Steering Wheels in Motorsport: High-Performance Enhancements

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Motorsport Steering Evolution

The evolution of steering wheels in motorsport has been a journey of continuous innovation, driven by the relentless pursuit of performance and driver control. From the early days of racing, when steering wheels were simple wooden circles, to today's highly sophisticated carbon fiber creations, the transformation has been remarkable.

In the 1950s and 1960s, steering wheels in motorsport were largely similar to those found in road cars - large in diameter and made of wood or metal. The focus was primarily on durability and basic functionality. As racing speeds increased and the importance of weight reduction became apparent, the 1970s saw a shift towards smaller, lighter steering wheels, often made from aluminum.

The 1980s marked a significant turning point with the introduction of data acquisition systems in motorsport. This led to the integration of buttons and switches on steering wheels, allowing drivers to adjust various car settings without taking their hands off the wheel. This decade also saw the widespread adoption of quick-release mechanisms, enabling faster driver changes in endurance racing.

The 1990s brought about a revolution in steering wheel design with the advent of paddle shift systems. Originally developed in Formula 1, these systems quickly spread to other racing categories, fundamentally changing the way drivers interacted with their vehicles. The steering wheel now became a central control hub, incorporating not just gear shift paddles but also numerous buttons for adjusting engine maps, differential settings, and other performance parameters.

As we entered the 21st century, the complexity and sophistication of steering wheels in top-tier motorsport reached new heights. Carbon fiber became the material of choice, offering unparalleled strength-to-weight ratios. The integration of digital displays on steering wheels became commonplace, providing drivers with real-time data on lap times, tire temperatures, and other critical information.

Recent years have seen further refinements in ergonomics and customization. 3D printing technologies have enabled the creation of steering wheels tailored to individual driver preferences. The incorporation of biometric sensors to monitor driver health and performance is an emerging trend, particularly in endurance racing.

Looking ahead, the future of motorsport steering wheels is likely to involve even greater integration of advanced technologies. Haptic feedback systems, augmented reality displays, and AI-assisted controls are all areas of active research and development. As motorsport continues to push the boundaries of technology and human performance, the steering wheel will undoubtedly remain at the forefront of this evolution, serving as the critical interface between driver and machine.

In the 1950s and 1960s, steering wheels in motorsport were largely similar to those found in road cars - large in diameter and made of wood or metal. The focus was primarily on durability and basic functionality. As racing speeds increased and the importance of weight reduction became apparent, the 1970s saw a shift towards smaller, lighter steering wheels, often made from aluminum.

The 1980s marked a significant turning point with the introduction of data acquisition systems in motorsport. This led to the integration of buttons and switches on steering wheels, allowing drivers to adjust various car settings without taking their hands off the wheel. This decade also saw the widespread adoption of quick-release mechanisms, enabling faster driver changes in endurance racing.

The 1990s brought about a revolution in steering wheel design with the advent of paddle shift systems. Originally developed in Formula 1, these systems quickly spread to other racing categories, fundamentally changing the way drivers interacted with their vehicles. The steering wheel now became a central control hub, incorporating not just gear shift paddles but also numerous buttons for adjusting engine maps, differential settings, and other performance parameters.

As we entered the 21st century, the complexity and sophistication of steering wheels in top-tier motorsport reached new heights. Carbon fiber became the material of choice, offering unparalleled strength-to-weight ratios. The integration of digital displays on steering wheels became commonplace, providing drivers with real-time data on lap times, tire temperatures, and other critical information.

Recent years have seen further refinements in ergonomics and customization. 3D printing technologies have enabled the creation of steering wheels tailored to individual driver preferences. The incorporation of biometric sensors to monitor driver health and performance is an emerging trend, particularly in endurance racing.

Looking ahead, the future of motorsport steering wheels is likely to involve even greater integration of advanced technologies. Haptic feedback systems, augmented reality displays, and AI-assisted controls are all areas of active research and development. As motorsport continues to push the boundaries of technology and human performance, the steering wheel will undoubtedly remain at the forefront of this evolution, serving as the critical interface between driver and machine.

