Nichrome Wire Advancements for Better Energy Efficiency

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution and Objectives

Nichrome wire, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications for over a century. Its evolution has been driven by the constant pursuit of improved energy efficiency and performance in various industrial and consumer applications.

The journey of nichrome wire began in the early 1900s when Albert Marsh discovered the unique properties of this alloy. Initially used in electrical resistance heating elements, nichrome quickly gained popularity due to its high resistivity and excellent oxidation resistance at elevated temperatures. These characteristics made it ideal for use in toasters, hair dryers, and other household appliances.

As technology advanced, so did the demands placed on nichrome wire. The mid-20th century saw a surge in industrial applications, pushing researchers to develop nichrome variants with enhanced properties. This led to the creation of different grades of nichrome, each tailored for specific temperature ranges and environmental conditions.

The late 20th and early 21st centuries brought about a renewed focus on energy efficiency. With growing concerns about climate change and rising energy costs, manufacturers and researchers began exploring ways to optimize nichrome wire performance. This period saw the introduction of more precise composition control and advanced manufacturing techniques, resulting in nichrome wires with improved uniformity and consistency.

Recent years have witnessed a shift towards nanoscale engineering of nichrome wires. By manipulating the alloy's microstructure, researchers have been able to enhance its electrical and thermal properties significantly. This has opened up new possibilities for energy-efficient heating solutions in various sectors, including aerospace, automotive, and renewable energy.

The current objectives in nichrome wire advancement are multifaceted. Firstly, there is a push to increase the maximum operating temperature of nichrome wires without compromising their longevity. This would allow for more efficient high-temperature applications, potentially reducing energy consumption in industrial processes.

Secondly, researchers are focusing on improving the wire's thermal response time. Faster heating and cooling cycles could lead to more precise temperature control and reduced energy waste in applications such as 3D printing and semiconductor manufacturing.

Another key objective is to enhance the wire's resistance to corrosion and oxidation, particularly in harsh environments. This would extend the lifespan of nichrome wire components, reducing replacement frequency and associated costs.

Lastly, there is a growing interest in developing nichrome wire composites that incorporate advanced materials such as carbon nanotubes or graphene. These hybrid materials could potentially offer unprecedented levels of energy efficiency and performance, paving the way for next-generation heating technologies.

As we look to the future, the evolution of nichrome wire continues to be driven by the need for greater energy efficiency. The objectives set forth by researchers and industry leaders aim to push the boundaries of what is possible with this versatile alloy, ensuring its relevance in an increasingly energy-conscious world.

The journey of nichrome wire began in the early 1900s when Albert Marsh discovered the unique properties of this alloy. Initially used in electrical resistance heating elements, nichrome quickly gained popularity due to its high resistivity and excellent oxidation resistance at elevated temperatures. These characteristics made it ideal for use in toasters, hair dryers, and other household appliances.

As technology advanced, so did the demands placed on nichrome wire. The mid-20th century saw a surge in industrial applications, pushing researchers to develop nichrome variants with enhanced properties. This led to the creation of different grades of nichrome, each tailored for specific temperature ranges and environmental conditions.

The late 20th and early 21st centuries brought about a renewed focus on energy efficiency. With growing concerns about climate change and rising energy costs, manufacturers and researchers began exploring ways to optimize nichrome wire performance. This period saw the introduction of more precise composition control and advanced manufacturing techniques, resulting in nichrome wires with improved uniformity and consistency.

Recent years have witnessed a shift towards nanoscale engineering of nichrome wires. By manipulating the alloy's microstructure, researchers have been able to enhance its electrical and thermal properties significantly. This has opened up new possibilities for energy-efficient heating solutions in various sectors, including aerospace, automotive, and renewable energy.

The current objectives in nichrome wire advancement are multifaceted. Firstly, there is a push to increase the maximum operating temperature of nichrome wires without compromising their longevity. This would allow for more efficient high-temperature applications, potentially reducing energy consumption in industrial processes.

Secondly, researchers are focusing on improving the wire's thermal response time. Faster heating and cooling cycles could lead to more precise temperature control and reduced energy waste in applications such as 3D printing and semiconductor manufacturing.

Another key objective is to enhance the wire's resistance to corrosion and oxidation, particularly in harsh environments. This would extend the lifespan of nichrome wire components, reducing replacement frequency and associated costs.

