Nichrome’s Efficiency in Industrial Manufacturing Equipment

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Goals

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in industrial manufacturing equipment since its inception in the early 20th century. The evolution of nichrome has been closely tied to the advancements in electrical heating technologies and the growing demands of various industries for reliable, high-temperature resistant materials.

Initially developed as a heating element for electric appliances, nichrome quickly found its way into industrial applications due to its exceptional properties. The alloy's high electrical resistivity, coupled with its ability to withstand extreme temperatures without oxidizing, made it an ideal candidate for use in furnaces, kilns, and other high-temperature industrial processes.

As manufacturing processes became more sophisticated, the demand for precise temperature control and energy efficiency grew. This led to continuous improvements in nichrome composition and manufacturing techniques. The addition of small amounts of other elements, such as silicon and aluminum, further enhanced the alloy's performance characteristics, leading to the development of various grades of nichrome tailored for specific industrial applications.

The goals for nichrome in industrial manufacturing equipment have evolved alongside technological advancements. In the early stages, the primary focus was on achieving higher operating temperatures and longer service life. As energy costs became a significant concern, the emphasis shifted towards improving electrical efficiency and reducing heat loss.

Currently, the main objectives for nichrome in industrial manufacturing equipment center around three key areas: energy efficiency, durability, and precision. Manufacturers are striving to develop nichrome-based heating elements that can deliver more heat with less electrical input, thereby reducing energy consumption and operational costs. Simultaneously, there is a push to extend the lifespan of nichrome components, minimizing downtime and replacement costs in industrial settings.

Precision in temperature control has become increasingly critical in many manufacturing processes, particularly in industries such as semiconductor fabrication and advanced materials production. This has led to research into nichrome alloys with more stable resistance characteristics across a wider temperature range, enabling more accurate and responsive heating systems.

Looking ahead, the goals for nichrome technology in industrial manufacturing equipment are likely to focus on further improving energy efficiency, exploring novel alloy compositions for enhanced performance, and integrating smart technologies for better monitoring and control of heating processes. Additionally, there is growing interest in developing nichrome-based solutions that are more environmentally friendly, both in terms of their production and their impact on overall manufacturing sustainability.

Initially developed as a heating element for electric appliances, nichrome quickly found its way into industrial applications due to its exceptional properties. The alloy's high electrical resistivity, coupled with its ability to withstand extreme temperatures without oxidizing, made it an ideal candidate for use in furnaces, kilns, and other high-temperature industrial processes.

As manufacturing processes became more sophisticated, the demand for precise temperature control and energy efficiency grew. This led to continuous improvements in nichrome composition and manufacturing techniques. The addition of small amounts of other elements, such as silicon and aluminum, further enhanced the alloy's performance characteristics, leading to the development of various grades of nichrome tailored for specific industrial applications.

The goals for nichrome in industrial manufacturing equipment have evolved alongside technological advancements. In the early stages, the primary focus was on achieving higher operating temperatures and longer service life. As energy costs became a significant concern, the emphasis shifted towards improving electrical efficiency and reducing heat loss.

Currently, the main objectives for nichrome in industrial manufacturing equipment center around three key areas: energy efficiency, durability, and precision. Manufacturers are striving to develop nichrome-based heating elements that can deliver more heat with less electrical input, thereby reducing energy consumption and operational costs. Simultaneously, there is a push to extend the lifespan of nichrome components, minimizing downtime and replacement costs in industrial settings.

Precision in temperature control has become increasingly critical in many manufacturing processes, particularly in industries such as semiconductor fabrication and advanced materials production. This has led to research into nichrome alloys with more stable resistance characteristics across a wider temperature range, enabling more accurate and responsive heating systems.

Looking ahead, the goals for nichrome technology in industrial manufacturing equipment are likely to focus on further improving energy efficiency, exploring novel alloy compositions for enhanced performance, and integrating smart technologies for better monitoring and control of heating processes. Additionally, there is growing interest in developing nichrome-based solutions that are more environmentally friendly, both in terms of their production and their impact on overall manufacturing sustainability.