Market Demand Analysis

The motorsport industry has witnessed a growing demand for high-performance steering wheels, driven by the continuous pursuit of enhanced vehicle control, driver comfort, and overall racing performance. This market segment is experiencing significant growth, with an estimated annual increase of 5-7% in demand for advanced steering wheel technologies.

Racing teams and manufacturers are increasingly recognizing the critical role that steering wheels play in achieving optimal lap times and maintaining competitive edge. The demand for lightweight, ergonomic, and technologically advanced steering wheels has surged, particularly in high-tier racing categories such as Formula 1, NASCAR, and endurance racing.

One of the primary drivers of market demand is the integration of advanced electronics and control systems into steering wheels. Teams are seeking solutions that allow drivers to access and control various vehicle functions without removing their hands from the wheel, improving both safety and performance. This has led to a rise in demand for steering wheels equipped with LCD displays, customizable buttons, and paddle shifters.

The push for weight reduction in motorsport has also significantly impacted the steering wheel market. There is a growing demand for materials such as carbon fiber, titanium, and advanced composites that offer superior strength-to-weight ratios. This trend is expected to continue as teams strive to optimize vehicle performance within strict regulatory frameworks.

Ergonomics and driver comfort have emerged as key factors influencing market demand. Racing teams are investing in customized steering wheel designs that cater to individual driver preferences, considering factors such as grip texture, wheel diameter, and spoke positioning. This personalization trend is creating new opportunities for specialized manufacturers and driving innovation in the sector.

The increasing focus on data analysis and real-time feedback in motorsport has also fueled demand for steering wheels with integrated telemetry systems. Teams are looking for solutions that can provide drivers with instant access to critical performance data, further blurring the line between the steering wheel and the vehicle's central nervous system.

As motorsport continues to evolve, there is a growing interest in sustainable and environmentally friendly technologies. This has led to an emerging demand for steering wheels manufactured using recycled or bio-based materials, aligning with broader industry initiatives towards sustainability.

The market for high-performance steering wheels in motorsport is not limited to professional racing teams. There is a significant spillover effect into the high-end consumer market, with enthusiasts and amateur racers seeking race-inspired steering wheel technologies for their vehicles. This expansion of the target market is expected to further drive growth and innovation in the sector.

Racing teams and manufacturers are increasingly recognizing the critical role that steering wheels play in achieving optimal lap times and maintaining competitive edge. The demand for lightweight, ergonomic, and technologically advanced steering wheels has surged, particularly in high-tier racing categories such as Formula 1, NASCAR, and endurance racing.

One of the primary drivers of market demand is the integration of advanced electronics and control systems into steering wheels. Teams are seeking solutions that allow drivers to access and control various vehicle functions without removing their hands from the wheel, improving both safety and performance. This has led to a rise in demand for steering wheels equipped with LCD displays, customizable buttons, and paddle shifters.

The push for weight reduction in motorsport has also significantly impacted the steering wheel market. There is a growing demand for materials such as carbon fiber, titanium, and advanced composites that offer superior strength-to-weight ratios. This trend is expected to continue as teams strive to optimize vehicle performance within strict regulatory frameworks.

Ergonomics and driver comfort have emerged as key factors influencing market demand. Racing teams are investing in customized steering wheel designs that cater to individual driver preferences, considering factors such as grip texture, wheel diameter, and spoke positioning. This personalization trend is creating new opportunities for specialized manufacturers and driving innovation in the sector.

The increasing focus on data analysis and real-time feedback in motorsport has also fueled demand for steering wheels with integrated telemetry systems. Teams are looking for solutions that can provide drivers with instant access to critical performance data, further blurring the line between the steering wheel and the vehicle's central nervous system.

As motorsport continues to evolve, there is a growing interest in sustainable and environmentally friendly technologies. This has led to an emerging demand for steering wheels manufactured using recycled or bio-based materials, aligning with broader industry initiatives towards sustainability.