Lastly, there is a growing interest in developing nichrome wire composites that incorporate advanced materials such as carbon nanotubes or graphene. These hybrid materials could potentially offer unprecedented levels of energy efficiency and performance, paving the way for next-generation heating technologies.

As we look to the future, the evolution of nichrome wire continues to be driven by the need for greater energy efficiency. The objectives set forth by researchers and industry leaders aim to push the boundaries of what is possible with this versatile alloy, ensuring its relevance in an increasingly energy-conscious world.

Energy Efficiency Market Demand

The global energy efficiency market has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues, rising energy costs, and stringent government regulations. This trend has created a substantial demand for advanced technologies that can improve energy efficiency across various sectors, including residential, commercial, and industrial applications. Nichrome wire, known for its high electrical resistance and heat-generating properties, plays a crucial role in this market, particularly in heating elements and electrical resistors.

The demand for energy-efficient heating solutions has been steadily increasing, with the global electric heating equipment market expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is largely attributed to the rising adoption of electric heating systems in residential and commercial buildings, as well as the industrial sector's shift towards more energy-efficient processes. Nichrome wire, being a key component in many heating applications, is poised to benefit from this market expansion.

In the industrial sector, the push for energy efficiency has led to increased demand for precision heating elements and temperature control systems. Nichrome wire's ability to provide accurate and consistent heat output makes it an ideal choice for these applications. The industrial process heating market, which heavily relies on nichrome wire technology, is projected to reach a value of $56.7 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025.

The automotive industry is another significant driver of demand for energy-efficient nichrome wire applications. With the growing popularity of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increased need for efficient heating systems that do not drain the vehicle's battery. Nichrome wire-based heating elements are being increasingly used in EV battery thermal management systems and cabin heating solutions, contributing to the overall energy efficiency of these vehicles.

In the consumer electronics sector, the demand for energy-efficient appliances has been rising steadily. Nichrome wire is widely used in household appliances such as toasters, hair dryers, and space heaters. As consumers become more conscious of their energy consumption and seek out products with higher energy ratings, manufacturers are focusing on developing more efficient heating elements using advanced nichrome wire technologies.

The push for energy efficiency has also led to increased research and development efforts in the field of nichrome wire technology. There is a growing demand for nichrome wire with improved properties, such as higher resistance to oxidation, better thermal stability, and enhanced electrical conductivity. These advancements aim to further improve the energy efficiency of heating systems and electrical components across various applications.

As governments worldwide implement stricter energy efficiency standards and offer incentives for energy-saving technologies, the market demand for advanced nichrome wire solutions is expected to continue its upward trajectory. This presents significant opportunities for innovation and market growth in the nichrome wire industry, particularly in developing more energy-efficient and cost-effective solutions for a wide range of applications.

The demand for energy-efficient heating solutions has been steadily increasing, with the global electric heating equipment market expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is largely attributed to the rising adoption of electric heating systems in residential and commercial buildings, as well as the industrial sector's shift towards more energy-efficient processes. Nichrome wire, being a key component in many heating applications, is poised to benefit from this market expansion.

In the industrial sector, the push for energy efficiency has led to increased demand for precision heating elements and temperature control systems. Nichrome wire's ability to provide accurate and consistent heat output makes it an ideal choice for these applications. The industrial process heating market, which heavily relies on nichrome wire technology, is projected to reach a value of $56.7 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025.

The automotive industry is another significant driver of demand for energy-efficient nichrome wire applications. With the growing popularity of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increased need for efficient heating systems that do not drain the vehicle's battery. Nichrome wire-based heating elements are being increasingly used in EV battery thermal management systems and cabin heating solutions, contributing to the overall energy efficiency of these vehicles.

In the consumer electronics sector, the demand for energy-efficient appliances has been rising steadily. Nichrome wire is widely used in household appliances such as toasters, hair dryers, and space heaters. As consumers become more conscious of their energy consumption and seek out products with higher energy ratings, manufacturers are focusing on developing more efficient heating elements using advanced nichrome wire technologies.

The push for energy efficiency has also led to increased research and development efforts in the field of nichrome wire technology. There is a growing demand for nichrome wire with improved properties, such as higher resistance to oxidation, better thermal stability, and enhanced electrical conductivity. These advancements aim to further improve the energy efficiency of heating systems and electrical components across various applications.

As governments worldwide implement stricter energy efficiency standards and offer incentives for energy-saving technologies, the market demand for advanced nichrome wire solutions is expected to continue its upward trajectory. This presents significant opportunities for innovation and market growth in the nichrome wire industry, particularly in developing more energy-efficient and cost-effective solutions for a wide range of applications.