Industrial Demand Analysis

The industrial demand for nichrome in manufacturing equipment has been steadily increasing due to its unique properties and versatile applications. Nichrome, an alloy primarily composed of nickel and chromium, exhibits excellent resistance to high temperatures and corrosion, making it indispensable in various industrial processes. The market for nichrome-based equipment is driven by the growing need for efficient and durable heating elements across multiple sectors.

In the automotive industry, nichrome is extensively used in the production of catalytic converters, exhaust systems, and engine components. As emission standards become more stringent globally, the demand for high-performance catalytic converters incorporating nichrome elements continues to rise. This trend is further amplified by the increasing production of electric vehicles, which require specialized heating systems for battery temperature management.

The aerospace sector represents another significant market for nichrome-based manufacturing equipment. The alloy's ability to withstand extreme temperatures and maintain structural integrity makes it crucial in the production of jet engine components, turbine blades, and exhaust systems. As the commercial and military aviation industries expand, the demand for nichrome in aerospace manufacturing equipment is expected to grow substantially.

The electronics industry heavily relies on nichrome for the production of resistors, heating elements in semiconductor manufacturing, and various other components. With the ongoing miniaturization of electronic devices and the increasing complexity of integrated circuits, the demand for precise and reliable nichrome-based equipment in electronics manufacturing continues to surge.

In the energy sector, nichrome plays a vital role in the production of power generation equipment, particularly in the manufacturing of heating elements for industrial furnaces, boilers, and nuclear reactors. The global push towards cleaner energy sources has led to increased investments in advanced power generation technologies, further driving the demand for nichrome-based manufacturing equipment.

The food processing industry also contributes significantly to the industrial demand for nichrome. The alloy's corrosion resistance and ability to maintain consistent temperatures make it ideal for use in industrial ovens, food packaging equipment, and sterilization systems. As the global population grows and food safety regulations become more stringent, the demand for efficient and hygienic food processing equipment incorporating nichrome elements continues to expand.

The chemical and petrochemical industries utilize nichrome-based equipment in various processes, including distillation, catalytic cracking, and heat exchangers. The alloy's resistance to corrosive chemicals and high temperatures makes it essential in these demanding applications. As these industries continue to evolve and adopt more advanced processes, the demand for specialized nichrome-based manufacturing equipment is expected to increase.

In the automotive industry, nichrome is extensively used in the production of catalytic converters, exhaust systems, and engine components. As emission standards become more stringent globally, the demand for high-performance catalytic converters incorporating nichrome elements continues to rise. This trend is further amplified by the increasing production of electric vehicles, which require specialized heating systems for battery temperature management.

The aerospace sector represents another significant market for nichrome-based manufacturing equipment. The alloy's ability to withstand extreme temperatures and maintain structural integrity makes it crucial in the production of jet engine components, turbine blades, and exhaust systems. As the commercial and military aviation industries expand, the demand for nichrome in aerospace manufacturing equipment is expected to grow substantially.

The electronics industry heavily relies on nichrome for the production of resistors, heating elements in semiconductor manufacturing, and various other components. With the ongoing miniaturization of electronic devices and the increasing complexity of integrated circuits, the demand for precise and reliable nichrome-based equipment in electronics manufacturing continues to surge.

In the energy sector, nichrome plays a vital role in the production of power generation equipment, particularly in the manufacturing of heating elements for industrial furnaces, boilers, and nuclear reactors. The global push towards cleaner energy sources has led to increased investments in advanced power generation technologies, further driving the demand for nichrome-based manufacturing equipment.

