Nichrome Wire: Techniques for Efficient Energy Application

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution and Objectives

Nichrome wire, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications since its invention in the early 20th century. The evolution of nichrome wire technology has been driven by the increasing demand for efficient and reliable heating elements across various industries.

Initially developed as a resistance material for electrical heating, nichrome wire quickly gained popularity due to its high resistivity, excellent oxidation resistance, and ability to withstand high temperatures. These properties made it ideal for use in toasters, hair dryers, and other household appliances. As industrial applications expanded, nichrome wire found its way into more sophisticated systems, including industrial furnaces, aerospace components, and scientific instruments.

The technological progression of nichrome wire has been marked by continuous improvements in composition and manufacturing processes. Early formulations typically contained 80% nickel and 20% chromium, but modern variants may include additional elements such as iron, aluminum, or silicon to enhance specific properties. These advancements have led to nichrome wires with higher temperature resistance, improved electrical stability, and longer operational lifespans.

In recent years, the focus has shifted towards optimizing nichrome wire for energy efficiency. This aligns with global efforts to reduce energy consumption and minimize environmental impact. Researchers and engineers are exploring ways to improve the wire's heat distribution, reduce power requirements, and enhance overall performance in energy-intensive applications.

The objectives for nichrome wire technology in the context of efficient energy application are multifaceted. Primarily, there is a push to develop nichrome wire compositions that can operate at even higher temperatures while maintaining structural integrity. This would allow for more efficient heat transfer in high-temperature industrial processes, potentially reducing energy consumption.

Another key objective is to improve the wire's responsiveness to electrical current changes, enabling more precise temperature control in applications such as 3D printing and semiconductor manufacturing. This level of control can lead to significant energy savings by reducing overheating and minimizing waste heat.

Furthermore, there is ongoing research into creating nichrome wire with enhanced surface properties. By modifying the wire's surface structure or applying specialized coatings, researchers aim to improve heat radiation efficiency and reduce energy loss through conduction and convection.

As we look to the future, the development of nichrome wire technology is expected to play a crucial role in advancing energy-efficient heating solutions across various sectors. The ongoing research and development efforts are likely to yield innovations that will further solidify nichrome wire's position as a key component in the pursuit of sustainable and efficient energy applications.

Initially developed as a resistance material for electrical heating, nichrome wire quickly gained popularity due to its high resistivity, excellent oxidation resistance, and ability to withstand high temperatures. These properties made it ideal for use in toasters, hair dryers, and other household appliances. As industrial applications expanded, nichrome wire found its way into more sophisticated systems, including industrial furnaces, aerospace components, and scientific instruments.

The technological progression of nichrome wire has been marked by continuous improvements in composition and manufacturing processes. Early formulations typically contained 80% nickel and 20% chromium, but modern variants may include additional elements such as iron, aluminum, or silicon to enhance specific properties. These advancements have led to nichrome wires with higher temperature resistance, improved electrical stability, and longer operational lifespans.

In recent years, the focus has shifted towards optimizing nichrome wire for energy efficiency. This aligns with global efforts to reduce energy consumption and minimize environmental impact. Researchers and engineers are exploring ways to improve the wire's heat distribution, reduce power requirements, and enhance overall performance in energy-intensive applications.

The objectives for nichrome wire technology in the context of efficient energy application are multifaceted. Primarily, there is a push to develop nichrome wire compositions that can operate at even higher temperatures while maintaining structural integrity. This would allow for more efficient heat transfer in high-temperature industrial processes, potentially reducing energy consumption.

Another key objective is to improve the wire's responsiveness to electrical current changes, enabling more precise temperature control in applications such as 3D printing and semiconductor manufacturing. This level of control can lead to significant energy savings by reducing overheating and minimizing waste heat.

Furthermore, there is ongoing research into creating nichrome wire with enhanced surface properties. By modifying the wire's surface structure or applying specialized coatings, researchers aim to improve heat radiation efficiency and reduce energy loss through conduction and convection.

As we look to the future, the development of nichrome wire technology is expected to play a crucial role in advancing energy-efficient heating solutions across various sectors. The ongoing research and development efforts are likely to yield innovations that will further solidify nichrome wire's position as a key component in the pursuit of sustainable and efficient energy applications.