Nichrome Wire Challenges

Despite the widespread use of nichrome wire in heating applications, several challenges persist in improving its energy efficiency. One of the primary issues is the inherent limitations of the material's electrical resistivity. While nichrome's high resistance is beneficial for generating heat, it also results in significant energy losses during operation, particularly in high-temperature applications.

The thermal stability of nichrome wire at elevated temperatures presents another challenge. Although it performs well compared to many other alloys, prolonged exposure to extreme heat can lead to structural changes in the wire, affecting its performance and longevity. This necessitates frequent replacements in industrial settings, increasing operational costs and energy consumption associated with manufacturing new wires.

Corrosion resistance is another area of concern, especially in environments with aggressive chemicals or high humidity. While nichrome generally exhibits good corrosion resistance, certain applications may require enhanced protection to prevent degradation and maintain optimal energy efficiency over time.

The uniformity of heat distribution along the length of nichrome wire can be inconsistent, leading to hotspots and cold zones. This non-uniform heating not only reduces overall energy efficiency but can also impact the quality of processes relying on precise temperature control, such as in laboratory equipment or specialized manufacturing.

Miniaturization of heating elements poses a significant challenge for nichrome wire applications. As devices become smaller and more compact, there is a growing demand for heating elements that can deliver the same performance in reduced sizes. This requires innovations in wire design and manufacturing to maintain efficiency while decreasing dimensions.

The integration of nichrome wire with advanced control systems and smart technologies presents both opportunities and challenges. While such integration can potentially improve energy efficiency through precise power management, it also introduces complexities in design and implementation, particularly in retrofitting existing systems.

Lastly, the environmental impact of nichrome wire production and disposal is an emerging concern. As global focus shifts towards sustainable technologies, there is pressure to develop more eco-friendly alternatives or improve the recyclability of nichrome wire without compromising its performance characteristics.

The thermal stability of nichrome wire at elevated temperatures presents another challenge. Although it performs well compared to many other alloys, prolonged exposure to extreme heat can lead to structural changes in the wire, affecting its performance and longevity. This necessitates frequent replacements in industrial settings, increasing operational costs and energy consumption associated with manufacturing new wires.

Corrosion resistance is another area of concern, especially in environments with aggressive chemicals or high humidity. While nichrome generally exhibits good corrosion resistance, certain applications may require enhanced protection to prevent degradation and maintain optimal energy efficiency over time.

The uniformity of heat distribution along the length of nichrome wire can be inconsistent, leading to hotspots and cold zones. This non-uniform heating not only reduces overall energy efficiency but can also impact the quality of processes relying on precise temperature control, such as in laboratory equipment or specialized manufacturing.

Miniaturization of heating elements poses a significant challenge for nichrome wire applications. As devices become smaller and more compact, there is a growing demand for heating elements that can deliver the same performance in reduced sizes. This requires innovations in wire design and manufacturing to maintain efficiency while decreasing dimensions.

The integration of nichrome wire with advanced control systems and smart technologies presents both opportunities and challenges. While such integration can potentially improve energy efficiency through precise power management, it also introduces complexities in design and implementation, particularly in retrofitting existing systems.

Lastly, the environmental impact of nichrome wire production and disposal is an emerging concern. As global focus shifts towards sustainable technologies, there is pressure to develop more eco-friendly alternatives or improve the recyclability of nichrome wire without compromising its performance characteristics.

Current Nichrome Solutions

01 Improved heating element design

Nichrome wire heating elements can be optimized for energy efficiency through improved designs. This includes using specific wire configurations, coil shapes, and spacing to maximize heat distribution and minimize energy loss. Advanced designs may incorporate multiple layers or specialized structures to enhance performance.- Improved heating element design: Nichrome wire heating elements can be optimized for energy efficiency through improved designs. This includes using specific wire configurations, coil shapes, and spacing to maximize heat distribution while minimizing energy consumption. Advanced designs may incorporate multiple layers or specialized structures to enhance performance.

- Material composition optimization: The energy efficiency of nichrome wire can be enhanced by optimizing its material composition. This may involve adjusting the ratio of nickel and chromium or incorporating additional elements to improve electrical resistance and heat generation properties. Specialized alloys can be developed to achieve better energy efficiency in specific applications.