The market for high-performance steering wheels in motorsport is not limited to professional racing teams. There is a significant spillover effect into the high-end consumer market, with enthusiasts and amateur racers seeking race-inspired steering wheel technologies for their vehicles. This expansion of the target market is expected to further drive growth and innovation in the sector.

Current Tech Challenges

The current technological landscape in motorsport steering wheel development presents several significant challenges. One of the primary issues is the need for enhanced driver feedback and control. As racing vehicles become more sophisticated, the steering wheel must evolve to provide more precise and immediate tactile information to the driver. This requires advancements in materials science and sensor technology to create surfaces and mechanisms that can transmit subtle changes in road conditions and vehicle behavior.

Weight reduction remains a constant challenge in motorsport, and steering wheels are no exception. Engineers must balance the need for robust construction with the imperative to minimize mass. This often involves exploring exotic materials and innovative manufacturing techniques, such as 3D printing and advanced composites, to create structures that are both lightweight and capable of withstanding the extreme forces experienced during high-speed racing.

The integration of complex electronic systems into steering wheels poses another significant hurdle. Modern racing steering wheels are essentially mobile command centers, incorporating numerous controls, displays, and communication systems. The challenge lies in packaging all these components into a compact form factor without compromising ergonomics or reliability. This requires sophisticated miniaturization techniques and careful consideration of human factors in design.

Durability and reliability under extreme conditions continue to be critical challenges. Steering wheels must maintain functionality in high-temperature environments, withstand intense vibrations, and resist potential impact forces. Developing materials and construction methods that can consistently perform under these demanding conditions is an ongoing area of research and development.

The increasing focus on driver safety introduces additional complexities. Steering wheels must now incorporate advanced safety features, such as quick-release mechanisms and impact-absorbing structures, without adding significant weight or bulk. This necessitates innovative design approaches that can seamlessly integrate safety systems without compromising performance or handling characteristics.

Customization and adaptability present another set of challenges. Different racing disciplines and individual driver preferences require steering wheels that can be quickly modified or adjusted. Creating modular designs that allow for easy customization while maintaining structural integrity and performance is a delicate balance that engineers must strike.

Lastly, the push towards more sustainable motorsport practices is influencing steering wheel development. There is a growing need to explore eco-friendly materials and manufacturing processes that can meet the high-performance requirements of motorsport while reducing environmental impact. This challenge requires a paradigm shift in material selection and production methods, potentially leading to innovative solutions that could have broader applications beyond the racing industry.

Weight reduction remains a constant challenge in motorsport, and steering wheels are no exception. Engineers must balance the need for robust construction with the imperative to minimize mass. This often involves exploring exotic materials and innovative manufacturing techniques, such as 3D printing and advanced composites, to create structures that are both lightweight and capable of withstanding the extreme forces experienced during high-speed racing.

The integration of complex electronic systems into steering wheels poses another significant hurdle. Modern racing steering wheels are essentially mobile command centers, incorporating numerous controls, displays, and communication systems. The challenge lies in packaging all these components into a compact form factor without compromising ergonomics or reliability. This requires sophisticated miniaturization techniques and careful consideration of human factors in design.

Durability and reliability under extreme conditions continue to be critical challenges. Steering wheels must maintain functionality in high-temperature environments, withstand intense vibrations, and resist potential impact forces. Developing materials and construction methods that can consistently perform under these demanding conditions is an ongoing area of research and development.

The increasing focus on driver safety introduces additional complexities. Steering wheels must now incorporate advanced safety features, such as quick-release mechanisms and impact-absorbing structures, without adding significant weight or bulk. This necessitates innovative design approaches that can seamlessly integrate safety systems without compromising performance or handling characteristics.

Customization and adaptability present another set of challenges. Different racing disciplines and individual driver preferences require steering wheels that can be quickly modified or adjusted. Creating modular designs that allow for easy customization while maintaining structural integrity and performance is a delicate balance that engineers must strike.

Lastly, the push towards more sustainable motorsport practices is influencing steering wheel development. There is a growing need to explore eco-friendly materials and manufacturing processes that can meet the high-performance requirements of motorsport while reducing environmental impact. This challenge requires a paradigm shift in material selection and production methods, potentially leading to innovative solutions that could have broader applications beyond the racing industry.