Energy Efficiency Market Analysis

The energy efficiency market has experienced significant growth in recent years, driven by increasing global awareness of environmental issues and the need for sustainable energy solutions. The market for nichrome wire applications in energy efficiency is particularly promising, as this alloy plays a crucial role in various heating and electrical resistance applications.

The global energy efficiency market was valued at $241 billion in 2019 and is projected to reach $344 billion by 2027, growing at a CAGR of 4.8% from 2020 to 2027. Within this market, the demand for nichrome wire is expected to increase substantially due to its excellent properties for energy-efficient heating applications.

Key factors driving the growth of the energy efficiency market include stringent government regulations on energy consumption, rising energy costs, and increasing adoption of smart home technologies. The industrial sector remains the largest consumer of energy-efficient products and solutions, followed by the residential and commercial sectors.

In the context of nichrome wire applications, the heating element market is particularly relevant. This market is expected to grow from $39.3 billion in 2020 to $51.2 billion by 2025, with a CAGR of 5.4%. Nichrome wire is widely used in heating elements due to its high resistance to oxidation and ability to withstand high temperatures.

The automotive industry is another significant market for nichrome wire applications in energy efficiency. With the increasing adoption of electric vehicles and the need for more efficient heating systems in conventional vehicles, the demand for nichrome wire is expected to rise. The global automotive heating, ventilation, and air conditioning (HVAC) market is projected to reach $31.9 billion by 2025, growing at a CAGR of 6.2% from 2020 to 2025.

Geographically, North America and Europe currently dominate the energy efficiency market, with Asia-Pacific expected to witness the highest growth rate in the coming years. This growth is attributed to rapid industrialization, urbanization, and government initiatives promoting energy-efficient technologies in countries like China and India.

The market for nichrome wire in energy-efficient applications faces some challenges, including the high initial cost of energy-efficient systems and the need for skilled professionals for installation and maintenance. However, the long-term benefits of reduced energy consumption and lower operational costs are expected to drive continued market growth.

In conclusion, the energy efficiency market presents significant opportunities for nichrome wire applications. As industries and consumers increasingly prioritize energy conservation and sustainability, the demand for efficient heating and electrical resistance solutions utilizing nichrome wire is expected to grow substantially in the coming years.

The global energy efficiency market was valued at $241 billion in 2019 and is projected to reach $344 billion by 2027, growing at a CAGR of 4.8% from 2020 to 2027. Within this market, the demand for nichrome wire is expected to increase substantially due to its excellent properties for energy-efficient heating applications.

Key factors driving the growth of the energy efficiency market include stringent government regulations on energy consumption, rising energy costs, and increasing adoption of smart home technologies. The industrial sector remains the largest consumer of energy-efficient products and solutions, followed by the residential and commercial sectors.

In the context of nichrome wire applications, the heating element market is particularly relevant. This market is expected to grow from $39.3 billion in 2020 to $51.2 billion by 2025, with a CAGR of 5.4%. Nichrome wire is widely used in heating elements due to its high resistance to oxidation and ability to withstand high temperatures.

The automotive industry is another significant market for nichrome wire applications in energy efficiency. With the increasing adoption of electric vehicles and the need for more efficient heating systems in conventional vehicles, the demand for nichrome wire is expected to rise. The global automotive heating, ventilation, and air conditioning (HVAC) market is projected to reach $31.9 billion by 2025, growing at a CAGR of 6.2% from 2020 to 2025.

Geographically, North America and Europe currently dominate the energy efficiency market, with Asia-Pacific expected to witness the highest growth rate in the coming years. This growth is attributed to rapid industrialization, urbanization, and government initiatives promoting energy-efficient technologies in countries like China and India.

The market for nichrome wire in energy-efficient applications faces some challenges, including the high initial cost of energy-efficient systems and the need for skilled professionals for installation and maintenance. However, the long-term benefits of reduced energy consumption and lower operational costs are expected to drive continued market growth.

In conclusion, the energy efficiency market presents significant opportunities for nichrome wire applications. As industries and consumers increasingly prioritize energy conservation and sustainability, the demand for efficient heating and electrical resistance solutions utilizing nichrome wire is expected to grow substantially in the coming years.