- Insulation and heat retention techniques: Implementing effective insulation and heat retention techniques can significantly improve the energy efficiency of nichrome wire-based systems. This includes using high-quality insulating materials, designing enclosures to minimize heat loss, and incorporating reflective surfaces to redirect heat towards the intended target.

- Control systems for optimized power usage: Advanced control systems can be employed to optimize the power usage of nichrome wire heating elements. These systems may include temperature sensors, microcontrollers, and intelligent algorithms to regulate power input based on real-time heating requirements, thereby reducing overall energy consumption.

- Integration with energy-efficient appliances: Nichrome wire heating elements can be integrated into energy-efficient appliances and systems. This involves designing the overall appliance architecture to maximize heat utilization, minimize waste, and incorporate energy-saving features such as automatic shut-off or power-saving modes.

02 Material composition optimization

The energy efficiency of nichrome wire can be enhanced by optimizing its material composition. This may involve adjusting the ratio of nickel and chromium or incorporating additional elements to improve electrical resistance and heat generation properties. Advanced alloys can offer better performance and longevity.Expand Specific Solutions03 Insulation and heat retention techniques

Implementing effective insulation and heat retention techniques can significantly improve the energy efficiency of nichrome wire applications. This includes using high-quality insulating materials, creating thermal barriers, and designing systems that minimize heat loss to the environment.Expand Specific Solutions04 Control systems for power management

Incorporating advanced control systems can optimize power management in nichrome wire applications. This may include using sensors, microcontrollers, and intelligent algorithms to regulate power input, adjust heating cycles, and maintain desired temperatures with minimal energy consumption.Expand Specific Solutions05 Integration with energy-efficient technologies

Combining nichrome wire heating elements with other energy-efficient technologies can enhance overall system performance. This may involve integrating renewable energy sources, heat recovery systems, or smart home technologies to optimize energy usage and reduce waste.Expand Specific Solutions

Key Nichrome Manufacturers

The market for Nichrome wire advancements is in a growth phase, driven by increasing demand for energy-efficient solutions across industries. The global market size is expanding, with key players like Yancheng Xinyang Electric Heating Material Co., Ltd. and Furuya Metal Co., Ltd. leading innovation. The technology is reaching maturity, with companies like Panasonic and YAZAKI Corp. investing in R&D to improve energy efficiency. Emerging players such as Wuxi Dongheng New Energy Technology Co., Ltd. are also contributing to advancements. The competitive landscape is diverse, with both established manufacturers and new entrants focusing on developing high-performance Nichrome wire solutions for various applications.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed advanced nichrome wire technology for improved energy efficiency in heating applications. Their approach involves creating a multi-layered nichrome wire structure with optimized composition and thickness ratios. This design enhances electrical resistance and thermal conductivity, resulting in faster heating and more uniform heat distribution[1]. The company has also implemented a proprietary surface treatment process that increases the wire's corrosion resistance and extends its lifespan[3]. Additionally, Panasonic has integrated smart control systems that adjust power output based on real-time temperature feedback, further improving energy efficiency[5].

Strengths: Superior heat distribution, extended lifespan, and intelligent power management. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Furuya Metal Co., Ltd.

Technical Solution: Furuya Metal has pioneered the development of ultra-thin nichrome wire technology for enhanced energy efficiency. Their innovative approach involves refining the metallurgical process to produce nichrome wires with diameters as small as 10 microns[2]. This ultra-thin wire allows for more precise temperature control and faster heating response times. The company has also developed a proprietary alloy composition that increases the wire's electrical resistance while maintaining its mechanical strength[4]. Furthermore, Furuya Metal has implemented advanced coating techniques to improve the wire's oxidation resistance at high temperatures, extending its operational life in demanding applications[6].

Strengths: Exceptional precision in temperature control, rapid heating response, and improved durability. Weaknesses: Potential fragility of ultra-thin wires and higher production costs.

Nichrome Wire Innovations

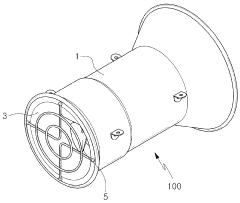

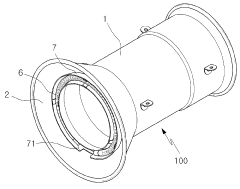

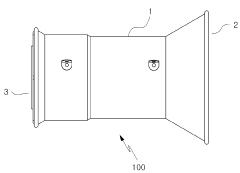

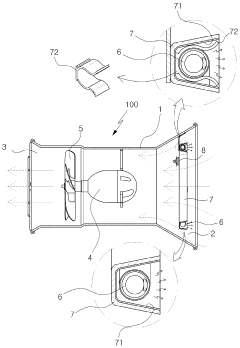

Greenhouse heaters improve heating efficiency and safety

PatentActiveKR1020210110066A

Innovation

- A hot air heater with a power control device that cuts off power to the heating wire and blower when a set temperature is reached, featuring a disk-shaped heating fixing plate with a heat reflective coating to enhance safety and efficiency.