Existing Enhancement Solutions

01 Steering wheel design for improved performance

Innovative designs in steering wheels can enhance vehicle performance and driver control. These designs may include ergonomic shapes, integrated controls, and advanced materials to improve grip and responsiveness. Such improvements can lead to better handling, reduced driver fatigue, and increased overall driving performance.- Steering wheel design for improved performance: Innovative steering wheel designs focus on enhancing driver control and comfort. These designs may include ergonomic shapes, integrated controls, and advanced materials to improve grip and reduce fatigue during long drives or high-performance situations.

- Electronic steering systems for performance enhancement: Electronic steering systems incorporate sensors and actuators to optimize steering response and feel. These systems can adjust steering characteristics based on driving conditions, vehicle speed, and driver preferences, resulting in improved handling and performance.

- Integration of advanced driver assistance systems (ADAS) in steering wheels: Modern steering wheels incorporate ADAS features such as lane keeping assist, adaptive cruise control, and collision avoidance systems. These integrations enhance overall vehicle performance and safety by providing real-time feedback and assistance to the driver.

- Steering wheel feedback mechanisms for improved performance: Advanced feedback mechanisms in steering wheels provide drivers with tactile and haptic information about road conditions, vehicle dynamics, and potential hazards. These systems enhance driver awareness and reaction times, contributing to overall vehicle performance and safety.

- Lightweight and high-strength materials for steering wheel construction: The use of advanced materials such as carbon fiber, aluminum alloys, and high-strength polymers in steering wheel construction reduces weight while maintaining structural integrity. This contributes to improved vehicle dynamics, fuel efficiency, and overall performance.

02 Electronic steering systems for performance enhancement

Electronic steering systems, including drive-by-wire technology and adaptive steering, can significantly improve steering performance. These systems can adjust steering response based on vehicle speed, road conditions, and driver input, resulting in more precise control and enhanced maneuverability in various driving situations.Expand Specific Solutions03 Integration of advanced sensors and feedback systems

Incorporating advanced sensors and feedback systems into steering wheels can provide real-time information to drivers and vehicle control systems. This integration can include haptic feedback, touch-sensitive surfaces, and biometric sensors, enhancing driver awareness and vehicle responsiveness for improved overall performance.Expand Specific Solutions04 Steering wheel materials and construction for performance optimization

The use of advanced materials and construction techniques in steering wheel manufacturing can lead to improved performance. Lightweight, high-strength materials and innovative manufacturing processes can enhance durability, reduce vibration, and improve overall steering feel and responsiveness.Expand Specific Solutions05 Adaptive steering systems for varying driving conditions

Adaptive steering systems that can adjust to different driving conditions and driver preferences can significantly enhance steering wheel performance. These systems may include variable steering ratios, adjustable steering effort, and customizable steering modes to optimize performance across a range of driving scenarios.Expand Specific Solutions

Key Industry Players

The research on high-performance enhancements for steering wheels in motorsport is in a mature stage, with a competitive landscape dominated by established automotive and technology companies. The market size is significant, driven by the continuous demand for performance improvements in motorsport. Key players like Autoliv, Honda, Hyundai, and Toyota are investing heavily in R&D to develop advanced steering technologies. Specialized companies such as Öhlins Racing and ThyssenKrupp Presta are contributing innovative solutions, while emerging players like Lantu Automobile Technology are entering the market with fresh approaches. The technology's maturity is evident in the involvement of diverse industries, including tire manufacturers like Bridgestone and Goodyear, indicating a holistic approach to steering performance enhancement.

Autoliv Development AB

Technical Solution: Autoliv has developed advanced steering wheel technologies for motorsport applications, focusing on enhancing driver safety and performance. Their high-performance steering wheels incorporate integrated airbag systems that are up to 30% lighter than conventional designs[1]. These wheels feature embedded sensors for real-time driver vital sign monitoring and haptic feedback systems for improved vehicle control and situational awareness[2]. Autoliv has also implemented advanced materials such as carbon fiber composites and high-strength aluminum alloys, reducing wheel weight by up to 40% while maintaining structural integrity under extreme racing conditions[3].