The food processing industry also contributes significantly to the industrial demand for nichrome. The alloy's corrosion resistance and ability to maintain consistent temperatures make it ideal for use in industrial ovens, food packaging equipment, and sterilization systems. As the global population grows and food safety regulations become more stringent, the demand for efficient and hygienic food processing equipment incorporating nichrome elements continues to expand.

The chemical and petrochemical industries utilize nichrome-based equipment in various processes, including distillation, catalytic cracking, and heat exchangers. The alloy's resistance to corrosive chemicals and high temperatures makes it essential in these demanding applications. As these industries continue to evolve and adopt more advanced processes, the demand for specialized nichrome-based manufacturing equipment is expected to increase.

Nichrome Tech Challenges

Nichrome, a widely used alloy in industrial manufacturing equipment, faces several significant challenges that impact its efficiency and performance. One of the primary issues is the material's susceptibility to oxidation at high temperatures. When exposed to extreme heat, nichrome can form a layer of chromium oxide on its surface, which may affect its electrical conductivity and heat transfer properties. This oxidation process can lead to a gradual decrease in the efficiency of heating elements and other components made from nichrome.

Another challenge lies in the thermal expansion of nichrome. As the material heats up, it expands, which can cause stress and deformation in the equipment. This thermal expansion can lead to warping, cracking, or even failure of nichrome components, particularly in applications where precise dimensions and shapes are critical. Managing this expansion while maintaining the structural integrity of the equipment poses a significant engineering challenge.

The cost of nichrome is also a concern for industrial manufacturers. While it offers excellent resistance to corrosion and oxidation compared to other alloys, nichrome is relatively expensive due to its nickel content. This high cost can impact the overall production expenses of manufacturing equipment, especially for large-scale operations or when frequent replacements are necessary.

Nichrome's limited strength at high temperatures presents another challenge. Although it maintains its resistance to oxidation, the alloy's mechanical properties can degrade when subjected to prolonged exposure to extreme heat. This limitation can restrict its use in certain high-stress applications or require additional design considerations to ensure the longevity and reliability of nichrome components.

The uniformity of heating in nichrome elements is another area of concern. Achieving consistent heat distribution across large surfaces or complex geometries can be challenging, potentially leading to hotspots or uneven heating in industrial processes. This non-uniformity can affect the quality of products and the efficiency of manufacturing processes that rely on precise temperature control.

Lastly, the electrical resistance of nichrome, while beneficial for heating applications, can pose challenges in certain electrical systems. The high resistance can lead to significant voltage drops in long nichrome wires or elements, potentially affecting the performance of equipment that requires stable electrical characteristics. Balancing the electrical properties of nichrome with its thermal performance is crucial for optimizing its efficiency in industrial manufacturing equipment.

Another challenge lies in the thermal expansion of nichrome. As the material heats up, it expands, which can cause stress and deformation in the equipment. This thermal expansion can lead to warping, cracking, or even failure of nichrome components, particularly in applications where precise dimensions and shapes are critical. Managing this expansion while maintaining the structural integrity of the equipment poses a significant engineering challenge.

The cost of nichrome is also a concern for industrial manufacturers. While it offers excellent resistance to corrosion and oxidation compared to other alloys, nichrome is relatively expensive due to its nickel content. This high cost can impact the overall production expenses of manufacturing equipment, especially for large-scale operations or when frequent replacements are necessary.

Nichrome's limited strength at high temperatures presents another challenge. Although it maintains its resistance to oxidation, the alloy's mechanical properties can degrade when subjected to prolonged exposure to extreme heat. This limitation can restrict its use in certain high-stress applications or require additional design considerations to ensure the longevity and reliability of nichrome components.

The uniformity of heating in nichrome elements is another area of concern. Achieving consistent heat distribution across large surfaces or complex geometries can be challenging, potentially leading to hotspots or uneven heating in industrial processes. This non-uniformity can affect the quality of products and the efficiency of manufacturing processes that rely on precise temperature control.