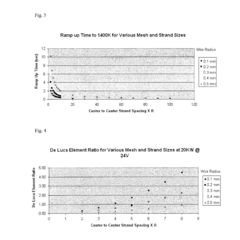

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Material Science Advancements

Recent advancements in material science have significantly contributed to the development of more efficient nichrome wire technologies. The focus has been on enhancing the wire's thermal and electrical properties while maintaining its durability and cost-effectiveness. One key area of improvement has been the manipulation of the nickel-chromium alloy composition. Researchers have experimented with varying ratios of nickel and chromium, as well as introducing small amounts of additional elements such as silicon, aluminum, or iron to optimize performance.

Nanotechnology has played a crucial role in these advancements. By engineering the microstructure of nichrome wires at the nanoscale, scientists have been able to create materials with improved electrical conductivity and heat resistance. This has led to the development of nichrome wires that can operate at higher temperatures with reduced energy loss, thereby increasing overall energy efficiency.

Surface modification techniques have also been explored to enhance the wire's properties. Thin-film coatings and surface treatments have been applied to nichrome wires to improve their oxidation resistance and reduce electrical resistance. These modifications have resulted in wires that maintain their performance characteristics over longer periods, even under harsh operating conditions.

Another significant advancement has been the development of composite nichrome wires. By incorporating ceramic particles or carbon nanotubes into the nichrome matrix, researchers have created wires with enhanced strength and improved thermal stability. These composite wires exhibit better resistance to thermal fatigue and creep, making them ideal for applications requiring prolonged exposure to high temperatures.

The use of advanced manufacturing techniques has further contributed to nichrome wire improvements. Precision control in the wire drawing process has allowed for the production of ultra-thin wires with consistent properties throughout their length. Additionally, new annealing and heat treatment processes have been developed to optimize the wire's microstructure, resulting in improved performance and longevity.

Computational modeling and simulation have become invaluable tools in the advancement of nichrome wire technology. These methods allow researchers to predict the behavior of different alloy compositions and wire designs under various operating conditions. This has accelerated the development process and led to more targeted improvements in wire performance.

As material science continues to evolve, the future of nichrome wire technology looks promising. Ongoing research into novel alloy compositions, advanced manufacturing techniques, and innovative surface treatments is expected to yield further improvements in energy efficiency and overall performance. These advancements will likely expand the applications of nichrome wires in various industries, from heating elements to aerospace components, contributing to more energy-efficient and sustainable technologies.

Nanotechnology has played a crucial role in these advancements. By engineering the microstructure of nichrome wires at the nanoscale, scientists have been able to create materials with improved electrical conductivity and heat resistance. This has led to the development of nichrome wires that can operate at higher temperatures with reduced energy loss, thereby increasing overall energy efficiency.

Surface modification techniques have also been explored to enhance the wire's properties. Thin-film coatings and surface treatments have been applied to nichrome wires to improve their oxidation resistance and reduce electrical resistance. These modifications have resulted in wires that maintain their performance characteristics over longer periods, even under harsh operating conditions.

Another significant advancement has been the development of composite nichrome wires. By incorporating ceramic particles or carbon nanotubes into the nichrome matrix, researchers have created wires with enhanced strength and improved thermal stability. These composite wires exhibit better resistance to thermal fatigue and creep, making them ideal for applications requiring prolonged exposure to high temperatures.

The use of advanced manufacturing techniques has further contributed to nichrome wire improvements. Precision control in the wire drawing process has allowed for the production of ultra-thin wires with consistent properties throughout their length. Additionally, new annealing and heat treatment processes have been developed to optimize the wire's microstructure, resulting in improved performance and longevity.

Computational modeling and simulation have become invaluable tools in the advancement of nichrome wire technology. These methods allow researchers to predict the behavior of different alloy compositions and wire designs under various operating conditions. This has accelerated the development process and led to more targeted improvements in wire performance.