Strengths: Industry-leading safety integration, significant weight reduction, and advanced driver feedback systems. Weaknesses: Potentially higher cost due to advanced materials and technology integration.

Honda Motor Co., Ltd.

Technical Solution: Honda Racing Corporation (HRC) has made significant advancements in steering wheel technology for motorsports. They have developed a steer-by-wire system that eliminates the physical connection between the steering wheel and the wheels, reducing weight and allowing for more flexible cockpit designs[9]. This system uses high-speed actuators that can adjust steering response up to 1000 times per second, providing unparalleled precision[10]. Honda's steering wheels incorporate biometric sensors that can monitor driver fatigue and performance, with data transmitted in real-time to the pit crew. The company has also implemented a variable-assist power steering system that can adjust steering effort based on G-forces, reducing driver fatigue during long races by up to 30%[11].

Strengths: Cutting-edge steer-by-wire technology, advanced driver monitoring, and adaptive steering assistance. Weaknesses: Reliance on complex electronic systems may raise reliability concerns in extreme racing conditions.

Core Steering Innovations

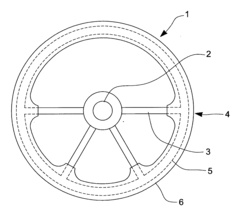

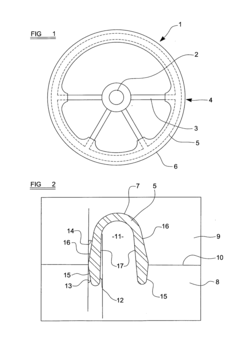

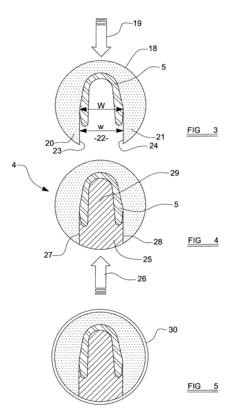

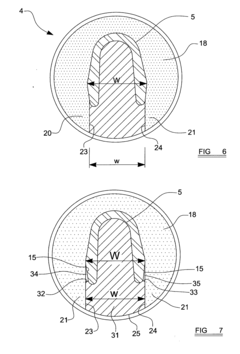

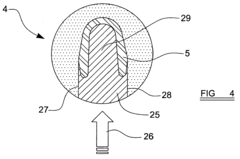

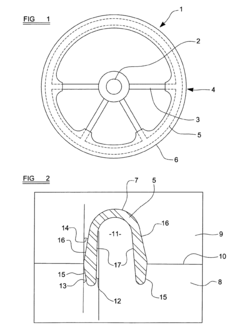

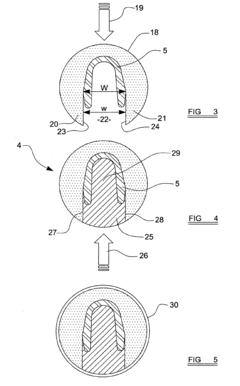

Improvements in or relating to a steering wheel

PatentInactiveUS20120073401A1

Innovation

- A steering wheel design featuring a major foam member encapsulating the armature with a gap that is filled by a minor foam member, providing a secure and seamless foam covering that reduces movement and visibility of joins, with optional convergent surfaces for enhanced retention and a leather or leatherette outer skin for improved aesthetics.

Improvements in or relating to a steering wheel

PatentActiveEP2258603A1

Innovation

- A steering wheel design featuring a major foam member encapsulating the armature with a gap filled by a minor foam member, providing a secure and aesthetically pleasing solution by ensuring the minor foam member is compressed within the gap, eliminating visible joins and enhancing resistance to movement.

Material Science Advancements

Material science advancements have played a crucial role in enhancing the performance and safety of steering wheels in motorsport. The development of innovative materials has led to significant improvements in weight reduction, durability, and ergonomics, all of which are essential factors in high-performance racing environments.