Lastly, the electrical resistance of nichrome, while beneficial for heating applications, can pose challenges in certain electrical systems. The high resistance can lead to significant voltage drops in long nichrome wires or elements, potentially affecting the performance of equipment that requires stable electrical characteristics. Balancing the electrical properties of nichrome with its thermal performance is crucial for optimizing its efficiency in industrial manufacturing equipment.

Current Nichrome Solutions

01 Composition and structure optimization

Improving nichrome efficiency involves optimizing its composition and structure. This includes adjusting the ratio of nickel to chromium, adding other elements to enhance properties, and modifying the microstructure through heat treatment or manufacturing processes. These optimizations can lead to improved electrical resistance, thermal stability, and overall performance of nichrome components.- Composition and structure optimization: Improving nichrome efficiency involves optimizing its composition and structure. This includes adjusting the ratio of nickel to chromium, adding other elements to enhance properties, and developing specific microstructures or nanostructures to improve performance. These modifications can lead to better electrical conductivity, heat resistance, and overall efficiency.

- Heat treatment and manufacturing processes: Efficiency of nichrome can be enhanced through various heat treatment and manufacturing processes. These may include controlled heating and cooling cycles, annealing, and specific forming techniques. Such processes can improve the material's uniformity, reduce internal stresses, and optimize its electrical and thermal properties.

- Surface treatment and coating technologies: Applying surface treatments or coatings to nichrome can significantly improve its efficiency. These treatments may include oxidation-resistant coatings, nanoparticle deposition, or surface texturing. Such modifications can enhance the material's durability, reduce energy loss, and improve its overall performance in various applications.

- Application-specific design optimization: Enhancing nichrome efficiency often involves optimizing its design for specific applications. This may include creating specialized shapes or configurations, adjusting thickness or cross-sectional area, or developing composite structures. Such tailored designs can maximize performance in areas like heating elements, sensors, or electronic components.

- Integration with advanced materials and technologies: Combining nichrome with other advanced materials or integrating it into novel technologies can lead to improved efficiency. This may involve creating nichrome-based composites, incorporating it into thin-film structures, or using it in conjunction with smart materials. Such integrations can enhance the overall system performance and expand the range of applications for nichrome.

02 Application in heating elements

Nichrome is widely used in heating elements due to its high electrical resistance and heat tolerance. Efficiency improvements in this application focus on designing heating elements with optimal shapes, sizes, and configurations to maximize heat distribution and energy transfer. This includes developing coiled or serpentine structures and integrating insulation materials to minimize heat loss.Expand Specific Solutions03 Thin film and coating technologies

Applying nichrome as thin films or coatings can enhance its efficiency in various applications. Advanced deposition techniques, such as sputtering or vapor deposition, are used to create uniform and precise nichrome layers. These thin films can be utilized in sensors, resistors, and other electronic components, offering improved performance and miniaturization capabilities.Expand Specific Solutions04 Integration with other materials

Combining nichrome with other materials can lead to enhanced efficiency and functionality. This includes creating composite materials, layered structures, or alloys that leverage the properties of nichrome while addressing its limitations. Such integrations can result in improved conductivity, durability, or specific performance characteristics tailored to particular applications.Expand Specific Solutions05 Manufacturing and processing techniques

Developing advanced manufacturing and processing techniques can significantly improve nichrome efficiency. This includes precision control of alloying processes, innovative forming methods, and post-processing treatments. These techniques aim to enhance the material's homogeneity, reduce impurities, and optimize its microstructure, resulting in more consistent and efficient performance across various applications.Expand Specific Solutions

Key Industry Players

The competition landscape for Nichrome's efficiency in industrial manufacturing equipment is evolving rapidly. The market is in a growth phase, driven by increasing demand for high-performance materials in various industries. The global market size for nichrome-based equipment is expanding, with projections indicating substantial growth in the coming years. Technologically, the field is advancing, with companies like Tata Steel, Baowu Special Metallurgy, and Furukawa Co. leading innovations in nichrome applications. These firms are investing heavily in R&D to enhance nichrome's properties and manufacturing processes. Academic institutions such as Central South University and Lanzhou University of Technology are contributing to fundamental research, fostering industry-academia collaborations to push the boundaries of nichrome technology.