As material science continues to evolve, the future of nichrome wire technology looks promising. Ongoing research into novel alloy compositions, advanced manufacturing techniques, and innovative surface treatments is expected to yield further improvements in energy efficiency and overall performance. These advancements will likely expand the applications of nichrome wires in various industries, from heating elements to aerospace components, contributing to more energy-efficient and sustainable technologies.

Environmental Impact Assessment

The environmental impact of nichrome wire advancements for better energy efficiency is a critical consideration in the development and implementation of this technology. As nichrome wire is widely used in heating elements across various industries, improvements in its energy efficiency can lead to significant environmental benefits.

One of the primary environmental advantages of enhancing nichrome wire efficiency is the reduction in energy consumption. More efficient nichrome wires require less electricity to produce the same amount of heat, resulting in lower power demand from energy grids. This decrease in energy usage translates to reduced greenhouse gas emissions from power plants, particularly in regions where fossil fuels are still a significant source of electricity generation.

The improved durability and longevity of advanced nichrome wires also contribute to environmental sustainability. Longer-lasting heating elements mean fewer replacements are needed over time, reducing the demand for raw materials and the energy required for manufacturing new components. This reduction in material consumption and production processes helps to minimize the overall carbon footprint associated with nichrome wire applications.

Furthermore, the enhanced heat distribution capabilities of advanced nichrome wires can lead to more efficient heating systems. This improved efficiency can result in shorter operating times for heating appliances, further reducing energy consumption and associated emissions. In industrial settings, such as furnaces and kilns, these advancements can lead to significant energy savings and reduced environmental impact on a larger scale.

The potential for miniaturization of heating elements due to nichrome wire advancements also has positive environmental implications. Smaller, more efficient heating components can lead to the development of more compact appliances and industrial equipment. This reduction in size can result in less material usage during manufacturing and potentially lower transportation-related emissions when distributing these products.

However, it is important to consider the potential environmental challenges associated with the production of advanced nichrome wires. The manufacturing process may require new or modified techniques, which could potentially introduce additional environmental concerns. It is crucial to assess and mitigate any negative impacts that may arise from changes in production methods or the use of new materials in the wire composition.

In conclusion, the environmental impact assessment of nichrome wire advancements for better energy efficiency reveals a predominantly positive outlook. The potential for significant energy savings, reduced emissions, and more sustainable resource utilization outweighs the possible challenges in manufacturing processes. As this technology continues to evolve, it is essential to maintain a focus on environmental considerations to ensure that the benefits are maximized while minimizing any potential negative impacts.

One of the primary environmental advantages of enhancing nichrome wire efficiency is the reduction in energy consumption. More efficient nichrome wires require less electricity to produce the same amount of heat, resulting in lower power demand from energy grids. This decrease in energy usage translates to reduced greenhouse gas emissions from power plants, particularly in regions where fossil fuels are still a significant source of electricity generation.

The improved durability and longevity of advanced nichrome wires also contribute to environmental sustainability. Longer-lasting heating elements mean fewer replacements are needed over time, reducing the demand for raw materials and the energy required for manufacturing new components. This reduction in material consumption and production processes helps to minimize the overall carbon footprint associated with nichrome wire applications.

Furthermore, the enhanced heat distribution capabilities of advanced nichrome wires can lead to more efficient heating systems. This improved efficiency can result in shorter operating times for heating appliances, further reducing energy consumption and associated emissions. In industrial settings, such as furnaces and kilns, these advancements can lead to significant energy savings and reduced environmental impact on a larger scale.

The potential for miniaturization of heating elements due to nichrome wire advancements also has positive environmental implications. Smaller, more efficient heating components can lead to the development of more compact appliances and industrial equipment. This reduction in size can result in less material usage during manufacturing and potentially lower transportation-related emissions when distributing these products.

However, it is important to consider the potential environmental challenges associated with the production of advanced nichrome wires. The manufacturing process may require new or modified techniques, which could potentially introduce additional environmental concerns. It is crucial to assess and mitigate any negative impacts that may arise from changes in production methods or the use of new materials in the wire composition.

In conclusion, the environmental impact assessment of nichrome wire advancements for better energy efficiency reveals a predominantly positive outlook. The potential for significant energy savings, reduced emissions, and more sustainable resource utilization outweighs the possible challenges in manufacturing processes. As this technology continues to evolve, it is essential to maintain a focus on environmental considerations to ensure that the benefits are maximized while minimizing any potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!