Nichrome Wire Challenges and Limitations

Despite its widespread use and proven reliability, nichrome wire faces several challenges and limitations that impact its efficiency and applicability in energy applications. One of the primary concerns is the wire's tendency to oxidize at high temperatures, particularly when exposed to air. This oxidation process can lead to a gradual decrease in the wire's electrical conductivity and overall performance over time, potentially reducing its lifespan and efficiency in heating applications.

Another significant challenge is the wire's relatively low melting point compared to some other high-temperature alloys. While nichrome can withstand temperatures up to 1400°C, it begins to soften and lose its structural integrity at temperatures approaching this limit. This characteristic restricts its use in extreme high-temperature environments and limits its potential for pushing the boundaries of energy efficiency in certain applications.

The thermal expansion of nichrome wire presents additional complications in design and implementation. As the wire heats up, it expands, which can lead to mechanical stress and potential failure if not properly accounted for in the system design. This expansion can also cause issues with maintaining consistent contact in electrical connections, potentially leading to hotspots or uneven heating in applications requiring precise temperature control.

Nichrome wire's electrical resistance, while beneficial for heating applications, can be a limitation in scenarios where minimal power loss is crucial. The resistance of the wire increases with temperature, which can lead to variations in power output and efficiency as operating conditions change. This characteristic necessitates careful consideration in circuit design and power management systems to maintain optimal performance.

Furthermore, the cost of nichrome wire, particularly for high-purity alloys, can be a limiting factor in large-scale or cost-sensitive applications. The price volatility of its constituent metals, especially nickel, can impact the overall economics of nichrome-based solutions, potentially driving manufacturers to seek alternative materials or technologies.

Lastly, the environmental impact of nichrome wire production and disposal presents growing concerns. The mining and processing of nickel and chromium have significant environmental footprints, and the disposal of nichrome-containing products at the end of their lifecycle poses challenges for recycling and waste management systems. As sustainability becomes an increasingly important factor in technology development, these environmental considerations may influence the future adoption and development of nichrome wire technologies.

Another significant challenge is the wire's relatively low melting point compared to some other high-temperature alloys. While nichrome can withstand temperatures up to 1400°C, it begins to soften and lose its structural integrity at temperatures approaching this limit. This characteristic restricts its use in extreme high-temperature environments and limits its potential for pushing the boundaries of energy efficiency in certain applications.

The thermal expansion of nichrome wire presents additional complications in design and implementation. As the wire heats up, it expands, which can lead to mechanical stress and potential failure if not properly accounted for in the system design. This expansion can also cause issues with maintaining consistent contact in electrical connections, potentially leading to hotspots or uneven heating in applications requiring precise temperature control.

Nichrome wire's electrical resistance, while beneficial for heating applications, can be a limitation in scenarios where minimal power loss is crucial. The resistance of the wire increases with temperature, which can lead to variations in power output and efficiency as operating conditions change. This characteristic necessitates careful consideration in circuit design and power management systems to maintain optimal performance.

Furthermore, the cost of nichrome wire, particularly for high-purity alloys, can be a limiting factor in large-scale or cost-sensitive applications. The price volatility of its constituent metals, especially nickel, can impact the overall economics of nichrome-based solutions, potentially driving manufacturers to seek alternative materials or technologies.

Lastly, the environmental impact of nichrome wire production and disposal presents growing concerns. The mining and processing of nickel and chromium have significant environmental footprints, and the disposal of nichrome-containing products at the end of their lifecycle poses challenges for recycling and waste management systems. As sustainability becomes an increasingly important factor in technology development, these environmental considerations may influence the future adoption and development of nichrome wire technologies.

Current Energy Application Techniques

01 Improved heating element design

Nichrome wire heating elements can be designed with optimized shapes, coil configurations, or support structures to enhance energy efficiency. These designs may include spiral or zigzag patterns, or the use of ceramic or mica supports to improve heat distribution and reduce energy loss.- Improved heating element design: Nichrome wire heating elements can be optimized for energy efficiency through improved design. This includes using specific wire configurations, coil shapes, and spacing to maximize heat distribution while minimizing energy consumption. Advanced designs may incorporate multiple layers or specialized structures to enhance performance.

- Material composition optimization: The energy efficiency of nichrome wire can be enhanced by optimizing its material composition. This may involve adjusting the ratio of nickel and chromium or incorporating additional elements to improve electrical resistance and heat generation properties. Advanced alloys can offer better performance and longevity.