Tata Steel Ltd.

Technical Solution: Tata Steel has developed advanced nichrome alloys for industrial manufacturing equipment, focusing on improving efficiency and durability. Their proprietary nichrome composition includes precise ratios of nickel and chromium, with trace elements added to enhance specific properties. The company utilizes a controlled atmosphere melting process to ensure high purity and consistent quality of the alloy[1]. Tata Steel's nichrome products are engineered for optimal electrical resistivity and oxidation resistance at elevated temperatures, making them ideal for heating elements in industrial furnaces and ovens. They have also implemented advanced surface treatment techniques to further improve the alloy's corrosion resistance and extend its operational lifespan[2].

Strengths: High-quality alloy production, advanced manufacturing processes, and extensive R&D capabilities. Weaknesses: Potentially higher production costs compared to standard nichrome alloys, which may impact pricing competitiveness.

Baowu Special Metallurgy Co., Ltd.

Technical Solution: Baowu Special Metallurgy has developed a range of high-performance nichrome alloys tailored for industrial manufacturing equipment. Their approach focuses on microstructure control and precise alloying to achieve superior mechanical properties and electrical resistance. The company employs advanced powder metallurgy techniques to produce nichrome components with enhanced uniformity and reduced grain size, resulting in improved strength and ductility[3]. Baowu's nichrome alloys incorporate carefully selected rare earth elements to optimize high-temperature stability and oxidation resistance. They have also developed a proprietary heat treatment process that further enhances the alloy's creep resistance and extends its service life in demanding industrial applications[4].

Strengths: Advanced metallurgical techniques, customized alloy compositions for specific applications, and strong focus on microstructure optimization. Weaknesses: Potential limitations in large-scale production capacity compared to some global competitors.

Core Nichrome Innovations

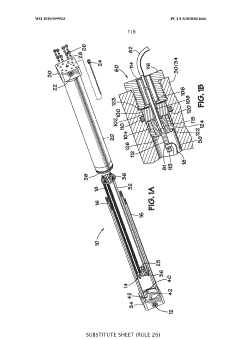

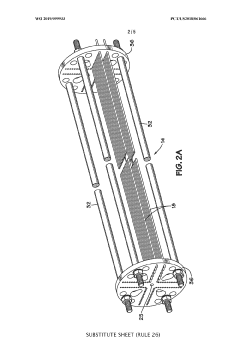

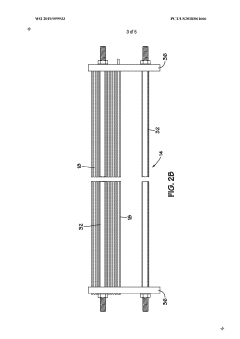

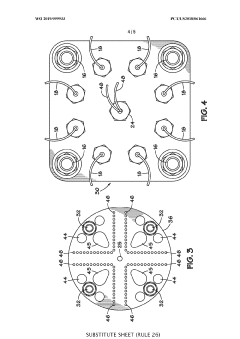

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

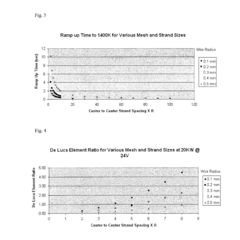

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Energy Efficiency Metrics

Energy efficiency metrics play a crucial role in evaluating the performance of Nichrome in industrial manufacturing equipment. These metrics provide quantitative measures to assess the energy consumption, heat transfer efficiency, and overall effectiveness of Nichrome-based heating elements. One of the primary metrics used is the coefficient of performance (COP), which compares the useful heat output to the electrical energy input. For Nichrome applications, a higher COP indicates better energy efficiency.

