The distribution network for nichrome involves specialized metal suppliers, electronics component distributors, and direct relationships between manufacturers and end-users in the high-security electronics sector. Many companies in this field maintain strategic partnerships or long-term contracts with suppliers to ensure a stable and secure supply of nichrome materials.

In recent years, there has been a growing emphasis on supply chain transparency and traceability in the nichrome industry. This is particularly important for high-security applications, where the provenance and integrity of materials are critical. Advanced tracking systems and blockchain technology are being explored to enhance supply chain visibility and security.

The nichrome supply chain also intersects with broader trends in the electronics industry, such as the push for miniaturization and increased energy efficiency. This has led to ongoing research and development efforts to optimize nichrome alloy compositions and manufacturing processes to meet evolving requirements in high-security electronics applications.

Nichrome Safety Standards

Nichrome safety standards play a crucial role in ensuring the reliability and security of high-security electronic devices. These standards encompass a wide range of requirements and guidelines that manufacturers must adhere to when incorporating nichrome components into their products.

One of the primary safety considerations for nichrome applications in high-security electronics is thermal management. Nichrome, being a resistive alloy, generates heat when an electric current passes through it. Safety standards dictate specific temperature thresholds that must not be exceeded during normal operation to prevent overheating and potential fire hazards. These standards often require the implementation of advanced thermal dissipation techniques and the use of temperature-sensing devices to monitor and control heat generation.

Electrical safety is another critical aspect addressed by nichrome safety standards. These guidelines specify the maximum allowable current densities and voltage ratings for nichrome components to prevent electrical failures and short circuits. Additionally, insulation requirements are outlined to ensure proper isolation between nichrome elements and other conductive parts of the device, minimizing the risk of electrical shock or unintended current paths.

Mechanical integrity is also a key focus of nichrome safety standards in high-security electronics. These standards define the minimum tensile strength and durability requirements for nichrome wires and films to withstand mechanical stresses and vibrations commonly encountered in secure environments. Specifications for proper mounting and anchoring of nichrome components are provided to prevent displacement or breakage during operation or in case of physical tampering attempts.

Environmental resistance is another crucial aspect covered by nichrome safety standards. High-security electronic devices often operate in challenging environments, and nichrome components must maintain their integrity and performance under various conditions. Standards specify requirements for corrosion resistance, humidity tolerance, and temperature cycling capabilities to ensure long-term reliability and functionality.

Electromagnetic compatibility (EMC) is a critical consideration in high-security electronics, and nichrome safety standards address this aspect as well. Guidelines are provided for shielding and grounding techniques to minimize electromagnetic interference (EMI) generated by nichrome components and to protect them from external electromagnetic disturbances. These standards ensure that nichrome-based devices can operate reliably in environments with high electromagnetic activity without compromising their security features.

Lastly, nichrome safety standards for high-security electronics often include specific requirements for quality control and testing procedures. These guidelines outline the necessary inspection and verification methods to ensure compliance with safety standards throughout the manufacturing process. Regular testing protocols are defined to assess the long-term reliability and performance of nichrome components under various operating conditions and stress scenarios.

One of the primary safety considerations for nichrome applications in high-security electronics is thermal management. Nichrome, being a resistive alloy, generates heat when an electric current passes through it. Safety standards dictate specific temperature thresholds that must not be exceeded during normal operation to prevent overheating and potential fire hazards. These standards often require the implementation of advanced thermal dissipation techniques and the use of temperature-sensing devices to monitor and control heat generation.

Electrical safety is another critical aspect addressed by nichrome safety standards. These guidelines specify the maximum allowable current densities and voltage ratings for nichrome components to prevent electrical failures and short circuits. Additionally, insulation requirements are outlined to ensure proper isolation between nichrome elements and other conductive parts of the device, minimizing the risk of electrical shock or unintended current paths.

Mechanical integrity is also a key focus of nichrome safety standards in high-security electronics. These standards define the minimum tensile strength and durability requirements for nichrome wires and films to withstand mechanical stresses and vibrations commonly encountered in secure environments. Specifications for proper mounting and anchoring of nichrome components are provided to prevent displacement or breakage during operation or in case of physical tampering attempts.

Environmental resistance is another crucial aspect covered by nichrome safety standards. High-security electronic devices often operate in challenging environments, and nichrome components must maintain their integrity and performance under various conditions. Standards specify requirements for corrosion resistance, humidity tolerance, and temperature cycling capabilities to ensure long-term reliability and functionality.

Electromagnetic compatibility (EMC) is a critical consideration in high-security electronics, and nichrome safety standards address this aspect as well. Guidelines are provided for shielding and grounding techniques to minimize electromagnetic interference (EMI) generated by nichrome components and to protect them from external electromagnetic disturbances. These standards ensure that nichrome-based devices can operate reliably in environments with high electromagnetic activity without compromising their security features.

Lastly, nichrome safety standards for high-security electronics often include specific requirements for quality control and testing procedures. These guidelines outline the necessary inspection and verification methods to ensure compliance with safety standards throughout the manufacturing process. Regular testing protocols are defined to assess the long-term reliability and performance of nichrome components under various operating conditions and stress scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!