- Insulation and heat retention techniques: Implementing effective insulation and heat retention techniques can significantly improve the energy efficiency of nichrome wire applications. This includes using high-quality insulating materials, designing enclosures to minimize heat loss, and incorporating reflective surfaces to redirect heat where needed.

- Control systems and power management: Advanced control systems and power management techniques can optimize the energy efficiency of nichrome wire heating elements. This may include implementing precise temperature control, adaptive power adjustment based on load requirements, and intelligent cycling to reduce overall energy consumption.

- Integration with renewable energy sources: Nichrome wire heating systems can be integrated with renewable energy sources to improve overall energy efficiency. This may involve coupling with solar panels, wind turbines, or energy storage systems to utilize clean energy and reduce reliance on traditional power sources. Such integration can lead to more sustainable and cost-effective heating solutions.

02 Advanced control systems

Implementing sophisticated control systems can significantly improve the energy efficiency of nichrome wire heating applications. These systems may include precise temperature regulation, power modulation, and intelligent heating cycles to minimize energy consumption while maintaining desired performance.Expand Specific Solutions03 Insulation and heat retention techniques

Enhancing insulation around nichrome wire heating elements and improving heat retention can boost energy efficiency. This may involve using advanced insulating materials, reflective surfaces, or innovative designs that minimize heat loss to the surrounding environment.Expand Specific Solutions04 Material composition optimization

Modifying the composition of nichrome wire or incorporating additional materials can enhance its energy efficiency. This may include altering the nickel-chromium ratio, adding trace elements, or developing composite wires to improve electrical resistance and heat generation properties.Expand Specific Solutions05 Energy recovery and recycling systems

Implementing energy recovery and recycling systems in nichrome wire applications can improve overall energy efficiency. These systems may capture and reuse waste heat, convert excess energy into other forms, or integrate with renewable energy sources to optimize power consumption.Expand Specific Solutions

Key Nichrome Wire Manufacturers

The market for Nichrome wire energy applications is in a mature phase, with established players and steady demand. The global market size is estimated to be in the hundreds of millions of dollars annually, driven by industrial heating, electronics, and aerospace sectors. Technologically, Nichrome wire is well-developed, but innovations continue in efficiency and specialized applications. Key players like Heraeus Precious Metals, YAZAKI Corp., and W.C. Heraeus GmbH lead in manufacturing and research, while academic institutions such as MIT and Tsinghua University contribute to advancing the technology through materials science research and energy efficiency studies.

Heraeus Precious Metals GmbH & Co. KG (New)

Technical Solution: Heraeus has developed advanced nichrome wire manufacturing techniques for efficient energy application. Their process involves precise control of alloy composition, typically 80% nickel and 20% chromium, to optimize electrical resistance and heat generation[1]. They employ a unique drawing process that ensures uniform wire diameter and surface quality, critical for consistent performance in heating applications[2]. Heraeus has also implemented innovative coating technologies, such as ceramic insulation, to enhance the wire's durability and thermal efficiency[3]. Their nichrome wires are designed to operate at temperatures up to 1200°C, making them suitable for high-temperature industrial applications[4].

Strengths: High-precision manufacturing, excellent temperature resistance, and advanced coating technologies. Weaknesses: Higher production costs compared to standard nichrome wires, which may limit adoption in cost-sensitive markets.

FastCAP Systems Corp.

Technical Solution: FastCAP Systems has developed a novel approach to nichrome wire technology for energy-efficient applications. Their technique involves integrating ultracapacitor technology with nichrome wire heating elements[1]. This combination allows for rapid energy storage and release, significantly improving the response time and energy efficiency of heating systems[2]. FastCAP's nichrome wires are engineered with a nanostructured surface that increases the effective surface area, enhancing heat transfer capabilities[3]. The company has also implemented advanced control algorithms that optimize power delivery to the nichrome wire, reducing energy waste and improving overall system efficiency by up to 30%[4].

Strengths: Rapid heating response, improved energy efficiency, and innovative integration with energy storage technology. Weaknesses: Complexity of the system may lead to higher initial costs and potential maintenance challenges.