Carbon fiber composites have emerged as a game-changing material in steering wheel design. These advanced composites offer an exceptional strength-to-weight ratio, allowing for the creation of ultra-lightweight steering wheels that maintain structural integrity under extreme racing conditions. The use of carbon fiber has enabled manufacturers to reduce the overall weight of steering wheels by up to 50% compared to traditional materials, contributing to improved vehicle handling and driver responsiveness.

Advancements in polymer science have also contributed to the evolution of steering wheel materials. High-performance polymers, such as polyurethane and thermoplastic elastomers, are now commonly used for grip surfaces. These materials offer superior tactile properties, ensuring optimal grip even in high-stress situations or varying weather conditions. Additionally, these polymers can be engineered to provide vibration damping properties, reducing driver fatigue during long races.

Nanotechnology has opened up new possibilities in material engineering for steering wheels. Nano-enhanced materials, such as carbon nanotubes and graphene-reinforced composites, are being explored to further improve strength and reduce weight. These materials show promise in enhancing the overall performance and durability of steering wheels while maintaining minimal mass.

The integration of smart materials in steering wheel design is an emerging trend in motorsport. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive steering wheels that can change shape or provide haptic feedback based on racing conditions or driver preferences. This technology could revolutionize the way drivers interact with their vehicles during high-performance racing.

Biomimetic materials inspired by natural structures are also gaining attention in steering wheel development. Materials that mimic the properties of spider silk or the structure of bamboo are being researched for their potential to combine strength, flexibility, and lightweight characteristics in novel ways.

The ongoing research in material science continues to push the boundaries of what is possible in steering wheel design for motorsport. As new materials and manufacturing techniques emerge, we can expect to see further advancements in performance, safety, and driver comfort. The future of steering wheels in motorsport will likely involve a combination of these advanced materials, tailored to meet the specific demands of different racing disciplines and driver preferences.

Carbon fiber composites have emerged as a game-changing material in steering wheel design. These advanced composites offer an exceptional strength-to-weight ratio, allowing for the creation of ultra-lightweight steering wheels that maintain structural integrity under extreme racing conditions. The use of carbon fiber has enabled manufacturers to reduce the overall weight of steering wheels by up to 50% compared to traditional materials, contributing to improved vehicle handling and driver responsiveness.

Advancements in polymer science have also contributed to the evolution of steering wheel materials. High-performance polymers, such as polyurethane and thermoplastic elastomers, are now commonly used for grip surfaces. These materials offer superior tactile properties, ensuring optimal grip even in high-stress situations or varying weather conditions. Additionally, these polymers can be engineered to provide vibration damping properties, reducing driver fatigue during long races.

Nanotechnology has opened up new possibilities in material engineering for steering wheels. Nano-enhanced materials, such as carbon nanotubes and graphene-reinforced composites, are being explored to further improve strength and reduce weight. These materials show promise in enhancing the overall performance and durability of steering wheels while maintaining minimal mass.

The integration of smart materials in steering wheel design is an emerging trend in motorsport. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive steering wheels that can change shape or provide haptic feedback based on racing conditions or driver preferences. This technology could revolutionize the way drivers interact with their vehicles during high-performance racing.

Biomimetic materials inspired by natural structures are also gaining attention in steering wheel development. Materials that mimic the properties of spider silk or the structure of bamboo are being researched for their potential to combine strength, flexibility, and lightweight characteristics in novel ways.

The ongoing research in material science continues to push the boundaries of what is possible in steering wheel design for motorsport. As new materials and manufacturing techniques emerge, we can expect to see further advancements in performance, safety, and driver comfort. The future of steering wheels in motorsport will likely involve a combination of these advanced materials, tailored to meet the specific demands of different racing disciplines and driver preferences.

Safety Regulations Impact

Safety regulations play a crucial role in shaping the development and implementation of high-performance enhancements for steering wheels in motorsport. These regulations are designed to ensure the safety of drivers, teams, and spectators while maintaining the competitive nature of the sport. The impact of safety regulations on steering wheel technology is multifaceted and far-reaching.