Another important metric is the thermal efficiency, which measures the ratio of heat energy transferred to the target material or process compared to the total energy input. This metric is particularly relevant for Nichrome heating elements in industrial ovens, furnaces, and heat treatment equipment. The thermal efficiency of Nichrome-based systems can vary depending on factors such as insulation quality, heat distribution, and operating temperature ranges.

Power density is a key metric that quantifies the amount of heat generated per unit area or volume of the Nichrome element. This metric is essential for optimizing the design of heating systems, ensuring that the required temperature is achieved while minimizing energy consumption. Higher power density can lead to more compact and efficient heating solutions in industrial manufacturing equipment.

The response time of Nichrome heating elements is another critical efficiency metric. It measures how quickly the element can reach the desired temperature and respond to temperature changes. Faster response times contribute to improved energy efficiency by reducing warm-up periods and allowing for more precise temperature control in manufacturing processes.

Energy consumption per unit of production is a comprehensive metric that relates the energy used by Nichrome-based equipment to the output of the manufacturing process. This metric helps manufacturers assess the overall energy efficiency of their production lines and identify opportunities for optimization. It is often expressed in kilowatt-hours per unit of product or per hour of operation.

The heat loss coefficient is an important metric for evaluating the insulation effectiveness of Nichrome-equipped industrial equipment. Lower heat loss coefficients indicate better energy retention and reduced energy waste. This metric is particularly relevant for maintaining consistent temperatures in industrial ovens and furnaces, where heat loss can significantly impact energy efficiency.

Lastly, the energy efficiency ratio (EER) is used to compare the cooling output of Nichrome-based systems to the electrical energy input. While Nichrome is primarily used for heating, this metric becomes relevant in applications where the material is used in conjunction with cooling systems or in temperature control equipment. A higher EER indicates better overall energy efficiency in these dual-purpose applications.

Another important metric is the thermal efficiency, which measures the ratio of heat energy transferred to the target material or process compared to the total energy input. This metric is particularly relevant for Nichrome heating elements in industrial ovens, furnaces, and heat treatment equipment. The thermal efficiency of Nichrome-based systems can vary depending on factors such as insulation quality, heat distribution, and operating temperature ranges.

Power density is a key metric that quantifies the amount of heat generated per unit area or volume of the Nichrome element. This metric is essential for optimizing the design of heating systems, ensuring that the required temperature is achieved while minimizing energy consumption. Higher power density can lead to more compact and efficient heating solutions in industrial manufacturing equipment.

The response time of Nichrome heating elements is another critical efficiency metric. It measures how quickly the element can reach the desired temperature and respond to temperature changes. Faster response times contribute to improved energy efficiency by reducing warm-up periods and allowing for more precise temperature control in manufacturing processes.

Energy consumption per unit of production is a comprehensive metric that relates the energy used by Nichrome-based equipment to the output of the manufacturing process. This metric helps manufacturers assess the overall energy efficiency of their production lines and identify opportunities for optimization. It is often expressed in kilowatt-hours per unit of product or per hour of operation.

The heat loss coefficient is an important metric for evaluating the insulation effectiveness of Nichrome-equipped industrial equipment. Lower heat loss coefficients indicate better energy retention and reduced energy waste. This metric is particularly relevant for maintaining consistent temperatures in industrial ovens and furnaces, where heat loss can significantly impact energy efficiency.

Lastly, the energy efficiency ratio (EER) is used to compare the cooling output of Nichrome-based systems to the electrical energy input. While Nichrome is primarily used for heating, this metric becomes relevant in applications where the material is used in conjunction with cooling systems or in temperature control equipment. A higher EER indicates better overall energy efficiency in these dual-purpose applications.