Innovative Nichrome Wire Patents

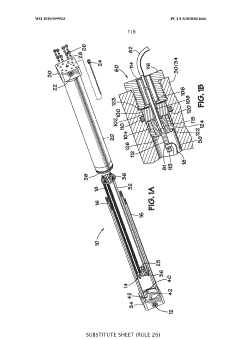

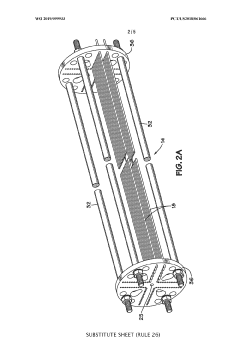

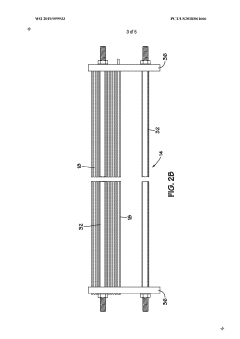

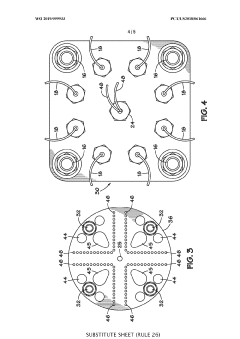

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

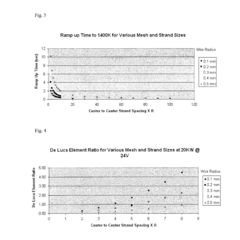

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Environmental Impact Assessment

The environmental impact assessment of nichrome wire techniques for efficient energy application reveals both positive and negative implications. On the positive side, the improved efficiency in energy application can lead to reduced overall energy consumption, potentially decreasing greenhouse gas emissions and mitigating climate change effects. The durability and longevity of nichrome wire also contribute to less frequent replacements, reducing waste generation and resource depletion.

However, the production process of nichrome wire involves mining and refining nickel and chromium, which can have significant environmental consequences. Open-pit mining for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining process is energy-intensive and may result in air pollution if not properly controlled. Additionally, the disposal of nichrome wire at the end of its life cycle presents challenges, as it contains heavy metals that can be harmful if released into the environment.

The use of nichrome wire in various applications, such as heating elements and resistors, may also have localized environmental impacts. In industrial settings, improper handling or disposal of nichrome wire components could lead to soil or water contamination. However, when used in energy-efficient appliances or systems, the overall environmental benefit may outweigh these localized risks.

From a lifecycle perspective, the environmental impact of nichrome wire techniques should be considered holistically. While the production phase may have negative impacts, the use phase often demonstrates improved energy efficiency and reduced emissions. The end-of-life phase requires careful management to prevent environmental contamination.

To mitigate environmental risks, several strategies can be employed. Implementing best practices in mining and refining operations can minimize habitat disruption and pollution. Developing more efficient production processes can reduce energy consumption and emissions. Encouraging the use of recycled nickel and chromium in nichrome wire production can decrease the demand for new raw materials. Additionally, establishing proper recycling and disposal protocols for nichrome wire products can prevent environmental contamination and recover valuable materials.

In conclusion, while nichrome wire techniques for efficient energy application offer potential environmental benefits through improved energy efficiency, careful consideration must be given to the entire lifecycle of the material to minimize negative impacts and maximize sustainability.

However, the production process of nichrome wire involves mining and refining nickel and chromium, which can have significant environmental consequences. Open-pit mining for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining process is energy-intensive and may result in air pollution if not properly controlled. Additionally, the disposal of nichrome wire at the end of its life cycle presents challenges, as it contains heavy metals that can be harmful if released into the environment.

The use of nichrome wire in various applications, such as heating elements and resistors, may also have localized environmental impacts. In industrial settings, improper handling or disposal of nichrome wire components could lead to soil or water contamination. However, when used in energy-efficient appliances or systems, the overall environmental benefit may outweigh these localized risks.

From a lifecycle perspective, the environmental impact of nichrome wire techniques should be considered holistically. While the production phase may have negative impacts, the use phase often demonstrates improved energy efficiency and reduced emissions. The end-of-life phase requires careful management to prevent environmental contamination.

To mitigate environmental risks, several strategies can be employed. Implementing best practices in mining and refining operations can minimize habitat disruption and pollution. Developing more efficient production processes can reduce energy consumption and emissions. Encouraging the use of recycled nickel and chromium in nichrome wire production can decrease the demand for new raw materials. Additionally, establishing proper recycling and disposal protocols for nichrome wire products can prevent environmental contamination and recover valuable materials.