One of the primary areas affected by safety regulations is the materials used in steering wheel construction. Regulations often dictate the use of specific materials that meet stringent safety standards, such as fire-resistant composites and impact-absorbing structures. These requirements have led to the development of innovative materials that combine lightweight properties with enhanced durability and safety features.

The ergonomics of steering wheels have also been significantly influenced by safety regulations. Mandates for quick-release mechanisms have become standard, allowing drivers to exit their vehicles rapidly in emergency situations. This has resulted in the development of sophisticated quick-release systems that maintain steering precision while enabling swift detachment when necessary.

Safety regulations have driven advancements in steering wheel-mounted controls and displays. The integration of critical information and control systems directly onto the steering wheel has been guided by regulations aimed at minimizing driver distraction and improving situational awareness. This has led to the development of compact, intuitive interfaces that provide essential data and controls without compromising safety.

The impact of safety regulations extends to the testing and certification processes for steering wheels. Manufacturers must subject their designs to rigorous testing procedures to ensure compliance with safety standards. This has resulted in the establishment of specialized testing facilities and methodologies specifically tailored to evaluate steering wheel performance under various stress conditions.

Regulations have also influenced the design of steering wheel grips and padding. Requirements for enhanced grip in wet conditions and during high-G maneuvers have led to innovations in surface textures and materials. Additionally, regulations governing impact protection have spurred the development of advanced padding technologies that absorb energy in the event of a collision.

The integration of driver biometric monitoring systems into steering wheels has been another area impacted by safety regulations. Requirements for monitoring driver health and fatigue levels have led to the incorporation of sensors and data collection systems directly into the steering wheel, providing real-time information to teams and race officials.

In conclusion, safety regulations have been a driving force behind many of the technological advancements in motorsport steering wheels. While these regulations may sometimes pose challenges to designers and engineers, they ultimately contribute to the continuous improvement of safety standards in motorsport, fostering innovation and pushing the boundaries of steering wheel technology.

One of the primary areas affected by safety regulations is the materials used in steering wheel construction. Regulations often dictate the use of specific materials that meet stringent safety standards, such as fire-resistant composites and impact-absorbing structures. These requirements have led to the development of innovative materials that combine lightweight properties with enhanced durability and safety features.

The ergonomics of steering wheels have also been significantly influenced by safety regulations. Mandates for quick-release mechanisms have become standard, allowing drivers to exit their vehicles rapidly in emergency situations. This has resulted in the development of sophisticated quick-release systems that maintain steering precision while enabling swift detachment when necessary.

Safety regulations have driven advancements in steering wheel-mounted controls and displays. The integration of critical information and control systems directly onto the steering wheel has been guided by regulations aimed at minimizing driver distraction and improving situational awareness. This has led to the development of compact, intuitive interfaces that provide essential data and controls without compromising safety.

The impact of safety regulations extends to the testing and certification processes for steering wheels. Manufacturers must subject their designs to rigorous testing procedures to ensure compliance with safety standards. This has resulted in the establishment of specialized testing facilities and methodologies specifically tailored to evaluate steering wheel performance under various stress conditions.

Regulations have also influenced the design of steering wheel grips and padding. Requirements for enhanced grip in wet conditions and during high-G maneuvers have led to innovations in surface textures and materials. Additionally, regulations governing impact protection have spurred the development of advanced padding technologies that absorb energy in the event of a collision.

The integration of driver biometric monitoring systems into steering wheels has been another area impacted by safety regulations. Requirements for monitoring driver health and fatigue levels have led to the incorporation of sensors and data collection systems directly into the steering wheel, providing real-time information to teams and race officials.

In conclusion, safety regulations have been a driving force behind many of the technological advancements in motorsport steering wheels. While these regulations may sometimes pose challenges to designers and engineers, they ultimately contribute to the continuous improvement of safety standards in motorsport, fostering innovation and pushing the boundaries of steering wheel technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!