Environmental Impact

The environmental impact of nichrome's use in industrial manufacturing equipment is a critical consideration in today's sustainability-focused industrial landscape. Nichrome, an alloy primarily composed of nickel and chromium, offers excellent heat resistance and electrical conductivity, making it a popular choice for heating elements in various manufacturing processes. However, its production and application have significant environmental implications.

The mining and processing of nickel and chromium, the primary components of nichrome, contribute to environmental degradation. Open-pit mining for these metals can lead to deforestation, soil erosion, and habitat destruction. Furthermore, the refining process of these metals is energy-intensive, resulting in substantial greenhouse gas emissions. The production of nichrome alloy itself also requires high temperatures, further adding to its carbon footprint.

In industrial applications, nichrome's efficiency in converting electrical energy to heat energy is a double-edged sword from an environmental perspective. While its high efficiency can lead to reduced energy consumption in manufacturing processes, the heat generated can contribute to local thermal pollution if not properly managed. This can affect nearby ecosystems and potentially alter local microclimates.

The durability and corrosion resistance of nichrome contribute to the longevity of industrial equipment, which can be seen as an environmental positive. Longer-lasting equipment reduces the need for frequent replacements, thereby decreasing the demand for raw materials and the associated environmental impacts of manufacturing new equipment. However, the disposal of nichrome-containing equipment at the end of its life cycle presents challenges, as the alloy is not easily recyclable and may require special handling to prevent environmental contamination.

Nichrome's resistance to oxidation at high temperatures reduces the formation of harmful oxides during industrial processes, potentially lowering air pollution levels. However, in cases where nichrome does degrade or particles are released, there are concerns about the potential toxicity of nickel and chromium compounds in the environment. These metals can accumulate in soil and water systems, potentially entering food chains and causing long-term ecological damage.

Efforts to mitigate the environmental impact of nichrome in industrial manufacturing are ongoing. These include developing more efficient mining and refining processes, improving recycling techniques for nichrome-containing equipment, and researching alternative materials with similar properties but lower environmental footprints. Additionally, optimizing the design of nichrome heating elements to maximize efficiency and minimize waste heat can further reduce the overall environmental impact of industrial processes utilizing this alloy.

The mining and processing of nickel and chromium, the primary components of nichrome, contribute to environmental degradation. Open-pit mining for these metals can lead to deforestation, soil erosion, and habitat destruction. Furthermore, the refining process of these metals is energy-intensive, resulting in substantial greenhouse gas emissions. The production of nichrome alloy itself also requires high temperatures, further adding to its carbon footprint.

In industrial applications, nichrome's efficiency in converting electrical energy to heat energy is a double-edged sword from an environmental perspective. While its high efficiency can lead to reduced energy consumption in manufacturing processes, the heat generated can contribute to local thermal pollution if not properly managed. This can affect nearby ecosystems and potentially alter local microclimates.

The durability and corrosion resistance of nichrome contribute to the longevity of industrial equipment, which can be seen as an environmental positive. Longer-lasting equipment reduces the need for frequent replacements, thereby decreasing the demand for raw materials and the associated environmental impacts of manufacturing new equipment. However, the disposal of nichrome-containing equipment at the end of its life cycle presents challenges, as the alloy is not easily recyclable and may require special handling to prevent environmental contamination.

Nichrome's resistance to oxidation at high temperatures reduces the formation of harmful oxides during industrial processes, potentially lowering air pollution levels. However, in cases where nichrome does degrade or particles are released, there are concerns about the potential toxicity of nickel and chromium compounds in the environment. These metals can accumulate in soil and water systems, potentially entering food chains and causing long-term ecological damage.

Efforts to mitigate the environmental impact of nichrome in industrial manufacturing are ongoing. These include developing more efficient mining and refining processes, improving recycling techniques for nichrome-containing equipment, and researching alternative materials with similar properties but lower environmental footprints. Additionally, optimizing the design of nichrome heating elements to maximize efficiency and minimize waste heat can further reduce the overall environmental impact of industrial processes utilizing this alloy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!