In conclusion, while nichrome wire techniques for efficient energy application offer potential environmental benefits through improved energy efficiency, careful consideration must be given to the entire lifecycle of the material to minimize negative impacts and maximize sustainability.

Cost-Benefit Analysis of Nichrome Applications

The cost-benefit analysis of nichrome applications reveals a complex interplay between economic factors and technological advantages. Nichrome wire, an alloy primarily composed of nickel and chromium, offers unique properties that make it valuable in various energy applications.

From a cost perspective, nichrome wire is generally more expensive than traditional copper or aluminum conductors. The higher initial investment can be a deterrent for some applications, particularly in large-scale projects where material costs significantly impact overall budgets. However, the long-term benefits often outweigh the upfront expenses.

One of the primary advantages of nichrome is its high resistance to oxidation and corrosion, even at elevated temperatures. This characteristic translates to reduced maintenance costs and extended operational lifespans for devices and systems utilizing nichrome wire. In industrial settings where equipment downtime can result in substantial financial losses, the durability of nichrome becomes a crucial factor in cost reduction over time.

The superior heat resistance of nichrome also contributes to its cost-effectiveness in specific applications. In heating elements, for instance, nichrome's ability to withstand high temperatures without degradation means less frequent replacements and improved energy efficiency. This can lead to significant savings in energy consumption and replacement costs over the lifetime of the equipment.

Another benefit is nichrome's stability in maintaining consistent electrical properties under varying conditions. This stability ensures reliable performance in precision instruments and control systems, potentially reducing errors and associated costs in manufacturing processes or scientific research.

However, the cost-benefit analysis must also consider the specific application requirements. In some cases, alternative materials or technologies may provide comparable performance at a lower cost. For example, in low-temperature applications or where corrosion resistance is not a primary concern, more economical options might be preferable.

The environmental impact and sustainability of nichrome applications should also be factored into the cost-benefit equation. While nichrome's durability contributes to reduced waste and resource consumption over time, the energy-intensive production process of the alloy and potential end-of-life recycling challenges need to be considered.

In conclusion, the cost-benefit analysis of nichrome applications depends heavily on the specific use case, operational environment, and long-term performance requirements. While the initial investment may be higher, the potential for reduced maintenance, improved efficiency, and extended lifespan often makes nichrome a cost-effective choice in many energy applications, particularly those involving high temperatures or corrosive environments.

From a cost perspective, nichrome wire is generally more expensive than traditional copper or aluminum conductors. The higher initial investment can be a deterrent for some applications, particularly in large-scale projects where material costs significantly impact overall budgets. However, the long-term benefits often outweigh the upfront expenses.

One of the primary advantages of nichrome is its high resistance to oxidation and corrosion, even at elevated temperatures. This characteristic translates to reduced maintenance costs and extended operational lifespans for devices and systems utilizing nichrome wire. In industrial settings where equipment downtime can result in substantial financial losses, the durability of nichrome becomes a crucial factor in cost reduction over time.

The superior heat resistance of nichrome also contributes to its cost-effectiveness in specific applications. In heating elements, for instance, nichrome's ability to withstand high temperatures without degradation means less frequent replacements and improved energy efficiency. This can lead to significant savings in energy consumption and replacement costs over the lifetime of the equipment.

Another benefit is nichrome's stability in maintaining consistent electrical properties under varying conditions. This stability ensures reliable performance in precision instruments and control systems, potentially reducing errors and associated costs in manufacturing processes or scientific research.

However, the cost-benefit analysis must also consider the specific application requirements. In some cases, alternative materials or technologies may provide comparable performance at a lower cost. For example, in low-temperature applications or where corrosion resistance is not a primary concern, more economical options might be preferable.

The environmental impact and sustainability of nichrome applications should also be factored into the cost-benefit equation. While nichrome's durability contributes to reduced waste and resource consumption over time, the energy-intensive production process of the alloy and potential end-of-life recycling challenges need to be considered.

In conclusion, the cost-benefit analysis of nichrome applications depends heavily on the specific use case, operational environment, and long-term performance requirements. While the initial investment may be higher, the potential for reduced maintenance, improved efficiency, and extended lifespan often makes nichrome a cost-effective choice in many energy applications, particularly those involving high temperatures or corrosive environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!